Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

16 views3D SSB Case Study 3D Printed Solid State

3D SSB Case Study 3D Printed Solid State

Uploaded by

Rahul DeshpandeThe document discusses a collaborative R&D project to develop 3D printed solid-state batteries with controlled geometry. Key outcomes included demonstrating the feasibility of 3D printing solid-state batteries of any shape using novel composite materials and a functional binder via additive manufacturing without requiring energy-intensive sintering processes. The project formulated electrode and electrolyte resins for 3D printing through material characterization, functional resin development, and rheology testing to enable high-throughput evaluation of 3D printed films.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Visa ApplicationformDocument3 pagesVisa ApplicationformFaraz HaiderNo ratings yet

- NR L2 Civ 177Document14 pagesNR L2 Civ 177Alberto LeónNo ratings yet

- Royal Enfield IndiaDocument20 pagesRoyal Enfield IndiaKapil Manchanda100% (3)

- Simcenter STAR-CCM+ Electrochemistry - Technology Spotlight PresentationDocument58 pagesSimcenter STAR-CCM+ Electrochemistry - Technology Spotlight Presentationvivek shajiNo ratings yet

- EN ZEISS Emobility SolutionsDocument91 pagesEN ZEISS Emobility SolutionsPetar TakovNo ratings yet

- Fabrication of Directional Optocouplers Via Two-Photon Absorption PolymerizationDocument1 pageFabrication of Directional Optocouplers Via Two-Photon Absorption Polymerizationgabriel.henrique.jorgeNo ratings yet

- CH 2 - Nanofabrication - Photolithography (2022.02) - DR - BaoDocument70 pagesCH 2 - Nanofabrication - Photolithography (2022.02) - DR - BaoLe Xuan HuyNo ratings yet

- And Quality: Scan Compression Techniques To Improve Test TimeDocument5 pagesAnd Quality: Scan Compression Techniques To Improve Test TimeSudhir BorraNo ratings yet

- Vat Polymerization (1) - MergedDocument79 pagesVat Polymerization (1) - MergedHarsh BansalNo ratings yet

- Improving EV Battery Performance With Customized Lithium Ion Battery BindersDocument33 pagesImproving EV Battery Performance With Customized Lithium Ion Battery BindersProvocateur SamaraNo ratings yet

- Optimization of FDM 3D Printing Process Parameters On ABS Based Bone Hammer Using RSM TechniqueDocument13 pagesOptimization of FDM 3D Printing Process Parameters On ABS Based Bone Hammer Using RSM TechniqueJohnNo ratings yet

- ME516 Final Project PresentationDocument14 pagesME516 Final Project PresentationSURAJNo ratings yet

- Cholleti 2018 IOP Conf. Ser. Mater. Sci. Eng. 455 012038Document14 pagesCholleti 2018 IOP Conf. Ser. Mater. Sci. Eng. 455 012038AynamawNo ratings yet

- Fused Deposition Modeling: Process, Materials, Parameters, Properties, and ApplicationsDocument41 pagesFused Deposition Modeling: Process, Materials, Parameters, Properties, and ApplicationsNaveenkumar ANo ratings yet

- Optimization of The SEM Working Conditions EsB Detector at Low VoltageDocument10 pagesOptimization of The SEM Working Conditions EsB Detector at Low VoltageArunbabu AyiriveetilNo ratings yet

- EHD HS BrochureDocument6 pagesEHD HS BrochureAvinash KamuniNo ratings yet

- 3d Printing Hybrid Additive Manufacturing (Research Paper IEEE)Document5 pages3d Printing Hybrid Additive Manufacturing (Research Paper IEEE)Abhishek KaleNo ratings yet

- 10.1515 - Nanoph 2017 0073Document7 pages10.1515 - Nanoph 2017 0073sumanta.kundu318020No ratings yet

- Jia 2020 IOP Conf. Ser. Mater. Sci. Eng. 772 012023Document7 pagesJia 2020 IOP Conf. Ser. Mater. Sci. Eng. 772 012023HERLINA PEBRIANINo ratings yet

- Akash Aggarwal ICSSP PosterDocument2 pagesAkash Aggarwal ICSSP PosteralirafiqNo ratings yet

- Research On Defect Detection Method For Steel Metal Surface Based On Deep LearningDocument5 pagesResearch On Defect Detection Method For Steel Metal Surface Based On Deep LearningRam KumarNo ratings yet

- BHARATHNARASIMMANDocument2 pagesBHARATHNARASIMMANBharath LNo ratings yet

- Chance-Constrained Yield Optimization of Photonic IC With Non-Gaussian Correlated Process VariationsDocument12 pagesChance-Constrained Yield Optimization of Photonic IC With Non-Gaussian Correlated Process VariationsGaston GBNo ratings yet

- STRATEC Consumables - PrototypingDocument1 pageSTRATEC Consumables - PrototypingNeelaj MaityNo ratings yet

- PC 2200 BrochureDocument2 pagesPC 2200 BrochureMuhammad AzeemNo ratings yet

- Grey - Relational - Analysis-Based - Optimization - of MacDocument32 pagesGrey - Relational - Analysis-Based - Optimization - of Macpuneet tyagiNo ratings yet

- Tuning The Laser Induced Processing of 3d Porous Graphenic Nanostructures by Boron Doped Diamond Par - 71488Document13 pagesTuning The Laser Induced Processing of 3d Porous Graphenic Nanostructures by Boron Doped Diamond Par - 71488Joel Stanley TylerNo ratings yet

- Radix Printable Dielectric Data SheetDocument2 pagesRadix Printable Dielectric Data SheetAbhiNo ratings yet

- Optimization and Design Numerical Modeling and Advances in Fabrication Technologies To Optical PerformanceDocument7 pagesOptimization and Design Numerical Modeling and Advances in Fabrication Technologies To Optical PerformanceEditor IJRITCCNo ratings yet

- 1-s2.0-S0278612521002089-main(robot)Document10 pages1-s2.0-S0278612521002089-main(robot)abourifa hananeNo ratings yet

- Ilg 2019 IOP Conf. Ser. Mater. Sci. Eng. 651 012070Document9 pagesIlg 2019 IOP Conf. Ser. Mater. Sci. Eng. 651 012070ansys fluentNo ratings yet

- Advancements in Photodetectors: Illuminating The Future: Mentor: Parth ShahDocument13 pagesAdvancements in Photodetectors: Illuminating The Future: Mentor: Parth Shahmsonali0311No ratings yet

- 5) Decarbonizing The Mining Industry From Grid-To-wheel - Electric Mine Conference May 2023 - Follow UpDocument42 pages5) Decarbonizing The Mining Industry From Grid-To-wheel - Electric Mine Conference May 2023 - Follow Upfabiana.cavalcanteNo ratings yet

- 3D Printing of Continuous Carbon Fiber Reinforced Thermoset Composites Using UV Curable ResinDocument10 pages3D Printing of Continuous Carbon Fiber Reinforced Thermoset Composites Using UV Curable ResinRaif SakinNo ratings yet

- Chien 2014Document12 pagesChien 2014Quang BùiNo ratings yet

- High Performance Molecular Visualization and Analysis With GPU ComputingDocument46 pagesHigh Performance Molecular Visualization and Analysis With GPU ComputingajithpadyanaNo ratings yet

- Approximate Multipliers For Optimal Utilization of FPGA ResourcesDocument6 pagesApproximate Multipliers For Optimal Utilization of FPGA Resourcesisha chaubeyNo ratings yet

- Artigo GABS UFMS-UFU - D2ay00803cDocument10 pagesArtigo GABS UFMS-UFU - D2ay00803cBruno LuccaNo ratings yet

- Diffractive Optical ElementsDocument8 pagesDiffractive Optical ElementsruskaNo ratings yet

- Machine-Learning-Based Prediction of Corrosion Behavior in Additively Manufactured Inconel 718Document16 pagesMachine-Learning-Based Prediction of Corrosion Behavior in Additively Manufactured Inconel 718KAORU AmaneNo ratings yet

- 2017 Inkjet-Printed OptoelectronicsDocument29 pages2017 Inkjet-Printed OptoelectronicsmarcianolocoNo ratings yet

- Precise in Situ Characterization and Cross Validation 2020 Artificial IntellDocument7 pagesPrecise in Situ Characterization and Cross Validation 2020 Artificial IntellShivam NikamNo ratings yet

- Naukri SunilKumar (6y 0m)Document3 pagesNaukri SunilKumar (6y 0m)dodla.naiduNo ratings yet

- Novel High Pressure Exfoliated Graphene-Based Semitransparent Stable DSSCs For Building Integrated PhotovoltaicsDocument8 pagesNovel High Pressure Exfoliated Graphene-Based Semitransparent Stable DSSCs For Building Integrated PhotovoltaicsPk dataNo ratings yet

- 0023 DPrintingtechnology ID338Document9 pages0023 DPrintingtechnology ID338athars248No ratings yet

- b2a3bb02-df36-4a80-99d9-ac43e3c8af8cDocument12 pagesb2a3bb02-df36-4a80-99d9-ac43e3c8af8cLuqman Hakim ZaimuriNo ratings yet

- Print Fidelity Evaluation of PVA Hydrogel Using Computational Fluid Dynamics For Extrusion Dependent 3D PrintingDocument9 pagesPrint Fidelity Evaluation of PVA Hydrogel Using Computational Fluid Dynamics For Extrusion Dependent 3D Printingventhan kalaiNo ratings yet

- Materials: Artificial Neural Network Algorithms For 3D PrintingDocument27 pagesMaterials: Artificial Neural Network Algorithms For 3D PrintingSagnik ChowdhuryNo ratings yet

- J Jmapro 2020 01 055Document5 pagesJ Jmapro 2020 01 055123No ratings yet

- Zhao 2020Document5 pagesZhao 2020Sidinei RibisckiNo ratings yet

- Nanomaterials 13 02334Document15 pagesNanomaterials 13 02334Abdullah FirozNo ratings yet

- A Seminar Ultra Violet Curing Based 3D Printer: Sri J. BhaskarDocument17 pagesA Seminar Ultra Violet Curing Based 3D Printer: Sri J. BhaskarSANJAY KUMAR YADAV MtechNo ratings yet

- Jiang 2022 Simulation of The Refractive IndexDocument16 pagesJiang 2022 Simulation of The Refractive IndexheheNo ratings yet

- Fabrication and Compressive Behavior of A Micro-Lattice Composite by High Resolution DLP StereolithographyDocument15 pagesFabrication and Compressive Behavior of A Micro-Lattice Composite by High Resolution DLP Stereolithographycsshin1No ratings yet

- New About SLS AdvancementDocument38 pagesNew About SLS Advancementdagimze456No ratings yet

- Starrc DsDocument7 pagesStarrc DsNishanth BaratamNo ratings yet

- Energy and AIDocument16 pagesEnergy and AIjabir sulaimanNo ratings yet

- 10 - A Surrogate Modelling Strategy To Improve The Surface Morphology Quality 2023Document14 pages10 - A Surrogate Modelling Strategy To Improve The Surface Morphology Quality 2023yasin yapiciNo ratings yet

- Evolution of 3D Printing Methods and Materials For Electrochemical Energy StorageDocument27 pagesEvolution of 3D Printing Methods and Materials For Electrochemical Energy StoragefarishaNo ratings yet

- Project Phase 2Document13 pagesProject Phase 2Lalit SinghalNo ratings yet

- 1-1. Fabrication of Bragg Mirrors by Multilayer Inkjet PrintingDocument8 pages1-1. Fabrication of Bragg Mirrors by Multilayer Inkjet Printingkamru55l.mzrllalNo ratings yet

- Final Posters SMALLDocument61 pagesFinal Posters SMALLTheodor BarticNo ratings yet

- AICTE IDEA LabDocument3 pagesAICTE IDEA LabRahul DeshpandeNo ratings yet

- 24th May Train TicketDocument3 pages24th May Train TicketRahul DeshpandeNo ratings yet

- Analysis and Research On Standard System and TechnDocument6 pagesAnalysis and Research On Standard System and TechnRahul DeshpandeNo ratings yet

- Digital Manufacturing Accelerates Time To MarketDocument13 pagesDigital Manufacturing Accelerates Time To MarketRahul DeshpandeNo ratings yet

- Battery Swapping For E2Ws in IndiaDocument25 pagesBattery Swapping For E2Ws in IndiaRahul DeshpandeNo ratings yet

- Analysis and Research On Standard System and Technical Requirements of Jib CraneDocument6 pagesAnalysis and Research On Standard System and Technical Requirements of Jib CraneRahul DeshpandeNo ratings yet

- The 3-2-1 Formula For Better Sleep (Backed by Science)Document8 pagesThe 3-2-1 Formula For Better Sleep (Backed by Science)Rahul DeshpandeNo ratings yet

- 7 Best Quantum Computing Research Institutes in IndiaDocument9 pages7 Best Quantum Computing Research Institutes in IndiaRahul DeshpandeNo ratings yet

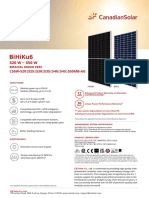

- CS Datasheet BiHiKu6 - CS6W MB AG - v2.1 - EN (Canadise)Document2 pagesCS Datasheet BiHiKu6 - CS6W MB AG - v2.1 - EN (Canadise)AlejandraNo ratings yet

- CEASIOM An Open Source Multi Module ConcDocument7 pagesCEASIOM An Open Source Multi Module ConcSab-Win DamadNo ratings yet

- Visible Surface Detection AlgorithmsDocument21 pagesVisible Surface Detection AlgorithmsTara ElanNo ratings yet

- Pile Cap DesignDocument95 pagesPile Cap Designpravin100% (1)

- Munier Hossain - Making Sense of Medical Statistics (2021, Cambridge University Press) - Libgen - LiDocument199 pagesMunier Hossain - Making Sense of Medical Statistics (2021, Cambridge University Press) - Libgen - LijonahiNo ratings yet

- PCR Measur Tektronix PDFDocument24 pagesPCR Measur Tektronix PDFGrzegorz ZissNo ratings yet

- Integrated Marketing Communication PDFDocument5 pagesIntegrated Marketing Communication PDFAmit SorathiyaNo ratings yet

- Computer Systems Performance Analysis Assignment-2:: R.V.C.E M.Tech, 3 SemDocument2 pagesComputer Systems Performance Analysis Assignment-2:: R.V.C.E M.Tech, 3 Semanisha shettyNo ratings yet

- RDO No. 36 - Puerto Princesa City, PalawanDocument491 pagesRDO No. 36 - Puerto Princesa City, PalawanDiana Lyn Bello CastilloNo ratings yet

- Catalog Sr10.1.1 Simeas R - R-Pmu - enDocument32 pagesCatalog Sr10.1.1 Simeas R - R-Pmu - enSuresh Kumar PariharNo ratings yet

- Chapter 16Document30 pagesChapter 16Rajashekhar B BeedimaniNo ratings yet

- A Clinician's Guide To Cost-Effectiveness Analysis: Annals of Internal Medicine. 1990 113:147-154Document8 pagesA Clinician's Guide To Cost-Effectiveness Analysis: Annals of Internal Medicine. 1990 113:147-154dsjervisNo ratings yet

- Arun 41Document4 pagesArun 41k.g.thri moorthyNo ratings yet

- SAEJ30Document38 pagesSAEJ30Jose Luis AusinNo ratings yet

- Case 1 - The London ClusterDocument3 pagesCase 1 - The London Clusterhanna.ericssonkleinNo ratings yet

- 002 Article A004 enDocument27 pages002 Article A004 enowenish9903No ratings yet

- Case SummaryDocument11 pagesCase SummaryAditya ChaudharyNo ratings yet

- How To Get Work Items From Workflow in Your Outlook Inbox PDFDocument9 pagesHow To Get Work Items From Workflow in Your Outlook Inbox PDFismailimran09No ratings yet

- Product NameDocument3 pagesProduct NameAyush NarayanNo ratings yet

- Fitsum Kelilie PDFDocument84 pagesFitsum Kelilie PDFYeabsera DemelashNo ratings yet

- ASTM D 2487 - 06 Soil Clasification PDFDocument12 pagesASTM D 2487 - 06 Soil Clasification PDFcatalina_tudosa100% (3)

- Eddy AxialDocument20 pagesEddy Axialandrea19711971No ratings yet

- United States v. Robert Williams, 3rd Cir. (2012)Document9 pagesUnited States v. Robert Williams, 3rd Cir. (2012)Scribd Government DocsNo ratings yet

- Admit Card 2019-20 Odd-SemDocument2 pagesAdmit Card 2019-20 Odd-SemRajitram PalNo ratings yet

- Angela Duckworth Grit ScaleDocument3 pagesAngela Duckworth Grit ScaleErsa ShasqiaNo ratings yet

- Ambiguity and orDocument32 pagesAmbiguity and orAqua LakeNo ratings yet

- Sustainable Tourism Development ProjectDocument4 pagesSustainable Tourism Development ProjectKularajah ThuthirajNo ratings yet

3D SSB Case Study 3D Printed Solid State

3D SSB Case Study 3D Printed Solid State

Uploaded by

Rahul Deshpande0 ratings0% found this document useful (0 votes)

16 views3 pagesThe document discusses a collaborative R&D project to develop 3D printed solid-state batteries with controlled geometry. Key outcomes included demonstrating the feasibility of 3D printing solid-state batteries of any shape using novel composite materials and a functional binder via additive manufacturing without requiring energy-intensive sintering processes. The project formulated electrode and electrolyte resins for 3D printing through material characterization, functional resin development, and rheology testing to enable high-throughput evaluation of 3D printed films.

Original Description:

Solid state battery 3D printing

Original Title

3D-SSB-Case-Study-3D-printed-solid-state

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses a collaborative R&D project to develop 3D printed solid-state batteries with controlled geometry. Key outcomes included demonstrating the feasibility of 3D printing solid-state batteries of any shape using novel composite materials and a functional binder via additive manufacturing without requiring energy-intensive sintering processes. The project formulated electrode and electrolyte resins for 3D printing through material characterization, functional resin development, and rheology testing to enable high-throughput evaluation of 3D printed films.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

16 views3 pages3D SSB Case Study 3D Printed Solid State

3D SSB Case Study 3D Printed Solid State

Uploaded by

Rahul DeshpandeThe document discusses a collaborative R&D project to develop 3D printed solid-state batteries with controlled geometry. Key outcomes included demonstrating the feasibility of 3D printing solid-state batteries of any shape using novel composite materials and a functional binder via additive manufacturing without requiring energy-intensive sintering processes. The project formulated electrode and electrolyte resins for 3D printing through material characterization, functional resin development, and rheology testing to enable high-throughput evaluation of 3D printed films.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

Custom formulation

OUTCOMES AND IMPACT

• Feasibility of 3D printing • Printed the cathode

a solid-state battery of materials using a

any shape which is less functional binder via a

hazardous and more Fused Deposition

3D printed solid-state sustainable than

conventional lithium-ion

Modelling process,

removing the need for

batteries with controlled batteries energy-intensive

sintering processes

geometry • Developed novel

composite materials,

including complete

curing for resins highly-

Developing custom-formulated materials to enable solid- filled with light-blocking

state battery manufacture with bespoke configurations anodes

using Additive Manufacturing.

“With CPI’s help, we now have a solid proof-of-concept that

we’ve been able to move forward in the development

process to higher TRL levels. CPI aided in delivering results

and knowledge with a reduced capital investment,

Collaborative R&D 18 months £120,399

allowing us to to achieve our goal in a shorter time span.”

Robert Young

Head of Chemistry and Batteries, Photocentric

Innovating together with CPI

3D printed solid-state batteries

with controlled geometry

Developing custom-formulated materials to enable solid-

state battery manufacture with bespoke configurations

using Additive Manufacturing.

Outcomes and impact Collaborative

R&D project

• Feasibility of 3D printing a solid-state battery of any shape

which is less hazardous and more sustainable than 18 months

conventional lithium-ion batteries

£120,399

• Developed novel composite materials, including complete

curing for resins highly-filled with light-blocking anodes

• Removed the need for energy intensive sintering processes

by using a polymer electrolyte binder

3D printed solid-state batteries

Formulation of electrode and electrolyte resins for subsequent 3D printing

Raw material Functional resin Formulation Rheology of resin 3D printed film

characterisation formulation screening using formulations characterisation

Photo-DSC

Anode, cathode and Developed and optimised Used rheology to confirm Efficient screening

electrolyte powder polymer electrolyte binders Explored photo-DSC to compatible flow properties methods utilised to enable

characterisation including and anode and cathode understand curing of and sufficient stability for high throughput testing of

XRD, iGC, DSC, SEM and powders into a printable photopolymer 3D printing, including melt 3D printed electrodes

dynamic vapour sorption photopolymer or formulations. rheology of thermoplastic including electrical

thermoplastic resin. polymers. impedance spectroscopy

Results used to inform 3D- (EIS) to measure ionic

Applied high throughput printing process, enabling conductivity and four-point

automation capabilities to identification of promising probe measurements to

explore photopolymer formulations. determine electrical

formulations. conductivity.

You might also like

- Visa ApplicationformDocument3 pagesVisa ApplicationformFaraz HaiderNo ratings yet

- NR L2 Civ 177Document14 pagesNR L2 Civ 177Alberto LeónNo ratings yet

- Royal Enfield IndiaDocument20 pagesRoyal Enfield IndiaKapil Manchanda100% (3)

- Simcenter STAR-CCM+ Electrochemistry - Technology Spotlight PresentationDocument58 pagesSimcenter STAR-CCM+ Electrochemistry - Technology Spotlight Presentationvivek shajiNo ratings yet

- EN ZEISS Emobility SolutionsDocument91 pagesEN ZEISS Emobility SolutionsPetar TakovNo ratings yet

- Fabrication of Directional Optocouplers Via Two-Photon Absorption PolymerizationDocument1 pageFabrication of Directional Optocouplers Via Two-Photon Absorption Polymerizationgabriel.henrique.jorgeNo ratings yet

- CH 2 - Nanofabrication - Photolithography (2022.02) - DR - BaoDocument70 pagesCH 2 - Nanofabrication - Photolithography (2022.02) - DR - BaoLe Xuan HuyNo ratings yet

- And Quality: Scan Compression Techniques To Improve Test TimeDocument5 pagesAnd Quality: Scan Compression Techniques To Improve Test TimeSudhir BorraNo ratings yet

- Vat Polymerization (1) - MergedDocument79 pagesVat Polymerization (1) - MergedHarsh BansalNo ratings yet

- Improving EV Battery Performance With Customized Lithium Ion Battery BindersDocument33 pagesImproving EV Battery Performance With Customized Lithium Ion Battery BindersProvocateur SamaraNo ratings yet

- Optimization of FDM 3D Printing Process Parameters On ABS Based Bone Hammer Using RSM TechniqueDocument13 pagesOptimization of FDM 3D Printing Process Parameters On ABS Based Bone Hammer Using RSM TechniqueJohnNo ratings yet

- ME516 Final Project PresentationDocument14 pagesME516 Final Project PresentationSURAJNo ratings yet

- Cholleti 2018 IOP Conf. Ser. Mater. Sci. Eng. 455 012038Document14 pagesCholleti 2018 IOP Conf. Ser. Mater. Sci. Eng. 455 012038AynamawNo ratings yet

- Fused Deposition Modeling: Process, Materials, Parameters, Properties, and ApplicationsDocument41 pagesFused Deposition Modeling: Process, Materials, Parameters, Properties, and ApplicationsNaveenkumar ANo ratings yet

- Optimization of The SEM Working Conditions EsB Detector at Low VoltageDocument10 pagesOptimization of The SEM Working Conditions EsB Detector at Low VoltageArunbabu AyiriveetilNo ratings yet

- EHD HS BrochureDocument6 pagesEHD HS BrochureAvinash KamuniNo ratings yet

- 3d Printing Hybrid Additive Manufacturing (Research Paper IEEE)Document5 pages3d Printing Hybrid Additive Manufacturing (Research Paper IEEE)Abhishek KaleNo ratings yet

- 10.1515 - Nanoph 2017 0073Document7 pages10.1515 - Nanoph 2017 0073sumanta.kundu318020No ratings yet

- Jia 2020 IOP Conf. Ser. Mater. Sci. Eng. 772 012023Document7 pagesJia 2020 IOP Conf. Ser. Mater. Sci. Eng. 772 012023HERLINA PEBRIANINo ratings yet

- Akash Aggarwal ICSSP PosterDocument2 pagesAkash Aggarwal ICSSP PosteralirafiqNo ratings yet

- Research On Defect Detection Method For Steel Metal Surface Based On Deep LearningDocument5 pagesResearch On Defect Detection Method For Steel Metal Surface Based On Deep LearningRam KumarNo ratings yet

- BHARATHNARASIMMANDocument2 pagesBHARATHNARASIMMANBharath LNo ratings yet

- Chance-Constrained Yield Optimization of Photonic IC With Non-Gaussian Correlated Process VariationsDocument12 pagesChance-Constrained Yield Optimization of Photonic IC With Non-Gaussian Correlated Process VariationsGaston GBNo ratings yet

- STRATEC Consumables - PrototypingDocument1 pageSTRATEC Consumables - PrototypingNeelaj MaityNo ratings yet

- PC 2200 BrochureDocument2 pagesPC 2200 BrochureMuhammad AzeemNo ratings yet

- Grey - Relational - Analysis-Based - Optimization - of MacDocument32 pagesGrey - Relational - Analysis-Based - Optimization - of Macpuneet tyagiNo ratings yet

- Tuning The Laser Induced Processing of 3d Porous Graphenic Nanostructures by Boron Doped Diamond Par - 71488Document13 pagesTuning The Laser Induced Processing of 3d Porous Graphenic Nanostructures by Boron Doped Diamond Par - 71488Joel Stanley TylerNo ratings yet

- Radix Printable Dielectric Data SheetDocument2 pagesRadix Printable Dielectric Data SheetAbhiNo ratings yet

- Optimization and Design Numerical Modeling and Advances in Fabrication Technologies To Optical PerformanceDocument7 pagesOptimization and Design Numerical Modeling and Advances in Fabrication Technologies To Optical PerformanceEditor IJRITCCNo ratings yet

- 1-s2.0-S0278612521002089-main(robot)Document10 pages1-s2.0-S0278612521002089-main(robot)abourifa hananeNo ratings yet

- Ilg 2019 IOP Conf. Ser. Mater. Sci. Eng. 651 012070Document9 pagesIlg 2019 IOP Conf. Ser. Mater. Sci. Eng. 651 012070ansys fluentNo ratings yet

- Advancements in Photodetectors: Illuminating The Future: Mentor: Parth ShahDocument13 pagesAdvancements in Photodetectors: Illuminating The Future: Mentor: Parth Shahmsonali0311No ratings yet

- 5) Decarbonizing The Mining Industry From Grid-To-wheel - Electric Mine Conference May 2023 - Follow UpDocument42 pages5) Decarbonizing The Mining Industry From Grid-To-wheel - Electric Mine Conference May 2023 - Follow Upfabiana.cavalcanteNo ratings yet

- 3D Printing of Continuous Carbon Fiber Reinforced Thermoset Composites Using UV Curable ResinDocument10 pages3D Printing of Continuous Carbon Fiber Reinforced Thermoset Composites Using UV Curable ResinRaif SakinNo ratings yet

- Chien 2014Document12 pagesChien 2014Quang BùiNo ratings yet

- High Performance Molecular Visualization and Analysis With GPU ComputingDocument46 pagesHigh Performance Molecular Visualization and Analysis With GPU ComputingajithpadyanaNo ratings yet

- Approximate Multipliers For Optimal Utilization of FPGA ResourcesDocument6 pagesApproximate Multipliers For Optimal Utilization of FPGA Resourcesisha chaubeyNo ratings yet

- Artigo GABS UFMS-UFU - D2ay00803cDocument10 pagesArtigo GABS UFMS-UFU - D2ay00803cBruno LuccaNo ratings yet

- Diffractive Optical ElementsDocument8 pagesDiffractive Optical ElementsruskaNo ratings yet

- Machine-Learning-Based Prediction of Corrosion Behavior in Additively Manufactured Inconel 718Document16 pagesMachine-Learning-Based Prediction of Corrosion Behavior in Additively Manufactured Inconel 718KAORU AmaneNo ratings yet

- 2017 Inkjet-Printed OptoelectronicsDocument29 pages2017 Inkjet-Printed OptoelectronicsmarcianolocoNo ratings yet

- Precise in Situ Characterization and Cross Validation 2020 Artificial IntellDocument7 pagesPrecise in Situ Characterization and Cross Validation 2020 Artificial IntellShivam NikamNo ratings yet

- Naukri SunilKumar (6y 0m)Document3 pagesNaukri SunilKumar (6y 0m)dodla.naiduNo ratings yet

- Novel High Pressure Exfoliated Graphene-Based Semitransparent Stable DSSCs For Building Integrated PhotovoltaicsDocument8 pagesNovel High Pressure Exfoliated Graphene-Based Semitransparent Stable DSSCs For Building Integrated PhotovoltaicsPk dataNo ratings yet

- 0023 DPrintingtechnology ID338Document9 pages0023 DPrintingtechnology ID338athars248No ratings yet

- b2a3bb02-df36-4a80-99d9-ac43e3c8af8cDocument12 pagesb2a3bb02-df36-4a80-99d9-ac43e3c8af8cLuqman Hakim ZaimuriNo ratings yet

- Print Fidelity Evaluation of PVA Hydrogel Using Computational Fluid Dynamics For Extrusion Dependent 3D PrintingDocument9 pagesPrint Fidelity Evaluation of PVA Hydrogel Using Computational Fluid Dynamics For Extrusion Dependent 3D Printingventhan kalaiNo ratings yet

- Materials: Artificial Neural Network Algorithms For 3D PrintingDocument27 pagesMaterials: Artificial Neural Network Algorithms For 3D PrintingSagnik ChowdhuryNo ratings yet

- J Jmapro 2020 01 055Document5 pagesJ Jmapro 2020 01 055123No ratings yet

- Zhao 2020Document5 pagesZhao 2020Sidinei RibisckiNo ratings yet

- Nanomaterials 13 02334Document15 pagesNanomaterials 13 02334Abdullah FirozNo ratings yet

- A Seminar Ultra Violet Curing Based 3D Printer: Sri J. BhaskarDocument17 pagesA Seminar Ultra Violet Curing Based 3D Printer: Sri J. BhaskarSANJAY KUMAR YADAV MtechNo ratings yet

- Jiang 2022 Simulation of The Refractive IndexDocument16 pagesJiang 2022 Simulation of The Refractive IndexheheNo ratings yet

- Fabrication and Compressive Behavior of A Micro-Lattice Composite by High Resolution DLP StereolithographyDocument15 pagesFabrication and Compressive Behavior of A Micro-Lattice Composite by High Resolution DLP Stereolithographycsshin1No ratings yet

- New About SLS AdvancementDocument38 pagesNew About SLS Advancementdagimze456No ratings yet

- Starrc DsDocument7 pagesStarrc DsNishanth BaratamNo ratings yet

- Energy and AIDocument16 pagesEnergy and AIjabir sulaimanNo ratings yet

- 10 - A Surrogate Modelling Strategy To Improve The Surface Morphology Quality 2023Document14 pages10 - A Surrogate Modelling Strategy To Improve The Surface Morphology Quality 2023yasin yapiciNo ratings yet

- Evolution of 3D Printing Methods and Materials For Electrochemical Energy StorageDocument27 pagesEvolution of 3D Printing Methods and Materials For Electrochemical Energy StoragefarishaNo ratings yet

- Project Phase 2Document13 pagesProject Phase 2Lalit SinghalNo ratings yet

- 1-1. Fabrication of Bragg Mirrors by Multilayer Inkjet PrintingDocument8 pages1-1. Fabrication of Bragg Mirrors by Multilayer Inkjet Printingkamru55l.mzrllalNo ratings yet

- Final Posters SMALLDocument61 pagesFinal Posters SMALLTheodor BarticNo ratings yet

- AICTE IDEA LabDocument3 pagesAICTE IDEA LabRahul DeshpandeNo ratings yet

- 24th May Train TicketDocument3 pages24th May Train TicketRahul DeshpandeNo ratings yet

- Analysis and Research On Standard System and TechnDocument6 pagesAnalysis and Research On Standard System and TechnRahul DeshpandeNo ratings yet

- Digital Manufacturing Accelerates Time To MarketDocument13 pagesDigital Manufacturing Accelerates Time To MarketRahul DeshpandeNo ratings yet

- Battery Swapping For E2Ws in IndiaDocument25 pagesBattery Swapping For E2Ws in IndiaRahul DeshpandeNo ratings yet

- Analysis and Research On Standard System and Technical Requirements of Jib CraneDocument6 pagesAnalysis and Research On Standard System and Technical Requirements of Jib CraneRahul DeshpandeNo ratings yet

- The 3-2-1 Formula For Better Sleep (Backed by Science)Document8 pagesThe 3-2-1 Formula For Better Sleep (Backed by Science)Rahul DeshpandeNo ratings yet

- 7 Best Quantum Computing Research Institutes in IndiaDocument9 pages7 Best Quantum Computing Research Institutes in IndiaRahul DeshpandeNo ratings yet

- CS Datasheet BiHiKu6 - CS6W MB AG - v2.1 - EN (Canadise)Document2 pagesCS Datasheet BiHiKu6 - CS6W MB AG - v2.1 - EN (Canadise)AlejandraNo ratings yet

- CEASIOM An Open Source Multi Module ConcDocument7 pagesCEASIOM An Open Source Multi Module ConcSab-Win DamadNo ratings yet

- Visible Surface Detection AlgorithmsDocument21 pagesVisible Surface Detection AlgorithmsTara ElanNo ratings yet

- Pile Cap DesignDocument95 pagesPile Cap Designpravin100% (1)

- Munier Hossain - Making Sense of Medical Statistics (2021, Cambridge University Press) - Libgen - LiDocument199 pagesMunier Hossain - Making Sense of Medical Statistics (2021, Cambridge University Press) - Libgen - LijonahiNo ratings yet

- PCR Measur Tektronix PDFDocument24 pagesPCR Measur Tektronix PDFGrzegorz ZissNo ratings yet

- Integrated Marketing Communication PDFDocument5 pagesIntegrated Marketing Communication PDFAmit SorathiyaNo ratings yet

- Computer Systems Performance Analysis Assignment-2:: R.V.C.E M.Tech, 3 SemDocument2 pagesComputer Systems Performance Analysis Assignment-2:: R.V.C.E M.Tech, 3 Semanisha shettyNo ratings yet

- RDO No. 36 - Puerto Princesa City, PalawanDocument491 pagesRDO No. 36 - Puerto Princesa City, PalawanDiana Lyn Bello CastilloNo ratings yet

- Catalog Sr10.1.1 Simeas R - R-Pmu - enDocument32 pagesCatalog Sr10.1.1 Simeas R - R-Pmu - enSuresh Kumar PariharNo ratings yet

- Chapter 16Document30 pagesChapter 16Rajashekhar B BeedimaniNo ratings yet

- A Clinician's Guide To Cost-Effectiveness Analysis: Annals of Internal Medicine. 1990 113:147-154Document8 pagesA Clinician's Guide To Cost-Effectiveness Analysis: Annals of Internal Medicine. 1990 113:147-154dsjervisNo ratings yet

- Arun 41Document4 pagesArun 41k.g.thri moorthyNo ratings yet

- SAEJ30Document38 pagesSAEJ30Jose Luis AusinNo ratings yet

- Case 1 - The London ClusterDocument3 pagesCase 1 - The London Clusterhanna.ericssonkleinNo ratings yet

- 002 Article A004 enDocument27 pages002 Article A004 enowenish9903No ratings yet

- Case SummaryDocument11 pagesCase SummaryAditya ChaudharyNo ratings yet

- How To Get Work Items From Workflow in Your Outlook Inbox PDFDocument9 pagesHow To Get Work Items From Workflow in Your Outlook Inbox PDFismailimran09No ratings yet

- Product NameDocument3 pagesProduct NameAyush NarayanNo ratings yet

- Fitsum Kelilie PDFDocument84 pagesFitsum Kelilie PDFYeabsera DemelashNo ratings yet

- ASTM D 2487 - 06 Soil Clasification PDFDocument12 pagesASTM D 2487 - 06 Soil Clasification PDFcatalina_tudosa100% (3)

- Eddy AxialDocument20 pagesEddy Axialandrea19711971No ratings yet

- United States v. Robert Williams, 3rd Cir. (2012)Document9 pagesUnited States v. Robert Williams, 3rd Cir. (2012)Scribd Government DocsNo ratings yet

- Admit Card 2019-20 Odd-SemDocument2 pagesAdmit Card 2019-20 Odd-SemRajitram PalNo ratings yet

- Angela Duckworth Grit ScaleDocument3 pagesAngela Duckworth Grit ScaleErsa ShasqiaNo ratings yet

- Ambiguity and orDocument32 pagesAmbiguity and orAqua LakeNo ratings yet

- Sustainable Tourism Development ProjectDocument4 pagesSustainable Tourism Development ProjectKularajah ThuthirajNo ratings yet