Professional Documents

Culture Documents

Trouble Shooting Guide Amp Research Power Step Table

Trouble Shooting Guide Amp Research Power Step Table

Uploaded by

juan primoCopyright:

Available Formats

You might also like

- Sample Answer AE06Document7 pagesSample Answer AE06wei foo80% (20)

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- Model: ASI4518R37v07: Antenna SpecificationsDocument3 pagesModel: ASI4518R37v07: Antenna SpecificationsSNEF Orange100% (3)

- Bigdog Section8 2002 Electrical RevisedDocument17 pagesBigdog Section8 2002 Electrical RevisedHOWARDB2010100% (1)

- 77-E-Z-GO DCS (1206SX) Install Sheet-370Document4 pages77-E-Z-GO DCS (1206SX) Install Sheet-370Sayed KhlileNo ratings yet

- Citroen zx-12Document48 pagesCitroen zx-12Tony LauNo ratings yet

- Electrical Symbols and SchematicsDocument42 pagesElectrical Symbols and Schematicsapi-384232693% (14)

- ACCEL-DFI Instructions 6a Digital Ignition Dfi 75606Document12 pagesACCEL-DFI Instructions 6a Digital Ignition Dfi 75606Ilango Panneerselvan0% (1)

- ACS800 - 304 - Suppl - User Manual PDFDocument82 pagesACS800 - 304 - Suppl - User Manual PDFAlamgir Robin0% (1)

- Skypatrol - Evolution Installer Guide TT85xxDocument9 pagesSkypatrol - Evolution Installer Guide TT85xxraguilar1abc1No ratings yet

- Estribos Electricos Lifeb - Optim PDFDocument5 pagesEstribos Electricos Lifeb - Optim PDFAldo PosadaNo ratings yet

- Classe CA401 PWR SMDocument26 pagesClasse CA401 PWR SMpingnan kangNo ratings yet

- Bulldog Security SystemDocument14 pagesBulldog Security SystemphilipisaiaNo ratings yet

- Electrical System DiagnosisDocument17 pagesElectrical System DiagnosisArnaldo Mejia Zhenea.100% (1)

- CA-400 Classé Audio Inc. Service Manual: Date: August 8, 2007 Model Number: SubjectDocument20 pagesCA-400 Classé Audio Inc. Service Manual: Date: August 8, 2007 Model Number: SubjectVictor TettehNo ratings yet

- Classe CAV180 PWR SMDocument24 pagesClasse CAV180 PWR SMpingnan kangNo ratings yet

- 4Cl-002 Remote 4 Door Central Locking Kit Installation GuideDocument2 pages4Cl-002 Remote 4 Door Central Locking Kit Installation GuideyayayalNo ratings yet

- Classe CA150 PWR SMDocument22 pagesClasse CA150 PWR SMpingnan kangNo ratings yet

- CA 1053 Install Rev A 8-14-2012Document20 pagesCA 1053 Install Rev A 8-14-2012Michel TanusNo ratings yet

- Installation Manual APS596C - IMDocument16 pagesInstallation Manual APS596C - IMMauro SteffenNo ratings yet

- Heater Fan Switch WorkaroundDocument3 pagesHeater Fan Switch WorkaroundJack MarlowNo ratings yet

- Popular Mechanics - Curing A Clicking StarterDocument4 pagesPopular Mechanics - Curing A Clicking StarterGeorgiana MarinNo ratings yet

- MB Inlet Port Shutoff Valve Emulator Installation Instruction enDocument8 pagesMB Inlet Port Shutoff Valve Emulator Installation Instruction enbruNo ratings yet

- Installation and Troubleshooting Guide: CDI P/N: 173-4849Document4 pagesInstallation and Troubleshooting Guide: CDI P/N: 173-4849Paul MartinNo ratings yet

- SP9100 Rev1.2 DirectionsDocument14 pagesSP9100 Rev1.2 Directionsscada.wupptclNo ratings yet

- DZKNSNDocument2 pagesDZKNSNAleksandria Donne D. FernandezNo ratings yet

- Cdi Troubleshooting Guide Johnson EvinrudeDocument35 pagesCdi Troubleshooting Guide Johnson EvinrudeEvan CollinsNo ratings yet

- Protecting Against Solenoid Coil FailuresDocument7 pagesProtecting Against Solenoid Coil FailuresPuri AyuNo ratings yet

- EW-46 Service Manual 2022Document46 pagesEW-46 Service Manual 2022palletlemurNo ratings yet

- Honda - Prelude - Wiring Diagram - 1994 - 1994Document8,924 pagesHonda - Prelude - Wiring Diagram - 1994 - 1994Kristen Phillips100% (1)

- Model 70 Classé Audio Inc. Service Manual: Date: August 27, 2007 Model Number: SubjectDocument15 pagesModel 70 Classé Audio Inc. Service Manual: Date: August 27, 2007 Model Number: SubjectVictor TettehNo ratings yet

- Er 105 3 1Document7 pagesEr 105 3 1edgarafonsecaNo ratings yet

- How To Diagnose Automotive Electrical Problems - The Mechanic DoctorDocument1 pageHow To Diagnose Automotive Electrical Problems - The Mechanic Doctormecanidec La MotteNo ratings yet

- Power Door Locks Chevrolet S10Document11 pagesPower Door Locks Chevrolet S10Maxi Sardi100% (1)

- Electrical Service Manual 96-0284C Rev C English June 2007Document240 pagesElectrical Service Manual 96-0284C Rev C English June 2007Ahmed Alejandro CarranzaNo ratings yet

- Classe dr-9Document12 pagesClasse dr-9rudiNo ratings yet

- ChassisElectrical PDFDocument111 pagesChassisElectrical PDFDhany SiregarNo ratings yet

- DENSO HD Starter Alternator TroubleshootingDocument3 pagesDENSO HD Starter Alternator TroubleshootinganilNo ratings yet

- Brinks AlarmDocument85 pagesBrinks AlarmDominick VerdiNo ratings yet

- Low Voltage Electrical Component of Electric Two - Three WheelerDocument6 pagesLow Voltage Electrical Component of Electric Two - Three WheelerENESH SOLANKINo ratings yet

- Trouble Shooting Pancake GeneratorsDocument7 pagesTrouble Shooting Pancake GeneratorsRomel José Londoño CamachoNo ratings yet

- Classé Audio Inc.: CAP-151 Service ManualDocument24 pagesClassé Audio Inc.: CAP-151 Service ManualdNo ratings yet

- Motor DiagnosticsDocument5 pagesMotor DiagnosticssabrahimaNo ratings yet

- Magicar 9000BDocument13 pagesMagicar 9000BDavid MartinNo ratings yet

- How To Repair Electric Windows Not WorkingDocument10 pagesHow To Repair Electric Windows Not Workingbyukusenge yves BonheurNo ratings yet

- Service Bulletin Trucks: Electrical System TroubleshootingDocument12 pagesService Bulletin Trucks: Electrical System TroubleshootingRegistr RegistrNo ratings yet

- SM 35Document6 pagesSM 35Communications ShipyardNo ratings yet

- Dynatek-S-Electronic-Ignition Dual FireDocument4 pagesDynatek-S-Electronic-Ignition Dual FireAdrián CasarrubiasNo ratings yet

- Druid Energizer User ManualDocument9 pagesDruid Energizer User ManualKatherine Weber100% (1)

- Electro FinalDocument9 pagesElectro FinalContinedo Rhem JulesNo ratings yet

- CS-2002DC Series IV: Remote Control Alarm System Installation & Operating InstructionsDocument20 pagesCS-2002DC Series IV: Remote Control Alarm System Installation & Operating InstructionsLuis_Alvarez_9112No ratings yet

- How To Test and Repair Small Engine Ignition System ProblemsDocument5 pagesHow To Test and Repair Small Engine Ignition System ProblemsAlfred E. NewmanNo ratings yet

- Trouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsDocument7 pagesTrouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsBilly MecanizadoNo ratings yet

- Danger Warning Caution: Safety InformationDocument7 pagesDanger Warning Caution: Safety InformationcombaheeNo ratings yet

- Mk120s ManualDocument306 pagesMk120s ManualParesh Chandra DebnathNo ratings yet

- Car Heater Not Blowing Air - Here's How To Fix It - Rustyautos - Com - Reader ViewDocument10 pagesCar Heater Not Blowing Air - Here's How To Fix It - Rustyautos - Com - Reader Viewabet_singkong8930No ratings yet

- WL 601 R 2Document2 pagesWL 601 R 2taaj77No ratings yet

- ConditionDocument12 pagesConditionأمجد راضي هادي /A1No ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

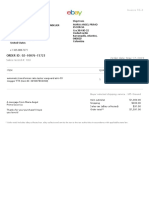

- Invoice VanguardDocument1 pageInvoice Vanguardjuan primoNo ratings yet

- Certifier Specifications Sheet Data Sheets enDocument2 pagesCertifier Specifications Sheet Data Sheets enjuan primoNo ratings yet

- HVA28TD Manual Rev 1 1Document78 pagesHVA28TD Manual Rev 1 1juan primoNo ratings yet

- Fuji Electric PortaflowDocument2 pagesFuji Electric Portaflowjuan primoNo ratings yet

- HZJB-1200 6 Phase Relay Protection Tester-User ManualDocument134 pagesHZJB-1200 6 Phase Relay Protection Tester-User Manualjuan primo100% (1)

- Datasheet SIKA Temperature CalibratorsDocument49 pagesDatasheet SIKA Temperature Calibratorsjuan primoNo ratings yet

- Vanguard Auto Ohm 100Document4 pagesVanguard Auto Ohm 100juan primoNo ratings yet

- VANGUARD ct8000Document6 pagesVANGUARD ct8000juan primoNo ratings yet

- DOBLE TDR9000 - SpecDocument4 pagesDOBLE TDR9000 - Specjuan primoNo ratings yet

- TK3 Proximity System Test Kit: DatasheetDocument6 pagesTK3 Proximity System Test Kit: Datasheetjuan primoNo ratings yet

- Page 1 of 17 CDG/SR0106/000/27Document17 pagesPage 1 of 17 CDG/SR0106/000/27juan primoNo ratings yet

- DOL Motor StarterDocument6 pagesDOL Motor StartermshahidshaukatNo ratings yet

- Smatrix Wave Wave PlusDocument112 pagesSmatrix Wave Wave Plusjamppajoo2No ratings yet

- User ManualDocument258 pagesUser ManualEdwin GiraldoNo ratings yet

- Transistorized Series Voltage RegulatorDocument4 pagesTransistorized Series Voltage RegulatorIpsita MishraNo ratings yet

- RCI 2014 Price ListDocument32 pagesRCI 2014 Price ListSecurity Lock DistributorsNo ratings yet

- NCERT Class 10 Science Lab Manual - Resistors in Parallel - CBSE TutsDocument15 pagesNCERT Class 10 Science Lab Manual - Resistors in Parallel - CBSE TutsVinodKumarTummalurNo ratings yet

- PSC-VS2200 Programação PDFDocument9 pagesPSC-VS2200 Programação PDFprfelicioNo ratings yet

- Seminar On Moving Coil Type Linear Compressor: Juned R. KaziDocument12 pagesSeminar On Moving Coil Type Linear Compressor: Juned R. KaziJuned Aashiqe RasoolNo ratings yet

- SCD-XB770 Service ManualDocument88 pagesSCD-XB770 Service ManualTechnics39No ratings yet

- 25782-Article Text-89683-1-10-20200810Document7 pages25782-Article Text-89683-1-10-20200810Venkatesan SwamyNo ratings yet

- Datasheet 3Document6 pagesDatasheet 3fenixtec1No ratings yet

- BCD AdderDocument23 pagesBCD Addersruharitha0% (1)

- Engineering Circuit Analysis Ebook PDF VersionDocument61 pagesEngineering Circuit Analysis Ebook PDF Versiondebra.glisson665100% (51)

- Assigment 2 AntennaDocument2 pagesAssigment 2 Antennaabdulwahab12100% (1)

- EV PaperDocument5 pagesEV PaperRITHVIKHA VNo ratings yet

- Dual-Port Memory Block Diagram PDFDocument8 pagesDual-Port Memory Block Diagram PDFivanramljakNo ratings yet

- FWB J Installation and Operation ManualDocument16 pagesFWB J Installation and Operation ManualselvamejiaNo ratings yet

- Ats - Geist Power - Atrn102-101r15st-1 PDFDocument2 pagesAts - Geist Power - Atrn102-101r15st-1 PDFCastellon DonaldNo ratings yet

- VT-8618, VT-8624, VT-8630 2022 - With Sensor EU MARKETDocument1 pageVT-8618, VT-8624, VT-8630 2022 - With Sensor EU MARKETyulian.stanevNo ratings yet

- Simulation de PCM, DPCM y DM SimulinkDocument6 pagesSimulation de PCM, DPCM y DM SimulinkМигель Кастижо0% (1)

- TEL 7208 Test 1 QuestionsDocument1 pageTEL 7208 Test 1 QuestionsSsejjuuko PaulNo ratings yet

- La 78040Document4 pagesLa 78040Wilton Carlos SilvaNo ratings yet

- LG 40UB800V шасси LD48VDocument90 pagesLG 40UB800V шасси LD48VRony ReyesNo ratings yet

- NDPLDocument27 pagesNDPLkaushal895No ratings yet

- Lippert - Slide Out Model In-Wall (Schwintek) Owner's ManualDocument26 pagesLippert - Slide Out Model In-Wall (Schwintek) Owner's Manual28larrysjunkmail100% (1)

- EXERCISE 6 + SolutionsDocument6 pagesEXERCISE 6 + SolutionsEmmanuel WadiraNo ratings yet

- Impedance and Conductance TestingDocument0 pagesImpedance and Conductance Testingjesus_hfNo ratings yet

- What Is Thermal Design An-EDocument5 pagesWhat Is Thermal Design An-EpkNo ratings yet

Trouble Shooting Guide Amp Research Power Step Table

Trouble Shooting Guide Amp Research Power Step Table

Uploaded by

juan primoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trouble Shooting Guide Amp Research Power Step Table

Trouble Shooting Guide Amp Research Power Step Table

Uploaded by

juan primoCopyright:

Available Formats

Trouble Shooting Guide – AMP Research Power Step

Table Of Contents:

1) Trouble Shooting Quick Guide

2) Frequently Asked Questions

3) System Operation Information

4) Knowledge Base

5) Trouble Shooting Flow Chart

6) Flow Chart Notes

TECH SUPPORT 1-888-983-2206 Monday – Friday 8:00 AM – 5:00 PM PST | Page 1 of 7

Concern Possible root-causes

Factory door ajar switch in-op?

Fuse burned

Steps inoperative Diodes connected in reverse polarity or faulty diode

Connections not secure

Connected to incorrect wire in vehicle electrical system

Connections not secure

Intermittent operation Faulty diode or connection

Bad ground

One or more doors deploy the step, others Diodes connected in reverse polarity or faulty diode

do not Connections not secure

Bad ground

Steps shake and/or shutter during operation

Connections not secure

Delay in step operation or steps deploy after

Diodes connected in reverse polarity or faulty diode

doors have been closed

Tighten wedge bolt.

Steps make a creaking noise during Loosen lower mount bolts and remove step extrusion

operation from lower mount. Re-install step extrusion to lower

mount and tighten.

Steps make a ticking noise when fully

Tolerance ring / clutch assembly failed / failing. Replace

deployed or fully retracted and motor

clutch assembly.

continues to run.

Diodes connected in reverse polarity or faulty diode

Steps operate randomly Connections not secure

Connected to incorrect wire in vehicle electrical system

Step stays down all the time and motor can Tolerance ring / clutch assembly faulty. Replace clutch

be heard running assembly.

Motor polarity reversed. Exchange location of wires going

Step go up when opening door and down

into motor plug. (Swap orange and white wires in motor

when closing door

plug.)

TECH SUPPORT 1-888-983-2206 Monday – Friday 8:00 AM – 5:00 PM PST | Page 2 of 7

Trouble Shooting Guide – Frequently Asked Questions

Q: The wire colors on my vehicle do not match the colors in your diagram. What

do I do?

A: Unfortunately vehicle manufactures frequently change the color of the wires in their wiring

harnesses. The wire that we need locate is the factory door-ajar signal located inside each

door. You can find this circuit by removing the door panel and physically tracing the wires

leading to the door latch / switch. Once you have located the bundle of wires that go to the

switch you will need to isolate the door-ajar circuit. This circuit will be a “negative switching”

circuit. Negative switching indicates that the circuit will be in a “ ground “ state where the circuit

is connected to the minus or negative side of the battery with the door open (Except 02 – 03

Ford Super Duty and 08 Ford Super Duty where the circuit is closed to ground with the door

shut). With the door closed the circuit will sometimes show a very small amount of current or

nothing at all.

The best and safest way to isolate this wire is to use a computer safe circuit tester like the

CTS24 Circuit Tester by Blue Point available from Snap On Tools. There are other

manufacturers of similar testers. The important thing about this kind of tester is that it is

specifically designed to be “computer and air bag safe”. This means the tester will not damage

sensitive electrical systems.

A multimeter or continuity tester can also be used by setting the tester to the Ohms setting and

connecting one probe to the negative battery terminal and probing the previously located wires.

With the door open, operate the door latch with the door handle to open the latch. Manually

close the latch with a screwdriver or other tool by actuating the latch and simulating the strike

pin located on the doorjamb. The correct wire will change readings on the tester from no

continuity to 100% continuity when opening and closing the latch (Except 02 – 03 Ford Super

Duty and 08 Ford Super Duty where the circuit is closed to ground with the door shut). Or

when using a tester like the CTS24 the reading will change from green (indicating ground or

minus) to nothing (in some cases red). Complete the balance of the wiring per our wiring

diagram.

Q: The step only goes up (down) halfway and stops. How can I fix it?

A: The body of certain vehicles is often not straight and can put the steps in a bind. Open the

door and put the step in the down position. On the underside of the step you will find two 3/16”

socket head bolts (Allen bolts) that hold the step to the linkage. Remove these two bolts and

dislodge the step from the linkage by tapping on the bottom of the step with a soft face mallet

as if you were going to remove step. It is important that the step is totally separated from the

linkage. Failure to do so will not allow the linkages to properly align. You only need to remove

the Allen bolts from the front or the rear linkage. Both are not necessary. Next put the step in

the up position and reinstall the step on the linkage and reinstall the 3/16” Allen bolts and

tighten. This will align the linkages and eliminate the binding that is causing the step to stop

half way up.

TECH SUPPORT 1-888-983-2206 Monday – Friday 8:00 AM – 5:00 PM PST | Page 3 of 7

Power Step System Operation

Control Module

The operation of the steps is driven by our controller that is mounted under the hood. The

controller is completely “potted“ in epoxy and is therefore totally sealed. There are no

serviceable parts inside the controller. The controller is the brain of the system and

contains hardware and software that not only actuates the steps, but also controls the

crucial “anti pinch” function. Controllers very rarely fail and are almost never intermittent.

Trigger Wires

The trigger wires that tap into the vehicle door ajar switches are ground actuated. That is:

these wires look for a ground signal. In general, closing the circuit to ground with one of

these wires lowers the step and an open circuit (no ground signal) retracts the step. This

can be a useful test to isolate concerns and to diagnose conditions.

Diodes

Most applications use diodes in the wiring circuit. Diodes are the electrical equivalent of a

one-way valve. Diodes isolate against unwanted actuation or delay of the steps, isolate

passenger and driver side door-ajar signals and insure proper operation of the factory

door-ajar warning light in the instrument panel. The orientation of the diode is of extreme

importance. An improperly installed diode or poorly secured diode connection can cause a

number of concerns.

Motor & Drive System

There is one motor per side of the vehicle that drives the steps up and down. This is

accomplished by alternating polarity between poles of the motor. Reversing polarity

causes the motor to reverse direction. Testing for voltage to the motor can be a useful test

in diagnosing concerns. If the motor is getting a 12 volt positive and a negative (ground)

signal and does not respond, in most instances the motor will need to be replaced. The

motor contains a gear drive system and employs rubber cushions that dampen start up

and shut down. Currently there are three types of motors in service. They are: black,

black with white gear case, and inline / CRH. There are no user service parts inside the

motor or gear case.

TECH SUPPORT 1-888-983-2206 Monday – Friday 8:00 AM – 5:00 PM PST | Page 4 of 7

Power Step Knowledge Base

Concern: Intermittent/Erratic Operation – Wire connection

The connector between the wire harness and controller can sometimes make

intermittent contact as a result of the terminals not being properly seated in the white

plastic connector. The corrective action is to check each wire by pulling on the wire

to determine if it pulls out of the back of the white plastic connector. If a wire pulls

free it was most likely not making secure contact. Secure the wire by re-inserting it

into the white plastic connecter and insuring that the metal terminal “prongs” engage

into the plastic and prevent it from backing out.

Concern: GM truck erratic step operation – Ground

Some owners of GM trucks equipped the Duramax diesel engines have reported

erratic operation of the Power Step. The corrective action is to move the Power

Step system ground wire from the 10 mm junction box mounting bracket to the air

conditioning support bracket bolt located behind the junction box. The resulting

improved ground signal path will correct erratic, unreliable operation.

Concern: Step deploys when shutting doors and / or hood – Shock

sensor

In vehicles equipped with a security system that utilizes a shock sensor the steps

can sometimes deploy as a result of shutting the hood and / or doors. The

corrective action is to reduce the sensitivity of the shock sensor.

Concern: Ford Super Duty – Sticking door ajar switch

In older Super Duty trucks there have been reports of the factory door ajar switch

sticking as a result of the original equipment lubricant drying out and causing the

switch to malfunction. Sometimes this condition can be rectified by liberal

application of a high solvent base lubricant like WD-40. Replacement and or

removal, cleaning and re-lubrication of the switch may be necessary.

Concern: Traction Bars

Some suspension manufacturer’s traction bars make contact with the Power Step

and will not work together. Fabtech traction bars on a Ford Super Duty truck will not

work with the Power Step. Major modifications to the inner rocker panel sheet metal

are required. Other manufacturer’s traction bars may also interfere with the Power

Step.

TECH SUPPORT 1-888-983-2206 Monday – Friday 8:00 AM – 5:00 PM PST | Page 5 of 7

Concern: Battery connections

Battery connections that are not secure or connections that have corroded over time

can cause the system to malfunction. Often a clicking sound can be heard coming

from the controller and the steps will not function when the battery connections are

weak.

Concern: Body lift

Some suspension manufacturer’s body lifts will cause the step to make contact with

the body mount(s) and cannot be used with the Power Step. GM SUVs with body lift

spacers cause the step to contact the body mount. The Power Step cannot be used

without major modifications to the frame/body mount.

TECH SUPPORT 1-888-983-2206 Monday – Friday 8:00 AM – 5:00 PM PST | Page 6 of 7

Flowchart Note

The purple trigger wires in the Power Step wire harness are a negative switching

circuit. When the purple trigger wire is connected to ground (negative battery

terminal) there will be an audible click sound from the controller and the step will

deploy. When ground is not present the step will retract. If grounding the purple

trigger wire deploys the step, the controller and motor are operating properly and the

next areas to examine are connections and diodes. In connecting the purple trigger

wire to ground under the hood we have bypassed the diodes and connections in the

balance of the system. Carefully review the wiring diagram for the vehicle make,

model and year under evaluation and insure that the factory door-ajar signal wire

has been properly identified and that the correct diodes are installed in the proper

location and orientation. The F.A.Q. section covers identifying the factory door-ajar

signal wire. If a diode is faulty or is connected backwards, the system will not

receive the necessary ground signal to deploy the step. The same is true if the

connections are not making proper contact with the door-ajar signal wire. Again, a

carefully review of the wiring diagram is in order as well as a thorough evaluation of

the connections to make certain they are secure and making contact.

If a faulty diode is suspected testing is recommended. Diodes transmit current in

only one direction. To test, isolate the diode by disconnecting it from the balance of

the system. The diode will have a silver stripe on one end. Connect the side of the

diode without the stripe to twelve volt positive and the end with the stripe to a tester

(continuity tester, test light, multimeter) and ground the tester. Current should flow in

this direction. Current should not flow through the diode if the end with the stripe is

connected to the twelve volt positive. The diode is bad if current flows in this

direction or if current does not flow in either direction. Any of the following diodes

can be used as replacements: 1N4002, 1N4003, 1N4004, 1N4005, 1N4006, and

1N4007. Diodes are available from AMP Research at no charge. Call 949-221-

4198 to request diodes.

TECH SUPPORT 1-888-983-2206 Monday – Friday 8:00 AM – 5:00 PM PST | Page 7 of 7

START Step not working

Step does not work

Disconnect Steps

Check factory Check factory

Dash light Power Step Dash light Repair factory Dash light Operational

door ajar light on door ajar light on Test step

Not working trigger wires Not working door ajar circut working

dash

from factory

dash END

door ajar circut

Dash light working

Note A

Dash light Steps

working Replace fuse Test step Operational Review wiring instructions.

END A diode connected incorrectly

will make the dash light in-op.

Check fuse Fuse

under hood at burned

battery

Fuse good Steps not working

Note B

Pierce insulation of

purple wire(s) at See detailed notes for additional

controller under troubleshooting

hood and connect

to ground one at a Step

Review wiring

time. Deploys

instructions. Possible

root causes:

Step does

Not deploy Connected to wrong

wire in factory system.

Pierce insulation of Diodes in backwards or

purple wire(s) at faulty diode.

controller under Connections not making

hood and contact.

momentary connect

to ground

individually.

Disconnect wire

harness from under Steps

vehicle and test for Voltage Operational

present Replace motor Test step

voltage ACROSS

orange and white

END

wires. Orange and

white WILL

REVERSE polarity

when cycling.

Aprox. 12 volts

should be present Steps do not work

for 3-5 seconds. CALL TECH

SUPPORT

Voltage not

present

Replace Power Step Steps

controller under hood Operational

and test END

Steps do not work

CALL TECH

SUPPORT

You might also like

- Sample Answer AE06Document7 pagesSample Answer AE06wei foo80% (20)

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- Model: ASI4518R37v07: Antenna SpecificationsDocument3 pagesModel: ASI4518R37v07: Antenna SpecificationsSNEF Orange100% (3)

- Bigdog Section8 2002 Electrical RevisedDocument17 pagesBigdog Section8 2002 Electrical RevisedHOWARDB2010100% (1)

- 77-E-Z-GO DCS (1206SX) Install Sheet-370Document4 pages77-E-Z-GO DCS (1206SX) Install Sheet-370Sayed KhlileNo ratings yet

- Citroen zx-12Document48 pagesCitroen zx-12Tony LauNo ratings yet

- Electrical Symbols and SchematicsDocument42 pagesElectrical Symbols and Schematicsapi-384232693% (14)

- ACCEL-DFI Instructions 6a Digital Ignition Dfi 75606Document12 pagesACCEL-DFI Instructions 6a Digital Ignition Dfi 75606Ilango Panneerselvan0% (1)

- ACS800 - 304 - Suppl - User Manual PDFDocument82 pagesACS800 - 304 - Suppl - User Manual PDFAlamgir Robin0% (1)

- Skypatrol - Evolution Installer Guide TT85xxDocument9 pagesSkypatrol - Evolution Installer Guide TT85xxraguilar1abc1No ratings yet

- Estribos Electricos Lifeb - Optim PDFDocument5 pagesEstribos Electricos Lifeb - Optim PDFAldo PosadaNo ratings yet

- Classe CA401 PWR SMDocument26 pagesClasse CA401 PWR SMpingnan kangNo ratings yet

- Bulldog Security SystemDocument14 pagesBulldog Security SystemphilipisaiaNo ratings yet

- Electrical System DiagnosisDocument17 pagesElectrical System DiagnosisArnaldo Mejia Zhenea.100% (1)

- CA-400 Classé Audio Inc. Service Manual: Date: August 8, 2007 Model Number: SubjectDocument20 pagesCA-400 Classé Audio Inc. Service Manual: Date: August 8, 2007 Model Number: SubjectVictor TettehNo ratings yet

- Classe CAV180 PWR SMDocument24 pagesClasse CAV180 PWR SMpingnan kangNo ratings yet

- 4Cl-002 Remote 4 Door Central Locking Kit Installation GuideDocument2 pages4Cl-002 Remote 4 Door Central Locking Kit Installation GuideyayayalNo ratings yet

- Classe CA150 PWR SMDocument22 pagesClasse CA150 PWR SMpingnan kangNo ratings yet

- CA 1053 Install Rev A 8-14-2012Document20 pagesCA 1053 Install Rev A 8-14-2012Michel TanusNo ratings yet

- Installation Manual APS596C - IMDocument16 pagesInstallation Manual APS596C - IMMauro SteffenNo ratings yet

- Heater Fan Switch WorkaroundDocument3 pagesHeater Fan Switch WorkaroundJack MarlowNo ratings yet

- Popular Mechanics - Curing A Clicking StarterDocument4 pagesPopular Mechanics - Curing A Clicking StarterGeorgiana MarinNo ratings yet

- MB Inlet Port Shutoff Valve Emulator Installation Instruction enDocument8 pagesMB Inlet Port Shutoff Valve Emulator Installation Instruction enbruNo ratings yet

- Installation and Troubleshooting Guide: CDI P/N: 173-4849Document4 pagesInstallation and Troubleshooting Guide: CDI P/N: 173-4849Paul MartinNo ratings yet

- SP9100 Rev1.2 DirectionsDocument14 pagesSP9100 Rev1.2 Directionsscada.wupptclNo ratings yet

- DZKNSNDocument2 pagesDZKNSNAleksandria Donne D. FernandezNo ratings yet

- Cdi Troubleshooting Guide Johnson EvinrudeDocument35 pagesCdi Troubleshooting Guide Johnson EvinrudeEvan CollinsNo ratings yet

- Protecting Against Solenoid Coil FailuresDocument7 pagesProtecting Against Solenoid Coil FailuresPuri AyuNo ratings yet

- EW-46 Service Manual 2022Document46 pagesEW-46 Service Manual 2022palletlemurNo ratings yet

- Honda - Prelude - Wiring Diagram - 1994 - 1994Document8,924 pagesHonda - Prelude - Wiring Diagram - 1994 - 1994Kristen Phillips100% (1)

- Model 70 Classé Audio Inc. Service Manual: Date: August 27, 2007 Model Number: SubjectDocument15 pagesModel 70 Classé Audio Inc. Service Manual: Date: August 27, 2007 Model Number: SubjectVictor TettehNo ratings yet

- Er 105 3 1Document7 pagesEr 105 3 1edgarafonsecaNo ratings yet

- How To Diagnose Automotive Electrical Problems - The Mechanic DoctorDocument1 pageHow To Diagnose Automotive Electrical Problems - The Mechanic Doctormecanidec La MotteNo ratings yet

- Power Door Locks Chevrolet S10Document11 pagesPower Door Locks Chevrolet S10Maxi Sardi100% (1)

- Electrical Service Manual 96-0284C Rev C English June 2007Document240 pagesElectrical Service Manual 96-0284C Rev C English June 2007Ahmed Alejandro CarranzaNo ratings yet

- Classe dr-9Document12 pagesClasse dr-9rudiNo ratings yet

- ChassisElectrical PDFDocument111 pagesChassisElectrical PDFDhany SiregarNo ratings yet

- DENSO HD Starter Alternator TroubleshootingDocument3 pagesDENSO HD Starter Alternator TroubleshootinganilNo ratings yet

- Brinks AlarmDocument85 pagesBrinks AlarmDominick VerdiNo ratings yet

- Low Voltage Electrical Component of Electric Two - Three WheelerDocument6 pagesLow Voltage Electrical Component of Electric Two - Three WheelerENESH SOLANKINo ratings yet

- Trouble Shooting Pancake GeneratorsDocument7 pagesTrouble Shooting Pancake GeneratorsRomel José Londoño CamachoNo ratings yet

- Classé Audio Inc.: CAP-151 Service ManualDocument24 pagesClassé Audio Inc.: CAP-151 Service ManualdNo ratings yet

- Motor DiagnosticsDocument5 pagesMotor DiagnosticssabrahimaNo ratings yet

- Magicar 9000BDocument13 pagesMagicar 9000BDavid MartinNo ratings yet

- How To Repair Electric Windows Not WorkingDocument10 pagesHow To Repair Electric Windows Not Workingbyukusenge yves BonheurNo ratings yet

- Service Bulletin Trucks: Electrical System TroubleshootingDocument12 pagesService Bulletin Trucks: Electrical System TroubleshootingRegistr RegistrNo ratings yet

- SM 35Document6 pagesSM 35Communications ShipyardNo ratings yet

- Dynatek-S-Electronic-Ignition Dual FireDocument4 pagesDynatek-S-Electronic-Ignition Dual FireAdrián CasarrubiasNo ratings yet

- Druid Energizer User ManualDocument9 pagesDruid Energizer User ManualKatherine Weber100% (1)

- Electro FinalDocument9 pagesElectro FinalContinedo Rhem JulesNo ratings yet

- CS-2002DC Series IV: Remote Control Alarm System Installation & Operating InstructionsDocument20 pagesCS-2002DC Series IV: Remote Control Alarm System Installation & Operating InstructionsLuis_Alvarez_9112No ratings yet

- How To Test and Repair Small Engine Ignition System ProblemsDocument5 pagesHow To Test and Repair Small Engine Ignition System ProblemsAlfred E. NewmanNo ratings yet

- Trouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsDocument7 pagesTrouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsBilly MecanizadoNo ratings yet

- Danger Warning Caution: Safety InformationDocument7 pagesDanger Warning Caution: Safety InformationcombaheeNo ratings yet

- Mk120s ManualDocument306 pagesMk120s ManualParesh Chandra DebnathNo ratings yet

- Car Heater Not Blowing Air - Here's How To Fix It - Rustyautos - Com - Reader ViewDocument10 pagesCar Heater Not Blowing Air - Here's How To Fix It - Rustyautos - Com - Reader Viewabet_singkong8930No ratings yet

- WL 601 R 2Document2 pagesWL 601 R 2taaj77No ratings yet

- ConditionDocument12 pagesConditionأمجد راضي هادي /A1No ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Invoice VanguardDocument1 pageInvoice Vanguardjuan primoNo ratings yet

- Certifier Specifications Sheet Data Sheets enDocument2 pagesCertifier Specifications Sheet Data Sheets enjuan primoNo ratings yet

- HVA28TD Manual Rev 1 1Document78 pagesHVA28TD Manual Rev 1 1juan primoNo ratings yet

- Fuji Electric PortaflowDocument2 pagesFuji Electric Portaflowjuan primoNo ratings yet

- HZJB-1200 6 Phase Relay Protection Tester-User ManualDocument134 pagesHZJB-1200 6 Phase Relay Protection Tester-User Manualjuan primo100% (1)

- Datasheet SIKA Temperature CalibratorsDocument49 pagesDatasheet SIKA Temperature Calibratorsjuan primoNo ratings yet

- Vanguard Auto Ohm 100Document4 pagesVanguard Auto Ohm 100juan primoNo ratings yet

- VANGUARD ct8000Document6 pagesVANGUARD ct8000juan primoNo ratings yet

- DOBLE TDR9000 - SpecDocument4 pagesDOBLE TDR9000 - Specjuan primoNo ratings yet

- TK3 Proximity System Test Kit: DatasheetDocument6 pagesTK3 Proximity System Test Kit: Datasheetjuan primoNo ratings yet

- Page 1 of 17 CDG/SR0106/000/27Document17 pagesPage 1 of 17 CDG/SR0106/000/27juan primoNo ratings yet

- DOL Motor StarterDocument6 pagesDOL Motor StartermshahidshaukatNo ratings yet

- Smatrix Wave Wave PlusDocument112 pagesSmatrix Wave Wave Plusjamppajoo2No ratings yet

- User ManualDocument258 pagesUser ManualEdwin GiraldoNo ratings yet

- Transistorized Series Voltage RegulatorDocument4 pagesTransistorized Series Voltage RegulatorIpsita MishraNo ratings yet

- RCI 2014 Price ListDocument32 pagesRCI 2014 Price ListSecurity Lock DistributorsNo ratings yet

- NCERT Class 10 Science Lab Manual - Resistors in Parallel - CBSE TutsDocument15 pagesNCERT Class 10 Science Lab Manual - Resistors in Parallel - CBSE TutsVinodKumarTummalurNo ratings yet

- PSC-VS2200 Programação PDFDocument9 pagesPSC-VS2200 Programação PDFprfelicioNo ratings yet

- Seminar On Moving Coil Type Linear Compressor: Juned R. KaziDocument12 pagesSeminar On Moving Coil Type Linear Compressor: Juned R. KaziJuned Aashiqe RasoolNo ratings yet

- SCD-XB770 Service ManualDocument88 pagesSCD-XB770 Service ManualTechnics39No ratings yet

- 25782-Article Text-89683-1-10-20200810Document7 pages25782-Article Text-89683-1-10-20200810Venkatesan SwamyNo ratings yet

- Datasheet 3Document6 pagesDatasheet 3fenixtec1No ratings yet

- BCD AdderDocument23 pagesBCD Addersruharitha0% (1)

- Engineering Circuit Analysis Ebook PDF VersionDocument61 pagesEngineering Circuit Analysis Ebook PDF Versiondebra.glisson665100% (51)

- Assigment 2 AntennaDocument2 pagesAssigment 2 Antennaabdulwahab12100% (1)

- EV PaperDocument5 pagesEV PaperRITHVIKHA VNo ratings yet

- Dual-Port Memory Block Diagram PDFDocument8 pagesDual-Port Memory Block Diagram PDFivanramljakNo ratings yet

- FWB J Installation and Operation ManualDocument16 pagesFWB J Installation and Operation ManualselvamejiaNo ratings yet

- Ats - Geist Power - Atrn102-101r15st-1 PDFDocument2 pagesAts - Geist Power - Atrn102-101r15st-1 PDFCastellon DonaldNo ratings yet

- VT-8618, VT-8624, VT-8630 2022 - With Sensor EU MARKETDocument1 pageVT-8618, VT-8624, VT-8630 2022 - With Sensor EU MARKETyulian.stanevNo ratings yet

- Simulation de PCM, DPCM y DM SimulinkDocument6 pagesSimulation de PCM, DPCM y DM SimulinkМигель Кастижо0% (1)

- TEL 7208 Test 1 QuestionsDocument1 pageTEL 7208 Test 1 QuestionsSsejjuuko PaulNo ratings yet

- La 78040Document4 pagesLa 78040Wilton Carlos SilvaNo ratings yet

- LG 40UB800V шасси LD48VDocument90 pagesLG 40UB800V шасси LD48VRony ReyesNo ratings yet

- NDPLDocument27 pagesNDPLkaushal895No ratings yet

- Lippert - Slide Out Model In-Wall (Schwintek) Owner's ManualDocument26 pagesLippert - Slide Out Model In-Wall (Schwintek) Owner's Manual28larrysjunkmail100% (1)

- EXERCISE 6 + SolutionsDocument6 pagesEXERCISE 6 + SolutionsEmmanuel WadiraNo ratings yet

- Impedance and Conductance TestingDocument0 pagesImpedance and Conductance Testingjesus_hfNo ratings yet

- What Is Thermal Design An-EDocument5 pagesWhat Is Thermal Design An-EpkNo ratings yet