Professional Documents

Culture Documents

C150Y LDPE Petlin Malaysia

C150Y LDPE Petlin Malaysia

Uploaded by

Long Trịnh ĐìnhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C150Y LDPE Petlin Malaysia

C150Y LDPE Petlin Malaysia

Uploaded by

Long Trịnh ĐìnhCopyright:

Available Formats

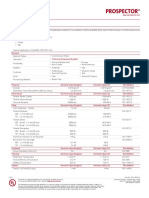

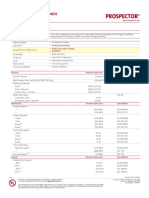

PETLIN

LD C150Y

Low Density Polyethylene

PETLIN (MALAYSIA) SDN BHD

Product Description

PETLIN LD C150Y is a low density polyethylene resin for general purpose and film applications. It is produced by the state-of-the-art DSM

Stamicarbon tubular process. It contains antioxidant (BHT free), slip and antiblock additives. It is intended primarily for blown film process.

General

Material Status • Commercial: Active

Availability • Asia Pacific

Additive • Antioxidant • High Antiblock • High Slip

• Antioxidant • Heat Sealable • High Gloss

Features • Food Contact Acceptable • High Antiblocking • High Slip

• Good Drawdown • High Clarity • Low Gel

• Bags • Foam

Uses

• Film • Laundry Bags

Agency Ratings • FDA 21 CFR 177.1520

Forms • Pellets

Processing Method • Blown Film • Film Extrusion

Physical Nominal Value Unit Test Method

Density 0.921 g/cm³ ISO 1183/A

Melt Mass-Flow Rate (MFR) (190°C/2.16 kg) 5.0 g/10 min ISO 1133

Mechanical Nominal Value Unit Test Method

Coefficient of Friction 0.10 ASTM D1894

Films Nominal Value Unit Test Method

Film Thickness - Tested 25 µm

Film Thickness - Recommended / Available 150 to 60 µm

Tensile Modulus ISO 527-3

MD: 25 µm 202 MPa

TD: 25 µm 224 MPa

Tensile Stress ISO 527-3

MD: Break, 25 µm 26.0 MPa

TD: Break, 25 µm 15.0 MPa

Tensile Elongation ISO 527-3

MD: Break, 25 µm 150 %

TD: Break, 25 µm 610 %

Dart Drop Impact (25 µm) 86 g ASTM D1709

Elmendorf Tear Strength ISO 6383-2

MD: 25 µm 80000 N

TD: 25 µm 30000 N

Optical Nominal Value Unit Test Method

Gloss (45°, 25.0 µm) 66 ASTM D2457

Haze (25.0 µm) 6.5 % ASTM D1003

Extrusion Nominal Value Unit

Melt Temperature 145 to 165 °C

Notes

1

Typical properties: these are not to be construed as specifications.

1 of 1

Copyright © 2011 - IDES - The Plastics Web ® | 800-788-4668 or 307-742-9227 | www.ides.com. Revision History

Document Created: Saturday, August 20, 2011

The information presented on this datasheet was acquired by IDES from the producer of the material. IDES makes substantial efforts to assure the accuracy of Added to Prospector: September, 2008

this data. However, IDES assumes no responsibility for the data values and strongly encourages that upon final material selection, data points are validated with Last Updated: 9/25/2008

the material supplier.

You might also like

- Multicomponent Polymeric Materials, 2016 PDFDocument411 pagesMulticomponent Polymeric Materials, 2016 PDFCosmin TăbăcaruNo ratings yet

- Lldpe HD21HS Qamar SPDC SpecsDocument2 pagesLldpe HD21HS Qamar SPDC SpecsChu ChuNo ratings yet

- Certene™ Llbf-218aDocument1 pageCertene™ Llbf-218aJose FernandezNo ratings yet

- DOWLEX™ 2607GC: The Dow Chemical CompanyDocument3 pagesDOWLEX™ 2607GC: The Dow Chemical CompanyTruc Thao NguyenNo ratings yet

- Certene™ Llhc-318aDocument1 pageCertene™ Llhc-318aJose FernandezNo ratings yet

- 8176 - Pelld Sabic 218wjDocument2 pages8176 - Pelld Sabic 218wjLê Đình QuânNo ratings yet

- Product PDF 244478Document3 pagesProduct PDF 244478lorejaz84071127No ratings yet

- Qamar Fd21Hn: SPDC LTDDocument3 pagesQamar Fd21Hn: SPDC LTDBastian HübnerNo ratings yet

- Adsyl 5 C 39 F: Lyondellbasell IndustriesDocument3 pagesAdsyl 5 C 39 F: Lyondellbasell Industriesnouman ashrafNo ratings yet

- Dow Ldpe 0 75 Mfi Non Slip 310eDocument3 pagesDow Ldpe 0 75 Mfi Non Slip 310eaman.chaudhary3663No ratings yet

- Certene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneDocument1 pageCertene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneRoberto De Mesa PNo ratings yet

- CEFOR™ 1221P: Linear Low Density Polyethylene ResinDocument3 pagesCEFOR™ 1221P: Linear Low Density Polyethylene ResincuppycuppycupNo ratings yet

- DOW™ Butene 1221P: Linear Low Density Polyethylene ResinDocument3 pagesDOW™ Butene 1221P: Linear Low Density Polyethylene ResinMinh TranNo ratings yet

- ULTEM™ AUT230 Resin: SABIC Innovative PlasticsDocument4 pagesULTEM™ AUT230 Resin: SABIC Innovative PlasticsLeandro LacerdaNo ratings yet

- Marpol® LDF 720 CSBDocument1 pageMarpol® LDF 720 CSBDiana SarmientoNo ratings yet

- Dow Ldpe 310lg Low Density Polyethylene ResinDocument4 pagesDow Ldpe 310lg Low Density Polyethylene ResinLeductoan LeNo ratings yet

- Nirumand Polymer: Technical Data SheetDocument1 pageNirumand Polymer: Technical Data SheetMahaNo ratings yet

- Qamar Resin Properties: Item Grade HB18N FC21HS FC21HN FC20H FC18N FD21HS FD21HN FD18N CD18N Test Method UnitDocument3 pagesQamar Resin Properties: Item Grade HB18N FC21HS FC21HN FC20H FC18N FD21HS FD21HN FD18N CD18N Test Method UnitGia Dinh HotrokithuatNo ratings yet

- Solvay - Ixef BXT2000Document5 pagesSolvay - Ixef BXT2000Renan GadioliNo ratings yet

- PP GF30 - Hostacom PC072-3 Naturale-2Document2 pagesPP GF30 - Hostacom PC072-3 Naturale-2armando0% (1)

- Braskem Braskem PE GP100ORXP Pead GAS PE100Document2 pagesBraskem Braskem PE GP100ORXP Pead GAS PE100weimar solizNo ratings yet

- ACRYLITE® Satinice df21 8NDocument3 pagesACRYLITE® Satinice df21 8NEnriqueNo ratings yet

- Technical Information: Coextruded Biaxially Oriented Polypropylene FilmDocument1 pageTechnical Information: Coextruded Biaxially Oriented Polypropylene FilmAlzena badzlinNo ratings yet

- PBT-PC Valox 357Document5 pagesPBT-PC Valox 357countzeroaslNo ratings yet

- Dowlex Lldpe 2645GDocument3 pagesDowlex Lldpe 2645GSalustraNo ratings yet

- UmaPET - AODocument1 pageUmaPET - AOñeNo ratings yet

- Akulon F136-C1: DSM Engineering Materials - Polyamide 6Document2 pagesAkulon F136-C1: DSM Engineering Materials - Polyamide 6bobNo ratings yet

- Datasheet 2102TN PDFDocument1 pageDatasheet 2102TN PDFjavadmohammadiNo ratings yet

- Global Synthetics Proliner HDPE Smooth DatasheetDocument1 pageGlobal Synthetics Proliner HDPE Smooth DatasheetMatt GhanaviNo ratings yet

- Product 301485Document1 pageProduct 301485Geovani Daniel Gonzalez LopezNo ratings yet

- Ryton R-4-200NA: Polyphenylene SulfideDocument3 pagesRyton R-4-200NA: Polyphenylene SulfideMatteo BaldiniNo ratings yet

- Nirumand Polymer: Technical Data SheetDocument1 pageNirumand Polymer: Technical Data SheetMahaNo ratings yet

- Tenac C 4520Document2 pagesTenac C 4520Phung LucNo ratings yet

- Dow Elite 5400G TDSDocument2 pagesDow Elite 5400G TDSAli RazuNo ratings yet

- Ds CoPP-20900Document1 pageDs CoPP-20900rubser05No ratings yet

- XENOY™ Resin 1760E - AmericasDocument4 pagesXENOY™ Resin 1760E - AmericasWellington C. de AraujoNo ratings yet

- LTL - MeDocument2 pagesLTL - MeQUALITY CONTROLNo ratings yet

- UK NatureFlex NMDocument2 pagesUK NatureFlex NMRic MnsNo ratings yet

- PermaStat 600 UVDocument2 pagesPermaStat 600 UVPhung LucNo ratings yet

- Adsyl 7423 XCP: Lyondellbasell IndustriesDocument4 pagesAdsyl 7423 XCP: Lyondellbasell Industriesnouman ashrafNo ratings yet

- Tenac 4013ADocument3 pagesTenac 4013APhung LucNo ratings yet

- Bapolene 200fDocument2 pagesBapolene 200fDiana SarmientoNo ratings yet

- UK NatureFlex NMDocument2 pagesUK NatureFlex NMjituniNo ratings yet

- Product PDF 71351Document2 pagesProduct PDF 71351Gia Dinh HotrokithuatNo ratings yet

- 3M™ Scotch® Cellophane Film Tape 610: October, 2016Document3 pages3M™ Scotch® Cellophane Film Tape 610: October, 2016真幸运No ratings yet

- Resina Nueva Validacion SkytronDocument2 pagesResina Nueva Validacion SkytronAlbert FortunatoNo ratings yet

- Dow Corning 785 Technical DatasheetDocument4 pagesDow Corning 785 Technical DatasheetShuvenduNo ratings yet

- LF410 (영문)Document1 pageLF410 (영문)coordinador.comercialNo ratings yet

- TDS GLACE - enDocument1 pageTDS GLACE - enmr.mennensNo ratings yet

- Technical Data Glass Fiber Geocomposite - AIC-50Document1 pageTechnical Data Glass Fiber Geocomposite - AIC-50mahesh.kumarNo ratings yet

- Infino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateDocument2 pagesInfino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateVenkatesan Manikandan0% (1)

- TDS HMTDocument1 pageTDS HMTKarthiNo ratings yet

- Product PDF 137904Document2 pagesProduct PDF 137904Igor GonçalvesNo ratings yet

- FICHA Tecnica PVC Estandar - Pelplast OKDocument2 pagesFICHA Tecnica PVC Estandar - Pelplast OKRaul PerezNo ratings yet

- SBRS-DZDocument1 pageSBRS-DZAlejandro FonsecaNo ratings yet

- PC-Transparent 144RDocument5 pagesPC-Transparent 144Rsantosh.bhattNo ratings yet

- MV HV Cable ManufacturingDocument33 pagesMV HV Cable ManufacturingAris BudiantoNo ratings yet

- Dyneon PTFE All Grades PDFDocument11 pagesDyneon PTFE All Grades PDFRajanSharmaNo ratings yet

- Louvres TechguideDocument8 pagesLouvres TechguideImtiaz AhmedNo ratings yet

- Practical Guide To Blow Moulding PDFDocument216 pagesPractical Guide To Blow Moulding PDFГеорги ВеждаровNo ratings yet

- Hambach and Volkmer. 2017 - Properties of 3d-Printed Fiber-Reinforced Portlannd Cement Paste PDFDocument9 pagesHambach and Volkmer. 2017 - Properties of 3d-Printed Fiber-Reinforced Portlannd Cement Paste PDFManu K MohanNo ratings yet

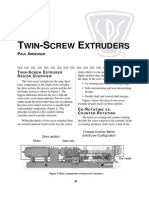

- Paul AndersenDocument24 pagesPaul AndersenAli Nurrakhmad Siregar100% (1)

- Advancements in PVC Compounding PaperDocument5 pagesAdvancements in PVC Compounding PaperSagar Salunkhe100% (1)

- Fiche Technique PVC WL1230PDocument1 pageFiche Technique PVC WL1230PMokrane HamaidiNo ratings yet

- GEV 2022 Company Presentation & Application - ENGDocument33 pagesGEV 2022 Company Presentation & Application - ENGSunil R HasabnisNo ratings yet

- PVC Conduit Pipes and FittingsDocument7 pagesPVC Conduit Pipes and FittingsSamrat SarkarNo ratings yet

- JJ FMEA SampleDocument6 pagesJJ FMEA SampleRahul YadavNo ratings yet

- Sika Backing FillerDocument2 pagesSika Backing Fillerthe pilotNo ratings yet

- Plastics ManufacturingDocument39 pagesPlastics ManufacturingSparsh KatiyarNo ratings yet

- Case Study On Swastik PipesDocument10 pagesCase Study On Swastik Pipesnkhilwani007No ratings yet

- ATT-13/96, FORMING MARSHALL SPECIMENS, Field MethodDocument5 pagesATT-13/96, FORMING MARSHALL SPECIMENS, Field MethodCE PassajNo ratings yet

- 17-3 Metal Doors & WindowsDocument10 pages17-3 Metal Doors & WindowsZuberYousufNo ratings yet

- Chapter 1: Polymerization: Definition, Objects, Types: POY and TEXTURISING ProcessDocument84 pagesChapter 1: Polymerization: Definition, Objects, Types: POY and TEXTURISING ProcessKaushal JoshiNo ratings yet

- Waste Recycling in Biaxially Oriented Polypropylene - BOPP: June 2020Document6 pagesWaste Recycling in Biaxially Oriented Polypropylene - BOPP: June 2020Ahmed SalahNo ratings yet

- Lecture 13 Processing of PlasticsDocument45 pagesLecture 13 Processing of PlasticsSilentxpireNo ratings yet

- TDS BorSafe ME3444 (E115026)Document2 pagesTDS BorSafe ME3444 (E115026)charlesNo ratings yet

- Feed Manufacturing Technology - Issues and ChallengesDocument8 pagesFeed Manufacturing Technology - Issues and ChallengesOnur DemirelNo ratings yet

- 6063 and 7003 Aluminum Alloy Tissue Properties and Quenching Sensitivity StudiesDocument1 page6063 and 7003 Aluminum Alloy Tissue Properties and Quenching Sensitivity StudiesSATHISH RC100% (1)

- Air-Cooled Heat Exchangers Fin-Fan: by M.M.SorourDocument64 pagesAir-Cooled Heat Exchangers Fin-Fan: by M.M.SorourNader GaafarNo ratings yet

- Selecting Manufacturing ProcessDocument57 pagesSelecting Manufacturing ProcessKamal ThummarNo ratings yet

- Polymer ProcessingDocument6 pagesPolymer ProcessingAldi RenaldhaNo ratings yet

- Virtual Manufacturing On The Web: Extrusion Die DesignDocument83 pagesVirtual Manufacturing On The Web: Extrusion Die DesignAmandeep Singh GujralNo ratings yet

- Khalsa: On Readymade Garment Manufacturing UnitDocument15 pagesKhalsa: On Readymade Garment Manufacturing Unitsaorabh13No ratings yet

- Br20 - B.Tech. - Mechanical Engineering Syllabus: Course ObjectivesDocument2 pagesBr20 - B.Tech. - Mechanical Engineering Syllabus: Course ObjectivesBashu Dev SanjelNo ratings yet