Professional Documents

Culture Documents

Pessing Libya INC: As Per P No.3,4 To As Per P No.3,4

Pessing Libya INC: As Per P No.3,4 To As Per P No.3,4

Uploaded by

Mahmoud HaggagCopyright:

Available Formats

You might also like

- Draft WPS For Carbon Steel PipeDocument2 pagesDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (3)

- Patient Privacy ActionDocument4 pagesPatient Privacy Actionjessica writes2021No ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- WPS GF170 As 1554.6Document1 pageWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- Document 419475.1Document12 pagesDocument 419475.1Jack WangNo ratings yet

- 12amy Accounting Outline Fall 2005Document73 pages12amy Accounting Outline Fall 2005Seungmi ParkNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CMahmoud HaggagNo ratings yet

- Pessing Libya INC: Sfa. No: A5.9Document1 pagePessing Libya INC: Sfa. No: A5.9Mahmoud HaggagNo ratings yet

- Pessing Libya INC: Fill: FCAW Sfa. No: 5.18&5.20 Post Weld Heat treatment:N/ADocument1 pagePessing Libya INC: Fill: FCAW Sfa. No: 5.18&5.20 Post Weld Heat treatment:N/AMahmoud HaggagNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CMahmoud HaggagNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CMahmoud HaggagNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- Pessing Libya INC: Fill: GTAW Sfa. No: 5.14 Post Weld Heat Treatment: N/ADocument1 pagePessing Libya INC: Fill: GTAW Sfa. No: 5.14 Post Weld Heat Treatment: N/AMahmoud HaggagNo ratings yet

- Pessing Libya INC: SA 312 TP 316 TO SA 312 TPDocument1 pagePessing Libya INC: SA 312 TP 316 TO SA 312 TPMahmoud HaggagNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- Wps 2-8Document1 pageWps 2-8Anonymous XYt4Y9qNo ratings yet

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya Barani100% (1)

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- WPS & PQRDocument13 pagesWPS & PQRValentin RadulescuNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- WPS PQR FormulirDocument2 pagesWPS PQR FormulirAZaiNo ratings yet

- PQRDocument3 pagesPQRPradeep Lakum100% (1)

- WPS 01 - Pipe - SSDocument1 pageWPS 01 - Pipe - SSAdvanced Quality Centre AQCNo ratings yet

- Welding Procedure Specification SampleDocument2 pagesWelding Procedure Specification SampleBrown's P LikoNo ratings yet

- WPSDocument4 pagesWPSdhirlisa8381No ratings yet

- PQR FLow LineDocument2 pagesPQR FLow Linesar sarNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- P WPSDocument3 pagesP WPSAnilkumar G NairNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Je C 006 WPSDocument4 pagesJe C 006 WPScameron toolseeNo ratings yet

- PQR No TECH-PS01 Rev.2 SMAW - NORMALDocument4 pagesPQR No TECH-PS01 Rev.2 SMAW - NORMALcfranciaNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- WPS ExampleDocument2 pagesWPS ExampleMarcio Jr.No ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- Prequalified X Qualified by Testing Procedure Qualification Records (PQR) YES .Document2 pagesPrequalified X Qualified by Testing Procedure Qualification Records (PQR) YES .Midhun K Chandrabose100% (1)

- RK PWPS PC 001Document2 pagesRK PWPS PC 001SudeepDPoojaryNo ratings yet

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Document2 pagesWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialNo ratings yet

- En Iso 15609Document2 pagesEn Iso 15609Parminder SinghNo ratings yet

- Je C 008 WPSDocument4 pagesJe C 008 WPScameron toolseeNo ratings yet

- GEG 206-1 Rev.0Document63 pagesGEG 206-1 Rev.0mb.pipingNo ratings yet

- Je C 006 PQRDocument5 pagesJe C 006 PQRcameron toolseeNo ratings yet

- 4 - PREPARATION OF WPS - StudentDocument22 pages4 - PREPARATION OF WPS - Studentrazlan ghazaliNo ratings yet

- DEE-920-11 - Rev 0Document3 pagesDEE-920-11 - Rev 0Karim ZahranNo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Welding Procedure Specification: Monday, April 27, 2009 Page 1 of 2Document2 pagesWelding Procedure Specification: Monday, April 27, 2009 Page 1 of 2srb metallurgNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationFrancisco HoyosNo ratings yet

- WPS 141-111 P460QH To SameDocument1 pageWPS 141-111 P460QH To SameakisdassasNo ratings yet

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- Welding Procedure Qualification Record: String or Weave Bead, Multipass, Single Electrode, Electrical Stick-Out:15-25mmDocument1 pageWelding Procedure Qualification Record: String or Weave Bead, Multipass, Single Electrode, Electrical Stick-Out:15-25mmBhanu Pratap ChoudhuryNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- Bdde PQR CS 001Document2 pagesBdde PQR CS 001mainur mechanical engineer0% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Judicial Notice When Mandatory - 4.Suplico-vs-NedaDocument1 pageJudicial Notice When Mandatory - 4.Suplico-vs-NedaBam Bathan100% (1)

- Manual Split ToshibaDocument86 pagesManual Split ToshibaTiago Melo0% (1)

- Ladaga vs. MapaguDocument5 pagesLadaga vs. MapaguGenerosa GenosaNo ratings yet

- Directory: AccommodationDocument35 pagesDirectory: AccommodationAle AleNo ratings yet

- Fowind Study Report - 29 06 2016 - Pages - JWG Update - v2Document124 pagesFowind Study Report - 29 06 2016 - Pages - JWG Update - v2Nemanja KomatinovicNo ratings yet

- Paul Pignataro Leveraged BuyoutsDocument11 pagesPaul Pignataro Leveraged Buyoutspriyanshu14No ratings yet

- Maharshi Dayanand University, Rohtak: A Project Report On "E-Commerce"Document58 pagesMaharshi Dayanand University, Rohtak: A Project Report On "E-Commerce"Shivraj CyberNo ratings yet

- PDF Conducting Systematic Reviews in Sport Exercise and Physical Activity David Tod Ebook Full ChapterDocument53 pagesPDF Conducting Systematic Reviews in Sport Exercise and Physical Activity David Tod Ebook Full Chapterrenee.walker170100% (3)

- Master Assessor - Trainer GuideDocument338 pagesMaster Assessor - Trainer GuideBME50% (2)

- Hospitality Management and Public Relations Solved MCQs (Set-1)Document5 pagesHospitality Management and Public Relations Solved MCQs (Set-1)Gilbert C NgomaNo ratings yet

- fb15 FBCCDocument3 pagesfb15 FBCCBob WattendorfNo ratings yet

- Modul 10 Mesin Listrik 1 PDFDocument13 pagesModul 10 Mesin Listrik 1 PDFaswardiNo ratings yet

- eSRS Reg Form PDFDocument1 pageeSRS Reg Form PDFDarlyn Etang100% (1)

- 3D TransformationDocument22 pages3D TransformationDeepa SNo ratings yet

- Hawke Optics Catalog 2015Document32 pagesHawke Optics Catalog 2015JA SaathoffNo ratings yet

- Article 1545 1560 ExplanationsDocument6 pagesArticle 1545 1560 ExplanationsWesNo ratings yet

- Research Data Management by DR RC GaurDocument29 pagesResearch Data Management by DR RC Gaursudheer babu arumbakaNo ratings yet

- Digital Booklet - ArularDocument17 pagesDigital Booklet - ArularMax Coates BurlingameNo ratings yet

- 3 s2.0 B9780128211397002233 Main PDFDocument8 pages3 s2.0 B9780128211397002233 Main PDFJulio Cesar de SouzaNo ratings yet

- Constitution and By-Laws Bula National High School Teachers League Constitution PreambleDocument12 pagesConstitution and By-Laws Bula National High School Teachers League Constitution PreambleMart TinNo ratings yet

- The Leela New NormalDocument24 pagesThe Leela New NormalDigvijay SinghNo ratings yet

- ESTIMATION AND CORRECTION OF GAIN MISMATCH AND TIMING ERROR IN TIME-INTERLEAVED ADCs BASED ON DFTDocument10 pagesESTIMATION AND CORRECTION OF GAIN MISMATCH AND TIMING ERROR IN TIME-INTERLEAVED ADCs BASED ON DFTvanthanhsqttNo ratings yet

- PHM and Value AdditionDocument3 pagesPHM and Value AdditionNikhil GourNo ratings yet

- Principles of Marketing Q2 Module 8 Grade 11Document27 pagesPrinciples of Marketing Q2 Module 8 Grade 11Lyn-lyn Suyom-BitosNo ratings yet

- 4 6021613740347099891Document18 pages4 6021613740347099891abdiNo ratings yet

- Gas ExpanderDocument12 pagesGas ExpanderArun KumarNo ratings yet

- Camsco E Catalog PDFDocument384 pagesCamsco E Catalog PDFKelvyn Raqui100% (1)

Pessing Libya INC: As Per P No.3,4 To As Per P No.3,4

Pessing Libya INC: As Per P No.3,4 To As Per P No.3,4

Uploaded by

Mahmoud HaggagOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pessing Libya INC: As Per P No.3,4 To As Per P No.3,4

Pessing Libya INC: As Per P No.3,4 To As Per P No.3,4

Uploaded by

Mahmoud HaggagCopyright:

Available Formats

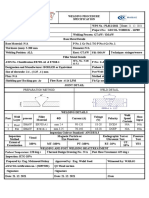

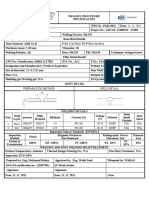

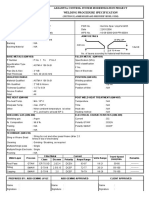

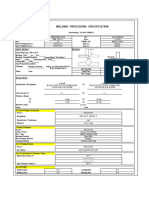

PESSING LIBYA INC WELDING PROCEDURE

CONSTRUCTION & ENGINEERING SERVICES SPECIFICATION

Client: WABAG WPS No.: PL04/2021 Date: 21. 12. 2021

PQR No.: PL/PQR-101 Project No.: GDCOL TOBRUK - 11P89

Weld Type: BW, Single Side Welding Process: GTAW / SMAW

Base Metal Details

Base Material: AS PER P NO.3,4 TO AS PER P NO.3,4 P No. 4 Gr No.1 TO P No.4 Gr No.1

Thickness (mm): 5-50.8 mm Diameter: N/A

Welding Position: All Root: GTAW Fill: GTAW Technique: stringer/weave

Filler Metal Details

SFA. No.:

AWS No. Classification: ER80S-B2 & E8018-B2H4 F No.: 6 & 4 A No.: 3&3

5.28&5.5

Designation and Manufacturer: BOHLER or Equivalent Preheat Temperature: 150 deg c min

Size of electrode: 2.4 & ( 3.2,4 ) mm Post Weld heat treatment: 680 deg c

Flux: N/A Method of prepare edges: Grinding

Shielding gas/ Backing gas: Ar Flow Rate : 10-18 Lpm Fit-Up method: Spacer

JOINT DETAIL

PREPARATION METHOD WELD DETAIL

WELDING DETAILS

Weld

Weld Filler Voltag Heat

Pass process ΦD Current (A) Polarity Speed

Layer Material e (V) Input

Cm/min

1 Root GTAW ER80S-B2 mm 2.4 90-180 10-25 DCEN N/A N/A

2 Fill SMAW mm 4&3.2

E8018-B2H4 100-200 10-30 DCEP N/A N/A

Inspection Code or Standard: ANSI B31.3

Inspection Magnetic Particle or Radiographic Test or Pressure

Visual

Method Dye Penetrant Ultrasonic Test Test

Extent of UT:

100% MT: 100% PT: 100% RT: 10% YES

Examination 10%

WELDING AND POST WELDING HEATTREATMENT

Preheat Temperature:150 deg c min Thermal Design Drawing No.: N/A Post Heat Treatment: 680 deg c

Inspection: RTG-10%

Prepared by: Eng. Mahmoud Helmy Approved by: Eng. Walid Saad Witnessed by: WABAG

AWS/CWI certification no.: (21097031) QC Head section

:Signature :Signature

Date: 21. 12. 2021 Date: 21. 12. 2021 :Date

You might also like

- Draft WPS For Carbon Steel PipeDocument2 pagesDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (3)

- Patient Privacy ActionDocument4 pagesPatient Privacy Actionjessica writes2021No ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- WPS GF170 As 1554.6Document1 pageWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- Document 419475.1Document12 pagesDocument 419475.1Jack WangNo ratings yet

- 12amy Accounting Outline Fall 2005Document73 pages12amy Accounting Outline Fall 2005Seungmi ParkNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CMahmoud HaggagNo ratings yet

- Pessing Libya INC: Sfa. No: A5.9Document1 pagePessing Libya INC: Sfa. No: A5.9Mahmoud HaggagNo ratings yet

- Pessing Libya INC: Fill: FCAW Sfa. No: 5.18&5.20 Post Weld Heat treatment:N/ADocument1 pagePessing Libya INC: Fill: FCAW Sfa. No: 5.18&5.20 Post Weld Heat treatment:N/AMahmoud HaggagNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CMahmoud HaggagNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CMahmoud HaggagNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- Pessing Libya INC: Fill: GTAW Sfa. No: 5.14 Post Weld Heat Treatment: N/ADocument1 pagePessing Libya INC: Fill: GTAW Sfa. No: 5.14 Post Weld Heat Treatment: N/AMahmoud HaggagNo ratings yet

- Pessing Libya INC: SA 312 TP 316 TO SA 312 TPDocument1 pagePessing Libya INC: SA 312 TP 316 TO SA 312 TPMahmoud HaggagNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- Wps 2-8Document1 pageWps 2-8Anonymous XYt4Y9qNo ratings yet

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya Barani100% (1)

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- WPS & PQRDocument13 pagesWPS & PQRValentin RadulescuNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- WPS PQR FormulirDocument2 pagesWPS PQR FormulirAZaiNo ratings yet

- PQRDocument3 pagesPQRPradeep Lakum100% (1)

- WPS 01 - Pipe - SSDocument1 pageWPS 01 - Pipe - SSAdvanced Quality Centre AQCNo ratings yet

- Welding Procedure Specification SampleDocument2 pagesWelding Procedure Specification SampleBrown's P LikoNo ratings yet

- WPSDocument4 pagesWPSdhirlisa8381No ratings yet

- PQR FLow LineDocument2 pagesPQR FLow Linesar sarNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- P WPSDocument3 pagesP WPSAnilkumar G NairNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Je C 006 WPSDocument4 pagesJe C 006 WPScameron toolseeNo ratings yet

- PQR No TECH-PS01 Rev.2 SMAW - NORMALDocument4 pagesPQR No TECH-PS01 Rev.2 SMAW - NORMALcfranciaNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- WPS ExampleDocument2 pagesWPS ExampleMarcio Jr.No ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- Prequalified X Qualified by Testing Procedure Qualification Records (PQR) YES .Document2 pagesPrequalified X Qualified by Testing Procedure Qualification Records (PQR) YES .Midhun K Chandrabose100% (1)

- RK PWPS PC 001Document2 pagesRK PWPS PC 001SudeepDPoojaryNo ratings yet

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Document2 pagesWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialNo ratings yet

- En Iso 15609Document2 pagesEn Iso 15609Parminder SinghNo ratings yet

- Je C 008 WPSDocument4 pagesJe C 008 WPScameron toolseeNo ratings yet

- GEG 206-1 Rev.0Document63 pagesGEG 206-1 Rev.0mb.pipingNo ratings yet

- Je C 006 PQRDocument5 pagesJe C 006 PQRcameron toolseeNo ratings yet

- 4 - PREPARATION OF WPS - StudentDocument22 pages4 - PREPARATION OF WPS - Studentrazlan ghazaliNo ratings yet

- DEE-920-11 - Rev 0Document3 pagesDEE-920-11 - Rev 0Karim ZahranNo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Welding Procedure Specification: Monday, April 27, 2009 Page 1 of 2Document2 pagesWelding Procedure Specification: Monday, April 27, 2009 Page 1 of 2srb metallurgNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationFrancisco HoyosNo ratings yet

- WPS 141-111 P460QH To SameDocument1 pageWPS 141-111 P460QH To SameakisdassasNo ratings yet

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- Welding Procedure Qualification Record: String or Weave Bead, Multipass, Single Electrode, Electrical Stick-Out:15-25mmDocument1 pageWelding Procedure Qualification Record: String or Weave Bead, Multipass, Single Electrode, Electrical Stick-Out:15-25mmBhanu Pratap ChoudhuryNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- Bdde PQR CS 001Document2 pagesBdde PQR CS 001mainur mechanical engineer0% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Judicial Notice When Mandatory - 4.Suplico-vs-NedaDocument1 pageJudicial Notice When Mandatory - 4.Suplico-vs-NedaBam Bathan100% (1)

- Manual Split ToshibaDocument86 pagesManual Split ToshibaTiago Melo0% (1)

- Ladaga vs. MapaguDocument5 pagesLadaga vs. MapaguGenerosa GenosaNo ratings yet

- Directory: AccommodationDocument35 pagesDirectory: AccommodationAle AleNo ratings yet

- Fowind Study Report - 29 06 2016 - Pages - JWG Update - v2Document124 pagesFowind Study Report - 29 06 2016 - Pages - JWG Update - v2Nemanja KomatinovicNo ratings yet

- Paul Pignataro Leveraged BuyoutsDocument11 pagesPaul Pignataro Leveraged Buyoutspriyanshu14No ratings yet

- Maharshi Dayanand University, Rohtak: A Project Report On "E-Commerce"Document58 pagesMaharshi Dayanand University, Rohtak: A Project Report On "E-Commerce"Shivraj CyberNo ratings yet

- PDF Conducting Systematic Reviews in Sport Exercise and Physical Activity David Tod Ebook Full ChapterDocument53 pagesPDF Conducting Systematic Reviews in Sport Exercise and Physical Activity David Tod Ebook Full Chapterrenee.walker170100% (3)

- Master Assessor - Trainer GuideDocument338 pagesMaster Assessor - Trainer GuideBME50% (2)

- Hospitality Management and Public Relations Solved MCQs (Set-1)Document5 pagesHospitality Management and Public Relations Solved MCQs (Set-1)Gilbert C NgomaNo ratings yet

- fb15 FBCCDocument3 pagesfb15 FBCCBob WattendorfNo ratings yet

- Modul 10 Mesin Listrik 1 PDFDocument13 pagesModul 10 Mesin Listrik 1 PDFaswardiNo ratings yet

- eSRS Reg Form PDFDocument1 pageeSRS Reg Form PDFDarlyn Etang100% (1)

- 3D TransformationDocument22 pages3D TransformationDeepa SNo ratings yet

- Hawke Optics Catalog 2015Document32 pagesHawke Optics Catalog 2015JA SaathoffNo ratings yet

- Article 1545 1560 ExplanationsDocument6 pagesArticle 1545 1560 ExplanationsWesNo ratings yet

- Research Data Management by DR RC GaurDocument29 pagesResearch Data Management by DR RC Gaursudheer babu arumbakaNo ratings yet

- Digital Booklet - ArularDocument17 pagesDigital Booklet - ArularMax Coates BurlingameNo ratings yet

- 3 s2.0 B9780128211397002233 Main PDFDocument8 pages3 s2.0 B9780128211397002233 Main PDFJulio Cesar de SouzaNo ratings yet

- Constitution and By-Laws Bula National High School Teachers League Constitution PreambleDocument12 pagesConstitution and By-Laws Bula National High School Teachers League Constitution PreambleMart TinNo ratings yet

- The Leela New NormalDocument24 pagesThe Leela New NormalDigvijay SinghNo ratings yet

- ESTIMATION AND CORRECTION OF GAIN MISMATCH AND TIMING ERROR IN TIME-INTERLEAVED ADCs BASED ON DFTDocument10 pagesESTIMATION AND CORRECTION OF GAIN MISMATCH AND TIMING ERROR IN TIME-INTERLEAVED ADCs BASED ON DFTvanthanhsqttNo ratings yet

- PHM and Value AdditionDocument3 pagesPHM and Value AdditionNikhil GourNo ratings yet

- Principles of Marketing Q2 Module 8 Grade 11Document27 pagesPrinciples of Marketing Q2 Module 8 Grade 11Lyn-lyn Suyom-BitosNo ratings yet

- 4 6021613740347099891Document18 pages4 6021613740347099891abdiNo ratings yet

- Gas ExpanderDocument12 pagesGas ExpanderArun KumarNo ratings yet

- Camsco E Catalog PDFDocument384 pagesCamsco E Catalog PDFKelvyn Raqui100% (1)