Professional Documents

Culture Documents

MR R C GUPTA-Effective Utilizations of Marble Dust For Industrial ApplicationsMalaviyaNational

MR R C GUPTA-Effective Utilizations of Marble Dust For Industrial ApplicationsMalaviyaNational

Uploaded by

AjithOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MR R C GUPTA-Effective Utilizations of Marble Dust For Industrial ApplicationsMalaviyaNational

MR R C GUPTA-Effective Utilizations of Marble Dust For Industrial ApplicationsMalaviyaNational

Uploaded by

AjithCopyright:

Available Formats

A

Presentation

on

Effective Utilizations of Marble Dust for Industrial

Applications

Malaviya National Institute of Technology

Jaipur (Rajasthan)-302017

Work Done-1

Researcher Name : Dr. R. C. Gupta

Area of Research: Study of Mechanical Properties, Durability and Economy of Cement

Concrete Tiles and Bricks using Marble Slurry as one of the Ingredients

Supervisor

Prof. M. Raisinghani

Formal Professor & Director

Malaviya National Institution of Tech. Jaipur

Application: Construction Industry

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

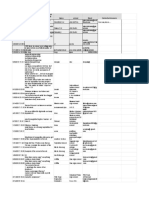

• work was done to use the marble powder

slurry in the preparation of bricks & tiles in

combination with different materials, such as

cement, fine aggregate, coarse aggregate, fly

ash, superplasticizer, etc., in different ratios.

• The feasibility and various mechanical

properties of the products were investigated.

• The various properties such as; compressive

strength, wet transverse strength, water

absorption, resistance to wear, durability,

weathering and acid effects on marble slurry

tiles & bricks were determined.

• Other properties such as stress strain

behaviour, modulus of elasticity, Poisson’s

ratio, flexural creep, effect of high

temperature on compressive strength were

also studied.

• One prism of size 190 mm x 295 mm x 900

mm was constructed by making use of these

bricks.

• About 400 tiles of of MPCC ( Marble Powder

Cement Concrete) used by Department of

Science & Technology, Government of

Rajasthan and have used in construction of

walkway in Science & Technology park, Jaipur

in year 2002. As on today, the tiles has shown

good performance under the trust of weather

and pedestrians

Work Done-2

Researcher Name : Dr. Rajesh Gupta

Area of Research: Durability of Self Compaction Concrete containing Marble Powder

Supervisor

Prof. R.C.Gupta

Professor, Civil Engg.

Malaviya National Institution of Tech. Jaipur

Funded By: CDOS

Application: Construction Industry

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

It was proposed to prepare SCC with different

water-cement(w/c) ratios containing cement,

fine aggregate and coarse aggregate only and

then replacing cement in each mix with

marble powder while keeping total volume of

powder (cement and filler) constant.

The study aimed at:

• Studying strength parameters e.g.

compressive and flexural strength of concrete

at different age of concrete.

• Studying water permeation property of

concrete.

• Studying other durability parameters e.g.

abrasion, carbonation, chloride ingress,

corrosion and drying shrinkage.

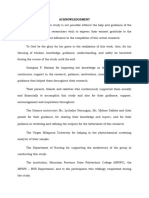

CDOS RESEARCH CHAIR

• Identified areas for the benefit and

sustainable Development of Dimension Stones

industry in India

• The chair is expected to formulate appropriate

research problem and methodology for

carrying out research in consultation with

CDOS.

POSSIBLE RESEARCH AREAS

• Mine productivity and safety

• Physical, Mechanical and thermo characterization

of stone properties for promoting usages of

stones as a sustainable green building material

specially for various structural applications

• Study of morphology of various stones with a

view to develop appropriate , cost effective and

suitable tool and machine development for

mining and processing of different varieties of

stones

• Stone conservation and restoration

• Standardization of Indian Natural Stones for

Structural application

• Gainful utilization of stone waste generated

during mining and processing

• Reclaimation of exploited lands /mines by

way of promoting urbanization, developing

fisheries, artificial reservoirs and

reestablishments of drainage system etc.

Problem-1

Ph.D Candidate Name : Sarbjeet Singh

Area of Research: Utilization Of Stone Powder Waste In Concrete as Partial Replacement of Sand and

Cement

Supervisor

Prof. Ravindra Nagar

Professor , Dean (P & D)

Civil Engineering Department.

MNIT, Jaipur

Application: Cement industry

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Objectives

1. To observe and analyze the strength (compression and flexure), workability and durability (permeability)

abrasion and ultrasonic pulse velocity test characteristics of concrete (M30) using stone slurry powder as

cement and sand replacement in various replacement ratios.

2. This study will help in obtaining an optimum replacement percentage of cement and sand by stone slurry

dust.

3. The use of waste stone slurry powder in concrete opens new avenues to further study in the area of

alternative uses for stone waste.

4. On one hand the extensive use of waste stone slurry dust in concrete will reduce the cost of concrete as use

of cement and sand would come down.

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Problem-2

PhD Candidate Name: Aditya Rana

Title of the project: Gainful Utilization of Kota Stone Slurry by Partial Replacement of Cement in

Concrete.

Supervisor

Dr. Pawan Kalla

Assistant Professor

Civil Engineering Department ,

MNIT, Jaipur

Applications: Construction Industry

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Introduction and problem statement:

1. Kota stone is basically a fine-grained variety of limestone. Its production is approximately 2868557 tones per

annum (DMG Rajasthan 2004-05).

2. Kota stone slurry is a waste generated from stone industries. This slurry is available in huge amount nearby

Jhalawar and Kota district in Rajasthan. Kota stone slurry causes health hazards such as Silicosis, irritation to

skin, throat and respiratory tract (coughing and sneezing).

3. The present investigation has been aimed to determine the influence of Kota stone slurry as a partial

replacement of cement in concrete mixes. This study falls under the gainful utilization of stone waste

generated during mining and processing. A systematic study pertaining to mechanical and durability

properties of concrete mixes containing Kota stone slurry will be carried out.

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Objectives

1. Characterization of Kota stone slurry and it’s utilization in concrete

2. To study the effect of Kota stone slurry addition on strength properties (compressive and

flexural) and abrasion resistance.

3. To study the resistance of mixes containing Kota stone slurry against water permeability,

chloride ingress, carbonation and corrosion.

4. To study the microstructure of concrete containing Kota stone slurry with the help of scanning

electron microscope and Mercury intrusion porosimetry.

5. To study the effect of fly ash on the concrete containing kota stone slurry.

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Problem-3

Ph.D Candidate Name : Shiv Ranjan Kumar (I. D No: 2012RME9549)

Area of Research: Development and performance assessment of a new Bionanocomposite dental

material for dental restoration and implant applications.

Supervisors:

Dr. Amar Patnaik Prof. I.K. Bhat

Assistant Prof. , MNIT Jaipur Director, MNIT Jaipur

Introduction and Problem Statement: The Major goals designed for material selection in the case of dental

replacement are (i) recreating function and (ii) aesthetic. Other important considerations are corrosion,

mechanical properties, thermal properties, cost, availability, and biocompatibility. Hence the variation in the

composition of dental material particularly filler type, size, orientation, volume, photo initiator, inhibitors,

pigments have potential to influence the wear performance of a composite. Gypsum nanoparticle derived

from Anhydrite Stone and/or its dust, as one of filler ingredients, can adequately and reliably contribute to

performance of composite material. It can greatly reduce the cost of artificial teeth material.

Applications: Dental restoration and implant applications

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Objectives

1. To develop nanofiller composite resin restorative dental material with proposed

formulation of resin and fillers and to investigate the friction and wear behavior of

natural teeth material under various conditions, such as dry condition, artificial saliva,

food slurry, and citric acid solution.

2. To study the influence of nanofillers and gypsum powder on the performance of dental

composite

3. To simulate occlusal wear loss, crack propagation and stress analysis during

polymerization in Altair Hyper mesh.

4. To measure radiopacity, cure depth, degree of conversion during polymerization.

5. To investigate the effects of different filler particles (different shapes, surface textures,

structures and materials) and different filler contents, as well as the relationships

between wear and mechanical properties on simulated occlusal wear and toothbrush

wear.

6. To study physical, chemical, mechanical, thermal and tribological properties of

proposed composite dental material.

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Problem-4

Ph.D Candidate Name : Swati Gangwar (I. D No: 2012RME9544)

Area of Research: Experimental and finite element analysis of fracture and wear behavior of particulate

filled metal alloy composites for bearing applications

Supervisors:

Dr. Amar Patnaik Prof. I.K. Bhat

Assistant Prof. , MNIT Jaipur Director, MNIT Jaipur

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Introduction and problem statement:

1. Metal matrix composites (MMCs) now-a-days have received increasing attention in the recent decades as

engineering materials for industrial applications.

2. The introduction of reinforcement into a metal matrix / metal alloy produces a composite material with an

attractive combination of physical and mechanical properties and that cannot be obtained with monolithic alloys

so far. Hence, MMCs are primary candidate materials for industrial applications in the aerospace, automotive and

power utility industries.

3. However, their mechanical and triblogyical properties such as strength, toughness, corrosion and wear

properties depend to a great extent on a number of factors of which matrix properties are very important .

4. It is well known that fillers have been functionally efficient not only in enhancing the reinforcement effects but

also in imparting specific characteristics that are conducive to the desired material performance. So the project

would therefore systematically involve critical investigation of metal alloy composites with the different types of

ingredients with a systematic variation in the different filler (like marble dust and CaO)content by using nanofluid

lubricant for kind of bearing applications.

Applications: Journal bearings

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Objectives

1. Fabrication of series of particulate filled alloy composites by stir casting techniques and also modeled through finite

element simulation method.

2. Characterization of physical and mechanical properties experimentally and comparison of the experimental results with

finite element method approach (i,e. with use of simulation software tool) as well as theoretical approach for validation

purposes.

3. Determination of fracture toughness or stress intensity factor (SIF) of unfilled and particulate filled proposed alloy

composites at five different crack lengths both in experimentally and finite element method also.

4. Characterization of thermal and thermo-mechanical properties such as thermal conductivity, thermo-gravimetric analysis

(TMA) and dynamic mechanical analysis (DMA) respectively.

5. Conduct sliding wear behavior of particulate filled alloy composites for estimation of wear rate under multiple operating

conditions and a simulation/FEM model (using simulation software) to validate the finite element results with experimental

obtained results.

6. Use of Taguchi experimental design for parametric appraisal of wear process analysis of all unfilled and particulate filled

alloy composites systematically.

7. Finally, the optimal performance analysis of particulate filled alloy composites for analysis of physical, mechanical, thermal

properties, fracture toughness and wear analysis of the said composites using TOPSIS method.

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Problem-5

Ph.D Candidate Name : ViKash Gautam (I. D No: 2012RME9546)

Area of Research: Design and Development of multilayered surface coating on marble dust filled nickel

based metal matrix composites for turbine blade Application

Supervisors:

Dr. Amar Patnaik Prof. I.K. Bhat

Asst. Professor , MNIT Jaipur Director, MNIT Jaipur

Applications: Turbine blades

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Introduction and problem statement:

1. Slurry erosion wear is a predominant factor in hydraulic turbine, as turbine blades are manufactured from

traditional metal matrix alloy and composites. Hydraulic power plant are switch off in rainy season because the

presence of slurry may cause savior slurry erosive wear, corrosion and some other problems with traditional

turbine blades.

2. In recent years, heat treatment of metal matrix composites have been an active area of research due to their

enhanced in mechanical, wear and corrosion performance over conventional coating on alloy and composites.

3. However, the tribological properties of heat treated metal matrix composites have not been thoroughly studied

under wet condition. In this research, the friction and wear characteristics of particulate filled heat treated

metal matrix composites were investigated using slurry jet erosion tester equipment for marble dust filled

three different compositions.

4. The effects of, particle hardness, speed and slurry concentration, erodent size and pH value of slurry on the

friction and wear characteristics were explored. The fundamental mechanisms of the friction reduction may

also investigate as well.

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Objectives

1. To synthesize a series of uncoated and multilayered magnetron sputter coated marble dust filled

nickel based metal matrix composites

2. To characterize the physical and mechanical properties of multilayered metal matrix alloy

composites both in experimentally and finite element method respectively.

3. To Determine the fracture toughness or stress intensity factor (SIF) of multilayered coated

particulate filled nickel based metal matrix composites with different crack lengths both in

experimentally and finite element method also.

4. To analyze the dynamic mechanical and corrosive behavior of the proposed composites under

different temperatures and environments respectively.

5. To determine the effect of coating thickness on the proposed composites both in dry and wet

environment for analysis of wear characteristics.

6. Finally, the optimal performance analysis of particulate filled alloy composites for analysis of

physical, mechanical, fracture toughness and wear analysis of the said composites using TOPSIS

method

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Problem-6

Ph.D Candidate Name : Pawar Manoj Janardan(I. D No: 2013RME9046)

Area of Research: Performance assessment of armor material for the protection of light

weight military vehicle

Supervisors:

Dr. Amar Patnaik Prof. Ravindra Nagar

Asst. Prof., MNIT Jaipur Dean (P & D), MNIT Jaipur

Applications: Ballistic panels for military vehicle,

bullet proof jacket, helmets

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Introduction and problem statement:

1. Traditionally Armor material is made of steel but this gives rise to extremely heavy structures which provide

logistical problems due to the need to transport the vehicles to a battle site. Mobility and speed of the armored

vehicle is a key component in its survival in a combat situation.

2. Recent advances revealed multi layer composite armor system includes a strong, brittle, hard faced material

which blunt and wear down the projectile. The hard faced materials may be selected any conventional ceramic

materials and the integral armor structure has a ductile backing plate, which can be steel, aluminum or glass

fiber reinforced plastics (GFRP) to absorb the remaining kinetic energy and arrest the projectile. As backing

plates, glass fibers are being employed with epoxy; vinyl ester and polyester resin systems due to their high

tensile and compressive strength, good energy absorption properties and relatively lower costs.

3. Marble dust as one of hard filler materials can adequately and reliably contribute to performance of composite

material. Leaving the Marble dust to the environment directly can cause environmental problems.

4. Therefore, in this scenario the proposed project conceptually aims to develop a new generation multilayer

composite materials by combining different fibre, resin, marble dust as filler material

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Objectives

1. To develop a series of marble dust filled fibre reinforced polymer composite for armor material

and determine their physical, thermal and mechanical characteristics of the proposed armor

materials.

2. Ballistic property analysis of armor material by experimental method and compared the results

with the simulated results for validation purposes.

3. Erosive wear analysis of the proposed armor material both in experimental techniques (i.e. solid

particle/slurry wear analysis), simulated analysis tool and compare the obtained results with

exist theoretical erosive mathematical models respectively.

4. Finally, optimization of all the above proposed physical, mechanical, ballistic and erosive wear

analysis i.e. mechanical, wear results and material properties by using AHP- and MCDM method

respectively, for Industrial applications.

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Problem-6

Study of morphology and physical, mechanical & thermal properties

of various stones with a view to develop cost effective and suitable

cutting tool and machining setup for mining and cutting.

Name of the Student :- Bhargav Prajwal Pathri (PhD Scholar)

Supervisor’s : Dr. Harlal Singh Mali & Prof. Ravindra Nagar

3/6/2014 MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY 31

New Facilities/Resources Required

• Financial support from Stone Industry.

• Different Grades of Stones.

• Cutting Facilities of Industry i.e. Gang Saw, Wire Saw and Abrasive Water

Jet Machining Setup.

• Plasma Bit Cutting Development Equipments.

• Plasma Bit Cutting Testing Equipments

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Expected outcomes and benefits for Stone Industry & Society at large

• Industry will be better place to use the property wise characterised stone of

Rajasthan.

• Industry will be better place to market the stone of Rajasthan with the morphology

known.

• The characterised stone in terms of machinability can give us a scope to improve

the cutting machines which would be more productive, environment friendly etc.

• The plasma bit cutting is a new technology which is under research phase with the

development of new machine the technology can be patented

• The problems faced by the society like marble dust, water pollution, air pollution,

noise pollution can be avoided by going to the new technologies

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY

Thank you

You might also like

- KIZEN - Infinite Off SeasonDocument13 pagesKIZEN - Infinite Off SeasonLeon50% (4)

- Utilization of Stone Dust To Improve The Properties of Expansive SoilDocument9 pagesUtilization of Stone Dust To Improve The Properties of Expansive SoilAmanulla KhanNo ratings yet

- Experimental Study of Partial Replacement of Cement in Concrete With Marble Dust and Recron Fibre As AdmixtureDocument9 pagesExperimental Study of Partial Replacement of Cement in Concrete With Marble Dust and Recron Fibre As AdmixtureEditor IJTSRDNo ratings yet

- FYP PresentationDocument21 pagesFYP PresentationalihassanNo ratings yet

- Comparative Study of Asphalt Concrete Using Sand and Stone DustDocument20 pagesComparative Study of Asphalt Concrete Using Sand and Stone Dustrajputganesh5630No ratings yet

- Influence of Stone Dust On Compressive Strength and Embodied Energy of MortarDocument9 pagesInfluence of Stone Dust On Compressive Strength and Embodied Energy of MortarInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Review On Use of Gold Mine Waste in Preparation of ConcreteDocument6 pagesA Review On Use of Gold Mine Waste in Preparation of ConcreteIJRASETPublicationsNo ratings yet

- A Study On Effect of Steel Fiber in FlyDocument5 pagesA Study On Effect of Steel Fiber in Flymohamme.arif63No ratings yet

- Journal Printabs 4haug14esrDocument11 pagesJournal Printabs 4haug14esrBruno CarleteNo ratings yet

- Re 8Document8 pagesRe 8Alamgir kabirNo ratings yet

- Exposure Effect of Mgso4 and HCL On Strength Properties of Ceramic Waste Powder by Partial Replacement With CementDocument8 pagesExposure Effect of Mgso4 and HCL On Strength Properties of Ceramic Waste Powder by Partial Replacement With CementIJIRSTNo ratings yet

- Analysis of Coarse Aggregate Performance Based On The Modified Micro Deval Abrasion TestDocument11 pagesAnalysis of Coarse Aggregate Performance Based On The Modified Micro Deval Abrasion TestJoseph MonteNo ratings yet

- 45 - Foundry Sand Utilisation As A Partial Replacement of Fine Aggregate For Establishing Sustainable Concrete PDFDocument4 pages45 - Foundry Sand Utilisation As A Partial Replacement of Fine Aggregate For Establishing Sustainable Concrete PDFArunkumar AKNo ratings yet

- Experimental Investigation On The Strength and Durability Properties of Concrete Using Manufactured SandDocument7 pagesExperimental Investigation On The Strength and Durability Properties of Concrete Using Manufactured SandChaitanya KumarNo ratings yet

- "Partial Replacement of Cement With Marble Dust Powder": August 2015Document10 pages"Partial Replacement of Cement With Marble Dust Powder": August 2015ADITYA JOSHI Dept of Civil EngineeringNo ratings yet

- Sustainable Stone Extraction For Using ADocument21 pagesSustainable Stone Extraction For Using AGilart A C KerrNo ratings yet

- Self-Compacting Concrete Using Marble Sludge PowdeDocument10 pagesSelf-Compacting Concrete Using Marble Sludge PowdeShaik Asif AliNo ratings yet

- Nanomaterials Applied in Asphalt Modi Fication: A Review: Changqing Fang, Ruien Yu, Shaolong Liu, Yan LiDocument6 pagesNanomaterials Applied in Asphalt Modi Fication: A Review: Changqing Fang, Ruien Yu, Shaolong Liu, Yan LiGiannis PappasNo ratings yet

- 1 s2.0 S2090447923002447 MainDocument11 pages1 s2.0 S2090447923002447 MainNANINDYA SOFIE ALIYYINAYANo ratings yet

- Stone Crusher Dust As A Fine Aggregate in Concrete For Paving BlocksDocument8 pagesStone Crusher Dust As A Fine Aggregate in Concrete For Paving Blocksaswaths007No ratings yet

- Analysis of Coarse Aggregate Performance Ba 2018 International Journal of PaDocument10 pagesAnalysis of Coarse Aggregate Performance Ba 2018 International Journal of PaRobby EvanderNo ratings yet

- Concoction of Eco Crumb Shell Paver Blocks IJERTCONV7IS02014Document7 pagesConcoction of Eco Crumb Shell Paver Blocks IJERTCONV7IS02014GUGANATHAN ANo ratings yet

- An Experimental Study On Mechanical Properties of Concrete Using Nano SilicaDocument4 pagesAn Experimental Study On Mechanical Properties of Concrete Using Nano SilicaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Experimental Study On Properties of Concrete Using Industrial Waste Ceramic and Stone Dust With Partial Replacement of Cement and SandDocument4 pagesExperimental Study On Properties of Concrete Using Industrial Waste Ceramic and Stone Dust With Partial Replacement of Cement and SandEditor IJTSRDNo ratings yet

- IJETR2833Document7 pagesIJETR2833Harsh ChordiyaNo ratings yet

- Durability Aspects of Standard ConcreteDocument9 pagesDurability Aspects of Standard ConcreteCristian VillavicencioNo ratings yet

- With ReadingsDocument44 pagesWith ReadingsGaurav JethleNo ratings yet

- Bitum MəqaləDocument6 pagesBitum Məqaləf.maharramovaNo ratings yet

- Stone Dust in Concrete: Effect On Compressive Strength: Amit Kumar Singh, Vikas Srivastava, V.C. AgarwalDocument4 pagesStone Dust in Concrete: Effect On Compressive Strength: Amit Kumar Singh, Vikas Srivastava, V.C. AgarwalerpublicationNo ratings yet

- Effects of Partial Replacement of Cement With Marble Dust Powder On Properties of ConcreteDocument5 pagesEffects of Partial Replacement of Cement With Marble Dust Powder On Properties of ConcreteIJIRSTNo ratings yet

- 1 s2.0 S0950061813002171 MainDocument9 pages1 s2.0 S0950061813002171 MainAtta MuhammadNo ratings yet

- With ReadingsDocument50 pagesWith ReadingsGaurav JethleNo ratings yet

- Abrasion Properties of Some Building Stone WastesDocument6 pagesAbrasion Properties of Some Building Stone WastesAmandita_geolNo ratings yet

- Ijaret 12 02 010Document13 pagesIjaret 12 02 010SANI HARUNANo ratings yet

- Experimental Investigation of Chemical and Physical Properties of Cements Manufactured in PakistanDocument15 pagesExperimental Investigation of Chemical and Physical Properties of Cements Manufactured in PakistanAyesha AyubNo ratings yet

- Properties - of - Green - Concrete - Containing - Quarry - Roc (1) REFDocument8 pagesProperties - of - Green - Concrete - Containing - Quarry - Roc (1) REFPriyamvada BijuNo ratings yet

- Recycled Aggregate Concrete For Transportation InfrastructureDocument10 pagesRecycled Aggregate Concrete For Transportation InfrastructureKan BunsamranjitNo ratings yet

- Behaviour of High Performance Blended Ternary Concrete Prepared Using Alternative MaterialsDocument9 pagesBehaviour of High Performance Blended Ternary Concrete Prepared Using Alternative MaterialsAnnals of Earth, Environment, and Infrastructure EngineeringNo ratings yet

- Use of Nano-Silica in Cement Based Materials-A Review: Civil & Environmental Engineering - Review ArticleDocument11 pagesUse of Nano-Silica in Cement Based Materials-A Review: Civil & Environmental Engineering - Review ArticleHanaNo ratings yet

- Utilization of Sawdust in Concrete Masonry Blocks: A ReviewDocument8 pagesUtilization of Sawdust in Concrete Masonry Blocks: A ReviewHaitham SaeedNo ratings yet

- An Experimental Analysis As Replacement of Natural Sand With Bamboo Fibre and M-Sand in ConcreteDocument18 pagesAn Experimental Analysis As Replacement of Natural Sand With Bamboo Fibre and M-Sand in ConcreteIJRASETPublicationsNo ratings yet

- Project On Shear Strength Fly AshDocument42 pagesProject On Shear Strength Fly AshSUMIT SENAPATINo ratings yet

- Ijciet 08 01 014Document9 pagesIjciet 08 01 014Dataniel RosarioNo ratings yet

- 20 Wjert 659Document16 pages20 Wjert 659Ashwini KotaNo ratings yet

- Partial Replacement of River Sand With Quarry Rock DustDocument8 pagesPartial Replacement of River Sand With Quarry Rock DustDharma banothuNo ratings yet

- Study On Mechanical Properties of Concrete On Partial Replacement of Fine Aggregate With Copper Slag and Granite PowderDocument4 pagesStudy On Mechanical Properties of Concrete On Partial Replacement of Fine Aggregate With Copper Slag and Granite PowderIJIRST100% (1)

- Report On Summer RainingDocument16 pagesReport On Summer RainingAr G S YadavNo ratings yet

- Utilization of Egg Shell Powder (ESP) and M-Sand For Sustainable ConstructionDocument5 pagesUtilization of Egg Shell Powder (ESP) and M-Sand For Sustainable ConstructionArun anandNo ratings yet

- 346experimental Study On Concrete by Partial Replacement of Marble Dust Powder With Cement Quarry Dust With Fine PDFDocument5 pages346experimental Study On Concrete by Partial Replacement of Marble Dust Powder With Cement Quarry Dust With Fine PDFMichael ShioNo ratings yet

- Performance of Self Compacting Concrete With Partial Replacement of Cement With Nano-SilicaDocument6 pagesPerformance of Self Compacting Concrete With Partial Replacement of Cement With Nano-SilicaIJRASETPublicationsNo ratings yet

- Referencia 4Document7 pagesReferencia 4Braian Gomez MendezNo ratings yet

- Evaluation of The Mechanical Properties of Translucent ConcreteDocument8 pagesEvaluation of The Mechanical Properties of Translucent ConcretesehunNo ratings yet

- 000.final Project Batch 12Document57 pages000.final Project Batch 12Teja bodduNo ratings yet

- Study of Gold Mine Tailings Utilization PDFDocument10 pagesStudy of Gold Mine Tailings Utilization PDFTajNo ratings yet

- Ferrosand Is A Highly Versatile Form of Reinforced Mortar Made Up of Wire MeshDocument6 pagesFerrosand Is A Highly Versatile Form of Reinforced Mortar Made Up of Wire MeshhodNo ratings yet

- Vol 28 No 2 Paper 3Document23 pagesVol 28 No 2 Paper 3Duong Ngoc Hoang DuongNo ratings yet

- Characteristics of Cement Mortar With M-Sand As Replacement ofDocument8 pagesCharacteristics of Cement Mortar With M-Sand As Replacement ofVikas SharmaNo ratings yet

- Mariyam PPT-2Document21 pagesMariyam PPT-2Mariyam FarhanaNo ratings yet

- Comparative Study On The Strength and Durability Properties of Concrete With Manufactured SandDocument7 pagesComparative Study On The Strength and Durability Properties of Concrete With Manufactured SandyoussefNo ratings yet

- Use of Quarry Dust in The Binding Mortar and Its Effect On Mechanical Characteristics of Brick MasonryDocument14 pagesUse of Quarry Dust in The Binding Mortar and Its Effect On Mechanical Characteristics of Brick MasonryCarlo ElopreNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Numerical Analysis of Steel Circular Structure With ButtweldDocument10 pagesNumerical Analysis of Steel Circular Structure With ButtweldAjithNo ratings yet

- Extension of A Semi-Analytical Approach To Determine Natural Frequency and Mode Shape of Orthotropic Steel BridgeDocument17 pagesExtension of A Semi-Analytical Approach To Determine Natural Frequency and Mode Shape of Orthotropic Steel BridgeAjithNo ratings yet

- Feasibility and Need of Use of Waste Marble Powder in Concrete ProductionDocument4 pagesFeasibility and Need of Use of Waste Marble Powder in Concrete ProductionAjithNo ratings yet

- DLR MazdoorDocument6 pagesDLR MazdoorAjithNo ratings yet

- Cat 444-16Document4 pagesCat 444-16AjithNo ratings yet

- Exercise 1. You Have Been Given A Form Which Shows The Details of Technical Jobs Carried OutDocument2 pagesExercise 1. You Have Been Given A Form Which Shows The Details of Technical Jobs Carried OutNgo Gia Huy (K15 HCM)No ratings yet

- A320 Ame Self ExaminationDocument6 pagesA320 Ame Self ExaminationKarwane MuntazireenNo ratings yet

- Communication and Ethics in Pharmacy Practice: What Is To BeDocument23 pagesCommunication and Ethics in Pharmacy Practice: What Is To BeMuhammad RezaNo ratings yet

- Chapter 1Document26 pagesChapter 1Reigner Jay B. Escartin100% (1)

- Presentation 2Document5 pagesPresentation 2TechLakeNo ratings yet

- Literature of Exile in Goli Taraqqi's Short StoriesDocument23 pagesLiterature of Exile in Goli Taraqqi's Short StoriesmarvehNo ratings yet

- G6RNDocument3 pagesG6RNValeri Luht Eurocargo FinlandNo ratings yet

- Nutri QuizDocument26 pagesNutri QuizChona Candace Christian AndalNo ratings yet

- Sala Ta Orn Dam Bill of QuantitiesDocument38 pagesSala Ta Orn Dam Bill of QuantitiesSothearaThengNo ratings yet

- SDM-v1 0Document32 pagesSDM-v1 0Franz NussmannNo ratings yet

- DSFSDFSDF Advanced Construction TechnologiesDocument3 pagesDSFSDFSDF Advanced Construction Technologiessarveshfdk48No ratings yet

- Pentavitin - DSMDocument3 pagesPentavitin - DSMRnD Roi SuryaNo ratings yet

- Mass. Proposed AddendumsDocument25 pagesMass. Proposed AddendumsKirk HartleyNo ratings yet

- Chapter 21 Electric Charge - Gui SVDocument5 pagesChapter 21 Electric Charge - Gui SVHậu Vũ100% (1)

- Application FormDocument8 pagesApplication FormCrystal KleistNo ratings yet

- Evelyn Glennie (Responses) PDFDocument8 pagesEvelyn Glennie (Responses) PDFRohit JhambNo ratings yet

- Anxiety DisordersDocument10 pagesAnxiety DisordersAhmed AntarNo ratings yet

- Busineplan 4Document13 pagesBusineplan 4Irish Gamboa DuenasNo ratings yet

- Steril DiskDocument3 pagesSteril DisklukasjoNo ratings yet

- TEST(s) Normal UNIT(s)Document1 pageTEST(s) Normal UNIT(s)HarisNo ratings yet

- Growth Evaluation and Meat Assessment of Native Pig in Romblon Province, PhilippinesDocument7 pagesGrowth Evaluation and Meat Assessment of Native Pig in Romblon Province, PhilippinesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Enfield Saheli: Funding NEWSDocument5 pagesEnfield Saheli: Funding NEWSenfieldclubhouseNo ratings yet

- Bosch ManualDocument56 pagesBosch Manualjhon manuel de jesus100% (1)

- Cheadle Area Committee 15th March 2016Document176 pagesCheadle Area Committee 15th March 2016IainRobertsNo ratings yet

- PC3SH21YFZBFDocument15 pagesPC3SH21YFZBFkrimoNo ratings yet

- Attorney General Report On NM Prison Riot - Part 1Document150 pagesAttorney General Report On NM Prison Riot - Part 1Albuquerque Journal100% (3)

- Final DraftDocument37 pagesFinal DraftMorareng MariettaNo ratings yet

- Gram Positive Cocci: Two GeneraDocument31 pagesGram Positive Cocci: Two GeneraGeorgeNecoară100% (1)

- Gate 2000 CyDocument9 pagesGate 2000 CyYocobSamandrewsNo ratings yet