Professional Documents

Culture Documents

LL HS Data Sheet

LL HS Data Sheet

Uploaded by

Santii CampitelliCopyright:

Available Formats

You might also like

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- LL KD Data Sheet 042720 1115Document1 pageLL KD Data Sheet 042720 1115Santii CampitelliNo ratings yet

- TgrsetgreDocument5 pagesTgrsetgreHoff FrenchNo ratings yet

- Unibraze 110S-1: ClassificationDocument1 pageUnibraze 110S-1: ClassificationraulangelNo ratings yet

- Stainless Steel Bar 431 Atlas 431: Colour Code: Signal RedDocument3 pagesStainless Steel Bar 431 Atlas 431: Colour Code: Signal RedNitin AggarwalNo ratings yet

- 409 Stainless Steel PDFDocument2 pages409 Stainless Steel PDFDang Thanh TuanNo ratings yet

- New Constructional Steels Structural Stability andDocument6 pagesNew Constructional Steels Structural Stability andLeonardoMadeira11No ratings yet

- ABB Pararrayos XPS - CatalogueDocument8 pagesABB Pararrayos XPS - CatalogueEdwin QuispeNo ratings yet

- E7018 1 Eutherme lh1 PDFDocument1 pageE7018 1 Eutherme lh1 PDFAnonymous dxsNnL6S8hNo ratings yet

- Rexnord Metal Table Top ChainDocument36 pagesRexnord Metal Table Top ChainWhisnu AlbertusNo ratings yet

- Smoothcor 120T5 K4 (E120T5 K4C)Document1 pageSmoothcor 120T5 K4 (E120T5 K4C)brunizzaNo ratings yet

- 400 SeriesDocument37 pages400 SeriesShashank SaxenaNo ratings yet

- Stabilized Ferritic Stainless Steel: General CharacteristicsDocument37 pagesStabilized Ferritic Stainless Steel: General CharacteristicsBina Niaga MultiusahaNo ratings yet

- First Philec DTDocument8 pagesFirst Philec DTJM Si MirNo ratings yet

- Polished Rod Profile - NEWDocument7 pagesPolished Rod Profile - NEWKevin XuNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6061 T6 Extrusions 145Document2 pagesAalco Metals LTD Aluminium Alloy 6061 T6 Extrusions 145Ahmad Jasir RasyidiNo ratings yet

- 409 Data SheetDocument2 pages409 Data SheetMatthieuNo ratings yet

- SS 6mo - 1.4547Document1 pageSS 6mo - 1.4547f_riseNo ratings yet

- Cast Resin Transformers Oil Immersed Transformer: Technical PerformanceDocument32 pagesCast Resin Transformers Oil Immersed Transformer: Technical PerformanceIm ChinithNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangNo ratings yet

- Pinnacle Alloys E11018 MDocument2 pagesPinnacle Alloys E11018 MMoch_adiganjarNo ratings yet

- Ak Steel Armco® Nitronic® 50 Product Data Bulletin - Jan 2019 - 94Document28 pagesAk Steel Armco® Nitronic® 50 Product Data Bulletin - Jan 2019 - 94st_calvoNo ratings yet

- Welding WireDocument20 pagesWelding WirefoxmancementNo ratings yet

- SS 410Document2 pagesSS 410saikarthik103212No ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerNo ratings yet

- Echnical Ulletin: Cmnsi P S CrmoDocument1 pageEchnical Ulletin: Cmnsi P S CrmoBenfil ViernezNo ratings yet

- Aluminium AlloyDocument14 pagesAluminium AlloyPenka VasilevaNo ratings yet

- Sandvik SAF 2507: Duplex Stainless SteelDocument8 pagesSandvik SAF 2507: Duplex Stainless SteelmattiaNo ratings yet

- Wilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200Document2 pagesWilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200williamNo ratings yet

- EN24T, EN24 SteelDocument1 pageEN24T, EN24 SteelNILESH SHAHNo ratings yet

- Carbonsteel SteelmetalguidebookDocument18 pagesCarbonsteel SteelmetalguidebookEyob AdNo ratings yet

- Catalogo Pararrayos PolimDocument8 pagesCatalogo Pararrayos PolimTomas VelasquezNo ratings yet

- Duplex Stainless Steel 2507 (UNS S32750) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDocument3 pagesDuplex Stainless Steel 2507 (UNS S32750) : Heanjia Super-Metals Co., LTD, Call-12068907337. Websudish mishraNo ratings yet

- Gresham Boiler Manufacturing CompanyDocument5 pagesGresham Boiler Manufacturing CompanymuddassirNo ratings yet

- Ak Dimax Hf-10 PDB 042312Document12 pagesAk Dimax Hf-10 PDB 042312human bodyNo ratings yet

- 2017 Kynar Wire and Cable SolutionsDocument8 pages2017 Kynar Wire and Cable SolutionsKaarthicNatarajanNo ratings yet

- Pinnacle Alloys E8018-B6 Code and Specification DataDocument2 pagesPinnacle Alloys E8018-B6 Code and Specification DataMurad AlmoudiNo ratings yet

- Weldability of Cr-Mo SteelsDocument20 pagesWeldability of Cr-Mo SteelsNitin Bajpai100% (2)

- BOHLER WerkzeugstahlDocument20 pagesBOHLER WerkzeugstahlByron Paul Yanez BonbomNo ratings yet

- Latest Shipbuilding MaterialsDocument9 pagesLatest Shipbuilding MaterialsAnonymous e3ceN15No ratings yet

- Hydroo Motors For Submersible Pumps - 4" CannedDocument2 pagesHydroo Motors For Submersible Pumps - 4" CannedBearingmanNo ratings yet

- Betanox 2594 16 2Document1 pageBetanox 2594 16 2VenkateshNo ratings yet

- Alloy 410S Spec SheetDocument2 pagesAlloy 410S Spec SheetPrakash SundharamNo ratings yet

- (17CrNiMo6) 4317 Case Hardening SteelDocument3 pages(17CrNiMo6) 4317 Case Hardening Steelazhar mohammedNo ratings yet

- Product 266: Technical Data SheetDocument2 pagesProduct 266: Technical Data SheetFabio ParceroNo ratings yet

- Super Tensile Blue Data SheetDocument1 pageSuper Tensile Blue Data Sheetdapp.70No ratings yet

- Chemical CompositionDocument6 pagesChemical CompositionAkbar DarmawansyahNo ratings yet

- Acero Inoxidable 253 MADocument2 pagesAcero Inoxidable 253 MADavid Alonso Cortez BautistaNo ratings yet

- Alloy 410s Spec SheetDocument2 pagesAlloy 410s Spec SheetALONSO GOMEZNo ratings yet

- Aluminium Alloy 1050 H14 TDSDocument1 pageAluminium Alloy 1050 H14 TDSfaria1969No ratings yet

- S 960 QDocument2 pagesS 960 Qmohsen_267No ratings yet

- Discover The Power Within:: LUV Boiler Recirculation PumpsDocument8 pagesDiscover The Power Within:: LUV Boiler Recirculation Pumpsmfhaleem@pgesco.comNo ratings yet

- Lesson2 STEEL PROPERTIES CDocument87 pagesLesson2 STEEL PROPERTIES CMaqMaikNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Pricelist ObeliaDocument2 pagesPricelist ObeliaYolandaNo ratings yet

- Concrete Pipes and Ancillary Concrete Products: BSI Standards PublicationDocument40 pagesConcrete Pipes and Ancillary Concrete Products: BSI Standards PublicationAwino LaureenNo ratings yet

- Dow Corning 983Document3 pagesDow Corning 983antoineNo ratings yet

- Resin Volume in Sockets (Reference Only)Document2 pagesResin Volume in Sockets (Reference Only)Anonymous ntE0hG2TPNo ratings yet

- Progress Template - Original ScopeDocument3 pagesProgress Template - Original Scopekhairul shahNo ratings yet

- Astm D1876 08 2023Document2 pagesAstm D1876 08 2023Michelle LCNo ratings yet

- Concept of Production Possibility CurveDocument4 pagesConcept of Production Possibility CurveMOHAMMED DEMMUNo ratings yet

- 014 - F10 Brick - Block WallingDocument8 pages014 - F10 Brick - Block WallingKHALID NAZKINo ratings yet

- Dispatch Program 15-1-2024Document6 pagesDispatch Program 15-1-2024Aman khanNo ratings yet

- 11.2 Group IV CompoundsDocument7 pages11.2 Group IV CompoundsTrevor TatendaNo ratings yet

- Aci sp-224-2004Document220 pagesAci sp-224-2004Abigael Valles RamirezNo ratings yet

- Section 11 ESP CABLEDocument50 pagesSection 11 ESP CABLEYassin MuhssenNo ratings yet

- Knelson - Recent Innovations in Gravity TechnologyDocument22 pagesKnelson - Recent Innovations in Gravity TechnologyJuan Carlos Quintuna EspinNo ratings yet

- Pre-Assessment of 3Dprinting-Teacher VersionDocument3 pagesPre-Assessment of 3Dprinting-Teacher VersionDhirenNo ratings yet

- Enumerate The Forms of Prestressed SteelDocument4 pagesEnumerate The Forms of Prestressed SteelHunter BravoNo ratings yet

- Reebol Emulsion ConcentrateDocument2 pagesReebol Emulsion ConcentrateJA WPKNo ratings yet

- Catalogue AWPDocument7 pagesCatalogue AWPAyah Ayra & ALNo ratings yet

- MOLDDocument22 pagesMOLDyusufj721No ratings yet

- Aisi 1008Document2 pagesAisi 1008GANESH GNo ratings yet

- Ibis-Paper-Directory 2023Document12 pagesIbis-Paper-Directory 2023Pavan upadhyay100% (1)

- REVIEWERDocument23 pagesREVIEWERThea VelascoNo ratings yet

- Marble Method StatementDocument10 pagesMarble Method StatementShyam SutharNo ratings yet

- Makaut Question Banks SolutionDocument63 pagesMakaut Question Banks SolutionTirtha DasNo ratings yet

- Annex 11: As Job DescriptionDocument36 pagesAnnex 11: As Job DescriptionAnna EmelineNo ratings yet

- Formulae and Data SheetDocument3 pagesFormulae and Data SheetHemantNo ratings yet

- Bakelite (Full)Document5 pagesBakelite (Full)Minh Anh NguyễnNo ratings yet

- Science Module Grade 5Document9 pagesScience Module Grade 5Patrick kenneth GacayanNo ratings yet

- Planning 21 Januari 2023Document1 pagePlanning 21 Januari 2023Ferdie OSNo ratings yet

- Design and Construction of Hydraulic Floor JackDocument34 pagesDesign and Construction of Hydraulic Floor Jackmayo ABIOYE100% (1)

- MKWL Ziplock Bag Organizer JsDocument84 pagesMKWL Ziplock Bag Organizer Jsmaria alejandra duncan teranNo ratings yet

LL HS Data Sheet

LL HS Data Sheet

Uploaded by

Santii CampitelliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LL HS Data Sheet

LL HS Data Sheet

Uploaded by

Santii CampitelliCopyright:

Available Formats

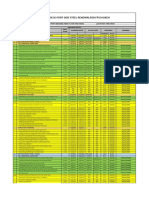

LL HS HIGH TENSILE

SUCKER ROD

The LL HS rod is extremely dependable and is designed for than other nickel-chrome-moly based steels used in the

high-strength service. manufacture of other high strength sucker rods.

Although the LL HS high tensile rods are not recognized by

These rods are manufactured from an AISI 4138MX API, they are manufactured to meet API dimensional

chrome-moly alloy SBQ steel, providing them with the specifications. They are also subjected to the same API

capability of handling the toughest stresses. This alloy quality control practices to insure manufacturing

provides a greater resistance to sulfide stress cracking consistency.

PROCESS

Rods are straightened and subjected to eddy current The rods are shot-peened for enhanced fatigue

testing prior to any further operations. Any rods that resistance. Random rod samples are subjected to

do not meet Liberty Lift’s specifications are removed Yield and Tensile testing. In addition, stringent

from further processing. The rods are forged to size. hardness and Charpy Impact tests are conducted for

The rods are brought to a normalizing temperature to further verification of the desired mechanical proper-

relieve previously induced stress and air cooled. All ties. The pin ends are precision machined and threads

rods will be brought to a temper temperature which are cold rolled, adding additional strength to the

will produce the desired mechanical properties and sucker rod pin connection.

air cooled.

CHEMISTRY

CARBON MANGANESE PHOSPHORUS SULPHUR SILICON COPPER NICKEL CHROMIUM MOLYBDENUM

0.38-0.42 1.00-1.30 < 0.025 < 0.025 0.20-0.40 <0.25 < 0.30 0.55-0.90 0.25-0.35

MECHANICAL PROPERTIES

MINIMUM YIELD TENSILE STRENGTH ELONGATION (% IN 8IN) REDUCTION OF AREA % ROCKWELL HARDNESS C

115,000 PSI 140,000-150,000 PSI 10Mn 40Mn 30 to 34

APPLICATIONS MAXIMUM OPERATING STRESS

Deep, highly loaded wells with mildly corrosive environments Sa = (T/2.8 + 0.375 Smin) SF

when satisfactory corrosion inhibition practices are followed.

16420 PARK TEN PLACE, SUITE 300

W W W. L I B E R T Y L I F T.CO M (713)-575-2300 HOUSTON, TEXAS 77084

You might also like

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- LL KD Data Sheet 042720 1115Document1 pageLL KD Data Sheet 042720 1115Santii CampitelliNo ratings yet

- TgrsetgreDocument5 pagesTgrsetgreHoff FrenchNo ratings yet

- Unibraze 110S-1: ClassificationDocument1 pageUnibraze 110S-1: ClassificationraulangelNo ratings yet

- Stainless Steel Bar 431 Atlas 431: Colour Code: Signal RedDocument3 pagesStainless Steel Bar 431 Atlas 431: Colour Code: Signal RedNitin AggarwalNo ratings yet

- 409 Stainless Steel PDFDocument2 pages409 Stainless Steel PDFDang Thanh TuanNo ratings yet

- New Constructional Steels Structural Stability andDocument6 pagesNew Constructional Steels Structural Stability andLeonardoMadeira11No ratings yet

- ABB Pararrayos XPS - CatalogueDocument8 pagesABB Pararrayos XPS - CatalogueEdwin QuispeNo ratings yet

- E7018 1 Eutherme lh1 PDFDocument1 pageE7018 1 Eutherme lh1 PDFAnonymous dxsNnL6S8hNo ratings yet

- Rexnord Metal Table Top ChainDocument36 pagesRexnord Metal Table Top ChainWhisnu AlbertusNo ratings yet

- Smoothcor 120T5 K4 (E120T5 K4C)Document1 pageSmoothcor 120T5 K4 (E120T5 K4C)brunizzaNo ratings yet

- 400 SeriesDocument37 pages400 SeriesShashank SaxenaNo ratings yet

- Stabilized Ferritic Stainless Steel: General CharacteristicsDocument37 pagesStabilized Ferritic Stainless Steel: General CharacteristicsBina Niaga MultiusahaNo ratings yet

- First Philec DTDocument8 pagesFirst Philec DTJM Si MirNo ratings yet

- Polished Rod Profile - NEWDocument7 pagesPolished Rod Profile - NEWKevin XuNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6061 T6 Extrusions 145Document2 pagesAalco Metals LTD Aluminium Alloy 6061 T6 Extrusions 145Ahmad Jasir RasyidiNo ratings yet

- 409 Data SheetDocument2 pages409 Data SheetMatthieuNo ratings yet

- SS 6mo - 1.4547Document1 pageSS 6mo - 1.4547f_riseNo ratings yet

- Cast Resin Transformers Oil Immersed Transformer: Technical PerformanceDocument32 pagesCast Resin Transformers Oil Immersed Transformer: Technical PerformanceIm ChinithNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangNo ratings yet

- Pinnacle Alloys E11018 MDocument2 pagesPinnacle Alloys E11018 MMoch_adiganjarNo ratings yet

- Ak Steel Armco® Nitronic® 50 Product Data Bulletin - Jan 2019 - 94Document28 pagesAk Steel Armco® Nitronic® 50 Product Data Bulletin - Jan 2019 - 94st_calvoNo ratings yet

- Welding WireDocument20 pagesWelding WirefoxmancementNo ratings yet

- SS 410Document2 pagesSS 410saikarthik103212No ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerNo ratings yet

- Echnical Ulletin: Cmnsi P S CrmoDocument1 pageEchnical Ulletin: Cmnsi P S CrmoBenfil ViernezNo ratings yet

- Aluminium AlloyDocument14 pagesAluminium AlloyPenka VasilevaNo ratings yet

- Sandvik SAF 2507: Duplex Stainless SteelDocument8 pagesSandvik SAF 2507: Duplex Stainless SteelmattiaNo ratings yet

- Wilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200Document2 pagesWilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200williamNo ratings yet

- EN24T, EN24 SteelDocument1 pageEN24T, EN24 SteelNILESH SHAHNo ratings yet

- Carbonsteel SteelmetalguidebookDocument18 pagesCarbonsteel SteelmetalguidebookEyob AdNo ratings yet

- Catalogo Pararrayos PolimDocument8 pagesCatalogo Pararrayos PolimTomas VelasquezNo ratings yet

- Duplex Stainless Steel 2507 (UNS S32750) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDocument3 pagesDuplex Stainless Steel 2507 (UNS S32750) : Heanjia Super-Metals Co., LTD, Call-12068907337. Websudish mishraNo ratings yet

- Gresham Boiler Manufacturing CompanyDocument5 pagesGresham Boiler Manufacturing CompanymuddassirNo ratings yet

- Ak Dimax Hf-10 PDB 042312Document12 pagesAk Dimax Hf-10 PDB 042312human bodyNo ratings yet

- 2017 Kynar Wire and Cable SolutionsDocument8 pages2017 Kynar Wire and Cable SolutionsKaarthicNatarajanNo ratings yet

- Pinnacle Alloys E8018-B6 Code and Specification DataDocument2 pagesPinnacle Alloys E8018-B6 Code and Specification DataMurad AlmoudiNo ratings yet

- Weldability of Cr-Mo SteelsDocument20 pagesWeldability of Cr-Mo SteelsNitin Bajpai100% (2)

- BOHLER WerkzeugstahlDocument20 pagesBOHLER WerkzeugstahlByron Paul Yanez BonbomNo ratings yet

- Latest Shipbuilding MaterialsDocument9 pagesLatest Shipbuilding MaterialsAnonymous e3ceN15No ratings yet

- Hydroo Motors For Submersible Pumps - 4" CannedDocument2 pagesHydroo Motors For Submersible Pumps - 4" CannedBearingmanNo ratings yet

- Betanox 2594 16 2Document1 pageBetanox 2594 16 2VenkateshNo ratings yet

- Alloy 410S Spec SheetDocument2 pagesAlloy 410S Spec SheetPrakash SundharamNo ratings yet

- (17CrNiMo6) 4317 Case Hardening SteelDocument3 pages(17CrNiMo6) 4317 Case Hardening Steelazhar mohammedNo ratings yet

- Product 266: Technical Data SheetDocument2 pagesProduct 266: Technical Data SheetFabio ParceroNo ratings yet

- Super Tensile Blue Data SheetDocument1 pageSuper Tensile Blue Data Sheetdapp.70No ratings yet

- Chemical CompositionDocument6 pagesChemical CompositionAkbar DarmawansyahNo ratings yet

- Acero Inoxidable 253 MADocument2 pagesAcero Inoxidable 253 MADavid Alonso Cortez BautistaNo ratings yet

- Alloy 410s Spec SheetDocument2 pagesAlloy 410s Spec SheetALONSO GOMEZNo ratings yet

- Aluminium Alloy 1050 H14 TDSDocument1 pageAluminium Alloy 1050 H14 TDSfaria1969No ratings yet

- S 960 QDocument2 pagesS 960 Qmohsen_267No ratings yet

- Discover The Power Within:: LUV Boiler Recirculation PumpsDocument8 pagesDiscover The Power Within:: LUV Boiler Recirculation Pumpsmfhaleem@pgesco.comNo ratings yet

- Lesson2 STEEL PROPERTIES CDocument87 pagesLesson2 STEEL PROPERTIES CMaqMaikNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Pricelist ObeliaDocument2 pagesPricelist ObeliaYolandaNo ratings yet

- Concrete Pipes and Ancillary Concrete Products: BSI Standards PublicationDocument40 pagesConcrete Pipes and Ancillary Concrete Products: BSI Standards PublicationAwino LaureenNo ratings yet

- Dow Corning 983Document3 pagesDow Corning 983antoineNo ratings yet

- Resin Volume in Sockets (Reference Only)Document2 pagesResin Volume in Sockets (Reference Only)Anonymous ntE0hG2TPNo ratings yet

- Progress Template - Original ScopeDocument3 pagesProgress Template - Original Scopekhairul shahNo ratings yet

- Astm D1876 08 2023Document2 pagesAstm D1876 08 2023Michelle LCNo ratings yet

- Concept of Production Possibility CurveDocument4 pagesConcept of Production Possibility CurveMOHAMMED DEMMUNo ratings yet

- 014 - F10 Brick - Block WallingDocument8 pages014 - F10 Brick - Block WallingKHALID NAZKINo ratings yet

- Dispatch Program 15-1-2024Document6 pagesDispatch Program 15-1-2024Aman khanNo ratings yet

- 11.2 Group IV CompoundsDocument7 pages11.2 Group IV CompoundsTrevor TatendaNo ratings yet

- Aci sp-224-2004Document220 pagesAci sp-224-2004Abigael Valles RamirezNo ratings yet

- Section 11 ESP CABLEDocument50 pagesSection 11 ESP CABLEYassin MuhssenNo ratings yet

- Knelson - Recent Innovations in Gravity TechnologyDocument22 pagesKnelson - Recent Innovations in Gravity TechnologyJuan Carlos Quintuna EspinNo ratings yet

- Pre-Assessment of 3Dprinting-Teacher VersionDocument3 pagesPre-Assessment of 3Dprinting-Teacher VersionDhirenNo ratings yet

- Enumerate The Forms of Prestressed SteelDocument4 pagesEnumerate The Forms of Prestressed SteelHunter BravoNo ratings yet

- Reebol Emulsion ConcentrateDocument2 pagesReebol Emulsion ConcentrateJA WPKNo ratings yet

- Catalogue AWPDocument7 pagesCatalogue AWPAyah Ayra & ALNo ratings yet

- MOLDDocument22 pagesMOLDyusufj721No ratings yet

- Aisi 1008Document2 pagesAisi 1008GANESH GNo ratings yet

- Ibis-Paper-Directory 2023Document12 pagesIbis-Paper-Directory 2023Pavan upadhyay100% (1)

- REVIEWERDocument23 pagesREVIEWERThea VelascoNo ratings yet

- Marble Method StatementDocument10 pagesMarble Method StatementShyam SutharNo ratings yet

- Makaut Question Banks SolutionDocument63 pagesMakaut Question Banks SolutionTirtha DasNo ratings yet

- Annex 11: As Job DescriptionDocument36 pagesAnnex 11: As Job DescriptionAnna EmelineNo ratings yet

- Formulae and Data SheetDocument3 pagesFormulae and Data SheetHemantNo ratings yet

- Bakelite (Full)Document5 pagesBakelite (Full)Minh Anh NguyễnNo ratings yet

- Science Module Grade 5Document9 pagesScience Module Grade 5Patrick kenneth GacayanNo ratings yet

- Planning 21 Januari 2023Document1 pagePlanning 21 Januari 2023Ferdie OSNo ratings yet

- Design and Construction of Hydraulic Floor JackDocument34 pagesDesign and Construction of Hydraulic Floor Jackmayo ABIOYE100% (1)

- MKWL Ziplock Bag Organizer JsDocument84 pagesMKWL Ziplock Bag Organizer Jsmaria alejandra duncan teranNo ratings yet