Professional Documents

Culture Documents

Caterpillar: Confidential Green - Reproduction Constitutes An Uncontrolled Document

Caterpillar: Confidential Green - Reproduction Constitutes An Uncontrolled Document

Uploaded by

Dinar OjakCopyright:

Available Formats

You might also like

- Cat Spec ListDocument9 pagesCat Spec ListDon DonNo ratings yet

- Ford Wa950Document2 pagesFord Wa950amanNo ratings yet

- Forging Machines and Automated Upsetters BrochureDocument16 pagesForging Machines and Automated Upsetters BrochurecelectricNo ratings yet

- Finish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019Document5 pagesFinish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019JoshNo ratings yet

- Oxygen-Free Copper in Wrought Forms For Electron DevicesDocument6 pagesOxygen-Free Copper in Wrought Forms For Electron DevicesErick Vargas100% (1)

- Cu Ni V Mo CR MN C WT CE: - Page 1 of 3Document3 pagesCu Ni V Mo CR MN C WT CE: - Page 1 of 3Ainsworth Noriega RiosNo ratings yet

- Corporate Product & Process Specification: Caterpillar: Confidential GreenDocument5 pagesCorporate Product & Process Specification: Caterpillar: Confidential GreenDEVIKA PHULENo ratings yet

- .250 .031 R Collar, An876 (Proper Dash No.) Silver Solder To TubeDocument3 pages.250 .031 R Collar, An876 (Proper Dash No.) Silver Solder To TubeAnonymous 1CBdStCXUNo ratings yet

- Preventing Scale Loss During Heat Treatment & Hot Forging - With ImagesDocument17 pagesPreventing Scale Loss During Heat Treatment & Hot Forging - With ImagesSrikar Shenoy100% (1)

- 930 Frame Weld Reference Example BookDocument39 pages930 Frame Weld Reference Example Booklarry67% (3)

- Manual Motor Fuji 50Document12 pagesManual Motor Fuji 50Jorge Guerra SepulvedaNo ratings yet

- Din 1624Document2 pagesDin 1624avinashchauhan2695No ratings yet

- Aerospace Material Specification Ams 2759 PDFDocument11 pagesAerospace Material Specification Ams 2759 PDFKarad KaradiasNo ratings yet

- Sintered Metal BushDocument5 pagesSintered Metal Bush124swadeshiNo ratings yet

- Jdma17 2Document8 pagesJdma17 2qualidadesider0% (1)

- Iron Ore Cost CurvesDocument32 pagesIron Ore Cost CurvesMartin EchevarriaNo ratings yet

- Format Change Only: Corporate Product & Process SpecificationDocument4 pagesFormat Change Only: Corporate Product & Process SpecificationsathyabalaramanNo ratings yet

- 1E2722 V04 - ProE DrawingsDocument2 pages1E2722 V04 - ProE DrawingsGarry TaylorNo ratings yet

- Asme 18 6.3Document1 pageAsme 18 6.3Andres Byke SepulvedaNo ratings yet

- 046 Casting TolerancesDocument17 pages046 Casting ToleranceschandrajeetshelkeNo ratings yet

- Ppap Contents: 1. Appearance Approval ReportDocument7 pagesPpap Contents: 1. Appearance Approval ReportMuhtadin RahmawatiNo ratings yet

- SurveyScoringGuidelines W-HTX 2000Document58 pagesSurveyScoringGuidelines W-HTX 2000guzinetti100% (1)

- Threads - Pre-Plate Vs Post Plate Class-MetricDocument3 pagesThreads - Pre-Plate Vs Post Plate Class-MetricNaveen MaliNo ratings yet

- ASTM E 505 Cast DefectsDocument3 pagesASTM E 505 Cast DefectsMario Moura JrNo ratings yet

- Fed STD H28 20BDocument30 pagesFed STD H28 20BL FNo ratings yet

- Page 1 of 8: Caterpillar: Confidential Yellow - Reproduction Constitutes An Uncontrolled DocumentDocument8 pagesPage 1 of 8: Caterpillar: Confidential Yellow - Reproduction Constitutes An Uncontrolled DocumentGuilherme Brandão100% (1)

- Geometric Dimensioning and Tolerancing (GD&T) : Part Production Communication ModelDocument76 pagesGeometric Dimensioning and Tolerancing (GD&T) : Part Production Communication Modelmariappan128No ratings yet

- RFQ of C45 SteelDocument3 pagesRFQ of C45 Steelnhirpara1No ratings yet

- Ball Joint TesterDocument3 pagesBall Joint TesterManikanta MechNo ratings yet

- Heat Treat CatalogDocument20 pagesHeat Treat CatalogGabriel Gonzalez100% (1)

- Sae J1131Document5 pagesSae J1131Felipe SoaresNo ratings yet

- Aws C3.6-99Document17 pagesAws C3.6-99Eduard JoseNo ratings yet

- SAE J1926, MS 16142 - CuttersDocument11 pagesSAE J1926, MS 16142 - CutterspbsurfNo ratings yet

- ASTM A842 - Corpo de Prova OmegaDocument4 pagesASTM A842 - Corpo de Prova OmegaFabiano MonteiroNo ratings yet

- Mil HDBK 5j 1Document1 pageMil HDBK 5j 1dzsergeyNo ratings yet

- AEDK0627 CAT Truck Body Operation and Maitenance Guide PDFDocument9 pagesAEDK0627 CAT Truck Body Operation and Maitenance Guide PDFCarlos Lobo100% (2)

- Process Design in Impression Die ForgingDocument12 pagesProcess Design in Impression Die Forgingmike vidalNo ratings yet

- Maximum Material Condition (GD&T)Document15 pagesMaximum Material Condition (GD&T)Kishor kumar Bhatia67% (3)

- Fixed Dummy BlocksDocument19 pagesFixed Dummy BlocksNaveen GuptaNo ratings yet

- C633 617621-1 PDFDocument8 pagesC633 617621-1 PDFAmy BurnsNo ratings yet

- Surface Vehicle Standard: Rev. JUL86Document3 pagesSurface Vehicle Standard: Rev. JUL86anupthatta100% (1)

- Welding MIL STD PDFDocument157 pagesWelding MIL STD PDFAnonymous L0ChmPGNo ratings yet

- JIS B0419-1991 (Dung Sai Kich Thuoc)Document1 pageJIS B0419-1991 (Dung Sai Kich Thuoc)Giang Nguyễn BáNo ratings yet

- Korloy Grades and Chip BreakersDocument33 pagesKorloy Grades and Chip Breakersznovak77No ratings yet

- Drill&Tap ChartDocument1 pageDrill&Tap Chartamit_87_pallaviNo ratings yet

- (Jaso) F102-09Document16 pages(Jaso) F102-09AJ100% (1)

- Is.1573.1986 ED Coating StandardDocument24 pagesIs.1573.1986 ED Coating StandardUlhas Kavathekar100% (1)

- Cast Sae J514 PDFDocument4 pagesCast Sae J514 PDFmanishkumar FETNo ratings yet

- Design and Analysis of A Ladder Frame ChassisDocument10 pagesDesign and Analysis of A Ladder Frame ChassisJuan Sebastian CameroNo ratings yet

- Aluminum BronzeDocument37 pagesAluminum Bronzelijojose1No ratings yet

- Saej 524 V 002Document5 pagesSaej 524 V 002Marcos Verissimo Juca de PaulaNo ratings yet

- SKK Folder EngDocument10 pagesSKK Folder EngAyush NarangNo ratings yet

- Weld Repair Procedure For The Rear Axle A-Frame and Rear Axle Housing On 785, 789, and 793 OHTDocument18 pagesWeld Repair Procedure For The Rear Axle A-Frame and Rear Axle Housing On 785, 789, and 793 OHTcarlosNo ratings yet

- MAGNI 565: Product Data SheetDocument1 pageMAGNI 565: Product Data SheetjulianaNo ratings yet

- Typical Heat Treatment Defects of GearsDocument8 pagesTypical Heat Treatment Defects of GearsRamon BrownNo ratings yet

- Automotive Parts - Hexagon Nuts and Hexagon Thin Nuts: Japanese Automobile Standard Jaso F102:2005Document11 pagesAutomotive Parts - Hexagon Nuts and Hexagon Thin Nuts: Japanese Automobile Standard Jaso F102:2005AJ100% (1)

- CNH Mat 1007 - 07-2009Document5 pagesCNH Mat 1007 - 07-2009rgi178No ratings yet

- 1e0001 - Steel - Heat Treated Cold Finished BarDocument3 pages1e0001 - Steel - Heat Treated Cold Finished BarPuneet EnterprisesNo ratings yet

- Material Specification: Specification: B-1 Revision Date: 09/06/2016 Revision Level: AEDocument13 pagesMaterial Specification: Specification: B-1 Revision Date: 09/06/2016 Revision Level: AEReginaldo SantosNo ratings yet

- Carraro India LTD Steel Mill Standard Rev 08Document7 pagesCarraro India LTD Steel Mill Standard Rev 08SUNDARNo ratings yet

- Ferritic Ductile Iron Pressure-Retaining Castings For Use at Elevated TemperaturesDocument8 pagesFerritic Ductile Iron Pressure-Retaining Castings For Use at Elevated TemperaturesAmit PathakNo ratings yet

- Ph8251 - Material ScienceDocument6 pagesPh8251 - Material ScienceAbc AcademyNo ratings yet

- System Plast PDFDocument436 pagesSystem Plast PDFCesar Uriel Oropeza GomezNo ratings yet

- Xylan 142X Series: VOC Compliant Extreme Performance CoatingsDocument2 pagesXylan 142X Series: VOC Compliant Extreme Performance CoatingsRajNo ratings yet

- PW POS Training MMA ENDocument1 pagePW POS Training MMA ENShaik Nizam UddinNo ratings yet

- Light Gauge Steel FrameDocument20 pagesLight Gauge Steel FrameConstro FacilitatorNo ratings yet

- METAL ARTS - Career Studies Certificate: Program InfoDocument1 pageMETAL ARTS - Career Studies Certificate: Program InfoBobbyNo ratings yet

- Steel Reinforced Polyethylene (PE) Corrugated Pipe: Standard Specification ForDocument7 pagesSteel Reinforced Polyethylene (PE) Corrugated Pipe: Standard Specification Formati.khan.wahidiNo ratings yet

- Anup Sir PPT All PDFDocument222 pagesAnup Sir PPT All PDFFAIQNo ratings yet

- EN1090 EngtipsDocument3 pagesEN1090 EngtipssoulsellNo ratings yet

- Otc 19880 MS PDFDocument11 pagesOtc 19880 MS PDFLara ArinelliNo ratings yet

- EHB en 9-MaterialsDocument57 pagesEHB en 9-MaterialsAnonymous 1hOgJqwZuzNo ratings yet

- Detail Spun Pile Dia 600mm (Rev-01) - Spun PileDocument1 pageDetail Spun Pile Dia 600mm (Rev-01) - Spun PileMenejeer SianturiNo ratings yet

- Good Fabrication in Architectural Stainless Steel: ISBN 2-87997-062-8Document10 pagesGood Fabrication in Architectural Stainless Steel: ISBN 2-87997-062-8tonyNo ratings yet

- BSEN 10025 2000 New EditionDocument68 pagesBSEN 10025 2000 New Editionpbp2956No ratings yet

- Floating JointDocument0 pagesFloating JointsugirinNo ratings yet

- 16 CR 5 NiDocument11 pages16 CR 5 NiNikhil VermaNo ratings yet

- HSG CatalogDocument18 pagesHSG Cataloghiec89No ratings yet

- SLV General Introduction To Welding TechnologyDocument35 pagesSLV General Introduction To Welding TechnologyMohammad Sobhan RajabiNo ratings yet

- Technology 5 Constant CurrentDocument7 pagesTechnology 5 Constant CurrentnoorNo ratings yet

- Practical Thermal Design of Shell-And-tube Heat ExchangersDocument243 pagesPractical Thermal Design of Shell-And-tube Heat ExchangersPato Banda100% (5)

- Please Visit Us at C116/8.1 From 16-21.09.2013 at Schweissen & Schneiden 2013Document2 pagesPlease Visit Us at C116/8.1 From 16-21.09.2013 at Schweissen & Schneiden 2013narendraNo ratings yet

- Mirdc Atd Fees - ChargesDocument12 pagesMirdc Atd Fees - Chargesnapster386No ratings yet

- NHT-P51-00032 04MDocument937 pagesNHT-P51-00032 04MnmosilvaNo ratings yet

- AWS Pocket Handbook 8 - The Everyday Pocket Handbook For GMAW of AluminumDocument30 pagesAWS Pocket Handbook 8 - The Everyday Pocket Handbook For GMAW of Aluminumfast100% (1)

- 50 Mechanical Engineering Interview Questions and AnswersDocument12 pages50 Mechanical Engineering Interview Questions and Answersmj03127477706No ratings yet

- Waterproofing and MaintenanceDocument14 pagesWaterproofing and MaintenanceJun ChuNo ratings yet

- Hridayeshwar Jha: Director, Projects-Since April 2016Document4 pagesHridayeshwar Jha: Director, Projects-Since April 2016SOURAV SINGHNo ratings yet

- 8 - CE 511 - Welded ConnectionsDocument32 pages8 - CE 511 - Welded ConnectionsVictor Czar AustriaNo ratings yet

- Mse8 2 PDFDocument27 pagesMse8 2 PDFKrishnanNo ratings yet

Caterpillar: Confidential Green - Reproduction Constitutes An Uncontrolled Document

Caterpillar: Confidential Green - Reproduction Constitutes An Uncontrolled Document

Uploaded by

Dinar OjakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caterpillar: Confidential Green - Reproduction Constitutes An Uncontrolled Document

Caterpillar: Confidential Green - Reproduction Constitutes An Uncontrolled Document

Uploaded by

Dinar OjakCopyright:

Available Formats

®

CORPORATE PRODUCT & PROCESS SPECIFICATION

1.0 SCOPE

This specification defines common requirements for wrought steels supplied to Caterpillar Inc.,

either directly in the form of steel products or indirectly in the form of steel parts. This is a multi-

variation specification (ref Article 4.0).

2.0 APPLICATION

2.1 1E0024 defines product requirements such as composition and grain size as well as

requirements for sampling, testing and data reporting. It outlines requirements for sourcing from

approved suppliers and for use of substitute materials, defined in more detail in 1E1861 and

1E2349 respectively.

2.2 Product requirements in individual 1E specifications referencing 1E0024 take priority over

the default requirements in 1E0024.

3.0 QUALIFYING SPECIFICATIONS

1E0038 Steel Hardenability Calculation

1E0552 Test Specimens - Metallic Materials

1E1821 Surface Quality - Plate and Sheet

1E1861 Wrought Steel - Approved Suppliers

1E2177 Mill Tolerances - Steel Products

1E2349 Materials Application - Substitute

1E2700 Strand Cast Steel - Application and Quality

1E4467 Registration, Evaluation, Authorization, and Restriction of Chemical Substance

4.0 DRAWING DESIGNATIONS

Current Former Application

Designation Designation

1E0024A 1E0024 Steels with Jominy hardenability requirements

1E0024B 1E0038 All other steels

Figure 1

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTEN

PERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO NUMBER

WROUGHT STEEL – GENERAL REQUIREMENTS 08 MAR 2018 45 1E0024

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - PAGE 1 OF 14

®

CORPORATE PRODUCT & PROCESS SPECIFICATION

5.0 PRODUCT REQUIREMENTS

5.1 Use of the word “shall”: The word “shall” is used in Caterpillar 1E specifications to

specify a requirement.

5.2 Composition

5.2.1 Carbon - Product analysis tolerance for carbon shall be ±0.01 WT %. All other elements

shall conform to the specified composition ranges with no product analysis tolerance. For 1E

steel specifications specifying a carbon range less than 0.05 WT %, the product analysis

tolerance for carbon shall be ±0.02 WT % for ingot cast steel only.

5.2.2 Sulfur - All bar and forging steels furnished to this specification, except bars without

further machining, flat bar, and rolled sections, shall contain at least 0.010 WT % sulfur.

NOTE: Suppliers of purchased finished parts may use bar steels with lower sulfur content for

parts that are not subsequently machined by Caterpillar.

5.2.3 Aluminum shall not exceed 0.08 WT % to prevent aluminum nitride grain boundary

embrittlement and rock candy (intergranular) type fracture.

5.2.4 Titanium shall not exceed 0.065 WT % to prevent detrimental effects on machinability.

5.2.5 Incidental Elements - Certain elements may be present in steel that are not specified or

required. These incidental elements shall not exceed the limits in Figure 2:

ELEMENT MAXIMUM

Nickel (Ni) 0.30 WT %

Chromium (Cr) 0.20 WT %

Molybdenum (Mo) 0.08 WT %

Copper (Cu) (*) 0.35 WT %

Lead (Pb) 0.02 WT %

Tin (Sn) 0.03 WT %

Arsenic (As) 0.03 WT %

Figure 2

Note (*): Copper up to 0.50 WT% maximum is permitted for sheet, plate and cutting edge

sections only.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTEN

PERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO NUMBER

WROUGHT STEEL – GENERAL REQUIREMENTS 08 MAR 2018 45 1E0024

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - PAGE 2 OF 14

®

CORPORATE PRODUCT & PROCESS SPECIFICATION

5.3 Boron Practice – 1E0024A qualified steels that specify boron for hardenability, for

example 1E5053, shall be produced by a steelmaking practice that has been approved and

noted in 1E1861. Boron steels require aluminum deoxidation and a titanium addition sufficient to

bind all nitrogen, protecting the boron so it effectively increases hardenability. Boron steels with

no Jominy requirements shall have a Ti:N ratio of 4.0 or greater. All boron steels require

nitrogen testing (from the final ladle sample or a tundish sample) and reporting of both nitrogen

and titanium.

5.4 Grain Refinement

5.4.1 When austenitic fine grain (5 or finer), measured according to ASTM E112, or fine grain

practice is specified in 1E steel specifications, a minimum of 0.015 WT % aluminum (Altotal) is

required, except as noted in section 5.4.2, or if a lower minimum aluminum value is stated in the

material specification. Unless requested, grain size testing is not required for steel heats with

aluminum ≥ 0.015 WT%.

5.4.2 Flat rolled steel, requiring fine grain practice, is not required to meet the minimum

aluminum content specified in 5.4.1, provided the steel does not require heat treatment after

rolling to meet specified mechanical property requirements.

5.4.3 For those heats requiring grain size measurement, austenitic grain size shall be

determined according to ASTM E112 Annex A3.2.1.2 (McQuaid-Ehn), A3.2.1.3, A3.2.1.4, or

A3.2.1.6.

5.4.4 For steel alloys intended for carburizing or induction hardening applications, only ASTM

E112 A3.2.1.2 (McQuaid-Ehn) or A3.2.1.3 testing at 927°C shall be applied for austenite grain

size measurement.

5.5 Soundness - For bar products and semi-finished forging steels, internal soundness and

quality shall be verified by macro-etch testing per ASTM E381 or equivalent procedure.

Samples shall represent the entire cross-section of the product. The face to be macro-etched

shall be ground to a finish with roughness average of 2.5 microns or less.

5.6 Cleanliness - When individual 1E steel specifications are not qualified by 1E2661,

assessment and reporting of microcleanliness is not required. However, maximum inclusion

content for all steel shall conform to the ASTM E45 Method A requirements in Figure 3. While

testing and reporting is not required, steel exceeding these limits is rejectable.

B C D

THIN HEAVY THIN HEAVY THIN HEAVY

2.5 2 1.5 1 1.5 1.5

Figure 3

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTEN

PERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO NUMBER

WROUGHT STEEL – GENERAL REQUIREMENTS 08 MAR 2018 45 1E0024

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - PAGE 3 OF 14

®

CORPORATE PRODUCT & PROCESS SPECIFICATION

5.7 Radioactivity - Steel for Caterpillar products shall not have levels of radioactivity

exceeding natural background levels.

5.8 Identification - Product shipped shall be identified to maintain heat traceability.

6.0 SAMPLING AND TESTING REQUIREMENTS

6.1 1E0024A Heat Sampling and Identification - Samples from each heat shall be identified

alphabetically with the letter “A” designating the first material cast for Caterpillar use, and the

letter “Z” designating the last material cast for Caterpillar use. All sampling shall be done after

routine cropping and discard. Details of this system depend on the casting process.

6.1.1 Bottom Poured Ingots - The “A” sample shall be taken from the top of a random ingot in

the first cluster (plate) cast and the “Z” sample from the bottom of an ingot in the last cluster

(plate) cast.

6.1.2 Strand Cast In Single Heats - The “A” sample shall be taken from the first usable

material regardless of strand and the “Z” sample from the last usable material regardless of

strand.

6.1.3 Sequence Cast Strand Cast Steel - “A” and “Z” samples shall be taken from the first

and last material assigned to a heat, with transition material defined according to Article 6.2.2.

6.1.4 Partial Heat Boron Steel Sampling - If the quantity applied to Caterpillar is less than

fifteen tons, a single random product sample is acceptable.

6.1.5 Small Heat Boron Steel Sampling - If the heat size is less than 50 tons, single random

Jominy and chemistry samples are acceptable. Small shipments from heats larger than 50 tons

do not qualify for this exemption from "A" and "Z" product sampling.

6.1.6 Alloy Steel Product Chemistry Sampling - A single ladle chemistry sample is

acceptable for steels that do not use boron as a hardenability intensifier.

6.2 Sequence Casting Restrictions - Multiple heats of strand cast steel may be cast in a

continuous sequence with the following restrictions:

6.2.1 Sequence casting shall only be done with heats of similar grade and carbon range. Boron

steels may not be sequence cast with non-boron steels.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTEN

PERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO NUMBER

WROUGHT STEEL – GENERAL REQUIREMENTS 08 MAR 2018 45 1E0024

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - PAGE 4 OF 14

®

CORPORATE PRODUCT & PROCESS SPECIFICATION

6.2.2 When grades with DI or Jominy hardenability requirements are cast as billets or blooms,

transition material between heats shall be tested and assigned to heats based on DI

calculations using the following ratios to ensure consistent heat treat response within each heat.

6.2.2.1 Front and back samples (“A” and “Z”) shall be tested for chemistry at transition

boundaries. Calculated DI per 1E0038, SAE J406, or ASTM A255 using all elements except

boron shall be used to assign the transition material to either of the adjacent heats.

6.2.2.2 If the ratio of the calculated DI for the two heats is between 0.80 and 1.20, the transition

metal may be assigned to either heat, provided that both fulfill the specified composition and

hardenability requirements.

6.2.2.3 If the ratio of the calculated DI for the two heats is not between 0.80 and 1.20, and both

heats satisfy specification requirements for chemistry and hardenability, extra testing shall be

done on the transition material to determine which billets or blooms can be assigned to either

heat. Such testing and assignment shall assure that the DI ratio of the transition material and its

assigned heat is between 0.80 and 1.20.

6.3 Specimens for Jominy Hardenability Testing (1E0024A Steels Only)

6.3.1 Forged Sampling - Specimens machined from forged samples representing the full

cross-section of the product are optimal. The forged sample dimensions and test specimen

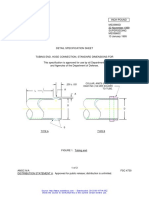

locations are shown in Figure 4.

Figure 4 - Forged Mill Sample and Test Locations

Note: Dimensions in Figure 4 are for reference only.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTEN

PERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO NUMBER

WROUGHT STEEL – GENERAL REQUIREMENTS 08 MAR 2018 45 1E0024

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - PAGE 5 OF 14

®

CORPORATE PRODUCT & PROCESS SPECIFICATION

6.3.2 Rolled Sampling - Specimens may be machined directly from rolled product, provided

the reduction ratio is at least 6:1 for bar and 3:1 for plate for both ingot cast and strand cast

product. Both the Jominy specimen and hardness measurement locations shall be as near as

possible to the mid-radius or quarter width of the rolled bars and plate.

6.3.2.1 Jominy Specimens from Bar - Jominy specimens shall be machined from bar as

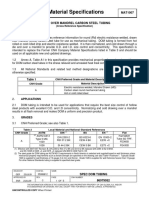

specified in SAE J406 and as shown in Figure 5.

Figure 5 - Jominy Location for Bar Samples

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTEN

PERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO NUMBER

WROUGHT STEEL – GENERAL REQUIREMENTS 08 MAR 2018 45 1E0024

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - PAGE 6 OF 14

®

CORPORATE PRODUCT & PROCESS SPECIFICATION

6.3.2.2 Jominy Specimens from Plate - As permitted by plate thickness, Jominy specimens

shall be machined with the specimen center axis at the quarter thickness of flat rolled products.

For thinner plates, Jominy samples shall be machined to place one side of the sample at the

quarter thickness location as shown in Figure 6. Hardness probes shall be taken on the quarter

thickness surface of the end quench specimen.

Figure 6 - Plate Sample

Note: Hardness probes shall be taken on the “PLATE THICKNESS/4” surface of the end

quench specimen.

6.3.3 Cast Specimens - Cast specimens are permitted for non-boron grades provided that the

practice has been approved by the regional dispositioning Caterpillar facility (ref Article 9.0).

6.4 Sampling for Chemical Analysis

6.4.1 Both 1E0024A and 1E0024B steels require analysis of a ladle sample.

6.4.2 Boron steels also require analysis of product samples.

6.4.2.1 Samples shall be identified with the heat number and the sample position within the

heat per Article 6.1.

6.4.2.2 Chemical analysis shall be determined at any of the following locations (ref. Figures 4

and 6):

Midway between the surface and center on Face A-B of the forged mill sample, or

Mid-radius on the 38 mm diameter section of the forged mill sample, or

Mid-radius on the Jominy hardenability specimen (as near as possible to ¼ section on plate).

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTEN

PERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO NUMBER

WROUGHT STEEL – GENERAL REQUIREMENTS 08 MAR 2018 45 1E0024

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - PAGE 7 OF 14

®

CORPORATE PRODUCT & PROCESS SPECIFICATION

6.5 Jominy Hardenability Testing (1E0024A Steels Only)

6.5.1 Hardenability shall be determined by the Jominy end quench test per ASTM A255 or SAE

J406 using specimen 1E0552-K1. In addition to those procedures contained in SAE J406C, the

following guidelines shall be employed to ensure accurate and reproducible results.

6.5.2 Rockwell C hardness measurements shall be reported in inch (ref 6.5.2.1) or mm (ref

6.5.2.2) increments from the quenched end.

6.5.2.1 Inch increments shall start at 1/16 inch from the quenched end stopping when Rockwell

C20 is reached or at 32/16 inches. Record Rockwell C hardness at 1/16-inch intervals up to

and including 10/16 inch, at 1/8-inch intervals from 10/16 inch up to and including 20/16 inch,

and at ¼ inch intervals beyond 20/16 inch.

6.5.2.2 Millimeter increments shall start at 1.5 mm from the quenched end stopping when

Rockwell C20 is reached or at 50 mm. Record Rockwell C hardness at 1.5 and 3.0 mm, at 2 mm

intervals up to and including 15 mm, and at 5 mm intervals beyond 15 mm.

6.5.3 Two traverses 180º apart shall be taken on each end quench specimen and the

Rockwell C readings rounded to the nearest whole number. For each end quench specimen,

the two hardness values at identical distances shall be averaged and rounded to the nearest

whole number and that value reported. A single traverse shall be taken and reported for thinner

plates (per 6.3.2.2).

6.5.4 If the two probes on opposite sides differ by more than 4 points RKW C at any one

position, the test shall be repeated on new flats ground 90º from the first two. If the retest also

has greater than 4 points RKW C variation, a new specimen shall be prepared and tested.

Reheat of Jominy specimens is not permitted.

6.5.5 The distance from the quenched end to the center of the first hardness indentation shall

be measured on each flat and reported as the “S” distance. If the “S” distance of either of the

probes is not between 1.50 mm and 1.70 mm a retest shall be done.

6.5.6 Jominy testing is not required for 1E0024B qualified steels. Jominy data may be included

in the specification for reference and may be requested in cases where there is question on the

actual hardenability of the material.

6.6 Mechanical Property Testing

6.6.1 Any specified mechanical property tests shall be conducted on the material in the

condition delivered to Caterpillar.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTEN

PERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO NUMBER

WROUGHT STEEL – GENERAL REQUIREMENTS 08 MAR 2018 45 1E0024

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - PAGE 8 OF 14

®

CORPORATE PRODUCT & PROCESS SPECIFICATION

6.6.2 Unless otherwise specified, methods of analysis, test and inspection shall conform to the

latest appropriate ASTM standard (or appropriate National Standard)

6.6.3 Unless otherwise specified in the individual 1E specification, tensile tests shall report

yield strength at 0.2% offset. If the material exhibits a well-defined yield point, this yield point

may be reported as the yield strength. (Refer to ASTM A6, Section 11.7)

6.6.4 Unless otherwise permitted, compliance with specification requirements shall be based

on the qualities of individual samples and not average qualities of a group of samples.

6.6.5 The testing frequency for tensile testing shall follow ASTM A6. Testing frequency for

Charpy impact testing shall follow ASTM A673 heat testing (H) requirements.

6.6.6 Retest allowance for tensile and Charpy testing shall follow the requirements of ASTM A6

and ASTM A673, respectively.

6.7 1E0024A Sample Retention - Samples from chemistry and hardenability tests on

1E0024A steels shall be retained for at least 120 days after the data is submitted to Caterpillar.

7.0 REPORTING REQUIRMENTS

7.1 Heat data shall be reported to the regional dispositioning facility (ref Article 9.0) for all

steels qualified by 1E0024.

7.2 Reporting Responsibility

7.2.1 Caterpillar approved mills and steel suppliers have the primary responsibility for

submitting heat data to their regional dispositioning facility for all steel produced to a Caterpillar

1E specification.

7.2.2 Forgers, service centers, or other suppliers that purchase steel to industry standard

grades (non-1E specifications) are responsible for reporting heat data to the receiving

Caterpillar facility or to the regional dispositioning facility designated by the receiving facility.

7.2.3 Service Centers, forgers or other component suppliers that purchase steel made to 1E

specifications from Caterpillar approved mills and steel suppliers are not required to report heat

data. Caterpillar approved mills producing the steel will report it directly to Caterpillar (per

7.2.1).

7.2.4 Producers of forgings with requirements for tensile, impact and/or hardness properties

after forging shall report test results with their submission of heat codes.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTEN

PERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO NUMBER

WROUGHT STEEL – GENERAL REQUIREMENTS 08 MAR 2018 45 1E0024

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - PAGE 9 OF 14

®

CORPORATE PRODUCT & PROCESS SPECIFICATION

7.2.5 Forgers shall report all part numbers and applied forging codes (per 1E0100) for a heat

of steel.

7.2.6 Semi-finished or finished component suppliers that purchase steel to a 1E specification

from forgers, service centers, or other second tier steel suppliers are not required to report heat

data.

7.3 Data requirements

7.3.1 Steel suppliers shall assure themselves that a heat fulfills the requirements of the

applicable 1E specifications before submitting samples or test results for approval by the

regional dispositioning facility.

7.3.2 Heat data shall be submitted to Caterpillar by electronic methods. Suppliers should

consult their regional dispositioning facility or their purchasing contact for details on the methods

used in their region.

7.3.3 Significant Digits in Test Data – For purposes of determining conformance to

specifications, an observed value or a calculated value shall be rounded to the nearest unit in

the last right-hand digit used in expressing the specification limit (1 MPa for Tensile and Yield

Strength), in accordance with the Rounding Method of ASTM Practice E29 for Using Significant

Digits in Test Data. As an alternate practice, tensile and yield strength data shall be rounded to

the nearest 1 MPa, 5 MPa or 10 MPa, depending on strength level, per ASTM A370, Annex A8.

Examples of rounding practice are provided in Figure 7.

Requirement Specification Measurement Heat Submission

Carbon 0.45-0.51 0.446 0.45

Manganese 0.60-0.90 0.712 0.71

Sulfur 0.050 MAX 0.009 0.009

Yield Strength 290-500 MPa 499.2 MPa 499 MPa

Alternate ASTM A370, Annex A8 Practice for Tensile Testing:

Yield Strength 550 MPa MIN 548 MPa 550 MPa

Figure 7

7.3.4 Minimum Requirements –Figure 8 lists the minimum data to be reported. Individual 1E

steel specifications may require additional data.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTEN

PERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO NUMBER

WROUGHT STEEL – GENERAL REQUIREMENTS 08 MAR 2018 45 1E0024

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - PAGE 10 OF 14

®

CORPORATE PRODUCT & PROCESS SPECIFICATION

Reference 1E0024A 1E0024B

Heat Number

Supplier Name

1E1861 Mill Code 1E1861 3 digits 3 digits

Purchasing Supplier

7 digits 7 digits

Code

Submission Date

Commodity e.g. bar, plate, sheet, e.g. bar, plate, sheet,

Description tubing tubing

Paragraph

Gauge Size

7.3.5

Cat 1E steel

specification

Reduction ratio 1E2700

Article 5.2 Ladle heat analysis and Ladle heat analysis shall

product analysis of “A” and be reported for the

“Z” mill samples shall be following elements: C, Mn,

reported for the following P, S, Si, Ni, Cr, Mo, Cu, Al

elements: C, Mn, P, S, Si,

Ni, Cr, Mo, Cu, Al

Ti, Zr, Nb, V, Ta, W, N, and Ti, Zr, Nb, V, Ta, W, N, and

Chemical

Ca when intentionally Ca when intentionally

Composition

added or specified. added or specified.

Paragraph B, Ti and N when B is

5.3 specified.

1E0038 Actual “A” and “Z” Boron

factors (per 1E38)

1E2661 O, Ca, or H (PPM) as O, Ca, or H (PPM) as

1E1801 required by these specs required by these specs

Articles 6.3 DI per 1E0038, when

Hardenability Jominy results

& 6.5 specified

Article 6.6 Test 3 specimens. Report

Charpy impact all 3 values, their average,

testing, when the specimen type,

specified. Test per orientation to the rolling

ASTM A370. direction, and test

temperature.

Tensile testing, when Article 6.6 Tensile results per

specified. Test per specification requirements

ASTM A370.

Figure 8

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTEN

PERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO NUMBER

WROUGHT STEEL – GENERAL REQUIREMENTS 08 MAR 2018 45 1E0024

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - PAGE 11 OF 14

®

CORPORATE PRODUCT & PROCESS SPECIFICATION

7.3.5 Gauge thickness reporting

Steel product size shall be reported in millimeters, based on product form per Figure 9.

Form Dimension Reported for Gauge.

Sheet and Plate Thickness

Round Bar Diameter

Round-Corner-Square (RCS) Bar Width Across Flat Faces

Flat Bar Thickness

Tubing Wall Thickness (ID and OD in note)

Sections Indicate section 1Espec or national spec in note

Figure 9

7.3.6 For steels specifying Carbon Equivalent, CE shall be calculated per the following formula:

Carbon Equivalent = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15

7.3.7 For steels specifying boron as a hardenability intensifier, boron effectiveness shall be

monitored and reported with the boron factor calculation defined in the 1E0038 Caterpillar

Hardenability Calculations. Predicted boron factors shall not be reported.

7.3.8 Predicted calculated, simulated, theoretical, or otherwise similarly described Jominy

hardenability results shall not be reported. If Jominy results are required per the 1E

specification, then the melting mill shall be contacted to measure and provide Jominy data.

7.4 Certification

7.4.1 Test certificates that accompany steel produced and purchased to a 1E specification or a

standard national steel grade used to fulfill a 1E specification shall affirmatively state that the

material satisfies the 1E specification or national grade’s requirements.

7.4.2 When requested in a 1E specification or on a purchase order, the mill shall also submit a

digital copy of the steel heat inspection certificate. The inspection certificate shall include all

information required to demonstrate conformance with the 1E specification or standard national

steel grade used to fulfill the 1E specification, as well as a statement of conformance with the 1E

specifications or a national grade approved to fulfill the 1E specification, consistent with

EN 10204, Inspection Certificate 3.1.

7.4.3 Suppliers shall contact their regional dispositioning facility for further information on

approved usage of the restricted heats, unless the test certificate specifically states the part

numbers involved.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTEN

PERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO NUMBER

WROUGHT STEEL – GENERAL REQUIREMENTS 08 MAR 2018 45 1E0024

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - PAGE 12 OF 14

®

CORPORATE PRODUCT & PROCESS SPECIFICATION

7.5 Release for Shipping

7.5.1 For 1E0024A qualified steels, the supplier shall obtain approval of the steel heat

submission from Caterpillar before shipment, when purchased by anyone other than Caterpillar

or its subsidiaries.

7.5.2 1E1861 approved suppliers may ship fully conforming steel before obtaining Caterpillar

disposition when this practice has been approved by the regional dispositioning facility. Test

data shall be transmitted before the steel is received.

7.5.3 Final application of a mill heat to Caterpillar orders shall include only that portion of a

heat that conforms within the extremes represented by the samples or test data approved by

Caterpillar.

8.0 APPROVED SUPPLIERS

All steel shall be purchased from mills on the Caterpillar Approved Supplier List (Ref 1E1861) or

from mills specifically authorized by the receiving or regional dispositioning Caterpillar facility

(ref Article 9.0).

9.0 DISPOSITIONING FACILITY AND HEAT DATA SUBMISSION PROCESS

9.1 A Caterpillar dispositioning facility is the Quality or Technical Department of the designated

Caterpillar plant within a geographical region which monitors steel quality, maintains the

corporate mill heat data base, dispositions heats of steel, and provides metallurgical approval

support for mills, service centers, and suppliers. 1E1861 lists the dispositioning facilities within

geographical regions. The receiving Caterpillar facility within a region is the primary disposition

facility.

9.2 Steel heat data for 1E0024 qualified materials shall be submitted via EDI or by using the

Mill Heat application in EtQ. Those steel suppliers without access to EtQ should contact their

regional dispositioning facility for guidance on steel heat data submission.

10.0 MATERIAL SUBSTITUTION

1E2349 governs the use of industry standard grades in place of Caterpillar steels defined by

individual 1E specifications. Suppliers must refer to both 1E2349 and the individual 1E steel

specification for information on how to identify acceptable substitutes and how to get approval

for their use.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTEN

PERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO NUMBER

WROUGHT STEEL – GENERAL REQUIREMENTS 08 MAR 2018 45 1E0024

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - PAGE 13 OF 14

®

CORPORATE PRODUCT & PROCESS SPECIFICATION

11.0 REFERENCES

Abbreviations 1E0011

Caterpillar Specifications 1E0038, 1E0100, 1E0522, 1E1801, 1E1861, 1E2349, 1E2661

1E2700, 1E5053

ASTM A6, A255, A370, A673, E29, E45, E112, E381

EN 10204

SAE J406

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTEN

PERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO NUMBER

WROUGHT STEEL – GENERAL REQUIREMENTS 08 MAR 2018 45 1E0024

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - PAGE 14 OF 14

You might also like

- Cat Spec ListDocument9 pagesCat Spec ListDon DonNo ratings yet

- Ford Wa950Document2 pagesFord Wa950amanNo ratings yet

- Forging Machines and Automated Upsetters BrochureDocument16 pagesForging Machines and Automated Upsetters BrochurecelectricNo ratings yet

- Finish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019Document5 pagesFinish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019JoshNo ratings yet

- Oxygen-Free Copper in Wrought Forms For Electron DevicesDocument6 pagesOxygen-Free Copper in Wrought Forms For Electron DevicesErick Vargas100% (1)

- Cu Ni V Mo CR MN C WT CE: - Page 1 of 3Document3 pagesCu Ni V Mo CR MN C WT CE: - Page 1 of 3Ainsworth Noriega RiosNo ratings yet

- Corporate Product & Process Specification: Caterpillar: Confidential GreenDocument5 pagesCorporate Product & Process Specification: Caterpillar: Confidential GreenDEVIKA PHULENo ratings yet

- .250 .031 R Collar, An876 (Proper Dash No.) Silver Solder To TubeDocument3 pages.250 .031 R Collar, An876 (Proper Dash No.) Silver Solder To TubeAnonymous 1CBdStCXUNo ratings yet

- Preventing Scale Loss During Heat Treatment & Hot Forging - With ImagesDocument17 pagesPreventing Scale Loss During Heat Treatment & Hot Forging - With ImagesSrikar Shenoy100% (1)

- 930 Frame Weld Reference Example BookDocument39 pages930 Frame Weld Reference Example Booklarry67% (3)

- Manual Motor Fuji 50Document12 pagesManual Motor Fuji 50Jorge Guerra SepulvedaNo ratings yet

- Din 1624Document2 pagesDin 1624avinashchauhan2695No ratings yet

- Aerospace Material Specification Ams 2759 PDFDocument11 pagesAerospace Material Specification Ams 2759 PDFKarad KaradiasNo ratings yet

- Sintered Metal BushDocument5 pagesSintered Metal Bush124swadeshiNo ratings yet

- Jdma17 2Document8 pagesJdma17 2qualidadesider0% (1)

- Iron Ore Cost CurvesDocument32 pagesIron Ore Cost CurvesMartin EchevarriaNo ratings yet

- Format Change Only: Corporate Product & Process SpecificationDocument4 pagesFormat Change Only: Corporate Product & Process SpecificationsathyabalaramanNo ratings yet

- 1E2722 V04 - ProE DrawingsDocument2 pages1E2722 V04 - ProE DrawingsGarry TaylorNo ratings yet

- Asme 18 6.3Document1 pageAsme 18 6.3Andres Byke SepulvedaNo ratings yet

- 046 Casting TolerancesDocument17 pages046 Casting ToleranceschandrajeetshelkeNo ratings yet

- Ppap Contents: 1. Appearance Approval ReportDocument7 pagesPpap Contents: 1. Appearance Approval ReportMuhtadin RahmawatiNo ratings yet

- SurveyScoringGuidelines W-HTX 2000Document58 pagesSurveyScoringGuidelines W-HTX 2000guzinetti100% (1)

- Threads - Pre-Plate Vs Post Plate Class-MetricDocument3 pagesThreads - Pre-Plate Vs Post Plate Class-MetricNaveen MaliNo ratings yet

- ASTM E 505 Cast DefectsDocument3 pagesASTM E 505 Cast DefectsMario Moura JrNo ratings yet

- Fed STD H28 20BDocument30 pagesFed STD H28 20BL FNo ratings yet

- Page 1 of 8: Caterpillar: Confidential Yellow - Reproduction Constitutes An Uncontrolled DocumentDocument8 pagesPage 1 of 8: Caterpillar: Confidential Yellow - Reproduction Constitutes An Uncontrolled DocumentGuilherme Brandão100% (1)

- Geometric Dimensioning and Tolerancing (GD&T) : Part Production Communication ModelDocument76 pagesGeometric Dimensioning and Tolerancing (GD&T) : Part Production Communication Modelmariappan128No ratings yet

- RFQ of C45 SteelDocument3 pagesRFQ of C45 Steelnhirpara1No ratings yet

- Ball Joint TesterDocument3 pagesBall Joint TesterManikanta MechNo ratings yet

- Heat Treat CatalogDocument20 pagesHeat Treat CatalogGabriel Gonzalez100% (1)

- Sae J1131Document5 pagesSae J1131Felipe SoaresNo ratings yet

- Aws C3.6-99Document17 pagesAws C3.6-99Eduard JoseNo ratings yet

- SAE J1926, MS 16142 - CuttersDocument11 pagesSAE J1926, MS 16142 - CutterspbsurfNo ratings yet

- ASTM A842 - Corpo de Prova OmegaDocument4 pagesASTM A842 - Corpo de Prova OmegaFabiano MonteiroNo ratings yet

- Mil HDBK 5j 1Document1 pageMil HDBK 5j 1dzsergeyNo ratings yet

- AEDK0627 CAT Truck Body Operation and Maitenance Guide PDFDocument9 pagesAEDK0627 CAT Truck Body Operation and Maitenance Guide PDFCarlos Lobo100% (2)

- Process Design in Impression Die ForgingDocument12 pagesProcess Design in Impression Die Forgingmike vidalNo ratings yet

- Maximum Material Condition (GD&T)Document15 pagesMaximum Material Condition (GD&T)Kishor kumar Bhatia67% (3)

- Fixed Dummy BlocksDocument19 pagesFixed Dummy BlocksNaveen GuptaNo ratings yet

- C633 617621-1 PDFDocument8 pagesC633 617621-1 PDFAmy BurnsNo ratings yet

- Surface Vehicle Standard: Rev. JUL86Document3 pagesSurface Vehicle Standard: Rev. JUL86anupthatta100% (1)

- Welding MIL STD PDFDocument157 pagesWelding MIL STD PDFAnonymous L0ChmPGNo ratings yet

- JIS B0419-1991 (Dung Sai Kich Thuoc)Document1 pageJIS B0419-1991 (Dung Sai Kich Thuoc)Giang Nguyễn BáNo ratings yet

- Korloy Grades and Chip BreakersDocument33 pagesKorloy Grades and Chip Breakersznovak77No ratings yet

- Drill&Tap ChartDocument1 pageDrill&Tap Chartamit_87_pallaviNo ratings yet

- (Jaso) F102-09Document16 pages(Jaso) F102-09AJ100% (1)

- Is.1573.1986 ED Coating StandardDocument24 pagesIs.1573.1986 ED Coating StandardUlhas Kavathekar100% (1)

- Cast Sae J514 PDFDocument4 pagesCast Sae J514 PDFmanishkumar FETNo ratings yet

- Design and Analysis of A Ladder Frame ChassisDocument10 pagesDesign and Analysis of A Ladder Frame ChassisJuan Sebastian CameroNo ratings yet

- Aluminum BronzeDocument37 pagesAluminum Bronzelijojose1No ratings yet

- Saej 524 V 002Document5 pagesSaej 524 V 002Marcos Verissimo Juca de PaulaNo ratings yet

- SKK Folder EngDocument10 pagesSKK Folder EngAyush NarangNo ratings yet

- Weld Repair Procedure For The Rear Axle A-Frame and Rear Axle Housing On 785, 789, and 793 OHTDocument18 pagesWeld Repair Procedure For The Rear Axle A-Frame and Rear Axle Housing On 785, 789, and 793 OHTcarlosNo ratings yet

- MAGNI 565: Product Data SheetDocument1 pageMAGNI 565: Product Data SheetjulianaNo ratings yet

- Typical Heat Treatment Defects of GearsDocument8 pagesTypical Heat Treatment Defects of GearsRamon BrownNo ratings yet

- Automotive Parts - Hexagon Nuts and Hexagon Thin Nuts: Japanese Automobile Standard Jaso F102:2005Document11 pagesAutomotive Parts - Hexagon Nuts and Hexagon Thin Nuts: Japanese Automobile Standard Jaso F102:2005AJ100% (1)

- CNH Mat 1007 - 07-2009Document5 pagesCNH Mat 1007 - 07-2009rgi178No ratings yet

- 1e0001 - Steel - Heat Treated Cold Finished BarDocument3 pages1e0001 - Steel - Heat Treated Cold Finished BarPuneet EnterprisesNo ratings yet

- Material Specification: Specification: B-1 Revision Date: 09/06/2016 Revision Level: AEDocument13 pagesMaterial Specification: Specification: B-1 Revision Date: 09/06/2016 Revision Level: AEReginaldo SantosNo ratings yet

- Carraro India LTD Steel Mill Standard Rev 08Document7 pagesCarraro India LTD Steel Mill Standard Rev 08SUNDARNo ratings yet

- Ferritic Ductile Iron Pressure-Retaining Castings For Use at Elevated TemperaturesDocument8 pagesFerritic Ductile Iron Pressure-Retaining Castings For Use at Elevated TemperaturesAmit PathakNo ratings yet

- Ph8251 - Material ScienceDocument6 pagesPh8251 - Material ScienceAbc AcademyNo ratings yet

- System Plast PDFDocument436 pagesSystem Plast PDFCesar Uriel Oropeza GomezNo ratings yet

- Xylan 142X Series: VOC Compliant Extreme Performance CoatingsDocument2 pagesXylan 142X Series: VOC Compliant Extreme Performance CoatingsRajNo ratings yet

- PW POS Training MMA ENDocument1 pagePW POS Training MMA ENShaik Nizam UddinNo ratings yet

- Light Gauge Steel FrameDocument20 pagesLight Gauge Steel FrameConstro FacilitatorNo ratings yet

- METAL ARTS - Career Studies Certificate: Program InfoDocument1 pageMETAL ARTS - Career Studies Certificate: Program InfoBobbyNo ratings yet

- Steel Reinforced Polyethylene (PE) Corrugated Pipe: Standard Specification ForDocument7 pagesSteel Reinforced Polyethylene (PE) Corrugated Pipe: Standard Specification Formati.khan.wahidiNo ratings yet

- Anup Sir PPT All PDFDocument222 pagesAnup Sir PPT All PDFFAIQNo ratings yet

- EN1090 EngtipsDocument3 pagesEN1090 EngtipssoulsellNo ratings yet

- Otc 19880 MS PDFDocument11 pagesOtc 19880 MS PDFLara ArinelliNo ratings yet

- EHB en 9-MaterialsDocument57 pagesEHB en 9-MaterialsAnonymous 1hOgJqwZuzNo ratings yet

- Detail Spun Pile Dia 600mm (Rev-01) - Spun PileDocument1 pageDetail Spun Pile Dia 600mm (Rev-01) - Spun PileMenejeer SianturiNo ratings yet

- Good Fabrication in Architectural Stainless Steel: ISBN 2-87997-062-8Document10 pagesGood Fabrication in Architectural Stainless Steel: ISBN 2-87997-062-8tonyNo ratings yet

- BSEN 10025 2000 New EditionDocument68 pagesBSEN 10025 2000 New Editionpbp2956No ratings yet

- Floating JointDocument0 pagesFloating JointsugirinNo ratings yet

- 16 CR 5 NiDocument11 pages16 CR 5 NiNikhil VermaNo ratings yet

- HSG CatalogDocument18 pagesHSG Cataloghiec89No ratings yet

- SLV General Introduction To Welding TechnologyDocument35 pagesSLV General Introduction To Welding TechnologyMohammad Sobhan RajabiNo ratings yet

- Technology 5 Constant CurrentDocument7 pagesTechnology 5 Constant CurrentnoorNo ratings yet

- Practical Thermal Design of Shell-And-tube Heat ExchangersDocument243 pagesPractical Thermal Design of Shell-And-tube Heat ExchangersPato Banda100% (5)

- Please Visit Us at C116/8.1 From 16-21.09.2013 at Schweissen & Schneiden 2013Document2 pagesPlease Visit Us at C116/8.1 From 16-21.09.2013 at Schweissen & Schneiden 2013narendraNo ratings yet

- Mirdc Atd Fees - ChargesDocument12 pagesMirdc Atd Fees - Chargesnapster386No ratings yet

- NHT-P51-00032 04MDocument937 pagesNHT-P51-00032 04MnmosilvaNo ratings yet

- AWS Pocket Handbook 8 - The Everyday Pocket Handbook For GMAW of AluminumDocument30 pagesAWS Pocket Handbook 8 - The Everyday Pocket Handbook For GMAW of Aluminumfast100% (1)

- 50 Mechanical Engineering Interview Questions and AnswersDocument12 pages50 Mechanical Engineering Interview Questions and Answersmj03127477706No ratings yet

- Waterproofing and MaintenanceDocument14 pagesWaterproofing and MaintenanceJun ChuNo ratings yet

- Hridayeshwar Jha: Director, Projects-Since April 2016Document4 pagesHridayeshwar Jha: Director, Projects-Since April 2016SOURAV SINGHNo ratings yet

- 8 - CE 511 - Welded ConnectionsDocument32 pages8 - CE 511 - Welded ConnectionsVictor Czar AustriaNo ratings yet

- Mse8 2 PDFDocument27 pagesMse8 2 PDFKrishnanNo ratings yet