Professional Documents

Culture Documents

03 - Product Support

03 - Product Support

Uploaded by

郝帅Copyright:

Available Formats

You might also like

- Hancock (2010-03) Momentum - A Contrarian Case For Following The HerdDocument13 pagesHancock (2010-03) Momentum - A Contrarian Case For Following The HerddrummondjacobNo ratings yet

- TCM IO520 OpsInstallManualDocument78 pagesTCM IO520 OpsInstallManualleather_nunNo ratings yet

- ATA 71 Issue1Document58 pagesATA 71 Issue1shazia Syed100% (1)

- Aircraft Maintenance ManualDocument370 pagesAircraft Maintenance ManualMatthias Barragan100% (4)

- WiFi Function Manual of Charge Point-181030 PDFDocument16 pagesWiFi Function Manual of Charge Point-181030 PDFfreesonNo ratings yet

- 04 - Test SystemsDocument4 pages04 - Test Systems郝帅No ratings yet

- 11 - Engine SystemsDocument4 pages11 - Engine Systems郝帅No ratings yet

- 15 - Landing GearDocument2 pages15 - Landing Gear郝帅No ratings yet

- 10 - Indicating SystemsDocument4 pages10 - Indicating Systems郝帅No ratings yet

- 07_Air Conditioning Systems rev1 slsDocument10 pages07_Air Conditioning Systems rev1 slsatoocloudNo ratings yet

- 06_Test Systems_GSE_Tooling rev1 slsDocument12 pages06_Test Systems_GSE_Tooling rev1 slsatoocloudNo ratings yet

- 01 Avionics PhilosophyDocument10 pages01 Avionics Philosophy郝帅No ratings yet

- 01 Avionics PhilosophyDocument20 pages01 Avionics Philosophy郝帅No ratings yet

- 03 - Electrical PowerDocument11 pages03 - Electrical Power郝帅No ratings yet

- 05 - Navigation SystemsDocument22 pages05 - Navigation Systems郝帅No ratings yet

- 23 LateDocument4 pages23 Late郝帅No ratings yet

- 16 - Hydraulic PowerMDocument1 page16 - Hydraulic PowerM郝帅No ratings yet

- 14 - Fuel SystemsDocument2 pages14 - Fuel Systems郝帅No ratings yet

- 21 - Water and WasteDocument5 pages21 - Water and Waste郝帅No ratings yet

- 01_Electrical Power rev1 slsDocument7 pages01_Electrical Power rev1 slsatoocloudNo ratings yet

- 13 LightingDocument3 pages13 Lighting郝帅No ratings yet

- 05 Management and Philosphy rev 1 slsDocument23 pages05 Management and Philosphy rev 1 slsatoocloudNo ratings yet

- 3_AutoFlight-Flight Controls Rev 1 slsDocument8 pages3_AutoFlight-Flight Controls Rev 1 slsatoocloudNo ratings yet

- 02_Hydraulic Power rev1 slsDocument4 pages02_Hydraulic Power rev1 slsatoocloudNo ratings yet

- Engine Systems PDFDocument5 pagesEngine Systems PDFteknikpembakaran2013No ratings yet

- 04_Navigation Systems rev1 slsDocument15 pages04_Navigation Systems rev1 slsatoocloudNo ratings yet

- 09 - Air Conditioning SystemsDocument12 pages09 - Air Conditioning Systems郝帅No ratings yet

- 07 - Communications SystemsDocument3 pages07 - Communications Systems郝帅No ratings yet

- 08_Pneumatic rev1 slsDocument2 pages08_Pneumatic rev1 slsatoocloudNo ratings yet

- 02 - Line MaintenanceDocument1 page02 - Line Maintenance郝帅No ratings yet

- CMM - 32-47-61 - Rev9 - F6137 - MENSAGENS ENGENHARIA - RDAS-2020-083 - Is.01Document272 pagesCMM - 32-47-61 - Rev9 - F6137 - MENSAGENS ENGENHARIA - RDAS-2020-083 - Is.01Bruce Polo100% (1)

- 19 - Nacelles and Thrust ReversersDocument11 pages19 - Nacelles and Thrust Reversers郝帅No ratings yet

- Operator E-Jets News Rel 039Document9 pagesOperator E-Jets News Rel 039jivomirNo ratings yet

- 06 - GSE Special ToolingDocument2 pages06 - GSE Special Tooling郝帅No ratings yet

- 30 45 00001Document6 pages30 45 00001ryan liaoNo ratings yet

- Airworthiness Directive: Federal Register Information Header InformationDocument7 pagesAirworthiness Directive: Federal Register Information Header InformationEdson Caillavi LafuenteNo ratings yet

- Dated November 12, 1984, Into A Hard Copy Service Bulletin. TheDocument15 pagesDated November 12, 1984, Into A Hard Copy Service Bulletin. Themarcfrancis.mercadoNo ratings yet

- AP737C-33-001 (-) Replacement of Relamp Identification Label For Anti Collision Winglet Strobe, 30-2849-1Document8 pagesAP737C-33-001 (-) Replacement of Relamp Identification Label For Anti Collision Winglet Strobe, 30-2849-1jlmoncadaNo ratings yet

- Engineering SupportDocument7 pagesEngineering SupportjordiNo ratings yet

- A330 Mmel Faa - Rev12Document235 pagesA330 Mmel Faa - Rev12Reynald FREYNo ratings yet

- Inability to operate cargo doors linked to EPDC LRU failuresDocument4 pagesInability to operate cargo doors linked to EPDC LRU failuresanarko arsipelNo ratings yet

- 2003 24 07Document7 pages2003 24 07Carlos MNo ratings yet

- SB 737 21 1101 01Document19 pagesSB 737 21 1101 01ramosvilledasraulNo ratings yet

- 1line Training BookletDocument50 pages1line Training BookletKshitiz Rastogi75% (4)

- Easa Ad 2010-0235R1 1Document3 pagesEasa Ad 2010-0235R1 1ohm3011No ratings yet

- EO ATR42-EO-98-374A - Aft Galley RemovalDocument8 pagesEO ATR42-EO-98-374A - Aft Galley RemovalshahzadNo ratings yet

- LEAP-1A - Oil Stains On The Fan Cowls: Purpose of This ArticleDocument3 pagesLEAP-1A - Oil Stains On The Fan Cowls: Purpose of This Articlejivomir100% (1)

- 20 OxygenDocument1 page20 Oxygen郝帅No ratings yet

- Service Bulletin: Piper Considers Compliance MandatoryDocument10 pagesService Bulletin: Piper Considers Compliance MandatoryJean AbrialNo ratings yet

- MOI - Modification Operational Impact: 34.42.00049 21-OCT-2021 21-OCT-2021 Open A350 34-42 Creation of The MOIDocument4 pagesMOI - Modification Operational Impact: 34.42.00049 21-OCT-2021 21-OCT-2021 Open A350 34-42 Creation of The MOITitoNo ratings yet

- Ds-pp-0108 - Data Sheet For Underwing Nozzle Connector (Rev.0)Document2 pagesDs-pp-0108 - Data Sheet For Underwing Nozzle Connector (Rev.0)Panisa BanimaNo ratings yet

- ABCD-GD-01-00 - Aeroplane General Description - 17.02.16 - V1Document11 pagesABCD-GD-01-00 - Aeroplane General Description - 17.02.16 - V1Edgar MartínezNo ratings yet

- 2018-19-04Document8 pages2018-19-04Juan Ruben GarciaNo ratings yet

- 622-7925-303 - PRIMARY SERVO - Aeroval®Document5 pages622-7925-303 - PRIMARY SERVO - Aeroval®amir ghaznaviNo ratings yet

- FAA AnA Tables May2020Document218 pagesFAA AnA Tables May2020namrtaNo ratings yet

- Easa Notification of A Proposal To Issue AN Airworthiness DirectiveDocument2 pagesEasa Notification of A Proposal To Issue AN Airworthiness Directivedsgarcia26No ratings yet

- Easa Ad 2020-0274 2Document4 pagesEasa Ad 2020-0274 2Evangelos KopanakisNo ratings yet

- A350 FTE Call MAR 19 2019Document5 pagesA350 FTE Call MAR 19 2019Bongyoun LeeNo ratings yet

- SB 538Document3 pagesSB 538shonuNo ratings yet

- Notification of A Proposal To Issue An Airworthiness DirectiveDocument4 pagesNotification of A Proposal To Issue An Airworthiness DirectiveBahadorNo ratings yet

- Tfu 21.52.00.021Document8 pagesTfu 21.52.00.021easwarNo ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- 05 - Navigation SystemsDocument22 pages05 - Navigation Systems郝帅No ratings yet

- 04 - AutoFlight SystemsDocument6 pages04 - AutoFlight Systems郝帅No ratings yet

- 19 - Nacelles and Thrust ReversersDocument11 pages19 - Nacelles and Thrust Reversers郝帅No ratings yet

- 03 - Electrical PowerDocument11 pages03 - Electrical Power郝帅No ratings yet

- 13 LightingDocument3 pages13 Lighting郝帅No ratings yet

- 01 Avionics PhilosophyDocument10 pages01 Avionics Philosophy郝帅No ratings yet

- RamaDocument48 pagesRamaSebastián Diez CáceresNo ratings yet

- Management Theories and Case StudyDocument5 pagesManagement Theories and Case StudyStephanie KrystelNo ratings yet

- Redhaired Mummies and Giants of The United StatesDocument7 pagesRedhaired Mummies and Giants of The United StatesMaria StancanNo ratings yet

- Introduction To Chemotherapy: A Presentation For Patients and FamiliesDocument55 pagesIntroduction To Chemotherapy: A Presentation For Patients and FamiliesjjNo ratings yet

- 4CC Carrier Aggregation - AlexDocument19 pages4CC Carrier Aggregation - Alexel yousfiNo ratings yet

- FC Sem 3 Science in Every Day LifeDocument12 pagesFC Sem 3 Science in Every Day LifeHamza GhadiallyNo ratings yet

- Aptitude Test InfosysDocument216 pagesAptitude Test InfosysJose PrakashNo ratings yet

- Gordon 2009 CatalogDocument68 pagesGordon 2009 Catalogpolanck100% (3)

- Schools of Criminology A Comparative AnalysisDocument9 pagesSchools of Criminology A Comparative AnalysisSudeep MishraNo ratings yet

- Freud's Model of The Human Mind - Journal Psyche PDFDocument1 pageFreud's Model of The Human Mind - Journal Psyche PDFJazmen folkNo ratings yet

- Checkliste - Leistungstabelle R44 Raven IIDocument2 pagesCheckliste - Leistungstabelle R44 Raven IIAfonso Henrique Rodrigues LonghiNo ratings yet

- Sustainable Competitive AdvantageDocument49 pagesSustainable Competitive AdvantageakashniranjaneNo ratings yet

- Phy110 Lab Report 1Document1 pagePhy110 Lab Report 1Khalila KhalishaNo ratings yet

- Hasil Stok Opname Untuk Bap (Fix)Document35 pagesHasil Stok Opname Untuk Bap (Fix)WARDA NABIELANo ratings yet

- Space FactorDocument5 pagesSpace FactorRafael Yap GNo ratings yet

- Areeba Hussain Ahmed: UmmaryDocument1 pageAreeba Hussain Ahmed: UmmaryAreeba Hussain AhmedNo ratings yet

- VMP 530vhmDocument2 pagesVMP 530vhmelienai10% (1)

- A MIL Q1M8 Teacher Copy FinalDocument22 pagesA MIL Q1M8 Teacher Copy FinalIvy BarnacheaNo ratings yet

- Management Control System MODULE IDocument17 pagesManagement Control System MODULE IDr Linda Mary Simon100% (1)

- Factor Effecting RecruitmentDocument4 pagesFactor Effecting RecruitmentsogatNo ratings yet

- Infinity Users GuideDocument172 pagesInfinity Users GuideSridhar DasariNo ratings yet

- Training Project ReportDocument62 pagesTraining Project ReportGaurav Singh Bhadoriya0% (1)

- 40K Bunker TutorialDocument26 pages40K Bunker TutorialRandomizm100% (2)

- Buying PlansDocument38 pagesBuying PlansAndrea VargasNo ratings yet

- Canadian Capital Providers Guide0415Document141 pagesCanadian Capital Providers Guide0415kohinoordas2007100% (1)

- ZKTeco+Fingerprint+Scanner+SDK+Selection+Guide-Ver3 0 PDFDocument1 pageZKTeco+Fingerprint+Scanner+SDK+Selection+Guide-Ver3 0 PDFYoussefNo ratings yet

- Gantry SystemDocument4 pagesGantry SystemTh NattapongNo ratings yet

- Exploring Information Quality in Accounting Information Systems AdoptionDocument12 pagesExploring Information Quality in Accounting Information Systems AdoptionJusteen BalcortaNo ratings yet

03 - Product Support

03 - Product Support

Uploaded by

郝帅Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

03 - Product Support

03 - Product Support

Uploaded by

郝帅Copyright:

Available Formats

REFERENCE 12-032/MSG-281 - Page 12

PRODUCT SUPPORT

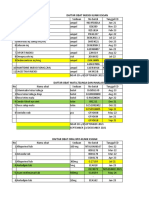

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

24 SRU Repair All All All ANA

ANA has a repair shop and is performing level 2 maintenance for several components. ANA send the removed

SRU to the vendor shop for repair. However, the removed SRU is rejected by non-capability, and we are

requested to send the unit assembly in the same cases. We believe the vendor shop should have capability for

SRU repair.

Rockwell Collins, Honeywell, Hamilton, and other vendor comment, please.

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

25 Restrictive All All TAP

Documentation

Policies

Recently, we have seen some vendors adopting restrictive documentation policies that reduce the scope of the

free-access Instructions for Continued Airworthiness and seek to tie down access to the documentation to

commercial issues, like the use of PMA parts.

We would like to seek the comments from this operator’s forum.

Will FAA memo AIR-100-11-100-002 be effective?

How are other operators dealing with this problem?

Estimated Annual Cost Penalty: $1,000,000+

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

26 Bearings and O O Ring Quality All All All MON

Rings

In Monarchs experience, we perceive a drop off in performance of bearings and O Rings due to poor quality

materials, especially components fitted to LRUs that operate in a hot environment. Heat distress is a frequently

reported as the cause of steel bearing failures.

Although this would prove difficult to substantiate, we would be interested in other operator’s feedback.

Estimated Annual Cost Penalty: $100,000

REFERENCE 12-032/MSG-281 - Page 13

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

27 Incomplete ATR ATR72-600 AZUL

Literature

AZUL Brazilian Airlines has recently received its first ATR72-600’s. This airplane has a great potential to further

expand AZUL’s route structure. The airplane has already been very well received by our customers. However,

AZUL has had problems with the new ATR72-600 fleet. This is largely due to the fact of it being a new fleet, but

there are things that are not acceptable, such as incomplete literature and/or wrong information. This has

increased the time to find answers for several cases of AOG, such as those that occurred with the autopilot

system as well as AHRS.

To illustrate the above:

• There are no TSM (Trouble Shooting Manual) instructions for the autopilot system.

• For the AHRS systems, there are JIC (maintenance instructions) instructions that are not applicable to the

fleet, and there is incomplete information for testing the flux valve after replacement.

To finalize, the operators cannot access the AFDX data bus. Due to this restriction, we had an aircraft on the

ground for nearly a week.

Other operators, comments, please.

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

28 PDL 11615-20 Aero Instruments & All 31-00 USA

Avionics

USA has experienced DSL and DSM Data Set Loader ground software issues when attempting to operate the

software in the network environment. Aero Instruments has worked with the airline to solve other PDL issues and

has promised to provide a solution for the network software issues since late November 2011. The airline is

asking for a commitment to fix the software with a timeline for the availability of the solution.

Other operator and Vendor comments, please.

Estimated Annual Cost Penalty: $20,000

REFERENCE 12-032/MSG-281 - Page 14

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

29 Aircraft Interface Unit 10647B01M02 Ametek MD-10 31-43 FDX

Ametek has recently started providing service quotes wanting to replace the complete PCB rather than doing

Level III repairs. Specific SBs (4084538-31- 0002, 0003 and 0004) have been cited. Ametek considers these

Mods “mandatory” but have not been able to tell us why they are mandatory.

After reviewing the SBs and previous tear-down reports that indicate several of our AIUs have had the SBs

incorporated as repair actions without prior Engineering approval via the FedEx Policy Sheet, we are questioning

the efficiency of exchanging entire PCBs in lieu of replacing failed piece parts on the PCBs. We contend that

cards should be troubleshot to specific faulty components and just those repairs be made rather than wholesale

card replacement via a SB Mod.

FedEx questioned this practice during a couple of conference calls with the Ametek rep, but to date have not

received a commitment to resolve our concerns. We have made it clear that if Ametek does not want to perform

Level III repairs, we will pursue this work in-house which will require Ametek to drastically improve the quality of

their CMMs.

The Level III maintenance issue was brought up at last year’s AMC Conference, Discussion Item 25.

Other operator and supplier comments, please.

Estimated Annual Cost Penalty: $25,000

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

30 Audio 5700-1 Avtech B777 23-50-70 AA

Management Unit

American has requested a quote for the Avtech TS5700SYS-1 tester listed in CMM 23-50-70, as well as any

available tech data for this tester. After many attempts to get any response at all from August through November

of 2011 using the contact information in the CMM, a reply was finally obtained in late November by a field service

representative who, of no fault of their own, had little knowledge of the tester. After assurance that we would be

contacted and our issue addressed by the appropriate people, another three months have passed with no further

reply.

Further, from the limited conversation with Avtech described above, it was indicated that this equipment has not

been provided before, would most likely take significant time to quote, and may have issues with proprietary

information. Again, very general as we have not been contacted with details, but this type of answer does not

give us much confidence that our request will be answered.

Have any other operators had issues of this nature with Avtech? Do any other operators have this test

equipment?

Estimated Annual Cost Penalty: $25,000

REFERENCE 12-032/MSG-281 - Page 15

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

31 APU Door Actuator 1051T100-21 Aerocontrolex MD90 49-50 DAL

Telair

Talley

A high use item

This was originally a TELAIR part. Telair was purchased by Talley which was then purchased by Aerocontrolex.

The lead times for these parts is now anywhere from 60 days to 350 days after you request the quote, which

sometimes takes over a month to get. The vendor does not seem to care if they supply the parts or not.

Other operator or Aerocontrolex comments, please.

Estimated Annual Cost Penalty: $25,000

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

32 Attendant Control 115E1670G14 Boeing B737-NG (Boeing 3115 UAL

Panel Sky Interior)

115E1670G18 BAE

UAL received a new B737-900 (with Boeing Sky Interior) from Boeing in January 2012: the first airplane delivered

with the new attendant control panels P/N: 115E1670G14 and 115E1670G18. However, the new part information

is not available in the Boeing IPC and BAE CMM.

UAL experienced similar issues when we received our first B737NG Boeing Sky Interior (BSI) in December 2010:

many maintenance procedures are not available in the AMM and FIM, such that we could not perform basic

maintenance and system verification on these airplanes.

As part of the Instructions for Continued Airworthiness, manufacturers and suppliers are required to provide

proper documentation to operators in order to maintain airplane operation and component repair.

This situation is unacceptable to UAL. Furthermore, Boeing at least should be setting the industry standard to

maintain ICA requirements.

Other operators and Boeing, please comment.

Estimated Annual Cost Penalty: $30,000

REFERENCE 12-032/MSG-281 - Page 16

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

33 ATC/TCAS CP, WCP-701 G6990-53 Gables All 34-45 KLM

622-5129-XXX Rockwell

Collins

KLM experiences CMM and ATP revisions with mistakes. When prompted, the vendors update the CMM/ATP but

introduce new mistakes. Examples: Gables: Ref: ATP G6990-53 Collins: 34-45-14 p/n 622-5129-XXX New

reprint and full of errors. Old revision was better and there were no problems during test.

It cost a lot of time to fix the administrative errors.

Operators comments, please.

Estimated Annual Cost Penalty: $3,000

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

34 RAM Air Inlet 825206-2 GE Aviation (W 767 21-53 DAL

Actuator

R15062-5, -6 Boeing

S210T110-2015 Aviall

Delta continues to note issues of parts availability and unacceptable long lead times for parts for this actuator.

Most recently, some MPN 4990598 housing guides and IJKKP8AX bearings had forced us into an AOG situation.

Between Boeing, GE, and Aviall, we insist parts be available and support in place to prevent us from incurring any

more AOG.

Comments from Boeing, GE Aviation, and Aviall, please.

Estimated Annual Cost Penalty: $250,000

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

35 FQIC SIC5059-xx-xxxx GE Aviation (C A319 28-40 DAL

Computer

Ontic Engineer A320

Airbus

GE Aviation Clearwater will be transferring ownership of the fuels measurements business between January and

April 2012 to Ontic Engineering and Manufacturing BBA Aviation. Delta has grave concerns for the loss of

‘lessons learned’ over the years on the FQICs, indicators, and refueling panels, as well as possible interruptions

of service and availability of inventory.

To date, other than receiving an announcement letter of the transition, Delta has not received any formal plan nor

explanation of what/how this is all going to occur. Delta is asking Airbus and GE Aviation to ensure that this

product line transfer be transparent to Delta.

GE Aviation and Airbus comments, please.

REFERENCE 12-032/MSG-281 - Page 17

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

36 Actuator AR02404 Goodrich A330-200 32 EVA

Refer to AMC 2011 Discussion Item 61. Although Goodrich had revised CMM 32-33-18, Goodrich cannot provide

the component maintenance training and agree to give us the SRU quotation.

Other operator and Goodrich comments, please.

Estimated Annual Cost Penalty: $20,000

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

37 Proprietary 8ES005238-13 Goodrich Lighting A320 33 MON

8ES455012-00

2LA005469-00

8ES005309-00

We route a number of unserviceable units for repair to our preferred MRO's. Significantly, our preferred MRO’s

are no longer able to release any Monarch owned Goodrich units that are sent for repair. This is due to Goodrich

no longer providing written confirmation that shows that CMM revisions are up to date. This is not an isolated

case as other OEM’s have a similar approach to this issue.

As the operator and owner of these spares we would like clarification and justification of Goodrich’s and other

OEM’s stance with this issue.

Other operators comments, please.

Estimated Annual Cost Penalty: $50,000

REFERENCE 12-032/MSG-281 - Page 18

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

38 Communicating All Hamilton DAL

Required Sundstrand

Deviations

Boeing

Hamilton has started using Action Items (AI) in place of Temporary Revisions (TR) to communicate required

deviations to the CMMs. Delta has found that the quality of the AIs can vary greatly from documents near ATA

spec to documents that contain e-mail chatter. Delta has asked Boeing (Boeing Message: DAL-DAL-11-2734-

02B) if the AI meets the current standards for TRs, and Boeing has responded no.

Due to the nature of the AIs, Delta does not feel that we can confidently add these to our manuals and fully expect

compliance or full understanding by the mechanic on the floor. We are currently reviewing each AI individually,

verifying the content, and adding notes where appropriate to protect compliance.

Delta would like to ask the following:

1) To Operators: Are other operators having the same issues with the AI that Delta is, or are they being

accepted in the same way as TRs?

2) To Boeing: Can Delta expect other sub-tier vendors to go away from the TR format? Would this practice

not violate Boeing’s agreements with its vendors to provide ICAs in ATA format?

3) To Hamilton Sundstrand: TRs and AIs are only supposed to represent a temporary change that is in place

until the CMMs are revised. Many of the AIs that Delta is reviewing are well over 18 months old. What

steps are HS taking to insure content is properly, and promptly, added to the CMMs?

Operator, Boeing, and Hamilton Sundstrand comments, please.

Estimated Annual Cost Penalty: $50,000

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

39 Voltage Sensing Relay E308AH Hartman 24 BAW

Hartman (a division of TE Connectivity) called out commercially available Relay, 115 VAC, SPDT, Make-Before-

Break as part of the test equipment required for testing Voltage Sensing Relay E308AH per CMM 24-09-18.

We have not been able to locate such a relay and have asked Hartman, on several occasions since August 2011,

for help with identifying a suitable component. Hartman has not yet responded.

Response from a separate request to TE Connectivity Product Information Centre: “We don’t have anything like

this. Sorry.”

Other operator and vendor comments, please.

REFERENCE 12-032/MSG-281 - Page 19

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

40 ORI Process All Honeywell All All FDX

This item relates to AMC '11 Discussion Item 51. Honeywell's use of their Overhaual Repair Instruction process

has potential for creating a situation for the Operators that have in-house repair capability in which they are

unable to use the CMM as a stand-alone document for use in test/repair of our LRUs. For most ORI cases, we

have been given only title page short summary info and not the entire ORI for review and approval (a legal

compliance issue with FAR 121.363.a.2).

Honeywell has also not demonstrated to us a process for revision control of the ORIs. Honeywell made a

commitment at last year's AMC to start issuing service bulletins or revisions to CMMs for cases of 'ORIs

containing repair instructions that are appropriate for release and will be incorporated into the CMM at the earliest

opportunity. We understand the Honeywell Intellectual Property Dept has a very different view when it comes to

‘instructions that are appropriate for release’, but we would like to give Honeywell an opportunity to update us on

how many ORIs have been released as SBs or CMM revisions since their ‘earliest opportunity’ has been since the

last AMC.

Other operator, supplier, and airframer comments, please.

Estimated Annual Cost Penalty: $500,000

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

41 Pegasus MDCU 4077880-908 Honeywell B757 34-61 DAL

(ORI)

B767

This is a follow up question to Discussion Item # 51 from the 2011 AMC. Honeywell committed to eliminate

existing ORI’s for this LRU and incorporate the data into a SB or CMM change. As of Feb. 1, 2012, this has not

happened.

In addition, in Honeywell’s response to item #51 last year, they committed to reviewing ALL ORI’s, and if an ORI

dealt with an LRU’s serviceability, the data would be issued as an SB or CMM data. To date we have not seen

results from that review. Honeywell’s commitment was that the ORI process would only be used as a temporary

measure (to expedite the release of the information) or for optional repairs that the operator can chose to decline.

Can Honeywell provide a firm schedule on when this review will be complete and when the operators can expect

the ORI data to be properly released as SB or CMM data?

Honeywell comments, please.

Estimated Annual Cost Penalty: $10,000

REFERENCE 12-032/MSG-281 - Page 20

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

42 DU ORI 4086850-9XX Honeywell B777 31 AFR

During DU B777 repair processes at Honeywell facilities, ORI (Overhaul Repair Instruction) are used without a

formal agreement from the operator.

The release certificate makes reference to this data because they are not included inside the CMM (quality

process). ORI are Honeywell internal procedures, and they are not available for the operators and repair shops.

Without ORI performed, equipment could not be serviceable. Example of ORI performed by Honeywell on DU :

ORI EP00005 ; ORI EP00337.

Other cases of ORI applied on HNY equipment: MCDU Pegasus ORI EP00082 and ORI EP00085

CDU 777 : ORI EP00274

Regarding EASA/FAA requirements, this data (ICA) must be available for the operators and repair shops.

Other operators’ comments and Boeing comments.

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

43 ID Labels All Honeywell All 11-00 DAL

Delta is getting no support when trying to order replacement ID labels from the vendor. It has taken up to 5

months to get a single ID plate after providing ALL requested information. This is occurring across all product

lines. Onsite Rep's are not able to speed the process up when asked for assistance.

Honeywell comments, please.

Estimated Annual Cost Penalty: $10,000

REFERENCE 12-032/MSG-281 - Page 21

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

44 Mode Control 4082260-939 Honeywell B737 22-00 DAL

Panel

This is a follow up question to Discussion item # 52 from the 2011 AMC. It is very common for Honeywell to ship

the operators parts not listed in the CMM IPC and provide a Form, Fit, Function letter. The CMM’s are not being

updated. This particular unit has sub-assembly CMM's that have not been updated since 2007, even though we

have repeatedly asked for IPC updates. This causes the operator to spend engineering time and money to

approve the alternate part number internally.

We want to see the CMM IPC updated with the proper part numbers. We would also accept an Optional Part

Catalog, which is similar to what other OEM’s provide. All part numbers and all equivalents could be listed in a

single catalog. We understand in talking to the Honeywell order admin representatives that all this data already

exists in the Honeywell internal order system. We believe ATA spec and the Boeing PSAA require OEM and sub-

contract OEM part numbers to both be listed in the CMM IPC.

Would Honeywell please release this data in each CMM or a common catalog and provide a schedule for

completion?

Honeywell comments, please.

Estimated Annual Cost Penalty: $100,000

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

45 CDU/DU 4072800-901 Honeywell B777 31-61 UAL

4073610-905

4088240-901

EPROM software is available at Honeywell but not to outside repair vendors. When a unit fails due to memory

faults, we are unable to repair or reprogram the unit. This causes us to send the whole unit and not the

subassemblies to Honeywell.

Honeywell comments, please.

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

46 CDU/DU 4072800-901 Honeywell B777 31-61 UAL

There is no support for the BM-5A photometer and the older Goniometer hardware.

What are the upgrade differences, and what support will Honeywell provide in replacement?

Honeywell comments, please.

REFERENCE 12-032/MSG-281 - Page 22

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

47 CDU 4088240-901 Honeywell B777 31-61 UAL

EADS/Cassidian shows the Honeywell part to be 4088250-901 which is the hardware number, while the actual

Honeywell part number is 4088240-901. This is causing United Airlines problems. We are unable to update our

software on the ATEC 6000 station.

Honeywell comments, please.

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

48 AC Generator 28B26313B Honeywell 747-400 24 EVA

Reference :CMM: 24-21-04 Figure 6005 on page 6017 using PN: GSE 1106602 functional plate to check bearing

support assembly.

Eva Operator’s shop cannot follow CMM procedure steps. Eva has been in contact with Honeywell over one year

and there still is not a solution to this problem.

Honeywell shall update the CMM procedure and/or provide, if they are using addition tools to follow CMM

procedure.

Estimated Annual Cost Penalty: $250,000

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

49 VSCF Generator 4914-004060 Honeywell MD-90 24-10 DAL

Differential

Differential Oil pressure switch J3.

The manual provides test check procedures only. Costs to replace the switches are in excess of $1M in 1 year for

28 switches procured.

DAL requests switch details and a CMM with repair details, acceptance tests data, IPC, and warranty info as well.

New P/N 4914-004060 replaced old P/N 4914-003700.

Estimated Annual Cost Penalty: $1,000,000

REFERENCE 12-032/MSG-281 - Page 23

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

50 Solenoid Valve 320503-18 Honeywell B747-400 24-09-25 BAW

BA has developed repair capability for this unit but is having extreme difficulty obtaining certain spare parts which

are listed in the Honeywell CMM.

Examples: CMM 24-09-25

Fig 2, Item 6 967470-3 Valve Assy Set

Fig 2, Item 40 NAS1189E02P3LK Screw

Fig 2, Item 63 223-655-9020 Valve Assy Set

Fig 2, Item 70 967373-9 Cover Wireway

Will Honeywell please quote for these spares or supply an alternative solution or new part numbers.

Honeywell representative, please comment.

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

51 Light Assembly 30-2620-1 Honeywell EVA AIR 33 EVA

20-2620-2

EVA B777 has experienced a situation of the wingtip strobe light lens departing from the airplane and also found

a lot of wingtip strobe light lens cracks during A check. Please refer to Boeing FTD 777-FTD-33-09001 about this

issue.

According to Boeing FTD, Honeywell has concluded the loss of adhesion around the ACL lens which was caused

by contamination in the preparation process for painting and/or lens potting, and inadequate cleaning to remove

the contamination. Honeywell has issued SB 30-2620-33-0002 to introduce a new lens and add the SS4004

primer adhesive. When EVA returns the wingtip light assembly to Honeywell for repair due to the lens crack, they

denied our warranty repair.

EVA believes this issue should be a design problem, and Honeywell should provide FOC parts (lens) to

operators.

Vendor and other operators comments, please.

Estimated Annual Cost Penalty: $50,000

REFERENCE 12-032/MSG-281 - Page 24

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

52 RADAR Scanner 2041444-0401 Honeywell A319-A320 34 UAL

2041444-0402 B757

2041444-0403 B767

B747

B777

At United Airlines, our fleet uses three different Honeywell RADAR Scanners which all use the same Ribbon Cable

part # 8056354-0501 (newer version) or 2040875-0501 (older version). In 2011, we had 165 scanner repairs with

40% or 64 cables replaced because of broken wires or shorted out wiring. Damage occurs from the stress of cable

twisting through gear channel of scanner.

This is a manufactured defect with the cable not being strong enough to withstand the stresses of normal scanner

operations. Please reference Honeywell CMM/IPC 34-41-11, figure 1, items 133a and 133b.

Honeywell comments, please.

Estimated Annual Cost Penalty: $102,200

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

53 Flight Mgmt 4052500-927,-962 Honeywell B737 34-00 DAL

Computer

4052504-927 B757

4052506-941/952/955 B767

B777

MD88

MD90

Reference: AMC Discussion Item 2011-62.

Delta continues to see Circuit Card Assemblies (CCA) returned as Beyond Economical Repair (BER) because

experientially Honeywell refuses to spend more than two days troubleshooting for a repair. According to

Honeywell’s own standard practices manual, a BER is determined by repairs that exceed 70% of the catalog

market price (see below). Honeywell's premature BER determination is negatively impacting Delta through

increased cost, configuration changes, and unnecessary administrative functions. This issue was brought up

during the 2011 AMC but remains unresolved. Delta continues to bring up this issue, but Honeywell thus far has

remained silent.

Delta expects Honeywell to follow its own documented standard and repair a CCA if the repair cost is less than

70% of the catalog market price. Please let Delta know why Honeywell continues to ignore its standards and

prematurely determine BER.

(Honeywell Reference)

“BEYOND ECONOMICAL REPAIR (‘BER’). The estimated cost of repairs to Articles exceeds 70% of

Honeywell's then-current new catalog market price (also known as Honeywell's Operator Price) for the Article,

or the Article is Non-Repairable.”

Honeywell comments, please.

Estimated Annual Cost Penalty: $100,000

REFERENCE 12-032/MSG-281 - Page 25

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

54 Air Data Test 4083485-901,-902, AD Honeywell All 34-00 DAL

Set

Support for the service and calibration of the Honeywell Air Data Test Set p/n 4083485-901, -902, model ADT

222C is becoming increasingly difficult to acquire. These are critical transfer standards used in the return to

service all of Delta’s air data test boxes and ATE. These testers are still available for purchase yet lack the

support expected for such a critical piece of test equipment.

In the past eighteen months, the equipment sent to Honeywell for service and calibration has been repeatedly

misplaced, and information regarding this equipment has been difficult to ascertain. This is despite consistent

efforts to communicate with the support contacts at Honeywell’s MyAerospace and the local Honeywell

representative. Delta would like to understand Honeywell’s support options for this unit and their plans to improve

their customer service? Delta needs access to up-to-date information about the status of calibrations, expected

return dates, etc.?

Estimated Annual Cost Penalty: $120,000

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

55 ADIRU HG2060AD01 Honeywell B777 34 UAL

We are experiencing low time to first maintenance message (message #34-20010) after repair.

Other operator and Honeywell comments, please.

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

56 EPR Transmitter LG80E1 Honeywell MD88 77-10 DAL

Repeat item from 2010 AMC, Discussion Item 198. We are again encountering parts obsolescence notices from

Honeywell on this unit. Support was fixed for a while after the 2010 AMC.

What is Honeywell's long term plan to support this unit and provide piece parts?

For piece parts that can be machined, will Honeywell release the drawings to Delta so that we can manufacture

our own parts?

Honeywell comments, please.

Estimated Annual Cost Penalty: $50,000

REFERENCE 12-032/MSG-281 - Page 26

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA Fro If MRO, the

m Associate

Airline

57 FCV 1303A0000-03/4 LIEBHERR A320 21-36 AFR

HP Bleed Valve 6773B30000

Bleed Pressure Valve 6773E010000

6774B030000

6774E0000

On many Liebherr components, CMM stockage limitations are too restrictive to deal with:

• Temperature =+18 and +22°C

• Humidity= 65%

AFR is facing requests from authorities such as tropical areas where it is very hard and expensive to go below

70% humidity.

In addition, regarding CMM temperatures, in Toulouse (FR) in summer, theses requirement cannot be met.

This issue has been raised to Liebherr since September 2011, without any formal answer. Can they provide us an

official document to extend current limitations shown in CMM?

Estimated Annual Cost Penalty: $50 000

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

58 Zone Controller 775D0000-01 Liebherr A319/A320 21-63-17 UAL

With the release of CMM with IPL 21-63-17 Revision No. 2, dated June 01/11, the IPL no longer includes IPL

information sufficient to accomplish Level 3 (component level) repair.

Is the required IPL Detail Break Down (DBD) information available in another document? If so, please provide

document identification information and availability information. If not, why is the IPL DBD information no longer

available?

Other operator and vendor comments, please.

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

59 BSCU C2029339C9C9C Messier-Bugatti-Dowty A330 32 TAP

The purpose of SB C20293-32-157 is to inform the operators of a potential defect induced during the

manufacturing process of printed circuit date code 0849. According to this SB, the replacement of this SRU with

date code 0849 will be F.O.C. if it is under warranty and confirmed faulty.

As this situation involves a potential defect induced during the manufacturing process, should not the replacement

of the SRU be F.O.C. when confirmed faulty, regardless of whether it is under warranty or not?

Messier-Bugatti-Dowty and other operators comments, please.

REFERENCE 12-032/MSG-281 - Page 27

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

60 Printer 700750-1X15 Miltope E190 34-50 KLM

The KLM shop has been doing maintenance on printer p/n 706300-112 for many years. KLM wishes to add a new

p/n to the capability and is asking some questions about a new part number, but there is no response from the

vendor. We are not happy with Miltope’s attitude, because in the past, we always had a good relationship and

Miltope was always an example of a good vendor.

Do other MRO’s have similar experience?

Miltope comments, please.

Estimated Annual Cost Penalty: $10,000

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

61 Air Chiller 7000-2 Monogram B777-300 25 EVA

System

Monogram needs to support the operator to set up maintenance capability of air chiller’s subassembly-

compressor assembly P/N: 33366-1. Refer to the CMM 25-33-30 Rev: 08.

The CMM has no compressor service procedure on page 3005.

Note: “further disassembly of the compressor is neither necessary nor recommended.”

We request Monogram update the CMM for compressor service procedures or support operator air chiller’s

compressor flat rate service.

Comments from Monogram System, please.

Estimated Annual Cost Penalty: $13,500

REFERENCE 12-032/MSG-281 - Page 28

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

62 Actuator & Motor 2021814 Talley 747-400 25 EVA

series Actuators

544800 series

516550-2

Refer to AMC 2011 Discussion Item 59, Talley actuator (formerly Telair International Inc. ) had partially answered

the questions; however, some portions of the questions still need further response. Further to this point, we have

other questions that need OEM support.

After the 2011 AMC, we tried to contact Talley Actuators, but there was no response. EVA is requesting that

Talley Actuators provide the contact information. In addition, EVA is requesting that customers’ queries for

document and technical support be answered

Comments from Talley Actuator, please.

Estimated Annual Cost Penalty: $20,000

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

63 Fans & Valves VFT300 series Technofan A319 21 & 32 BAW

VFT210 series A320

V2T217 series A321

V2T152 series

Ref: Previous AMC Question 09-048

Technofan CMMs are very difficult to follow as they are unclear and contain many omissions and errors. We have

highlighted the problems to Technofan in 2009 following our product training, but the corrections and clarifications

still have not been made despite recent revisions to the CMMs.

We continue to find procedures in the CMMs that cannot be followed and have again highlighted these to

Technofan throughout 2011. Despite a meeting at our facility in November 2011, Technofan is unable to provide

a firm commitment as to when a thorough review of the documentation and updates will be made.

Do other operators and repair stations have the same issues?

Is it acceptable to the authorities and Airbus to allow maintenance data that cannot be followed?

We have made a large investment in test equipment and tooling but cannot use it with the procedures in the

manuals. We are asking for urgent updates to the CMMs and free of charge retraining from Technofan to prove

they are workable.

Comments from other operators, repair stations, and Airbus, please.

Please keep this question open until a satisfactory resolution is provided.

REFERENCE 12-032/MSG-281 - Page 29

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

64 Kapton Wire Various Nexans B767 24 Airborne Maintenance ABX Air

& Engineering

Services (AMES)

BMS13-51 Tensolite B757 ATI

B737

BMS13-51 Kapton Wire: While inspecting wire bundles during several of our customers’ Boeing aircraft

maintenance visits, we are discovering BMS13-51 Kapton wiring in a condition where the topcoat is peeling away

and releasing from the wire in several areas, sometimes along the entire length of the wire. This condition is

specifically addressed for Kapton wire in MIL-HDBK-522 as being acceptable unless the wire is located in a

severe weather and moisture problem (SWAMP) area or the wire has suffered fluid contamination: “If there is no

evidence of damaged or deteriorated insulation under the top coat, the condition of the wire insulation is

considered to be acceptable…repair or replace any wire with insulation that is crushed, cut, chafed, stretched,

missing, flaking, deteriorating, or shows evidence of abrasion or fluid saturation, excluding polyimide topcoat.”

Two vendors of this type of wiring were contacted, given photographic examples of topcoat peeling of the wire in

question and asked to provide feedback regarding the serviceability of the wire. One vendor responded that the

coating material itself does not provide any dielectric, environmental, or mechanical benefit to the insulation

system, and the final decision on whether the condition is acceptable would be made by the aircraft owner. The

vendor further explained that the topcoat was installed as a layer to provide contrast for marking the wire and for

helping to prevent the insulation tape beneath the topcoat from getting caught on something and becoming

damaged during installation.

Section 20-10-1, paragraph 11(B)(1)(a)1), of the current revision of Boeing’s SWPM D6-82481 for DC, MD, and

B717 models categorizes repair of the topcoat of other Kapton wire types as being for “cosmetic purposes only

and does not improve the integrity of the wire.”

The current revision of Boeing SWPM D6-54446 for B707, B727-B787 models does not specifically address the

wire type in question, and Boeing BMS13-51 is labeled “OBSOLETE.” Although obsolete, BMS13-51 F-G General

notes 2.5.1 d and e state that jackets on Grade A, B, and C shall have a topcoat for marking contrast but does not

mention the topcoat as having any insulative or other protective properties.

Operator comments? Boeing comments?

Estimated Annual Cost Penalty: $500,000

REFERENCE 12-032/MSG-281 - Page 30

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

65 LCDU 725 C19298AF05 Thales Airbus Family 31 AFR

MCDU C19266XA01

We are facing a lack of information concerning the NVM BITE decoding inside CMM Thales 31-63-30 rev 14

(LCDU) and 22-82-03 rev 12 (MCDU). The CMMs just refer to an internal document, "BITE User’s Manual

(J22419)", not available for Airlines.

Without this information, we cannot decode BITE data on ATEC bench. The efficiency of aircraft trouble shooting

process is reduced due to the slowest feedback from the avionics shop.

Other operator and Airbus comments, please.

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

66 Seat Actuator 413629000X (4/5/6) ZSE A320 25-11 AFR

(PRECILEC)

A330

A340

Regarding CMM 25-11-01, we do not agree with the following sentence: “Except for the tools manufactured by

PRECILEC, equivalent substitutes may be used”. There is not technical justification for this requirement.

This request is based on the 2 following arguments!

1. For all seat actuator (from several OEMs) fitted on the NHA (CAPTAIN SEAT and FIRST OFFICER SEAT

PN TAAI1-03XXXX-XX), only the CMM 25-11-01 from ZSE (PRECILEC) asks to use a specific test bench

made by ZSE (PRECILEC). All test specifications are described in the CMM 25-11-01 and the testing

concerns only standard measurements like Resistor (Ohm), Length (m), Force (N), Current (A), Speed

(m/s or rpm).

2. There is no technical reason to use a specific test bench made by ZSE (PRECILEC), and AF kindly asks

ZSE (PRECILEC) to remove the CMM sentence described above.

We consider that ZSE (PRECILEC) is not in conformity with SSCs requirements. We are still waiting the quotation

for tools since February 2011. For this issue, AF kindly asks ZSE (PRECILEC) to provide a better support.

Airbus and operator comments, please.

Estimated Annual Cost Penalty: $150,000

REFERENCE 12-032/MSG-281 - Page 31

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate Airline

67 PMAT 2000 80000-05 Teledyne All 00 DAL

The PMAT2000 Data Loader is serviced and repaired at Delta’s shop repair facility. Often, when we submit an

order for replacement parts, we receive a reply that the part is obsolete and no longer available. One example of

this is as follows: LC5512MV-75Q2081 U40 Programmed IC OEM of un-programmed IC is LATTICE. This part is

used in all versions of the PMAT2000. Teledyne indicates that this part is obsolete, however, they then

communicate that we can send the PMAT2000 to them for repair. This implies that the part must be available.

This part is used in all version of the PMAT2000.

We need parts availability for our in-house shop support capability. Teledyne has supplied us with repair support

documentation; however, they have also indicated that this documentation is old and may not always indicate

correct information for all versions of the PMAT2000 data loader. We have asked for, but not been supplied with,

the new documentation.

Estimated Annual Cost Penalty: $10,000.

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

68 APU Inlet Door Act 2R6211A Woodward MD-88 49-50 DAL

and Control MPC I

636216A

There is a parts and reliability issue with these units. The issue has been by addressed with MPC by a shop Lead

AMT, but the vendor has not resolved the problem. DAL is seeing internal damage to the housing of the

2R6211A. We believe the controller, 636216A, is causing the actuator damage by over-driving past the limits. We

suspect a design deficiency in the 5v regulator in the controller may be partially the cause. It seems that MPC is

always waiting on parts when units are sent back and the actuators sit at their facility longer than they should.

Delta Air Lines requests resolution of the reliability issues, resolution of the chronic parts shortages and improved

turn time, and that a CMM with complete test/repair information and IPC be provided.

Estimated Annual Cost Penalty: $50,000

REFERENCE 12-032/MSG-281 - Page 32

PRODUCT SUPPORT

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

69 Light, AFT Wing GE16720-010-2D BF Goodrich MD88 33-30 DAL

Strobe

Aviall

Avio Diepen

NHA GE16720-010-2D, -6, 9 has the most frequent part shortage job stopped in shop 320. The majority of those

have been for P/N GE16723-1 with no stock available. There are and have been a number of orders with our

vendors (Aviall and Avio Diepen), but the OEM (BF Goodrich Lighting) is failing to deliver the product to them on

time.

Aviall has a 98 day lead time and has been unable to deliver a PO written in Sept 2011 due to the OEM. Avio

Diepen is unable to fill its orders for the same reason. Averaged over the past three years, Delta has purchased

250ea GE16723-1's per year. The OEM and vendors alike should look at the history to forecast this item.

Request vendor comments and solution to chronic shortages.

Estimated Annual Cost Penalty: $114,000

******11-045******

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

Flight Data 980-4750-009 Honeywell B737-700 31-24 SWA

Recorder

The new Honeywell HFR5 FDR required on A/C manufactured after 12/2/10 has an ethernet download port which

is not compatible with the Honeywell HHDLU used on the earlier type of FDR. Honeywell has provided a solution

for downloading the HFR5 using either a laptop with download software or a preloaded Socket Mobile device.

However, SWA feels that neither of these solutions is adequate as they cannot be used with the earlier type of

FDR, which means that separate tools would need to be stocked to download the different types of FDR's.

Moreover, the current Honeywell HHDLU is increasingly unreliable (SWA has 10%-20% of its units out-of-service

on average) and uses PCMCIA cards as storage media, which are becoming outdated and difficult to obtain.

Honeywell has stated that they are developing a unit which will be compatible with both types of FDR's, but have

not given any proposed pricing or a schedule for when this might be available.

Flight Data Systems (FDS) currently has a HHMPI which is compatible with both types of FDR's and is authorized

for use on the earlier FDR's. SWA has used one for a trial period and found it to be very user-friendly, portable,

and durable. However, it is not currently authorized for use on the HFR5 because Honeywell has not given FDS

access to the interface documents at this time.

Honeywell was already late in their development of the HFR5, and now they are late in their development of

tooling to support the same. SWA feels that the entire industry would benefit if Honeywell reestablished a sound

working relationship with FDS, allowing them to finish development of the HHMPI. The final irony of all this is that

it was Honeywell who first brought the HHMPI to SWA’s attention in January of 2010.

Other operator and vendor comments, please.

REFERENCE 12-032/MSG-281 - Page 33

PRODUCT SUPPORT

******11-056******

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

APU Crank Contactor CC0708I-MUA34B Leach Intl B747 49-41 DAL

Boeing B757

B767

B777

This relay was installed via Boeing service bulletins and can be repaired by Leach. There needs to be a CMM

with complete test and IPC available to airlines.

Other operator and vendor comments, please.

Estimated Annual Cost Penalty: $20,000

******11-067******

Item LRU Name LRU PN Vendor Aircraft ATA From If MRO, the

Associate

Airline

TDR-94D 622-9210-00X Rockwell Collins EMB-120 34-50 SKW

TDR-94/94D current test software CPN 815-5058-010 new update: Why is this software update not available?

Why was available in 2005 and not available in 2010?

Other operator comments, please.

Estimated Annual Cost Penalty: $100,000

You might also like

- Hancock (2010-03) Momentum - A Contrarian Case For Following The HerdDocument13 pagesHancock (2010-03) Momentum - A Contrarian Case For Following The HerddrummondjacobNo ratings yet

- TCM IO520 OpsInstallManualDocument78 pagesTCM IO520 OpsInstallManualleather_nunNo ratings yet

- ATA 71 Issue1Document58 pagesATA 71 Issue1shazia Syed100% (1)

- Aircraft Maintenance ManualDocument370 pagesAircraft Maintenance ManualMatthias Barragan100% (4)

- WiFi Function Manual of Charge Point-181030 PDFDocument16 pagesWiFi Function Manual of Charge Point-181030 PDFfreesonNo ratings yet

- 04 - Test SystemsDocument4 pages04 - Test Systems郝帅No ratings yet

- 11 - Engine SystemsDocument4 pages11 - Engine Systems郝帅No ratings yet

- 15 - Landing GearDocument2 pages15 - Landing Gear郝帅No ratings yet

- 10 - Indicating SystemsDocument4 pages10 - Indicating Systems郝帅No ratings yet

- 07_Air Conditioning Systems rev1 slsDocument10 pages07_Air Conditioning Systems rev1 slsatoocloudNo ratings yet

- 06_Test Systems_GSE_Tooling rev1 slsDocument12 pages06_Test Systems_GSE_Tooling rev1 slsatoocloudNo ratings yet

- 01 Avionics PhilosophyDocument10 pages01 Avionics Philosophy郝帅No ratings yet

- 01 Avionics PhilosophyDocument20 pages01 Avionics Philosophy郝帅No ratings yet

- 03 - Electrical PowerDocument11 pages03 - Electrical Power郝帅No ratings yet

- 05 - Navigation SystemsDocument22 pages05 - Navigation Systems郝帅No ratings yet

- 23 LateDocument4 pages23 Late郝帅No ratings yet

- 16 - Hydraulic PowerMDocument1 page16 - Hydraulic PowerM郝帅No ratings yet

- 14 - Fuel SystemsDocument2 pages14 - Fuel Systems郝帅No ratings yet

- 21 - Water and WasteDocument5 pages21 - Water and Waste郝帅No ratings yet

- 01_Electrical Power rev1 slsDocument7 pages01_Electrical Power rev1 slsatoocloudNo ratings yet

- 13 LightingDocument3 pages13 Lighting郝帅No ratings yet

- 05 Management and Philosphy rev 1 slsDocument23 pages05 Management and Philosphy rev 1 slsatoocloudNo ratings yet

- 3_AutoFlight-Flight Controls Rev 1 slsDocument8 pages3_AutoFlight-Flight Controls Rev 1 slsatoocloudNo ratings yet

- 02_Hydraulic Power rev1 slsDocument4 pages02_Hydraulic Power rev1 slsatoocloudNo ratings yet

- Engine Systems PDFDocument5 pagesEngine Systems PDFteknikpembakaran2013No ratings yet

- 04_Navigation Systems rev1 slsDocument15 pages04_Navigation Systems rev1 slsatoocloudNo ratings yet

- 09 - Air Conditioning SystemsDocument12 pages09 - Air Conditioning Systems郝帅No ratings yet

- 07 - Communications SystemsDocument3 pages07 - Communications Systems郝帅No ratings yet

- 08_Pneumatic rev1 slsDocument2 pages08_Pneumatic rev1 slsatoocloudNo ratings yet

- 02 - Line MaintenanceDocument1 page02 - Line Maintenance郝帅No ratings yet

- CMM - 32-47-61 - Rev9 - F6137 - MENSAGENS ENGENHARIA - RDAS-2020-083 - Is.01Document272 pagesCMM - 32-47-61 - Rev9 - F6137 - MENSAGENS ENGENHARIA - RDAS-2020-083 - Is.01Bruce Polo100% (1)

- 19 - Nacelles and Thrust ReversersDocument11 pages19 - Nacelles and Thrust Reversers郝帅No ratings yet

- Operator E-Jets News Rel 039Document9 pagesOperator E-Jets News Rel 039jivomirNo ratings yet

- 06 - GSE Special ToolingDocument2 pages06 - GSE Special Tooling郝帅No ratings yet

- 30 45 00001Document6 pages30 45 00001ryan liaoNo ratings yet

- Airworthiness Directive: Federal Register Information Header InformationDocument7 pagesAirworthiness Directive: Federal Register Information Header InformationEdson Caillavi LafuenteNo ratings yet

- Dated November 12, 1984, Into A Hard Copy Service Bulletin. TheDocument15 pagesDated November 12, 1984, Into A Hard Copy Service Bulletin. Themarcfrancis.mercadoNo ratings yet

- AP737C-33-001 (-) Replacement of Relamp Identification Label For Anti Collision Winglet Strobe, 30-2849-1Document8 pagesAP737C-33-001 (-) Replacement of Relamp Identification Label For Anti Collision Winglet Strobe, 30-2849-1jlmoncadaNo ratings yet

- Engineering SupportDocument7 pagesEngineering SupportjordiNo ratings yet

- A330 Mmel Faa - Rev12Document235 pagesA330 Mmel Faa - Rev12Reynald FREYNo ratings yet

- Inability to operate cargo doors linked to EPDC LRU failuresDocument4 pagesInability to operate cargo doors linked to EPDC LRU failuresanarko arsipelNo ratings yet

- 2003 24 07Document7 pages2003 24 07Carlos MNo ratings yet

- SB 737 21 1101 01Document19 pagesSB 737 21 1101 01ramosvilledasraulNo ratings yet

- 1line Training BookletDocument50 pages1line Training BookletKshitiz Rastogi75% (4)

- Easa Ad 2010-0235R1 1Document3 pagesEasa Ad 2010-0235R1 1ohm3011No ratings yet

- EO ATR42-EO-98-374A - Aft Galley RemovalDocument8 pagesEO ATR42-EO-98-374A - Aft Galley RemovalshahzadNo ratings yet

- LEAP-1A - Oil Stains On The Fan Cowls: Purpose of This ArticleDocument3 pagesLEAP-1A - Oil Stains On The Fan Cowls: Purpose of This Articlejivomir100% (1)

- 20 OxygenDocument1 page20 Oxygen郝帅No ratings yet

- Service Bulletin: Piper Considers Compliance MandatoryDocument10 pagesService Bulletin: Piper Considers Compliance MandatoryJean AbrialNo ratings yet

- MOI - Modification Operational Impact: 34.42.00049 21-OCT-2021 21-OCT-2021 Open A350 34-42 Creation of The MOIDocument4 pagesMOI - Modification Operational Impact: 34.42.00049 21-OCT-2021 21-OCT-2021 Open A350 34-42 Creation of The MOITitoNo ratings yet

- Ds-pp-0108 - Data Sheet For Underwing Nozzle Connector (Rev.0)Document2 pagesDs-pp-0108 - Data Sheet For Underwing Nozzle Connector (Rev.0)Panisa BanimaNo ratings yet

- ABCD-GD-01-00 - Aeroplane General Description - 17.02.16 - V1Document11 pagesABCD-GD-01-00 - Aeroplane General Description - 17.02.16 - V1Edgar MartínezNo ratings yet

- 2018-19-04Document8 pages2018-19-04Juan Ruben GarciaNo ratings yet

- 622-7925-303 - PRIMARY SERVO - Aeroval®Document5 pages622-7925-303 - PRIMARY SERVO - Aeroval®amir ghaznaviNo ratings yet

- FAA AnA Tables May2020Document218 pagesFAA AnA Tables May2020namrtaNo ratings yet

- Easa Notification of A Proposal To Issue AN Airworthiness DirectiveDocument2 pagesEasa Notification of A Proposal To Issue AN Airworthiness Directivedsgarcia26No ratings yet

- Easa Ad 2020-0274 2Document4 pagesEasa Ad 2020-0274 2Evangelos KopanakisNo ratings yet

- A350 FTE Call MAR 19 2019Document5 pagesA350 FTE Call MAR 19 2019Bongyoun LeeNo ratings yet

- SB 538Document3 pagesSB 538shonuNo ratings yet

- Notification of A Proposal To Issue An Airworthiness DirectiveDocument4 pagesNotification of A Proposal To Issue An Airworthiness DirectiveBahadorNo ratings yet

- Tfu 21.52.00.021Document8 pagesTfu 21.52.00.021easwarNo ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- 05 - Navigation SystemsDocument22 pages05 - Navigation Systems郝帅No ratings yet

- 04 - AutoFlight SystemsDocument6 pages04 - AutoFlight Systems郝帅No ratings yet

- 19 - Nacelles and Thrust ReversersDocument11 pages19 - Nacelles and Thrust Reversers郝帅No ratings yet

- 03 - Electrical PowerDocument11 pages03 - Electrical Power郝帅No ratings yet

- 13 LightingDocument3 pages13 Lighting郝帅No ratings yet

- 01 Avionics PhilosophyDocument10 pages01 Avionics Philosophy郝帅No ratings yet

- RamaDocument48 pagesRamaSebastián Diez CáceresNo ratings yet

- Management Theories and Case StudyDocument5 pagesManagement Theories and Case StudyStephanie KrystelNo ratings yet

- Redhaired Mummies and Giants of The United StatesDocument7 pagesRedhaired Mummies and Giants of The United StatesMaria StancanNo ratings yet

- Introduction To Chemotherapy: A Presentation For Patients and FamiliesDocument55 pagesIntroduction To Chemotherapy: A Presentation For Patients and FamiliesjjNo ratings yet

- 4CC Carrier Aggregation - AlexDocument19 pages4CC Carrier Aggregation - Alexel yousfiNo ratings yet

- FC Sem 3 Science in Every Day LifeDocument12 pagesFC Sem 3 Science in Every Day LifeHamza GhadiallyNo ratings yet

- Aptitude Test InfosysDocument216 pagesAptitude Test InfosysJose PrakashNo ratings yet

- Gordon 2009 CatalogDocument68 pagesGordon 2009 Catalogpolanck100% (3)

- Schools of Criminology A Comparative AnalysisDocument9 pagesSchools of Criminology A Comparative AnalysisSudeep MishraNo ratings yet

- Freud's Model of The Human Mind - Journal Psyche PDFDocument1 pageFreud's Model of The Human Mind - Journal Psyche PDFJazmen folkNo ratings yet

- Checkliste - Leistungstabelle R44 Raven IIDocument2 pagesCheckliste - Leistungstabelle R44 Raven IIAfonso Henrique Rodrigues LonghiNo ratings yet

- Sustainable Competitive AdvantageDocument49 pagesSustainable Competitive AdvantageakashniranjaneNo ratings yet

- Phy110 Lab Report 1Document1 pagePhy110 Lab Report 1Khalila KhalishaNo ratings yet

- Hasil Stok Opname Untuk Bap (Fix)Document35 pagesHasil Stok Opname Untuk Bap (Fix)WARDA NABIELANo ratings yet

- Space FactorDocument5 pagesSpace FactorRafael Yap GNo ratings yet

- Areeba Hussain Ahmed: UmmaryDocument1 pageAreeba Hussain Ahmed: UmmaryAreeba Hussain AhmedNo ratings yet

- VMP 530vhmDocument2 pagesVMP 530vhmelienai10% (1)

- A MIL Q1M8 Teacher Copy FinalDocument22 pagesA MIL Q1M8 Teacher Copy FinalIvy BarnacheaNo ratings yet

- Management Control System MODULE IDocument17 pagesManagement Control System MODULE IDr Linda Mary Simon100% (1)

- Factor Effecting RecruitmentDocument4 pagesFactor Effecting RecruitmentsogatNo ratings yet

- Infinity Users GuideDocument172 pagesInfinity Users GuideSridhar DasariNo ratings yet

- Training Project ReportDocument62 pagesTraining Project ReportGaurav Singh Bhadoriya0% (1)

- 40K Bunker TutorialDocument26 pages40K Bunker TutorialRandomizm100% (2)

- Buying PlansDocument38 pagesBuying PlansAndrea VargasNo ratings yet

- Canadian Capital Providers Guide0415Document141 pagesCanadian Capital Providers Guide0415kohinoordas2007100% (1)

- ZKTeco+Fingerprint+Scanner+SDK+Selection+Guide-Ver3 0 PDFDocument1 pageZKTeco+Fingerprint+Scanner+SDK+Selection+Guide-Ver3 0 PDFYoussefNo ratings yet

- Gantry SystemDocument4 pagesGantry SystemTh NattapongNo ratings yet

- Exploring Information Quality in Accounting Information Systems AdoptionDocument12 pagesExploring Information Quality in Accounting Information Systems AdoptionJusteen BalcortaNo ratings yet