Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

17 viewsCertificate No - 021

Certificate No - 021

Uploaded by

RonThis certificate summarizes zinc coating testing on metal parts in compliance with industry standards. The zinc coating was found to have acceptable smoothness and continuity without surface imperfections. Coating thickness measurements for various items ranged from 135 to 265 microns, meeting the standard of 600 grams of zinc per square meter. An adhesion test also confirmed the coating did not lift or flake off as specified. The certificate confirms hot dip galvanization of the materials was performed according to industry standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Elements of Dance: Part 1 Space Shape 1: Shapes With Straight Lines and AnglesDocument3 pagesThe Elements of Dance: Part 1 Space Shape 1: Shapes With Straight Lines and AnglesEarl johnNo ratings yet

- Aqwa Theory ManualDocument168 pagesAqwa Theory ManualWeb Logueando100% (3)

- MC Book Final July 2014Document383 pagesMC Book Final July 2014Latosha TrevinoNo ratings yet

- Certificate No - 020Document1 pageCertificate No - 020RonNo ratings yet

- Falcon Zinc Metal Industries L.L.CDocument7 pagesFalcon Zinc Metal Industries L.L.Ccyril nbhhNo ratings yet

- G16S-0205-03 - Hot Drip GalvDocument2 pagesG16S-0205-03 - Hot Drip Galvpuwarin najaNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED (SA516 Gr.70N + SA 240 GR 316L)Document6 pagesPURCHASE SPEC. FOR PLATES-CLADDED (SA516 Gr.70N + SA 240 GR 316L)Daison Paul100% (1)

- 104 - Spec ITA TERNA SP-20-0622Document7 pages104 - Spec ITA TERNA SP-20-0622Bhagawati Prasad SharmaNo ratings yet

- Brochure The Precast Concrete Product: BetonDocument9 pagesBrochure The Precast Concrete Product: BetonA Akbar HawardiNo ratings yet

- Shield-Bright 2209: Gas-Shielded Flux-Cored Wires (Fcaw) Stainless Steel WiresDocument1 pageShield-Bright 2209: Gas-Shielded Flux-Cored Wires (Fcaw) Stainless Steel WiresvallirajuNo ratings yet

- 22009-Mar-Cv-0107 (Raised False Flooring and Their Accessories)Document28 pages22009-Mar-Cv-0107 (Raised False Flooring and Their Accessories)ADNAN ZIADNo ratings yet

- Stud - Catalogue-EDocument7 pagesStud - Catalogue-Emehmetmehmetmehmet111111No ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Document6 pagesPURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Daison PaulNo ratings yet

- Forging SDocument93 pagesForging SrichardchiamNo ratings yet

- B034 6 44 0074 PDFDocument14 pagesB034 6 44 0074 PDFShashi RanjanNo ratings yet

- Fitup Inspection ReportDocument2 pagesFitup Inspection ReportSalesNo ratings yet

- PURCHASE SPEC. FOR PLATES-WELD OVERLAY (SA516 Gr.70 + SA240 316L)Document4 pagesPURCHASE SPEC. FOR PLATES-WELD OVERLAY (SA516 Gr.70 + SA240 316L)Daison PaulNo ratings yet

- DayeDocument2 pagesDayeJosip JurčićNo ratings yet

- G16S-0205-01 - Repair Hot Drip Galv SurfaceDocument5 pagesG16S-0205-01 - Repair Hot Drip Galv Surfacepuwarin naja100% (1)

- 10089-1E-V11-SS00-00001 (Corrugated Sheet)Document5 pages10089-1E-V11-SS00-00001 (Corrugated Sheet)Ahmed KhalifaNo ratings yet

- AGS030-03 Hot Dip GalvanizingDocument16 pagesAGS030-03 Hot Dip GalvanizingmuzioscarNo ratings yet

- PC Bridge Catalog APB (Adhi Beton)Document7 pagesPC Bridge Catalog APB (Adhi Beton)A Akbar HawardiNo ratings yet

- LREF-00-SP-20-0015S-A4-2 Field Painting Spec. For Propane & Butane Tank (T-201 & 301) .Document25 pagesLREF-00-SP-20-0015S-A4-2 Field Painting Spec. For Propane & Butane Tank (T-201 & 301) .andri yanto100% (1)

- Annexure A To Z - 20191130113051-560-587Document28 pagesAnnexure A To Z - 20191130113051-560-587mondaldgpNo ratings yet

- Duplex UNS 32205Document1 pageDuplex UNS 32205Ercan YilmazNo ratings yet

- TDC-STD-PP012, Rev.02 (SA-234 Gr. WP11,12 and 22)Document1 pageTDC-STD-PP012, Rev.02 (SA-234 Gr. WP11,12 and 22)Tanpreet SinghNo ratings yet

- Itp Signage Rev.01Document8 pagesItp Signage Rev.01moytabura96No ratings yet

- TS Merged PgcilDocument422 pagesTS Merged PgcilsankhaginNo ratings yet

- Triocon Powder Coating - ProcedureDocument15 pagesTriocon Powder Coating - ProceduresindalisindiNo ratings yet

- Purchase Spec. For Plates-Weld Overlay (CS + S31803)Document7 pagesPurchase Spec. For Plates-Weld Overlay (CS + S31803)Daison PaulNo ratings yet

- Comparison Sheet - DUCTDocument2 pagesComparison Sheet - DUCTSavad AlwyeNo ratings yet

- WORD1Document1 pageWORD1ardi yansaNo ratings yet

- Technical Specifications For ValvesDocument32 pagesTechnical Specifications For ValvesEr Hussain GhadialiNo ratings yet

- Technical Note: Durability of Cold-Formed Steel Framing MembersDocument8 pagesTechnical Note: Durability of Cold-Formed Steel Framing MembersZubair ShafiqueNo ratings yet

- b2020-Tdc-Fas-004 Fasteners r3Document2 pagesb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranNo ratings yet

- Is 12594-1988 PDFDocument7 pagesIs 12594-1988 PDFSaurabh PatilNo ratings yet

- Report 14 - Sluice Gates EE-SP2-3-B18 + EE-SP2!3!19Document20 pagesReport 14 - Sluice Gates EE-SP2-3-B18 + EE-SP2!3!19HuthaifahM.DagamsehNo ratings yet

- 3010-PS003 - 3 Valve ScheduleDocument61 pages3010-PS003 - 3 Valve ScheduleMichael adu-boahenNo ratings yet

- Report 11 - Sluice Gates EE-SP2-3-B15 + EE-SP2-3-B10Document20 pagesReport 11 - Sluice Gates EE-SP2-3-B15 + EE-SP2-3-B10HuthaifahM.DagamsehNo ratings yet

- Standard Specification For Hot Dip GalvanizingDocument6 pagesStandard Specification For Hot Dip GalvanizingKrunal PanchalNo ratings yet

- Bomba SihiDocument24 pagesBomba SihiCristian PovedaNo ratings yet

- Report 21 Sluice Gates Ee Sp2 3 b22 + Ee Sp2 3 b26 + Ee Sp2 3 b28Document20 pagesReport 21 Sluice Gates Ee Sp2 3 b22 + Ee Sp2 3 b26 + Ee Sp2 3 b28HuthaifahM.DagamsehNo ratings yet

- Cems A 6 Part II AppxDocument4 pagesCems A 6 Part II AppxEngenharia APedroNo ratings yet

- Jed 021M1Document2 pagesJed 021M1Reginaldo Santos100% (1)

- DSMTS-0010.6 ZN WireDocument4 pagesDSMTS-0010.6 ZN WireMario Cortes FariasNo ratings yet

- Technical Data Sheet LG11 ENG 2021Document2 pagesTechnical Data Sheet LG11 ENG 2021KEMPCHEN COMDIFLEXNo ratings yet

- C 722 20 PDFDocument1 pageC 722 20 PDFazhar3iNo ratings yet

- Railing Glass Detail Calculation-1.75 KpaDocument7 pagesRailing Glass Detail Calculation-1.75 KpaSufiyan ShaikhNo ratings yet

- 1904-FG-ME-SPC-0016 BAC Coating SpecificationDocument6 pages1904-FG-ME-SPC-0016 BAC Coating Specificationmahan moradiNo ratings yet

- TDG 7467 001 Rev 00Document17 pagesTDG 7467 001 Rev 00Dilip PatilNo ratings yet

- T-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight GlassDocument3 pagesT-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight Glassvinoj chandranNo ratings yet

- MOS of Fabrication and Welding of F27B01 Stainless Steel LateralsDocument8 pagesMOS of Fabrication and Welding of F27B01 Stainless Steel LateralstinzarmoeNo ratings yet

- Interim Inspection Report: Final Inspection of StructuresDocument5 pagesInterim Inspection Report: Final Inspection of StructuresAbdul RahmanNo ratings yet

- 7.6 EPDM Gasket Compliance-AL-IMAN CODocument1 page7.6 EPDM Gasket Compliance-AL-IMAN COMohammad NowfalNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED&FORMING (SA516 Gr.70 + SA240 316L)Document3 pagesPURCHASE SPEC. FOR PLATES-CLADDED&FORMING (SA516 Gr.70 + SA240 316L)Daison PaulNo ratings yet

- Offer Legrand SandwichBBT BMTC EV 02.04.2022Document1 pageOffer Legrand SandwichBBT BMTC EV 02.04.2022Darshit VyasNo ratings yet

- PDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-TemplateDocument1 pagePDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-Templateيوسف عادل حسانينNo ratings yet

- Saic P 3311Document7 pagesSaic P 3311Arshad ImamNo ratings yet

- POLYTUNG-NICRBWC DatasheetDocument1 pagePOLYTUNG-NICRBWC Datasheetrajeevkv4No ratings yet

- TDC-STD-PP011, Rev.02 (SA-234 Gr. WPB and WPC)Document1 pageTDC-STD-PP011, Rev.02 (SA-234 Gr. WPB and WPC)Tanpreet SinghNo ratings yet

- Ss 316l 3.0 MTC NewDocument2 pagesSs 316l 3.0 MTC NewSahil Hashmi100% (1)

- Module Perdev Q1W1Document19 pagesModule Perdev Q1W1Nicole kate ColomaNo ratings yet

- Cambridge IGCSE: BIOLOGY 0610/33Document20 pagesCambridge IGCSE: BIOLOGY 0610/33Saleha ShafiqueNo ratings yet

- Bending StressDocument9 pagesBending StressUjjal Kalita 19355No ratings yet

- Muhammad ShayanDocument18 pagesMuhammad ShayanMALEEHA KHANNo ratings yet

- Urban Development - 2Document3 pagesUrban Development - 2APSDPS17 OFFICENo ratings yet

- Sonic Marketing Plan - Nguyen Thi Hong Diep, Truong Minh Hoang, Vu Quynh NgaDocument44 pagesSonic Marketing Plan - Nguyen Thi Hong Diep, Truong Minh Hoang, Vu Quynh NgaTruong Minh Hoang100% (1)

- Assignment No 1 8601Document18 pagesAssignment No 1 8601Sobia AtifNo ratings yet

- Evaluating 21 Century Skills: 4.0 Intended Learning OutcomesDocument21 pagesEvaluating 21 Century Skills: 4.0 Intended Learning OutcomesAriel AbarratigueNo ratings yet

- HRMDocument2 pagesHRMHariom BhatiNo ratings yet

- Lean Six Sigma HealthcareDocument4 pagesLean Six Sigma HealthcareSusmit Jain100% (1)

- Orligno 500: Instruction Manual & Service ManualDocument28 pagesOrligno 500: Instruction Manual & Service ManualAraNo ratings yet

- Enge 1013 Week 1 FinalsDocument16 pagesEnge 1013 Week 1 Finalsdarwin favilaNo ratings yet

- Canary Global Sourcing - 2023Document24 pagesCanary Global Sourcing - 2023John LongNo ratings yet

- Specifications Dimension: (Unit: MM) 55SVH7EDocument1 pageSpecifications Dimension: (Unit: MM) 55SVH7Edervis quinteroNo ratings yet

- Instruction Manual For Barber-Colman Series EA Electric High Torque ActuatorsDocument12 pagesInstruction Manual For Barber-Colman Series EA Electric High Torque ActuatorsMaximiliano SanchezNo ratings yet

- Bauxite Mining and Alumina Refining: Process Description and Occupational Health RisksDocument6 pagesBauxite Mining and Alumina Refining: Process Description and Occupational Health RisksRick HughesNo ratings yet

- An Essay On Islamic SchoolsDocument3 pagesAn Essay On Islamic Schoolsibnajami100% (1)

- People CodeDocument44 pagesPeople CodehardanuNo ratings yet

- Government Engineering College Dahod: Dadhichi HostelDocument5 pagesGovernment Engineering College Dahod: Dadhichi HostelSandip MouryaNo ratings yet

- During Compaction: Void SpacesDocument21 pagesDuring Compaction: Void SpacesMinilik Tikur SewNo ratings yet

- EA Requirements For The Accreditation of Flexible Scopes: Publication ReferenceDocument8 pagesEA Requirements For The Accreditation of Flexible Scopes: Publication ReferenceBrandon EricksonNo ratings yet

- Creative Writing MelcsDocument3 pagesCreative Writing MelcsArnel Navales100% (7)

- DeepFX LDocument1 pageDeepFX LSasha DimiciNo ratings yet

- Aviat ODU 600 Product BriefingDocument6 pagesAviat ODU 600 Product BriefingSihejiNo ratings yet

- Acting Shakespeare Scansion Assignment WorksheetDocument7 pagesActing Shakespeare Scansion Assignment WorksheetShalomNo ratings yet

- LG Research ReportDocument93 pagesLG Research ReportabhayNo ratings yet

- Caustinerf ForteDocument5 pagesCaustinerf Fortefadli_nugraha6109No ratings yet

Certificate No - 021

Certificate No - 021

Uploaded by

Ron0 ratings0% found this document useful (0 votes)

17 views1 pageThis certificate summarizes zinc coating testing on metal parts in compliance with industry standards. The zinc coating was found to have acceptable smoothness and continuity without surface imperfections. Coating thickness measurements for various items ranged from 135 to 265 microns, meeting the standard of 600 grams of zinc per square meter. An adhesion test also confirmed the coating did not lift or flake off as specified. The certificate confirms hot dip galvanization of the materials was performed according to industry standards.

Original Description:

Original Title

certificate no - 021

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis certificate summarizes zinc coating testing on metal parts in compliance with industry standards. The zinc coating was found to have acceptable smoothness and continuity without surface imperfections. Coating thickness measurements for various items ranged from 135 to 265 microns, meeting the standard of 600 grams of zinc per square meter. An adhesion test also confirmed the coating did not lift or flake off as specified. The certificate confirms hot dip galvanization of the materials was performed according to industry standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

17 views1 pageCertificate No - 021

Certificate No - 021

Uploaded by

RonThis certificate summarizes zinc coating testing on metal parts in compliance with industry standards. The zinc coating was found to have acceptable smoothness and continuity without surface imperfections. Coating thickness measurements for various items ranged from 135 to 265 microns, meeting the standard of 600 grams of zinc per square meter. An adhesion test also confirmed the coating did not lift or flake off as specified. The certificate confirms hot dip galvanization of the materials was performed according to industry standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

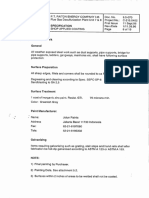

Format. No.

: FZM-IMS-FO-11E

Falcon Zinc Metal Industries Date : 20.02.2021

L.L.C. Rev : 2.0

ZINC COATING CERTIFICATE

Inspection and Testing in compliance with BS EN ISO 1461:2009/ASTM A 123-17

Certificate No: - 021 Date: 21.06.2022

Customer: - CONTROL CONTRACTING & TRADING CO. (PVT) LLC

ZINC COATING APPEARANCE

The acceptability of coating finish as judged by the inspection criteria laid down in BS EN ISO 1461:

2009/ASTM A 123-17 was found to be within the acceptable limits for smoothness, and continuity.

Zinc coating is free of gross surface imperfections.

COATING THICKNESS AND MASS OF ZINC COATING

Reading in Corresponding Mass of Zinc

Item Description Microns Average Coating – g/m2

159A HANDRAIL KICK PLATE 254

1. END SUPPORTS 189

Plates -09Nos 265

147

(R45,R40,R45,R41,R45,R38, 200 206 1471.43

2 R38,R39,R45) (DN -20879) 196

Flat bars -07Nos 222

(DN-20893) 135

248

Status of the Galvanization: Temperature of Zinc Bath : 445˚ Celsius

Dipping time in Zinc : 5min

Corresponding coating as per BS EN ISO 1461:2009/ASTM A 123-17 with respect of material

thickness, 600/m2 i.e. = 85 Microns. (1 G/m2 = 0.14 Micron)

Adhesion Test: Coating does not lift off in large flakes when tested with Stout

Knife as per BS EN ISO: 1461:2009/ASTM A 123-17.

We certify that the above material has been Hot Dip Galvanized to BS EN ISO 1461:2009 / ASTM

A123-17.

QC Engineer Division Manager

Test By Approved By

Tel : 00 (971) 2 5510018

Fax :

Address : ICAD II Musaffah Tower, Floor 24, Office 2352

E-mail : info@falconzinc.com

Website : www.falconzinc.com

You might also like

- The Elements of Dance: Part 1 Space Shape 1: Shapes With Straight Lines and AnglesDocument3 pagesThe Elements of Dance: Part 1 Space Shape 1: Shapes With Straight Lines and AnglesEarl johnNo ratings yet

- Aqwa Theory ManualDocument168 pagesAqwa Theory ManualWeb Logueando100% (3)

- MC Book Final July 2014Document383 pagesMC Book Final July 2014Latosha TrevinoNo ratings yet

- Certificate No - 020Document1 pageCertificate No - 020RonNo ratings yet

- Falcon Zinc Metal Industries L.L.CDocument7 pagesFalcon Zinc Metal Industries L.L.Ccyril nbhhNo ratings yet

- G16S-0205-03 - Hot Drip GalvDocument2 pagesG16S-0205-03 - Hot Drip Galvpuwarin najaNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED (SA516 Gr.70N + SA 240 GR 316L)Document6 pagesPURCHASE SPEC. FOR PLATES-CLADDED (SA516 Gr.70N + SA 240 GR 316L)Daison Paul100% (1)

- 104 - Spec ITA TERNA SP-20-0622Document7 pages104 - Spec ITA TERNA SP-20-0622Bhagawati Prasad SharmaNo ratings yet

- Brochure The Precast Concrete Product: BetonDocument9 pagesBrochure The Precast Concrete Product: BetonA Akbar HawardiNo ratings yet

- Shield-Bright 2209: Gas-Shielded Flux-Cored Wires (Fcaw) Stainless Steel WiresDocument1 pageShield-Bright 2209: Gas-Shielded Flux-Cored Wires (Fcaw) Stainless Steel WiresvallirajuNo ratings yet

- 22009-Mar-Cv-0107 (Raised False Flooring and Their Accessories)Document28 pages22009-Mar-Cv-0107 (Raised False Flooring and Their Accessories)ADNAN ZIADNo ratings yet

- Stud - Catalogue-EDocument7 pagesStud - Catalogue-Emehmetmehmetmehmet111111No ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Document6 pagesPURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Daison PaulNo ratings yet

- Forging SDocument93 pagesForging SrichardchiamNo ratings yet

- B034 6 44 0074 PDFDocument14 pagesB034 6 44 0074 PDFShashi RanjanNo ratings yet

- Fitup Inspection ReportDocument2 pagesFitup Inspection ReportSalesNo ratings yet

- PURCHASE SPEC. FOR PLATES-WELD OVERLAY (SA516 Gr.70 + SA240 316L)Document4 pagesPURCHASE SPEC. FOR PLATES-WELD OVERLAY (SA516 Gr.70 + SA240 316L)Daison PaulNo ratings yet

- DayeDocument2 pagesDayeJosip JurčićNo ratings yet

- G16S-0205-01 - Repair Hot Drip Galv SurfaceDocument5 pagesG16S-0205-01 - Repair Hot Drip Galv Surfacepuwarin naja100% (1)

- 10089-1E-V11-SS00-00001 (Corrugated Sheet)Document5 pages10089-1E-V11-SS00-00001 (Corrugated Sheet)Ahmed KhalifaNo ratings yet

- AGS030-03 Hot Dip GalvanizingDocument16 pagesAGS030-03 Hot Dip GalvanizingmuzioscarNo ratings yet

- PC Bridge Catalog APB (Adhi Beton)Document7 pagesPC Bridge Catalog APB (Adhi Beton)A Akbar HawardiNo ratings yet

- LREF-00-SP-20-0015S-A4-2 Field Painting Spec. For Propane & Butane Tank (T-201 & 301) .Document25 pagesLREF-00-SP-20-0015S-A4-2 Field Painting Spec. For Propane & Butane Tank (T-201 & 301) .andri yanto100% (1)

- Annexure A To Z - 20191130113051-560-587Document28 pagesAnnexure A To Z - 20191130113051-560-587mondaldgpNo ratings yet

- Duplex UNS 32205Document1 pageDuplex UNS 32205Ercan YilmazNo ratings yet

- TDC-STD-PP012, Rev.02 (SA-234 Gr. WP11,12 and 22)Document1 pageTDC-STD-PP012, Rev.02 (SA-234 Gr. WP11,12 and 22)Tanpreet SinghNo ratings yet

- Itp Signage Rev.01Document8 pagesItp Signage Rev.01moytabura96No ratings yet

- TS Merged PgcilDocument422 pagesTS Merged PgcilsankhaginNo ratings yet

- Triocon Powder Coating - ProcedureDocument15 pagesTriocon Powder Coating - ProceduresindalisindiNo ratings yet

- Purchase Spec. For Plates-Weld Overlay (CS + S31803)Document7 pagesPurchase Spec. For Plates-Weld Overlay (CS + S31803)Daison PaulNo ratings yet

- Comparison Sheet - DUCTDocument2 pagesComparison Sheet - DUCTSavad AlwyeNo ratings yet

- WORD1Document1 pageWORD1ardi yansaNo ratings yet

- Technical Specifications For ValvesDocument32 pagesTechnical Specifications For ValvesEr Hussain GhadialiNo ratings yet

- Technical Note: Durability of Cold-Formed Steel Framing MembersDocument8 pagesTechnical Note: Durability of Cold-Formed Steel Framing MembersZubair ShafiqueNo ratings yet

- b2020-Tdc-Fas-004 Fasteners r3Document2 pagesb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranNo ratings yet

- Is 12594-1988 PDFDocument7 pagesIs 12594-1988 PDFSaurabh PatilNo ratings yet

- Report 14 - Sluice Gates EE-SP2-3-B18 + EE-SP2!3!19Document20 pagesReport 14 - Sluice Gates EE-SP2-3-B18 + EE-SP2!3!19HuthaifahM.DagamsehNo ratings yet

- 3010-PS003 - 3 Valve ScheduleDocument61 pages3010-PS003 - 3 Valve ScheduleMichael adu-boahenNo ratings yet

- Report 11 - Sluice Gates EE-SP2-3-B15 + EE-SP2-3-B10Document20 pagesReport 11 - Sluice Gates EE-SP2-3-B15 + EE-SP2-3-B10HuthaifahM.DagamsehNo ratings yet

- Standard Specification For Hot Dip GalvanizingDocument6 pagesStandard Specification For Hot Dip GalvanizingKrunal PanchalNo ratings yet

- Bomba SihiDocument24 pagesBomba SihiCristian PovedaNo ratings yet

- Report 21 Sluice Gates Ee Sp2 3 b22 + Ee Sp2 3 b26 + Ee Sp2 3 b28Document20 pagesReport 21 Sluice Gates Ee Sp2 3 b22 + Ee Sp2 3 b26 + Ee Sp2 3 b28HuthaifahM.DagamsehNo ratings yet

- Cems A 6 Part II AppxDocument4 pagesCems A 6 Part II AppxEngenharia APedroNo ratings yet

- Jed 021M1Document2 pagesJed 021M1Reginaldo Santos100% (1)

- DSMTS-0010.6 ZN WireDocument4 pagesDSMTS-0010.6 ZN WireMario Cortes FariasNo ratings yet

- Technical Data Sheet LG11 ENG 2021Document2 pagesTechnical Data Sheet LG11 ENG 2021KEMPCHEN COMDIFLEXNo ratings yet

- C 722 20 PDFDocument1 pageC 722 20 PDFazhar3iNo ratings yet

- Railing Glass Detail Calculation-1.75 KpaDocument7 pagesRailing Glass Detail Calculation-1.75 KpaSufiyan ShaikhNo ratings yet

- 1904-FG-ME-SPC-0016 BAC Coating SpecificationDocument6 pages1904-FG-ME-SPC-0016 BAC Coating Specificationmahan moradiNo ratings yet

- TDG 7467 001 Rev 00Document17 pagesTDG 7467 001 Rev 00Dilip PatilNo ratings yet

- T-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight GlassDocument3 pagesT-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight Glassvinoj chandranNo ratings yet

- MOS of Fabrication and Welding of F27B01 Stainless Steel LateralsDocument8 pagesMOS of Fabrication and Welding of F27B01 Stainless Steel LateralstinzarmoeNo ratings yet

- Interim Inspection Report: Final Inspection of StructuresDocument5 pagesInterim Inspection Report: Final Inspection of StructuresAbdul RahmanNo ratings yet

- 7.6 EPDM Gasket Compliance-AL-IMAN CODocument1 page7.6 EPDM Gasket Compliance-AL-IMAN COMohammad NowfalNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED&FORMING (SA516 Gr.70 + SA240 316L)Document3 pagesPURCHASE SPEC. FOR PLATES-CLADDED&FORMING (SA516 Gr.70 + SA240 316L)Daison PaulNo ratings yet

- Offer Legrand SandwichBBT BMTC EV 02.04.2022Document1 pageOffer Legrand SandwichBBT BMTC EV 02.04.2022Darshit VyasNo ratings yet

- PDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-TemplateDocument1 pagePDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-Templateيوسف عادل حسانينNo ratings yet

- Saic P 3311Document7 pagesSaic P 3311Arshad ImamNo ratings yet

- POLYTUNG-NICRBWC DatasheetDocument1 pagePOLYTUNG-NICRBWC Datasheetrajeevkv4No ratings yet

- TDC-STD-PP011, Rev.02 (SA-234 Gr. WPB and WPC)Document1 pageTDC-STD-PP011, Rev.02 (SA-234 Gr. WPB and WPC)Tanpreet SinghNo ratings yet

- Ss 316l 3.0 MTC NewDocument2 pagesSs 316l 3.0 MTC NewSahil Hashmi100% (1)

- Module Perdev Q1W1Document19 pagesModule Perdev Q1W1Nicole kate ColomaNo ratings yet

- Cambridge IGCSE: BIOLOGY 0610/33Document20 pagesCambridge IGCSE: BIOLOGY 0610/33Saleha ShafiqueNo ratings yet

- Bending StressDocument9 pagesBending StressUjjal Kalita 19355No ratings yet

- Muhammad ShayanDocument18 pagesMuhammad ShayanMALEEHA KHANNo ratings yet

- Urban Development - 2Document3 pagesUrban Development - 2APSDPS17 OFFICENo ratings yet

- Sonic Marketing Plan - Nguyen Thi Hong Diep, Truong Minh Hoang, Vu Quynh NgaDocument44 pagesSonic Marketing Plan - Nguyen Thi Hong Diep, Truong Minh Hoang, Vu Quynh NgaTruong Minh Hoang100% (1)

- Assignment No 1 8601Document18 pagesAssignment No 1 8601Sobia AtifNo ratings yet

- Evaluating 21 Century Skills: 4.0 Intended Learning OutcomesDocument21 pagesEvaluating 21 Century Skills: 4.0 Intended Learning OutcomesAriel AbarratigueNo ratings yet

- HRMDocument2 pagesHRMHariom BhatiNo ratings yet

- Lean Six Sigma HealthcareDocument4 pagesLean Six Sigma HealthcareSusmit Jain100% (1)

- Orligno 500: Instruction Manual & Service ManualDocument28 pagesOrligno 500: Instruction Manual & Service ManualAraNo ratings yet

- Enge 1013 Week 1 FinalsDocument16 pagesEnge 1013 Week 1 Finalsdarwin favilaNo ratings yet

- Canary Global Sourcing - 2023Document24 pagesCanary Global Sourcing - 2023John LongNo ratings yet

- Specifications Dimension: (Unit: MM) 55SVH7EDocument1 pageSpecifications Dimension: (Unit: MM) 55SVH7Edervis quinteroNo ratings yet

- Instruction Manual For Barber-Colman Series EA Electric High Torque ActuatorsDocument12 pagesInstruction Manual For Barber-Colman Series EA Electric High Torque ActuatorsMaximiliano SanchezNo ratings yet

- Bauxite Mining and Alumina Refining: Process Description and Occupational Health RisksDocument6 pagesBauxite Mining and Alumina Refining: Process Description and Occupational Health RisksRick HughesNo ratings yet

- An Essay On Islamic SchoolsDocument3 pagesAn Essay On Islamic Schoolsibnajami100% (1)

- People CodeDocument44 pagesPeople CodehardanuNo ratings yet

- Government Engineering College Dahod: Dadhichi HostelDocument5 pagesGovernment Engineering College Dahod: Dadhichi HostelSandip MouryaNo ratings yet

- During Compaction: Void SpacesDocument21 pagesDuring Compaction: Void SpacesMinilik Tikur SewNo ratings yet

- EA Requirements For The Accreditation of Flexible Scopes: Publication ReferenceDocument8 pagesEA Requirements For The Accreditation of Flexible Scopes: Publication ReferenceBrandon EricksonNo ratings yet

- Creative Writing MelcsDocument3 pagesCreative Writing MelcsArnel Navales100% (7)

- DeepFX LDocument1 pageDeepFX LSasha DimiciNo ratings yet

- Aviat ODU 600 Product BriefingDocument6 pagesAviat ODU 600 Product BriefingSihejiNo ratings yet

- Acting Shakespeare Scansion Assignment WorksheetDocument7 pagesActing Shakespeare Scansion Assignment WorksheetShalomNo ratings yet

- LG Research ReportDocument93 pagesLG Research ReportabhayNo ratings yet

- Caustinerf ForteDocument5 pagesCaustinerf Fortefadli_nugraha6109No ratings yet