Professional Documents

Culture Documents

Concrete Pumping Risk Assessment

Concrete Pumping Risk Assessment

Uploaded by

lenindraCopyright:

Available Formats

You might also like

- 20) Pumping of WaterDocument7 pages20) Pumping of WaterMobin Thomas Abraham77% (13)

- STABLE Resource Toolkit-BipolarDocument67 pagesSTABLE Resource Toolkit-Bipolardidiisafitri100% (1)

- JHA For Cable Laying, Cable Glanding and TerminationDocument12 pagesJHA For Cable Laying, Cable Glanding and TerminationFrancis Enriquez Tan100% (2)

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 pagesRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Risk Assessment For External Façade & Canopies CleaningDocument8 pagesRisk Assessment For External Façade & Canopies CleaningFrancis Enriquez Tan100% (2)

- Risk Assessment For External Façade & Canopies CleaningDocument6 pagesRisk Assessment For External Façade & Canopies Cleaningjulius0% (1)

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- JSA - Installation of U G PipingDocument11 pagesJSA - Installation of U G PipingOws Anish100% (1)

- Meetings in A Company.Document37 pagesMeetings in A Company.armaanNo ratings yet

- Risk Assesment For GRP Pipe LayingDocument3 pagesRisk Assesment For GRP Pipe LayingSasi Kumar60% (5)

- RS Concrete Pumping Risk AssessmentDocument8 pagesRS Concrete Pumping Risk AssessmentLito PanchoNo ratings yet

- IDC SOP # 10 Operation of The Pipe SpinnerDocument2 pagesIDC SOP # 10 Operation of The Pipe SpinnerkareemNo ratings yet

- CTRA-20-TM-035-Lagoon Cleaning-R1-Not ApprovedDocument7 pagesCTRA-20-TM-035-Lagoon Cleaning-R1-Not ApprovedMohamed RizwanNo ratings yet

- Pipe Nitrogen Testing in Non Confined SpaceDocument4 pagesPipe Nitrogen Testing in Non Confined SpaceKannan KamalNo ratings yet

- R A - Mobile CraneDocument1 pageR A - Mobile CraneNick KrugerNo ratings yet

- Risk Assessment-Concrete Casting by Using PumpsDocument3 pagesRisk Assessment-Concrete Casting by Using PumpsSarfraz Randhawa100% (2)

- 1717690216690Document8 pages1717690216690Arun RajNo ratings yet

- Housekeeping JsaDocument9 pagesHousekeeping JsaShahid BhattiNo ratings yet

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Pdfslide - Us Jsa For Using Jack HammerDocument3 pagesPdfslide - Us Jsa For Using Jack HammerWidya BungaNo ratings yet

- PPR Installation & Pressure Testing RADocument19 pagesPPR Installation & Pressure Testing RAJomy JohnyNo ratings yet

- Risk Assesment For Connecting The Existing Pipe To Pump StationDocument4 pagesRisk Assesment For Connecting The Existing Pipe To Pump StationSasi Kumar100% (2)

- 03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressDocument16 pages03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressSavio SunnyNo ratings yet

- JSA For Pipe Installation TS 3Document8 pagesJSA For Pipe Installation TS 3Shilpiengg SafetyNo ratings yet

- CTRA-23-STM-093 - TK - 11-995 - Bund Wall CuttingDocument3 pagesCTRA-23-STM-093 - TK - 11-995 - Bund Wall CuttingMohamed RizwanNo ratings yet

- Risk Assessment For Installation of A New AC UnitDocument9 pagesRisk Assessment For Installation of A New AC Unitservice.amepNo ratings yet

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 pagesJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- All Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicableDocument6 pagesAll Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicablecrnkarlosNo ratings yet

- 069-JSA-MLCC JSA STRINGING - BGP-STA 0+012 TO 1+688 (Inside BGP) - Rev.01-ApprovedDocument10 pages069-JSA-MLCC JSA STRINGING - BGP-STA 0+012 TO 1+688 (Inside BGP) - Rev.01-ApprovedSn AhsanNo ratings yet

- Risk Assessment For Installation of Toilet Exhaust Fan (New)Document12 pagesRisk Assessment For Installation of Toilet Exhaust Fan (New)Anandu AshokanNo ratings yet

- 028 - JSA - Hydrotesting - 27-02-2012Document7 pages028 - JSA - Hydrotesting - 27-02-2012sathishkumarNo ratings yet

- Aintree Concrete Pumping Risk Assessment 2020Document4 pagesAintree Concrete Pumping Risk Assessment 2020Lito PanchoNo ratings yet

- Fill-Up This Card Before Commencement of Critical WorksDocument4 pagesFill-Up This Card Before Commencement of Critical WorksSiddhant choudharyNo ratings yet

- Precast Lifting Risk Assessment (0075) - Rev-01Document8 pagesPrecast Lifting Risk Assessment (0075) - Rev-01Muhammad OsamaNo ratings yet

- Job Safety Analysis (JSA) - CONCRETE WORKS - DateDocument2 pagesJob Safety Analysis (JSA) - CONCRETE WORKS - Datenabeel100% (1)

- Tie - in Mechanical Installation JHADocument7 pagesTie - in Mechanical Installation JHAmalik jahanNo ratings yet

- RA-for Glass Installation 30-04-2022Document6 pagesRA-for Glass Installation 30-04-2022Muideen Oyedele100% (2)

- HKGGA - ELS & Pile Cap RADocument12 pagesHKGGA - ELS & Pile Cap RAymkawai224No ratings yet

- TTEC Fencing RADocument7 pagesTTEC Fencing RAGeml TrinidadNo ratings yet

- Risk Assessment Record Activity: Installation ofDocument17 pagesRisk Assessment Record Activity: Installation ofvasanth pugazhendhi0% (1)

- JSA 03 Gate Entrance Traffic ProposalDocument10 pagesJSA 03 Gate Entrance Traffic Proposalrahul tkNo ratings yet

- Ra & Jsa FormatDocument19 pagesRa & Jsa Formatspecpro50% (2)

- 4-RADocument11 pages4-RAWaqar KhanNo ratings yet

- Risk Assessment For Installation of A New Air Conditioning SystemDocument5 pagesRisk Assessment For Installation of A New Air Conditioning SystemErich BuenoNo ratings yet

- JSA - 008 - Hydraulic Rig and Mobile Crane MarchingDocument2 pagesJSA - 008 - Hydraulic Rig and Mobile Crane MarchingAhmed AlderbiNo ratings yet

- JSA CTU Sand Clean Out BPPDocument8 pagesJSA CTU Sand Clean Out BPPLismi LismiNo ratings yet

- 63 - JSA For All Activity at KP-66 NGL Tie-In PointDocument21 pages63 - JSA For All Activity at KP-66 NGL Tie-In PointsathishkumarNo ratings yet

- CTRA TK 64 003 Scaffolding Inside OutsideDocument6 pagesCTRA TK 64 003 Scaffolding Inside OutsideMohamed RizwanNo ratings yet

- 14.03.2018 Shuaiba/PSCJV/CCC See Note 4Document8 pages14.03.2018 Shuaiba/PSCJV/CCC See Note 4arun kumarNo ratings yet

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocument12 pagesRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- 781 Prject Area Its BTPDocument7 pages781 Prject Area Its BTPferielvpkNo ratings yet

- SWMS Work in A Confined SpaceDocument5 pagesSWMS Work in A Confined SpaceTamo Kim ChowNo ratings yet

- 033 Risk Assessment For Construction of Chilled Water ChamberDocument13 pages033 Risk Assessment For Construction of Chilled Water ChamberVIRUPAKSHA KOOLINo ratings yet

- Revised-JSA On WTG InstallationDocument16 pagesRevised-JSA On WTG InstallationRaza Muhammad SoomroNo ratings yet

- CTRA-23-STM-127-TK-11-996 - Scaffolding-ExtDocument3 pagesCTRA-23-STM-127-TK-11-996 - Scaffolding-ExtMohamed RizwanNo ratings yet

- Baseline Risk Assessment (Bra)Document8 pagesBaseline Risk Assessment (Bra)aceNo ratings yet

- Risk Assessment For Installation of Water Supply SystemDocument2 pagesRisk Assessment For Installation of Water Supply Systemمقاول تكييف كهرباء وصحيNo ratings yet

- Concrete Pouring Risk AssessmentDocument19 pagesConcrete Pouring Risk AssessmentMuhammad OsamaNo ratings yet

- Mule Core ComponentsDocument7 pagesMule Core ComponentsRameshChNo ratings yet

- Guaranteed Specifications: LOW High LOW HighDocument4 pagesGuaranteed Specifications: LOW High LOW HighAlNo ratings yet

- Manager Performance Development Training in Norfolk VA Resume Ellen SimmonsDocument3 pagesManager Performance Development Training in Norfolk VA Resume Ellen SimmonsEllenSimmonsNo ratings yet

- The Failure of Pepsi Blue in Indian MarketDocument20 pagesThe Failure of Pepsi Blue in Indian MarketAdil MohammedNo ratings yet

- Carpio-Morales v. CA Case DigestDocument2 pagesCarpio-Morales v. CA Case DigestLIERANo ratings yet

- Eric Hatfield CF ReportDocument22 pagesEric Hatfield CF ReportshreveporttimesNo ratings yet

- Catalog de Produse 7-Blocuri Terminale Si Conectori Pentru Cablaj ImprimatDocument438 pagesCatalog de Produse 7-Blocuri Terminale Si Conectori Pentru Cablaj ImprimatDoina Roman100% (1)

- Installation Manual: Middle Static Pressure Duct TypeDocument35 pagesInstallation Manual: Middle Static Pressure Duct TypecelsofortoulNo ratings yet

- Asset As A Service: Blockchain CenterDocument16 pagesAsset As A Service: Blockchain CenterTrader CatNo ratings yet

- Humanbe, Self - Assessment Motivation SelfDocument5 pagesHumanbe, Self - Assessment Motivation SelfHans LeeNo ratings yet

- Engineering Solutions Have Always Had A Major Impact On SocietyDocument2 pagesEngineering Solutions Have Always Had A Major Impact On SocietyYasmine Grace EsguerraNo ratings yet

- National Sample Survey OfficeDocument3 pagesNational Sample Survey OfficeDeepak Dixit0% (2)

- DVTK Storage SCP Emulator User ManualDocument20 pagesDVTK Storage SCP Emulator User Manualsegurah0% (1)

- Infobright Community Edition-User GuideDocument90 pagesInfobright Community Edition-User GuidemishaIV100% (4)

- Audit Check List, All Elements ISO-TS-16949Document37 pagesAudit Check List, All Elements ISO-TS-16949Jose CepedaNo ratings yet

- Current LogDocument10 pagesCurrent LogMulyati AtiNo ratings yet

- Painitan, Catherine Manuel BSMB 1D NSTPDocument12 pagesPainitan, Catherine Manuel BSMB 1D NSTPFrancisNo ratings yet

- Annexure-1 NCR FormDocument1 pageAnnexure-1 NCR FormwaseemhengtongNo ratings yet

- BD Food EditDocument9 pagesBD Food EditRashed55No ratings yet

- Itu-T: Gigabit-Capable Passive Optical Networks (GPON) : General CharacteristicsDocument25 pagesItu-T: Gigabit-Capable Passive Optical Networks (GPON) : General CharacteristicsDeyber GómezNo ratings yet

- Twitter Case StudyDocument11 pagesTwitter Case StudyRen ConchaNo ratings yet

- 3 Star Hotel - BaalbeckDocument19 pages3 Star Hotel - BaalbeckAkm EngidaNo ratings yet

- Media-Services Provider Los Gatos, California Reed Hastings Marc Randolph Scotts Valley, California OTTDocument2 pagesMedia-Services Provider Los Gatos, California Reed Hastings Marc Randolph Scotts Valley, California OTTpapa shunkuNo ratings yet

- Reboiler Case StudyDocument6 pagesReboiler Case StudyamlhrdsNo ratings yet

- Far410 Test Dec2020-SsDocument2 pagesFar410 Test Dec2020-Ss2022478048No ratings yet

- Revision Test Papers MAY, 2023: Final Course Group - IDocument172 pagesRevision Test Papers MAY, 2023: Final Course Group - IEDGE VENTURESNo ratings yet

- 18 19 LSE Financial StatementsDocument72 pages18 19 LSE Financial StatementsAdityaNo ratings yet

- Calorimetry WorksheetDocument1 pageCalorimetry WorksheetCarlos ChNo ratings yet

Concrete Pumping Risk Assessment

Concrete Pumping Risk Assessment

Uploaded by

lenindraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Pumping Risk Assessment

Concrete Pumping Risk Assessment

Uploaded by

lenindraCopyright:

Available Formats

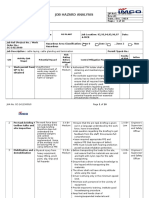

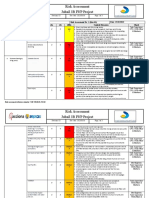

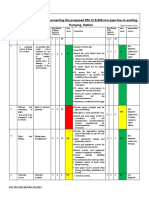

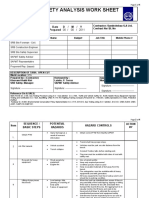

CONCRETE PUMPING RISK ASSESSMENT

Main Task / Activity: Concrete Pumping Risk Assessment

Location: Department: Date of Assessment:

LOGO HERE

RA Reference: Revision: 00 PTW Reference:

Assessment Team:

Client: Contractor Representatives: Page 1 of 5

General Guidelines:

1. Task Risk Assessment (also called Job Safety Analysis) is a qualitative hazard identification technique used for identifying, assessing and controlling major hazard(s) associated with a

specific task or operation where Permit to Work (PTW) precautions are deemed insufficient to execute the job safely.

2. No such work should be allowed to proceed until Risk Assessment has been completed and approved by a competent authority (normally Site Manager/Superintendent).

3. Risk Assessment should be carried out by a competent person and conducted in a team environment, involving all relevant parties.

4. Only trained and experienced staff should be deployed to execute high-risk jobs.

5. Conduct TRA well in advance as part of the work planning process.

6. Address all direct and indirect hazards associated with the task.

7. This TRA shall be conducted in conjunction with the above referenced PTW. A copy of the approved Risk Assessment must be attached to the permit throughout the work duration.

8. Use 5x5 Risk Assessment Matrix (provided separately) to assess the potential risks.

9. When determining safeguards, consider the ‘Hierarchy of Hazard Controls’ provided on this page.

10. Communicate TRA to all relevant personnel through meetings/toolbox talks before starting work.

11. Record Risk Assessment and revise if necessary.

Hierarchy of Hazard Controls:

(In order from most effective to least effective)

Elimination (by design or process changes)

Substitution (with less hazardous material or equipment)

Isolation (with barriers, machine guards)

Engineering Controls (interlocks, ESD system)

Administrative Controls (procedures, job rotations, training)

Warning Systems (signs, labels)

Personal Protective Equipment

HSE Documents-Risk Assessment for Concrete Pumping

*CPO-Concrete Pump Operator

CONCRETE PUMPING RISK ASSESSMENT

S/N Hazard Who Will be Control Measures Residual Additional

Initial Risk Action by

Affected? Risk Recommendation

L S R L S R s

1. Supervisor/CPO

Collapse or settlement of pump Operator, Ensure ground conditions at set up are adequate 1 2 2 Only competent

due to ground conditions / Workers, for a load of pump. personals should be

the overturning of the pump, or Visitors, Provide sufficient support (timbers, steel sheets) assigned the tasks,

the collapse of the boom due to Others 5 3 15 as required and ensure there is adequate space follow complete,

insufficient stability around the pump for the full deployment of Safety personnel

outriggers. surveillance, giving

Ensure outriggers are extended to the appropriate first aid, & proper

position. Sole plates are provided for placement toolbox talk.

below outrigger feet to support the pump. training

2. Crush or impact by the boom, Operator, CPO to operate via remote control unit from a Supervisor/CPO

or struck by placing hose, Workers, position of safety.

during set up or during “off Visitors, Hirer to ensure sufficient setup space and

the boom” placement of Others adequate light levels to ensure safe pump set up.

concrete 4 3 12 Ensure personnel remain clear of the area and 1 3 3

any operative controlling the position of the

placing hose should hold it at arm’s length.

Person(s) shall be nominated to converse with

and signal the CPO for minor boom positioning.

3. Contact with overhead Operator, Industry guidance specifies the minimum safe Supervisor/CPO

cables Workers, working distance from electric cables is

Visitors, 6m, this includes the fully extended boom radius.

Others Exceptions may apply and closer distances may

be permitted where controls are provided, 1 3 3

5 3 15 however, they must be managed by a Written Only competent

Safe System of Work. Where set up cannot be personals should be

clear of overhead cables, consideration should be assigned the tasks,

given to the provision of a ground-level pipeline. follow complete,

4. Vehicle Movements (reversing) Operator, Keep site personnel out of reversing area. Supervisor/CPO Safety personnel

– crushing or trapping of Workers, A competent Traffic Marshall should direct the surveillance, giving

persons when moving the pump Visitors, moving vehicle and look out for anyone in the first aid, & proper

to work in a position Others danger area. toolbox talk.

Vehicles fitted with reversing sirens and amber 1 5 5 training

3 3 9 flashing lights should have these engaged. High

visibility clothing must be worn and do not back

truck on out of view of

mixer driver who will be reversing using mirrors.

5. Back injury due to Operator, 2 3 6 Use of ropes and good manual handling practices 1 5 5 Supervisor/CPO

moving ground pipes Workers, to be adopted

Visitors,

Others

HSE Documents-Risk Assessment for Concrete Pumping

*CPO-Concrete Pump Operator

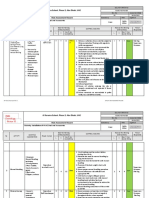

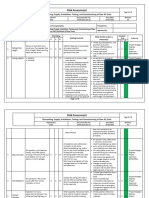

CONCRETE PUMPING RISK ASSESSMENT

6. Washout of pump Operator, The hirer/site management shall provide Supervisor/CPO

Workers, adequate washout facilities for concrete residues.

Visitors, The CPO to only wash out in areas defined and

Others 1 3 3 authorised by site management. If there is no 1 1 1

suitable area washout can be taken away but this

is an extra charge and should be agreed at the

time of booking

7. The collapse of placing boom Operator, All hydraulic rams are fitted with lock valves to Supervisor/CPO

due to failure of hydraulics Workers, limit movement should a failure occur. All

or structural failure of Visitors, 5 2 3 pumps undergo a boom test (which is 1 1 1

pump / boom Others certificated) and are also inspected as part of the

regular servicing schedule.

8. Contact with pump Operator, All moving parts on the concrete pump are fully Supervisor/CPO

moving parts Workers, guarded, ensure the CPO has carried out his Only competent

Visitors, 3 2 3 required daily / weekly checks 1 2 2 personals should be

Others No personnel other than the CPO may operate assigned the tasks,

the pump or climb onto the pump deck. follow complete,

Concrete splashing into Operator, Full PPE to be worn inc, helmet, goggles, gloves, Supervisor/CPO Safety personnel

9.

eyes from the end hose / Workers, safety wellingtons and barrier cream must be surveillance, giving

3 1 3 1 2 2

Concrete burns to hands Visitors, worn first aid, & proper

and feet Others toolbox talk.

10. Potential injury to persons Operator, Ensure that the pour area has adequate protection Supervisor/CPO training

and property damage due Workers, to contain any concrete spray or spillage.

to concrete spillage / Visitors, 2 1 2 1 2 2

splatter (predominantly Others

from upper floors)

11. High-pressure concrete Operator, Only pipes, hoses, clips of sufficient safety rating Supervisor/CPO

and aggregate going Workers, shall be used. Wear and damage

into eyes, face or any Visitors, shall be monitored by the CPO and checked

exposed skin due to Others during scheduled services. Excessively

3 2 6 1 2 2

standing or working damaged/worn components shall be withdrawn.

in front of end hose, or Also, see Blockages section below

opening up pipe joints

when pumping

12. Broken limbs, severe Operator, Do not kink placing hoses in the ground line. Supervisor/CPO

injury caused by Workers, Do not attempt to pump very old concrete or

the whiplash of placing hoses. Visitors, concrete other than a pump mix.

Others 2 3 6 1 2 2

The danger zone is the area around the end hose

in which it can strikeout. The diameter of the

zone is twice the length of the end hose.

13. Injury from splash due Operator, Keep hopper full and inform mixer driver of risk. Supervisor/CPO

to blowback from Workers, Full PPE to be worn. 1 3 3

concrete pump hopper Visitors,

Others

14. Working at height Operator, Access shall be restricted to “short duration” no Supervisor/CPO

(upon pump deck) Workers, hirer personnel shall be permitted to

3 3 9 1 3 3

Visitors, access the pump deck unless express permission

Others is given by the CPO.

HSE Documents-Risk Assessment for Concrete Pumping

*CPO-Concrete Pump Operator

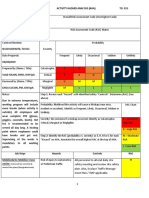

CONCRETE PUMPING RISK ASSESSMENT

15. Potential blockages Operator, Only “single-ended” hoses shall be used – double Supervisor/CPO Only competent

at start or restart of Workers, / steel collared ended hoses shall personals should be

pump, use of suspended Visitors, not be used “off the boom”. assigned the tasks,

hose “of the boom” Others The CPO shall request that all persons remain follow complete,

resulting in hose clear (a radial distance of at least twice the length Safety personnel

whipping into danger 3 2 6 1 2 2

of the hose) of the suspended hose at each start surveillance, giving

area or restart of the pump and until “smooth flow” first aid, & proper

has been achieved. Also, see Blockages section toolbox talk.

below training

Full PPE to be worn.

16. Bursting of pipelines / Operator, Only pipes, hoses, clips of sufficient safety rating Supervisor/CPO

hoses under pressure Workers, shall be used. Wear and damage

Visitors, shall be monitored by the CPO and checked

4 3 12 1 2 2

Others during scheduled services. Excessively

damaged/worn components shall be withdrawn.

Also, see Blockages section below

17. Forceful ejection of air / Operator, Pipe jointing seals shall be clean and in good Supervisor/CPO

concrete from the end Workers, order. Concrete level in the pump hopper O, S

of the pipeline. Air sucked Visitors, must be maintained at the required

into line and compressed Others level, where the CPO is required to

3 4 12 position himself remote of the 1 3 3

pump appoint a competent person

to monitor deliveries and hopper

level (to ensure air is not pumped into the pipe

system).

18. Pressurised concrete Operator, CPO to ensure the pipeline is depressurized Supervisor/CPO

release – dismantling Workers, before freeing jointing clips, hirer personnel must

4 4 16 1 3 3

of line Visitors, not uncouple pipes without the express

Others permission of the CPO

19. Pipeline cleaning with Operator, A demarcated and access restricted area shall be Supervisor/CPO

compressed air – Workers, provided at the end of the pipeline that is to be

pressurised release / Visitors, 2 3 6 air cleansed. 1 3 3

ejection of sponge ball / Others

concrete / water / air

HSE Documents-Risk Assessment for Concrete Pumping

*CPO-Concrete Pump Operator

CONCRETE PUMPING RISK ASSESSMENT

Blockages – Why do they occur? Risk Reduction / Control

Segregation of concrete / aggregates as it is pressurised through the pipeline with It shall be ensured that the appropriate grout mix is used. Maximum pipeline and delivery hose length shall be

the primer / grout considered – grouting may be more successful in shorter sections

Inappropriate concrete mix design or consistency – not suitable for pumping Only concrete that is of “pump mix design” and appropriate quality should be specified for delivery to

Hardening of the concrete in boom / pipeline from standing too long (usually when CPO shall circulate or move the concrete in the hopper / boom / pipeline. Deliveries shall be time managed and

awaiting delivery of fresh concrete) planned appropriately

Flexible placing hose become kinked The hose should never become kinked, it should be suspended vertically when used “off the boom”

Foreign objects delivered from visiting mixer drums The quality of the concrete should be monitored

Blockages – Reacting To

Where possible the CPO will stop the pump action and reverse the pumping direction (this may free the blockage). Before the CPO restarts the pumping action, he should ensure all persons retreat to a safe

distance away from the boom / pipeline. Should the blockage persist, the CPO will stop the pump, depressurize the line and investigate the location of the blockage before taking appropriate action (ie

disconnecting pipework to locate and remove the blockage).

A momentary blockage may occur that frees immediately this is often accompanied by increased engine / pump revs and noise. The CPO shall endeavour where possible to warn persons in the vicinity to

stand clear. However, the release is likely to cause the delivery hose and/or boom to move or “kick” before the pump action can be stopped.

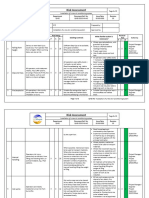

The Risk Matrix Likelihood

Consequences People Assets Environment Reputation

5-Almost Certain Multiple Fatalities Extensive damage Extensive International impact 5 0 5 10 15 20 25

Effect

4-Very Likely Single fatality or Permanent total Severe damage Severe Effect National impact 4 0 4 8 12 16 20

3 0 3 6 9 12 15

Severity

disability

3-Likely Major injury or health effects (long Major damage Major Effect Major impact 2 0 2 4 6 8 10

term or permanent partial disability)

1 0 1 2 3 4 5

2- Unlikely Minor injury or health effects leading Minor effect Minor Effect Minor impact

to LTI/RWC/MTC 0 0 0 0 0 0 0

1- Very Unlikely Single injury or health effects, Slight effect Slight Effect Slight impact 0 1 2 3 4 5

requiring first aid

Risk=Likelihood x Severity

0- Zero to Very

Low

Acceptabl Review Required Unacceptable

Risk Assessment by: e

Date:

HSE Documents-Risk Assessment for Concrete Pumping

*CPO-Concrete Pump Operator

You might also like

- 20) Pumping of WaterDocument7 pages20) Pumping of WaterMobin Thomas Abraham77% (13)

- STABLE Resource Toolkit-BipolarDocument67 pagesSTABLE Resource Toolkit-Bipolardidiisafitri100% (1)

- JHA For Cable Laying, Cable Glanding and TerminationDocument12 pagesJHA For Cable Laying, Cable Glanding and TerminationFrancis Enriquez Tan100% (2)

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 pagesRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Risk Assessment For External Façade & Canopies CleaningDocument8 pagesRisk Assessment For External Façade & Canopies CleaningFrancis Enriquez Tan100% (2)

- Risk Assessment For External Façade & Canopies CleaningDocument6 pagesRisk Assessment For External Façade & Canopies Cleaningjulius0% (1)

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- JSA - Installation of U G PipingDocument11 pagesJSA - Installation of U G PipingOws Anish100% (1)

- Meetings in A Company.Document37 pagesMeetings in A Company.armaanNo ratings yet

- Risk Assesment For GRP Pipe LayingDocument3 pagesRisk Assesment For GRP Pipe LayingSasi Kumar60% (5)

- RS Concrete Pumping Risk AssessmentDocument8 pagesRS Concrete Pumping Risk AssessmentLito PanchoNo ratings yet

- IDC SOP # 10 Operation of The Pipe SpinnerDocument2 pagesIDC SOP # 10 Operation of The Pipe SpinnerkareemNo ratings yet

- CTRA-20-TM-035-Lagoon Cleaning-R1-Not ApprovedDocument7 pagesCTRA-20-TM-035-Lagoon Cleaning-R1-Not ApprovedMohamed RizwanNo ratings yet

- Pipe Nitrogen Testing in Non Confined SpaceDocument4 pagesPipe Nitrogen Testing in Non Confined SpaceKannan KamalNo ratings yet

- R A - Mobile CraneDocument1 pageR A - Mobile CraneNick KrugerNo ratings yet

- Risk Assessment-Concrete Casting by Using PumpsDocument3 pagesRisk Assessment-Concrete Casting by Using PumpsSarfraz Randhawa100% (2)

- 1717690216690Document8 pages1717690216690Arun RajNo ratings yet

- Housekeeping JsaDocument9 pagesHousekeeping JsaShahid BhattiNo ratings yet

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Pdfslide - Us Jsa For Using Jack HammerDocument3 pagesPdfslide - Us Jsa For Using Jack HammerWidya BungaNo ratings yet

- PPR Installation & Pressure Testing RADocument19 pagesPPR Installation & Pressure Testing RAJomy JohnyNo ratings yet

- Risk Assesment For Connecting The Existing Pipe To Pump StationDocument4 pagesRisk Assesment For Connecting The Existing Pipe To Pump StationSasi Kumar100% (2)

- 03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressDocument16 pages03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressSavio SunnyNo ratings yet

- JSA For Pipe Installation TS 3Document8 pagesJSA For Pipe Installation TS 3Shilpiengg SafetyNo ratings yet

- CTRA-23-STM-093 - TK - 11-995 - Bund Wall CuttingDocument3 pagesCTRA-23-STM-093 - TK - 11-995 - Bund Wall CuttingMohamed RizwanNo ratings yet

- Risk Assessment For Installation of A New AC UnitDocument9 pagesRisk Assessment For Installation of A New AC Unitservice.amepNo ratings yet

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 pagesJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- All Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicableDocument6 pagesAll Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicablecrnkarlosNo ratings yet

- 069-JSA-MLCC JSA STRINGING - BGP-STA 0+012 TO 1+688 (Inside BGP) - Rev.01-ApprovedDocument10 pages069-JSA-MLCC JSA STRINGING - BGP-STA 0+012 TO 1+688 (Inside BGP) - Rev.01-ApprovedSn AhsanNo ratings yet

- Risk Assessment For Installation of Toilet Exhaust Fan (New)Document12 pagesRisk Assessment For Installation of Toilet Exhaust Fan (New)Anandu AshokanNo ratings yet

- 028 - JSA - Hydrotesting - 27-02-2012Document7 pages028 - JSA - Hydrotesting - 27-02-2012sathishkumarNo ratings yet

- Aintree Concrete Pumping Risk Assessment 2020Document4 pagesAintree Concrete Pumping Risk Assessment 2020Lito PanchoNo ratings yet

- Fill-Up This Card Before Commencement of Critical WorksDocument4 pagesFill-Up This Card Before Commencement of Critical WorksSiddhant choudharyNo ratings yet

- Precast Lifting Risk Assessment (0075) - Rev-01Document8 pagesPrecast Lifting Risk Assessment (0075) - Rev-01Muhammad OsamaNo ratings yet

- Job Safety Analysis (JSA) - CONCRETE WORKS - DateDocument2 pagesJob Safety Analysis (JSA) - CONCRETE WORKS - Datenabeel100% (1)

- Tie - in Mechanical Installation JHADocument7 pagesTie - in Mechanical Installation JHAmalik jahanNo ratings yet

- RA-for Glass Installation 30-04-2022Document6 pagesRA-for Glass Installation 30-04-2022Muideen Oyedele100% (2)

- HKGGA - ELS & Pile Cap RADocument12 pagesHKGGA - ELS & Pile Cap RAymkawai224No ratings yet

- TTEC Fencing RADocument7 pagesTTEC Fencing RAGeml TrinidadNo ratings yet

- Risk Assessment Record Activity: Installation ofDocument17 pagesRisk Assessment Record Activity: Installation ofvasanth pugazhendhi0% (1)

- JSA 03 Gate Entrance Traffic ProposalDocument10 pagesJSA 03 Gate Entrance Traffic Proposalrahul tkNo ratings yet

- Ra & Jsa FormatDocument19 pagesRa & Jsa Formatspecpro50% (2)

- 4-RADocument11 pages4-RAWaqar KhanNo ratings yet

- Risk Assessment For Installation of A New Air Conditioning SystemDocument5 pagesRisk Assessment For Installation of A New Air Conditioning SystemErich BuenoNo ratings yet

- JSA - 008 - Hydraulic Rig and Mobile Crane MarchingDocument2 pagesJSA - 008 - Hydraulic Rig and Mobile Crane MarchingAhmed AlderbiNo ratings yet

- JSA CTU Sand Clean Out BPPDocument8 pagesJSA CTU Sand Clean Out BPPLismi LismiNo ratings yet

- 63 - JSA For All Activity at KP-66 NGL Tie-In PointDocument21 pages63 - JSA For All Activity at KP-66 NGL Tie-In PointsathishkumarNo ratings yet

- CTRA TK 64 003 Scaffolding Inside OutsideDocument6 pagesCTRA TK 64 003 Scaffolding Inside OutsideMohamed RizwanNo ratings yet

- 14.03.2018 Shuaiba/PSCJV/CCC See Note 4Document8 pages14.03.2018 Shuaiba/PSCJV/CCC See Note 4arun kumarNo ratings yet

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocument12 pagesRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- 781 Prject Area Its BTPDocument7 pages781 Prject Area Its BTPferielvpkNo ratings yet

- SWMS Work in A Confined SpaceDocument5 pagesSWMS Work in A Confined SpaceTamo Kim ChowNo ratings yet

- 033 Risk Assessment For Construction of Chilled Water ChamberDocument13 pages033 Risk Assessment For Construction of Chilled Water ChamberVIRUPAKSHA KOOLINo ratings yet

- Revised-JSA On WTG InstallationDocument16 pagesRevised-JSA On WTG InstallationRaza Muhammad SoomroNo ratings yet

- CTRA-23-STM-127-TK-11-996 - Scaffolding-ExtDocument3 pagesCTRA-23-STM-127-TK-11-996 - Scaffolding-ExtMohamed RizwanNo ratings yet

- Baseline Risk Assessment (Bra)Document8 pagesBaseline Risk Assessment (Bra)aceNo ratings yet

- Risk Assessment For Installation of Water Supply SystemDocument2 pagesRisk Assessment For Installation of Water Supply Systemمقاول تكييف كهرباء وصحيNo ratings yet

- Concrete Pouring Risk AssessmentDocument19 pagesConcrete Pouring Risk AssessmentMuhammad OsamaNo ratings yet

- Mule Core ComponentsDocument7 pagesMule Core ComponentsRameshChNo ratings yet

- Guaranteed Specifications: LOW High LOW HighDocument4 pagesGuaranteed Specifications: LOW High LOW HighAlNo ratings yet

- Manager Performance Development Training in Norfolk VA Resume Ellen SimmonsDocument3 pagesManager Performance Development Training in Norfolk VA Resume Ellen SimmonsEllenSimmonsNo ratings yet

- The Failure of Pepsi Blue in Indian MarketDocument20 pagesThe Failure of Pepsi Blue in Indian MarketAdil MohammedNo ratings yet

- Carpio-Morales v. CA Case DigestDocument2 pagesCarpio-Morales v. CA Case DigestLIERANo ratings yet

- Eric Hatfield CF ReportDocument22 pagesEric Hatfield CF ReportshreveporttimesNo ratings yet

- Catalog de Produse 7-Blocuri Terminale Si Conectori Pentru Cablaj ImprimatDocument438 pagesCatalog de Produse 7-Blocuri Terminale Si Conectori Pentru Cablaj ImprimatDoina Roman100% (1)

- Installation Manual: Middle Static Pressure Duct TypeDocument35 pagesInstallation Manual: Middle Static Pressure Duct TypecelsofortoulNo ratings yet

- Asset As A Service: Blockchain CenterDocument16 pagesAsset As A Service: Blockchain CenterTrader CatNo ratings yet

- Humanbe, Self - Assessment Motivation SelfDocument5 pagesHumanbe, Self - Assessment Motivation SelfHans LeeNo ratings yet

- Engineering Solutions Have Always Had A Major Impact On SocietyDocument2 pagesEngineering Solutions Have Always Had A Major Impact On SocietyYasmine Grace EsguerraNo ratings yet

- National Sample Survey OfficeDocument3 pagesNational Sample Survey OfficeDeepak Dixit0% (2)

- DVTK Storage SCP Emulator User ManualDocument20 pagesDVTK Storage SCP Emulator User Manualsegurah0% (1)

- Infobright Community Edition-User GuideDocument90 pagesInfobright Community Edition-User GuidemishaIV100% (4)

- Audit Check List, All Elements ISO-TS-16949Document37 pagesAudit Check List, All Elements ISO-TS-16949Jose CepedaNo ratings yet

- Current LogDocument10 pagesCurrent LogMulyati AtiNo ratings yet

- Painitan, Catherine Manuel BSMB 1D NSTPDocument12 pagesPainitan, Catherine Manuel BSMB 1D NSTPFrancisNo ratings yet

- Annexure-1 NCR FormDocument1 pageAnnexure-1 NCR FormwaseemhengtongNo ratings yet

- BD Food EditDocument9 pagesBD Food EditRashed55No ratings yet

- Itu-T: Gigabit-Capable Passive Optical Networks (GPON) : General CharacteristicsDocument25 pagesItu-T: Gigabit-Capable Passive Optical Networks (GPON) : General CharacteristicsDeyber GómezNo ratings yet

- Twitter Case StudyDocument11 pagesTwitter Case StudyRen ConchaNo ratings yet

- 3 Star Hotel - BaalbeckDocument19 pages3 Star Hotel - BaalbeckAkm EngidaNo ratings yet

- Media-Services Provider Los Gatos, California Reed Hastings Marc Randolph Scotts Valley, California OTTDocument2 pagesMedia-Services Provider Los Gatos, California Reed Hastings Marc Randolph Scotts Valley, California OTTpapa shunkuNo ratings yet

- Reboiler Case StudyDocument6 pagesReboiler Case StudyamlhrdsNo ratings yet

- Far410 Test Dec2020-SsDocument2 pagesFar410 Test Dec2020-Ss2022478048No ratings yet

- Revision Test Papers MAY, 2023: Final Course Group - IDocument172 pagesRevision Test Papers MAY, 2023: Final Course Group - IEDGE VENTURESNo ratings yet

- 18 19 LSE Financial StatementsDocument72 pages18 19 LSE Financial StatementsAdityaNo ratings yet

- Calorimetry WorksheetDocument1 pageCalorimetry WorksheetCarlos ChNo ratings yet