Professional Documents

Culture Documents

PRO-EnV-SITE-SPV-020 A IFR Flushing and Blowing Procedure

PRO-EnV-SITE-SPV-020 A IFR Flushing and Blowing Procedure

Uploaded by

rizki projectOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PRO-EnV-SITE-SPV-020 A IFR Flushing and Blowing Procedure

PRO-EnV-SITE-SPV-020 A IFR Flushing and Blowing Procedure

Uploaded by

rizki projectCopyright:

Available Formats

Flushing and Blowing

PT. SOUTH PACIFIC VISCOSE

Procedure

CONTENT

1. SCOPE .......................................................................................................................... 5

2. RESPONSIBILITIES ...................................................................................................... 5

3. REFERENCES ............................................................................................................... 5

4. GENERAL REQUIREMENT .......................................................................................... 5

5. FLUSHING .......................................................................................................... 5

6. BLOWING ..................................................................................................................... 6

7. FORM REPORT .......................................................................................................... 7

Document Number Confidentiality Page No

PRO-ENV-SITE-SPV-020 - 4 OF 7

Flushing and Blowing

PT. SOUTH PACIFIC VISCOSE

Procedure

1. SCOPE

This procedure describes the control methods for internal cleaning pipe before and after

pressure testing commence.

2. RESPONSIBILITIES

2.1. The Production Dept. Manager shall be responsible for preparation and performing the

above test in accordance with this procedure, traveler and working instruction.

2.2. The QA/QC Manager shall be responsible for monitoring with process for internal

cleaning piping spools the witness of QC Inspector and Client.

3. REFERENCES

3.1. ASME B31.3 Process Piping : Appendix F para F 3335.9

3.2. ASTM D 4174

4. GENERAL REQUIREMENTS

Process internal cleaning pipe spools shall be conducted on all piping after :

a. All piping fabrication has been completed, except for operations which could not be

performed prior to the test such as weld end preparation, cosmetic grinding on the base

metal which does not affect the required thickness

b. All examination have been perform, except those required after the test.

5. FLUSHING

5.1. Flushing Process

During the process flushing, certainly when the water filling the line pipe spools in the

highest point of the pipe installation.

Flushing using Air Compressor with pressure 3 Barg to ensure no blocking was occured

before pressure test and continuosly to ensure all the instruments mounted on the pipe

installation in the open condition.

Flushing process must be conducted at least 10 minutes or until the condition of the air

compressor coming out the pipe installation is clean from kind of any dirt.

5.2. Acceptance Criteria

Flushing Process accepted if no blocking material or no foreign material.

Document Number Confidentiality Page No

PRO-ENV-SITE-SPV-020 - 5 OF 7

Flushing and Blowing

PT. SOUTH PACIFIC VISCOSE

Procedure

6. BLOWING

6.1. Blowing process performed after Hydrostatic Test using air blow with high pressure to

ensure no water is retained on pipe.

6.2. Blowing process accepted if no water retained on pipe.

Document Number Confidentiality Page No

PRO-ENV-SITE-SPV-020 - 6 OF 7

Flushing and Blowing

PT. SOUTH PACIFIC VISCOSE

Procedure

7. FORM REPORT

Document Number Confidentiality Page No

PRO-ENV-SITE-SPV-020 - 7 OF 7

You might also like

- Screw Conveyors Pre Commissioning ITPDocument9 pagesScrew Conveyors Pre Commissioning ITPdidi sudiartoNo ratings yet

- PDS CS Form No. 212 Revised Personal Data Sheet 2Document4 pagesPDS CS Form No. 212 Revised Personal Data Sheet 2Jay-Ar D. Barbadia50% (2)

- Hydrotest and Flushing ProcedureDocument16 pagesHydrotest and Flushing Procedureคุณพ่อน้อง บิ๊กบอส100% (9)

- Sales Promotion Process DTI DAO 2 Series of 1993 Consumer Act of The PhilippinesDocument12 pagesSales Promotion Process DTI DAO 2 Series of 1993 Consumer Act of The PhilippinesJanette Toral100% (3)

- QCP-12 Valve Leak Test Procedure PDFDocument21 pagesQCP-12 Valve Leak Test Procedure PDFIbrahim100% (3)

- Hydro Test ProcedureDocument14 pagesHydro Test ProcedureARJUN100% (5)

- Piping Fabrication Procedure.Document58 pagesPiping Fabrication Procedure.Janardhan Surya78% (23)

- C: P: D: Factory Acceptance Test Procedure For Control Valve C - D N .: - Ptcs D N .: FCS-SOP-001. R 01 S: 1 10Document13 pagesC: P: D: Factory Acceptance Test Procedure For Control Valve C - D N .: - Ptcs D N .: FCS-SOP-001. R 01 S: 1 10Hicham BelmaatiNo ratings yet

- Qa-Qc Check ListDocument8 pagesQa-Qc Check ListShankarEllampriam100% (3)

- Pro-Env-site-spv-019 A Ifc Piping Drying ProcedureDocument2 pagesPro-Env-site-spv-019 A Ifc Piping Drying Procedurerizki projectNo ratings yet

- Pro-Env-site-spv-038 A Ifr Boxing Up ProcedureDocument3 pagesPro-Env-site-spv-038 A Ifr Boxing Up Procedurerizki projectNo ratings yet

- Document No. REV. 0 Job No. Date Page 1 of 22Document5 pagesDocument No. REV. 0 Job No. Date Page 1 of 22Christiadi P. ArgaNo ratings yet

- MSAE014-QC-PRE-035-Quality Procedure For Hydrostatic TestingDocument12 pagesMSAE014-QC-PRE-035-Quality Procedure For Hydrostatic Testingqamar qateebNo ratings yet

- QCP-10 Hydrotest and Flushing ProcedureDocument15 pagesQCP-10 Hydrotest and Flushing ProcedureIbrahim67% (3)

- 4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Document8 pages4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Randu WatangNo ratings yet

- MST Valve TestingDocument7 pagesMST Valve TestingSiva RamNo ratings yet

- STS QAC SOP 008 Tube Plugging ProcedureDocument7 pagesSTS QAC SOP 008 Tube Plugging Proceduremohd as shahiddin jafriNo ratings yet

- FAT ProcedureDocument61 pagesFAT ProcedureBagus SigitNo ratings yet

- Hidrostatic Test Procedure: Hafizul - HasrolDocument7 pagesHidrostatic Test Procedure: Hafizul - HasrolRafique MunirNo ratings yet

- Procedure For Vacuum Box TestingDocument3 pagesProcedure For Vacuum Box TestingZakirUllahNo ratings yet

- Jif 20 Van 014 Fat Qad 2419 Fat ShelterDocument10 pagesJif 20 Van 014 Fat Qad 2419 Fat Shelteransalkr_6232335No ratings yet

- MGT (Manifold Group Trunkline) System For The Gcs 29, 30 and 31 in North Kuwait Company Contract No.: 15051614 Petrofac Job No.: JI-2031Document9 pagesMGT (Manifold Group Trunkline) System For The Gcs 29, 30 and 31 in North Kuwait Company Contract No.: 15051614 Petrofac Job No.: JI-2031velmurug_balaNo ratings yet

- q22 001 Fat Procedure Mt1 SK 4910 B ADocument18 pagesq22 001 Fat Procedure Mt1 SK 4910 B APham Thai Tuyen100% (1)

- DRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFDocument36 pagesDRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFrodman823No ratings yet

- Pt. Multi Fabrindo Gemilang: Hydrostatic Test ProcedureDocument6 pagesPt. Multi Fabrindo Gemilang: Hydrostatic Test Procedureluhur prandika100% (2)

- A.3.7 JP152-300-DQP-05.81-90005-02 Pneumatic Pressure TestingDocument12 pagesA.3.7 JP152-300-DQP-05.81-90005-02 Pneumatic Pressure TestingJabel Oil Services Technical DPTNo ratings yet

- Piping Inspect & Testing ProcedureDocument11 pagesPiping Inspect & Testing ProcedureErlanggaBonaparteNo ratings yet

- SGO-NPIW-EXE-GNR-QFE-01339 For The ValveDocument7 pagesSGO-NPIW-EXE-GNR-QFE-01339 For The ValveJosé BenjamínNo ratings yet

- Pressure TestingDocument9 pagesPressure TestingSanjay SinghNo ratings yet

- Cleaning and FlushingDocument11 pagesCleaning and FlushingDannis Ananto100% (2)

- Construction Leak Test ProcedureDocument9 pagesConstruction Leak Test Procedurezack zeeart100% (1)

- Fabrication, Testing ProcedureDocument11 pagesFabrication, Testing ProcedureAhmad FaujiNo ratings yet

- HYROTEST Procedure Tank NSIDocument4 pagesHYROTEST Procedure Tank NSIluhur prandika100% (1)

- Vaccum Box Procedure KOD GEN PRO 001Document4 pagesVaccum Box Procedure KOD GEN PRO 001Totan KarNo ratings yet

- Std-Insp-0127 Procedure For Commissioning ProcedureDocument54 pagesStd-Insp-0127 Procedure For Commissioning ProcedureAkshay KalraNo ratings yet

- Hydrostatic Test ProcedureDocument6 pagesHydrostatic Test ProcedureLuhur PrandikaNo ratings yet

- ENV-SPV-DR-B-003 Fabrication Procedure-Rev - ADocument11 pagesENV-SPV-DR-B-003 Fabrication Procedure-Rev - AyoeyNo ratings yet

- p103-Stts-gec-Asi-ms-hvac-002 Method Statemenr For Installation of Chemical Dosing, Chilled Water Pump Pressurization UnitsDocument8 pagesp103-Stts-gec-Asi-ms-hvac-002 Method Statemenr For Installation of Chemical Dosing, Chilled Water Pump Pressurization UnitsAnandu AshokanNo ratings yet

- PRO-EnV-SITE-SPV-031 - A - IFR - Gross Leak Test and Service Test ProcedureDocument2 pagesPRO-EnV-SITE-SPV-031 - A - IFR - Gross Leak Test and Service Test Procedurerizki projectNo ratings yet

- Engineering ProceduresDocument23 pagesEngineering ProceduresadammzjinNo ratings yet

- Api 653 Report-Hydrolic Test PDFDocument12 pagesApi 653 Report-Hydrolic Test PDFnaoufel1706No ratings yet

- Valve Testing Preservation Installation Sequence - UZ750Document15 pagesValve Testing Preservation Installation Sequence - UZ750Gaurav KhamkarNo ratings yet

- Method Statement For WellDocument7 pagesMethod Statement For WellDeffous AbdelhadiNo ratings yet

- Hydrostatic Pressure Test-SpoolDocument8 pagesHydrostatic Pressure Test-SpoolJoby JacobNo ratings yet

- Majnoon CPF 2 Project: Fired Heater CP2-F-50701 A/B Coil Prefabrication Hydrostatic Test ProcedureDocument14 pagesMajnoon CPF 2 Project: Fired Heater CP2-F-50701 A/B Coil Prefabrication Hydrostatic Test ProcedureMassimo FumarolaNo ratings yet

- Honing Procedure: Doc. No.: - Job No.: 26071Document10 pagesHoning Procedure: Doc. No.: - Job No.: 26071Muhammad GaneshaNo ratings yet

- P-T3109-EI-026 (Generator Leak Test)Document6 pagesP-T3109-EI-026 (Generator Leak Test)M MiftakhNo ratings yet

- Piping Hydrostatic Test Procedure Rev0Document8 pagesPiping Hydrostatic Test Procedure Rev0smsunil12345No ratings yet

- Quality Procedure For Pressure Test (Hydro) : QCP-HP110Document9 pagesQuality Procedure For Pressure Test (Hydro) : QCP-HP110AAISATNo ratings yet

- Pet-002-002 Procedimiento Tintas Penetrantes Ingles (v4)Document15 pagesPet-002-002 Procedimiento Tintas Penetrantes Ingles (v4)Emanuel PerillaNo ratings yet

- DHSV TestDocument7 pagesDHSV TestRonald Lucas Silva Lefundes OliveiraNo ratings yet

- MST For Below Ground UPVC Drainage PipesDocument13 pagesMST For Below Ground UPVC Drainage Pipesمقاول تكييف كهرباء وصحيNo ratings yet

- ENV-SPV-DR-B-021 Pickling & Passivation Procedure Rev - ADocument14 pagesENV-SPV-DR-B-021 Pickling & Passivation Procedure Rev - AyoeyNo ratings yet

- Method Statement For Hydro-Testing of Pipes: 0 Issued For Approval Rev Date Description Prepared Checked ApprovedDocument7 pagesMethod Statement For Hydro-Testing of Pipes: 0 Issued For Approval Rev Date Description Prepared Checked ApprovedAnish KumarNo ratings yet

- By Sekar - Rajesh at 6:47 PM, Jun 17, 2015Document11 pagesBy Sekar - Rajesh at 6:47 PM, Jun 17, 2015Rahmat BasukiNo ratings yet

- Lawsuit!: Reducing the Risk of Product Liability for ManufacturersFrom EverandLawsuit!: Reducing the Risk of Product Liability for ManufacturersNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- 75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014From Everand75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014S. K. SundaramNo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Guidelines for Integrating Process Safety into Engineering ProjectsFrom EverandGuidelines for Integrating Process Safety into Engineering ProjectsNo ratings yet

- Combined Gas Law Activity SheetDocument2 pagesCombined Gas Law Activity SheetVanessa QuinolNo ratings yet

- Cambridge AS Level Japanese Language Paper 3 Winter 2011Document2 pagesCambridge AS Level Japanese Language Paper 3 Winter 2011hikari39No ratings yet

- Faisalabad Punjab Intra-Party Elections (Contested Results)Document5 pagesFaisalabad Punjab Intra-Party Elections (Contested Results)PTI OfficialNo ratings yet

- DAR V Sarangani Agricultural CoDocument8 pagesDAR V Sarangani Agricultural Cocherry_romano_2No ratings yet

- IMPSDocument7 pagesIMPSRahul DhannurNo ratings yet

- Bois BSDocument7 pagesBois BSReyShandilyaNo ratings yet

- Assessing A New Venture's Financial Strength and ViabilityDocument32 pagesAssessing A New Venture's Financial Strength and Viabilitydedila nachar50% (2)

- Drinking and Driving PDFDocument1 pageDrinking and Driving PDFpepe pecasNo ratings yet

- ICOM IC-M604 Manual PDFDocument64 pagesICOM IC-M604 Manual PDFWahyusnkyahoo.com 64939AbimanyuNo ratings yet

- Ignacio v. Ignacio (A.C. No. 9426, 25 August 2020)Document64 pagesIgnacio v. Ignacio (A.C. No. 9426, 25 August 2020)aisea patrickNo ratings yet

- In Re FreemanDocument13 pagesIn Re Freemanapi-19751851No ratings yet

- Manual N5180-90002 InstallationDocument40 pagesManual N5180-90002 InstallationAna Safranec VasicNo ratings yet

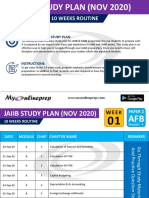

- Jaiib 10 Weeks Study Plan Nov 2020Document11 pagesJaiib 10 Weeks Study Plan Nov 2020Siva BantuNo ratings yet

- Political Ideologies: What I Need To KnowDocument16 pagesPolitical Ideologies: What I Need To KnowVictoria Quebral CarumbaNo ratings yet

- 59 Sta. Clara Homeowners' Asso. V Sps. Gaston, GR No. 141961, January 23, 2002Document7 pages59 Sta. Clara Homeowners' Asso. V Sps. Gaston, GR No. 141961, January 23, 2002Edgar Calzita AlotaNo ratings yet

- Tax1-Executive Order 93Document3 pagesTax1-Executive Order 93SuiNo ratings yet

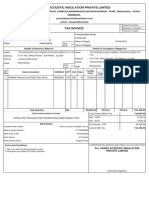

- Technosales Multimedia Technologies PVT LTD - 36Document1 pageTechnosales Multimedia Technologies PVT LTD - 36Fbsix ApNo ratings yet

- Costing Misty CharmDocument1 pageCosting Misty CharmRachana PanditNo ratings yet

- Chapter 1 The Accountancy ProfessionDocument23 pagesChapter 1 The Accountancy Professionsehun ohNo ratings yet

- Affidavit of Tenancy and LandholdingsDocument1 pageAffidavit of Tenancy and LandholdingsRemi Karissima GalvezNo ratings yet

- Turkish Economy (1980-1989)Document15 pagesTurkish Economy (1980-1989)ademNo ratings yet

- Criminals, Militias, and Insurgents: Organized Crime in IraqDocument293 pagesCriminals, Militias, and Insurgents: Organized Crime in IraqSSI-Strategic Studies Institute-US Army War CollegeNo ratings yet

- Resolutions About Overworked Teachers (Draft)Document4 pagesResolutions About Overworked Teachers (Draft)Vannie MonderoNo ratings yet

- IFRS 16 Leases - (Day 1)Document24 pagesIFRS 16 Leases - (Day 1)Nazmul KhanNo ratings yet

- PIL ProjectDocument11 pagesPIL ProjectAnasuya NairNo ratings yet

- Henas Shoes & Footwear Manufacturing Business PlanDocument23 pagesHenas Shoes & Footwear Manufacturing Business PlanMega SandalsNo ratings yet

- Transnational Organized Crime Its ConceptDocument12 pagesTransnational Organized Crime Its Conceptgagan deepNo ratings yet

- Stuvia 1968904 lcp4807 Exam Pack Questions and Answers For 2018 2022 Download FileDocument42 pagesStuvia 1968904 lcp4807 Exam Pack Questions and Answers For 2018 2022 Download FilebchiceleganceNo ratings yet