Professional Documents

Culture Documents

Wadhwa 2006

Wadhwa 2006

Uploaded by

Kini FamilyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wadhwa 2006

Wadhwa 2006

Uploaded by

Kini FamilyCopyright:

Available Formats

Zero Steady State Current Power-on-Reset Circuit with Brown-Out Detector

Sanjay Kumar Wadhwa1, G.K. Siddhartha2, Anand Gaurav3

Freescale Semiconductor India Pvt. Ltd.

1

sanjay.wadhwa@freescale.com, 2siddhartha.gk@freescale.com, 3anand.gaurav@freescale.com

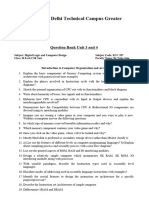

Abstract 2.1 Detector Circuit

A novel Power on reset (POR) circuit with Brown In Fig. 1, the detector circuit in the POR portion

out (BO) detector having zero steady state current consists of a resistor divider R1, R2 & Rds of PMOS

consumption is proposed. The circuit has been transistor M1 followed by two inverters INV1 and

designed in 65nm CMOS process at a single supply of INV2.

1.1V. Both the POR and BO thresholds are Voltage at node d1 is given as

independently adjustable in the circuit. Simulation R2

results show that the POR threshold does not depend V(d1) = VDD (1)

upon the supply ramp-rate at fixed process and R1 + R2 + R ds

temperature corner. BO circuit works for a large Fig. 3 shows the simulation waveforms of the POR

range of supply ramp down rates. Due to zero steady detector circuit with VDD ramp-rate equal to 500us,

state current consumption, the proposed circuit is well ramping up from 0 to 1.1V. As VDD starts rising from

suited for low power applications. 0V, initially node d1, output of the detector, det_out

and gate of M1, det_en are at 0V (low) and node d2

1. Introduction follows VDD. As VDD crosses threshold voltage (Vthp)

of M1, V(d1) starts rising. When V(d1) crosses the trip

Low power design has been a topic of interest of voltage of the inverter INV1, node d2 goes low. As a

researchers and designers that has compelled the result, node det_out goes high and starts following

industry to produce circuit designs with very low VDD. Thus, det_out remains low till VDD crosses the

supply voltage and current consumption. POR and BO trip voltage of INV1. The VDD voltage at which

detector circuits are an integral part in today’s System det_out goes high is called POR de-assertion threshold.

on Chip (SoC) designs. A POR circuit provides a reset Both Rds of M1 and trip voltage of INV1 vary with

signal to the chip when supply ramps up so that the process corner and temperature and therefore, POR de-

chip always starts in a known state [1]. A BO detector assertion threshold will vary with process corner and

provides reset signal to the chip when the chip supply temperature. The RC time constant of V(d1) rise will

voltage falls below a level required for its reliable be very low as compared to the VDD ramp up rate due

operation. Resetting of the chip in BO event avoids any to very low capacitance at node d1 (only the gate

unpredictable behavior of the overall system. capacitance of INV1 will be present ). Due to low RC

Normally, two separate circuits are employed to time constant at node d1, det_out will go high at the

generate POR and BO reset signals so as to have same voltage determined by the process corner and

independent control over POR and BO thresholds. The temperature at different VDD ramp up rates. Thus, the

proposed circuit works both as a POR and BO detector POR de-assertion threshold will remain constant at

with independently adjustable thresholds, with wide different VDD ramp up rates.

supply ramp up and ramp down rates without

consuming any steady state current [2, 3]. 2.2 Pulse latch circuit

2. Circuit Diagram The pulse latch circuit in the POR portion of the

proposed circuit shown in Fig. 1 latches the detector

The proposed circuit is shown in Fig. 1. The POR output, det_out rising edge. In pulse latch circuit,

and the BO portions of the circuit are shown with det_out is connected to source of PMOS transistor M2.

dashed outlines.

Proceedings of the 19th International Conference on VLSI Design (VLSID’06)

1063-9667/06 $20.00 © 2006 IEEE

Fig. 1. Proposed POR and BO detector circuit

As VDD starts rising from 0V, node PL5 starts turns off M2. With det_en high, M1 turns off, shutting

following it because C0 (Poly-Nwell Cap) maintains the direct current path through it and bringing node

the initial voltage difference (0V) across it. The trip det_out to low. Since M2 is already off, this low

voltages of INV4 and INV6 are kept low (~200mV) to transition at node det_out does not propagate through

quickly bring node PL1 and node latch_out low. Node the pulse latch circuit to the POR output.

PL3, connected to the gate of M2, also goes low and With M2 being off, node PL4 becomes floating and

M2 is turned on. As node latch_out goes low, INV5 may slowly discharge by the leakage current of M2. If

also starts charging node PL5 due to latch action. V(PL4) discharges below the trip voltage of INV3,

As shown in the simulation results in Fig. 4, during node PL5 will go high and por_out_b will go low,

VDD ramp up, initially, det_out and pulse latch output, asserting the POR again. This will reset the chip and

latch_out are low. Voltage at node latch_out is cause malfunctioning. To avoid this situation, an

buffered by a chain of buffers to generate voltage at NMOS transistor M3 with drain, gate and source

node det_en and at POR output, por_out_b. Thus, till connected to VDD, node latch_out and node PL4

the time node latch_out remains low, both node det_en respectively has been added. When node latch_out

and por_out_b remain low. In this condition, POR goes high, M3 turns on and pulls node PL4 to VDD -

remains asserted and chip remains in reset state. As Vthn where Vthn is the threshold voltage of M3.

VDD exceeds the POR de-assertion threshold, node Therefore, node PL4 will never discharge below VDD

det_out goes high and start following VDD as shown – Vthn ensuring that node por_out_b will remain high.

in Fig. 3. Since M2 is on, node PL4 also goes high. During VDD ramp up, node PL4 starts rising due to

Thus, INV3 trips, node PL5 goes low and node gate to source capacitance (Cgs) of PMOS transistor in

latch_out, det_en and POR output, por_out_b go high. INV3. If V(PL4) rises above the trip voltage of INV3,

Node PL3 goes high after 3 inverter delays after node node PL5 will go low, node latch_out and node

PL5 goes low (delay of INV6, INV7 and INV8) and por_out_b will go high. Thus, POR output, por_out_b

Proceedings of the 19th International Conference on VLSI Design (VLSID’06)

1063-9667/06 $20.00 © 2006 IEEE

will go high even before VDD has crossed the POR de- M4 goes into cutoff. However, due to leakage currents,

assertion threshold. To avoid this condition of false V(cap_vdd) starts discharging but capacitor C1 slows

POR de-assertion, a small value (~100f F) capacitor C2 down the rate of discharge of cap_vdd.

(Poly-Nwell Cap) has been placed between node PL4 During BO event, when VDD drops below V(cap_vdd)

and VSS. Capacitor C2 forms a voltage divider with by more than Vthp of PMOS transistor M5, it turns on

Cgs of PMOS transistor in INV3. Due to C2, V(PL4) and pulls node g1 towards cap_vdd ( M6 is kept very

does not rise beyond the trip voltage of INV3 and node weak to enable sufficient charging of node g1) and

latch_out remains low, preventing false POR de- subsequently, node PL4, node latch_out are pulled low

assertion condition. and node PL5 is pulled high towards cap_vdd. This

initiates a positive feedback action in latch composed

2.3 BO detector circuit of INV4 and INV5 and POR output, por_out_b goes

low.

The BO detector circuit shown in Fig. 1 works on A high value resistor can also be used in place of M4

the principle of storing charge on a capacitor to be to charge C1. The advantage of having a resistor in

utilized during brown out event. During supply brown place of M4 would that it will charge cap_vdd to full

out, this stored charge is used to pull-up or pull-down value of VDD. The RC time constant of diode

different POR internal nodes so that POR output, connected M4 and C1 will determine the slowest BO

por_out_b goes low. The circuit has a diode connected rate that can be detected.

PMOS transistor M4 with source connected to VDD

and gate-drain connected to capacitor C1 (Poly-Nwell 3. Simulation results

Cap) at node cap_vdd. When VDD ramps-up to its full

voltage, cap_vdd is charged at least to (VDD-Vthp) Fig. 3 and Fig. 4 show the simulation results of

through M4 and node g1 is pulled low by NMOS only the POR detector circuit and pulse latch circuit

transistor M6. In this condition, NMOS transistors M7, respectively, with VDD ramping up from 0V to 1.1V

M8 and PMOS transistor M9 are off. The drain of M7, in 500us. The simulation results in Fig. 3 and Fig. 4

M8 and M9 are connected to node PL4, node latch_out have been explained in section 2.1 and 2.2.

and node PL5 respectively. Depending upon the Fig. 5 and Fig. 6 show the simulation results of

number of nodes needed to be pulled high or pulled complete circuit shown in Fig. 1 with VDD ramp up

low in POR circuit during BO event, the number of rates of 10us and 25ms respectively at TYP corner,

outputs from BO circuit can be selected. This property 25C. For the sake of clarity, only POR action has been

of proposed BO detector circuit makes it generic in shown in Fig. 5 and Fig. 6.

nature and it can be used with different types of POR

circuits. BO circuit with multiple pull-up and pull-

down outputs is shown in Fig. 2.

Fig. 3. POR detector simulation results with VDD

Fig. 2. BO Detector Circuit with multiple pull-up ramp-rate = 500us

and pull-down outputs

When VDD is stable, the BO detector does not

consume any leakage current because all the current

paths from VDD to VSS are off. During a BO event,

when VDD drops below V(cap_vdd) , PMOS transistor

Proceedings of the 19th International Conference on VLSI Design (VLSID’06)

1063-9667/06 $20.00 © 2006 IEEE

It is clear from Fig. 5 and Fig. 6 that POR assertion and

de-assertion voltages are nearly same for 10us and

25ms VDD ramp up rates. This feature greatly

enhances the reliability of chip power up for different

VDD ramp up rates. It is also clear from Fig. 5 and

Fig. 6 that after POR action is over, the current

consumption of the proposed circuit is almost zero in

steady state. Only leakage current of the order of nA

flow in the circuit because in all the constituent

modules of the proposed circuit, direct current paths

from VDD to VSS are off after POR output, por_out_b

is de-asserted.

Fig. 7 and Fig. 8 show the simulation results of

complete circuit shown in Fig. 1 with brown out event.

In Fig. 7 and Fig. 8, VDD falls to 250mV from 1.1V in

1us and 25ms respectively and ramps up again to 1.1V

Fig. 4. Pulse latch simulation results with VDD in 10us. These simulation results are also at TYP

ramp-rate 500us corner, 25C.

Fig. 5. Simulation results showing POR action with

VDD ramp-rate = 10us

Fig. 7. Simulation results showing BO detection

with VDD ramp down rate during BO = 1us

In Fig. 7, node cap_vdd is at about 780mV before BO

event and drops to about 750mV during BO event due

Fig. 6. Simulation results showing POR action with

to charging of node g1 and node PL5. POR output,

VDD ramp-rate = 25ms

por_out_b is pulled low and as VDD ramps up again, it

Proceedings of the 19th International Conference on VLSI Design (VLSID’06)

1063-9667/06 $20.00 © 2006 IEEE

goes high after VDD crosses POR de-assertion VDD is ramped up from 0V to 1.1V in the given ramp

threshold. up time. It is apparent from Table 1 that POR de-

In Fig. 8, node cap_vdd starts decreasing with VDD assertion threshold remains almost constant for a wide

ramp down because of slow VDD ramp down rate in range of VDD ramp up rates (10us to 25ms) across

BO event. Before BO event, node cap_vdd is charged different process and temperature corners.

to about 850mV because of large time given for it to Table 2 shows the BO detect thresholds across

settle as compared to Fig. 7. As VDD falls to 250mV, different process and temperature corners at different

POR output, por_out_b goes low and again goes high VDD ramp down rates. The ramp down rates for VDD

when VDD crosses the POR de-assertion threshold. during BO event was varied from 10us to 25ms from

The ramp down rate of node cap_vdd voltage with 1.1V to 0V. It is apparent from Table 2 that the BO

VDD ramp down can be reduced by increasing the threshold decreases with the increase in VDD ramp

capacitor value C1 and/or by increasing the resistance down rate. At slow VDD ramp down during BO event,

(Rds) of diode connected transistor M4. The value of the BO threshold decreases because voltage on node

C1 and Rds determine the maximum time in which cap_vdd decreases much faster which makes it more

VDD can ramp down during BO event. The larger the difficult to charge node g1 and node PL5.

time required, the larger should be the value of C1 and

Rds. Table 2: BO detector thresholds across process and

temperature corners at different VDD ramp down

rates

Corner VDD ramp down rate during BO event

(VDD = 1.1V) 10us 1ms 25ms

Typ_fet, 25C 475m 352m 247m

wcs_4sig_fet,

546m 333m 217m

105C

bcs_4sig_fet,

445m 349m 264m

-25C

4. Design methodology

Equation (1) shows the voltage at node d1 which

Fig. 8. Simulation results showing BO detection is a fraction of VDD value. The fraction depends upon

with VDD ramp down rate during BO = 25ms the values of R1, R2 and Rds of M1 in detector circuit.

The POR will assert itself, i.e. will remain low till

Table 1 shows the POR de-assertion thresholds at V(d1) crosses the trip voltage of inverter INV1.

different VDD ramp up rates across different process Therefore, depending upon the value of POR de-

and temperature corners. Worst case (wcs) and best assertion voltage required, the values of R1, R2 and Rds

case (bcs) process parameters with 4-sigma variation of M1 and trip voltage of inverter INV1 should be

have been taken. decided. Trip voltage of INV1 can be adjusted by the

sizes of PMOS and NMOS transistors in INV1.

Table 1: POR de-assertion thresholds across The BO detector threshold depends upon the RC time

different process and temperature corners at constant of C1 and Rds of M4 and should be chosen

different VDD ramp up rates depending upon the slowest VDD ramp down rate

required. The sizes of M5 and M9 will also decide the

Corner VDD ramp up rate BO threshold. For higher BO threshold, sizes of M5

(VDD = 1.1V) 10us 1ms 25ms and M9 should be large and vice-versa. The large sizes

of M5 and M9 would charge node g1 and PL5 and

Typ_fet, 25C 763m 732m 730m discharge node PL4 faster, resulting in higher BO

threshold.

wcs_4sig_fet,

791m 765m 763m Table 3 shows the sizes of the transistors and value of

105C

the capacitors used in the proposed circuit shown in

bcs_4sig_fet,

721m 695m 693m Fig. 1. These sizes have been obtained for a typical

-25C

Proceedings of the 19th International Conference on VLSI Design (VLSID’06)

1063-9667/06 $20.00 © 2006 IEEE

POR de-assertion threshold of 750mV and typical BO b) Both POR and BO circuits work for large variation

threshold of 450mV at 1.1V VDD voltage. in VDD ramp up and ramp down rates.

c) Very low variation in POR de-assertion threshold

Table 3: Sizes of devices in the proposed circuit occurs at different VDD ramp rates at particular

process and temperature corner.

Device Device

d) Zero steady sate current consumption makes the

Size Size( W/L) circuit ideal for low power applications.

Name Name

1.2u/0.06u

C1 20pF INV3/PMOS

(X2)

6. References

1.0u/0.06u

M1 0.8u/0.24 INV3/NMOS [1] Yasuda, T.R.; Yamamoto, M.; Nishi, T. “A power on

(X2)

reset pulse generator for low voltage applications”, IEEE

M2 0.3u/0.2u INV4/PMOS 0.12u/0.09u ISCAS 2001, Volume 4, 6-9 May 2001, pp 598 – 601.

M3 0.5u/0.06u INV4/NMOS 1.0u/0.06u

[2] Gola et. Al, “Power on Reset circuit having a low static

M4 0.3u/5u INV4/NMOS 1.0u/0.06u

power consumption”, US patent 5528184, Jun. 18, 1996.

M5 3u/0.16u INV4/NMOS 1.0u/0.06u

M6 0.5u/3.0u INV5/NMOS 0.5u/0.06u [3] Gubbins, “Brown-Out Detector”, US patent 2004 /

0239413 A1, Dec. 2, 2004.

M7 4.0u/0.1u INV5/NMOS 0.12u/0.06u

M8 4.0u/0.1u INV6/NMOS 0.32u/0.06u

M9 0.12u/0.12u INV7/NMOS 0.32u/0.06u

INV1/PMOS 0.4u/0.06u INV7/NMOS 0.23u/0.06u

INV1/NMOS 0.2u/0.06u INV8/NMOS 0.32u/0.06u

INV2/PMOS 0.5u/0.06u (X2) R1 10K

INV2/NMOS 0.5u/0.06u (X2) R2 25K

C2 100f - -

Fig. 9 shows the layout of the proposed POR with BO

circuit. The circuit consumes a total die size of only

120umX60um.

Fig. 9. Layout of the proposed circuit (120um X

60um)

5. Conclusion

A novel POR with BO detector circuit with zero

steady state current has been proposed. Simulation

results show that

a) The design is able to work at low supply voltage,

down to 1.1V

Proceedings of the 19th International Conference on VLSI Design (VLSID’06)

1063-9667/06 $20.00 © 2006 IEEE

You might also like

- Alfred Crouch - Design-For-Test For Digital IC's and Embedded Core Systems-Prentice Hall (1999)Document378 pagesAlfred Crouch - Design-For-Test For Digital IC's and Embedded Core Systems-Prentice Hall (1999)mohamed oubellaNo ratings yet

- Ler para CCIDocument114 pagesLer para CCIjonas1446No ratings yet

- Voltage References and BiasingDocument15 pagesVoltage References and BiasingSintherNo ratings yet

- Mini Project Report (CLAP SWITCH)Document22 pagesMini Project Report (CLAP SWITCH)Om Prakash Singh100% (4)

- Uncontrolled RectifierDocument18 pagesUncontrolled RectifierM. IslamNo ratings yet

- Diode and Its ApplicationsDocument39 pagesDiode and Its ApplicationsUsama Sidhu100% (1)

- Unit 2 CMOS InverterDocument14 pagesUnit 2 CMOS InverterHarsh kumarNo ratings yet

- Diode CktsDocument30 pagesDiode CktsUday RaiNo ratings yet

- Unit 5Document6 pagesUnit 5Tarun SinghalNo ratings yet

- CD4049/CD4050: 7400 V 7400 Inputs 7400 Output CD4050 V CD4050 in CD4050 OutDocument11 pagesCD4049/CD4050: 7400 V 7400 Inputs 7400 Output CD4050 V CD4050 in CD4050 OutBobyNo ratings yet

- EC8261-Circuits and Devices LaboratoryDocument60 pagesEC8261-Circuits and Devices LaboratoryNandha KumarNo ratings yet

- Diode-Transistor Logic: Figure 4.1: A DTL NOR GateDocument7 pagesDiode-Transistor Logic: Figure 4.1: A DTL NOR Gateeng_magdyNo ratings yet

- Group 1 Experiment 3 1905063Document20 pagesGroup 1 Experiment 3 1905063Kazi Istiak Uddin ToriqeNo ratings yet

- Assignment 4Document10 pagesAssignment 4Arnon PukhrambamNo ratings yet

- Disenio LDODocument5 pagesDisenio LDOmarta fakeNo ratings yet

- Self Oscillating Flyback ConverterDocument7 pagesSelf Oscillating Flyback ConverterNaren DranNo ratings yet

- CMOS Logic FamilyDocument6 pagesCMOS Logic FamilyAjay GeorgeNo ratings yet

- Second Order EffectsDocument40 pagesSecond Order EffectsDhiraj Kumar100% (2)

- LPVLSI Unit 2 NotesDocument51 pagesLPVLSI Unit 2 NotesSai Sreeja100% (2)

- M.ABDULLAH FA19-BEE-110 Electronic 1 Lab 2 PDFDocument12 pagesM.ABDULLAH FA19-BEE-110 Electronic 1 Lab 2 PDFAtyia JavedNo ratings yet

- Chapter 09 Phase-Locked LoopsDocument82 pagesChapter 09 Phase-Locked LoopsMuresan GabrielNo ratings yet

- 114 - Fig 2 - PCB Layout (Nov 12) - 1kW SinewaveDocument1 page114 - Fig 2 - PCB Layout (Nov 12) - 1kW Sinewaveolumide100% (1)

- EE-215 Lecture 10, 11 Zener Diode, RectifierDocument24 pagesEE-215 Lecture 10, 11 Zener Diode, RectifierMazoon ButtNo ratings yet

- PLL B B: Description FeaturesDocument8 pagesPLL B B: Description FeaturesfaheinzNo ratings yet

- Lecture #8Document20 pagesLecture #8Teshome GirmaNo ratings yet

- Constant-Current Batter Char Er: IdeasDocument54 pagesConstant-Current Batter Char Er: IdeasKliffy Fernandes100% (1)

- Eldas - PRN - Aplikasi DiodaDocument43 pagesEldas - PRN - Aplikasi DiodanofiarozaNo ratings yet

- Lab 4 Diode Characteristics BBN 10205 (Done)Document5 pagesLab 4 Diode Characteristics BBN 10205 (Done)Zhamir ZhakwanNo ratings yet

- Snubber Circuits With ExplantionDocument9 pagesSnubber Circuits With ExplantioncoolsinghrkNo ratings yet

- Lec11 DiodesDocument59 pagesLec11 DiodescgchydtrainingNo ratings yet

- Chapter 2 - Diode Circuits (Clippers)Document12 pagesChapter 2 - Diode Circuits (Clippers)Devaraj VignesvaranNo ratings yet

- Study of Logic Gates: AnswersDocument5 pagesStudy of Logic Gates: AnswersPinakiRanjanSarkarNo ratings yet

- PE Lab Exp.4Document6 pagesPE Lab Exp.4sethyashis456No ratings yet

- EDC Lab ManualDocument102 pagesEDC Lab Manualvarshakarthika04No ratings yet

- Infineon-Application Note Applications For Depletion MOSFETs-An-V01 00-EnDocument13 pagesInfineon-Application Note Applications For Depletion MOSFETs-An-V01 00-EnP.r. Nuwan TharakaNo ratings yet

- Diode ApplicationsDocument20 pagesDiode ApplicationsOnoda SakamichiNo ratings yet

- 3rd LectureDocument40 pages3rd LectureAnasNo ratings yet

- Constant Current ChargerDocument3 pagesConstant Current ChargerchakralabsNo ratings yet

- NAND Gate DDL Complete PDFDocument4 pagesNAND Gate DDL Complete PDFSarkaraliNo ratings yet

- Fire Leakage Indicator: Pin Name PurposeDocument7 pagesFire Leakage Indicator: Pin Name Purposethasarathanr1993_939No ratings yet

- Edc Lab Exp 1aand1bDocument10 pagesEdc Lab Exp 1aand1bJames TonyNo ratings yet

- Lesson 3 - Electronics1Document30 pagesLesson 3 - Electronics1Ron Neil MicosaNo ratings yet

- Experiment No. 07Document4 pagesExperiment No. 07Ishrak MohammadNo ratings yet

- Chapter-1 Objective: 1.1 Objective of The ProjectDocument23 pagesChapter-1 Objective: 1.1 Objective of The ProjectPrashanth CooldudeNo ratings yet

- Electronics Lab 2019Document37 pagesElectronics Lab 2019Noor HussainNo ratings yet

- ppt-FETs & Other ComponentsDocument33 pagesppt-FETs & Other Componentsramya hegdeNo ratings yet

- Yashwant HDocument37 pagesYashwant HRohitUikeyNo ratings yet

- Edc Studentmanual 16-17Document90 pagesEdc Studentmanual 16-17balasubramanyam200517No ratings yet

- Buck ConvertersDocument15 pagesBuck Convertersחי לוגסיNo ratings yet

- 3rd Semester Lab 201Document36 pages3rd Semester Lab 201Noor HussainNo ratings yet

- Lecture 2Document24 pagesLecture 2faisal140No ratings yet

- UntitledDocument11 pagesUntitledJohn Mickelson FaustinoNo ratings yet

- Clipper and Clamper Circuits PPT 2Document16 pagesClipper and Clamper Circuits PPT 2Muhammad SohailNo ratings yet

- Buck BoostDocument5 pagesBuck BoostSyed Zeeshan Ali ZaidiNo ratings yet

- Sboa 383Document6 pagesSboa 383王政雄No ratings yet

- Diode Circuits and Applications Part 2Document32 pagesDiode Circuits and Applications Part 2Allen DagsilNo ratings yet

- Clippers NJHGDocument25 pagesClippers NJHGIjaz TalibNo ratings yet

- 555 IcDocument5 pages555 IcNabeel MuqarrabNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- NPIDocument34 pagesNPIMiguel GrandeNo ratings yet

- Characteristics of DSPDocument15 pagesCharacteristics of DSPParesh SawantNo ratings yet

- Dynamic Power DissipationDocument19 pagesDynamic Power DissipationKhilawan ChoudharyNo ratings yet

- Computer Architecture NotesDocument320 pagesComputer Architecture NotesgireeshkrNo ratings yet

- FSM Case StudiesDocument49 pagesFSM Case StudiespaldarjiNo ratings yet

- Fpga Ds 02008 2 2 Ice40 Ultraplus Family Data SheetDocument51 pagesFpga Ds 02008 2 2 Ice40 Ultraplus Family Data SheetyayaNo ratings yet

- Advanced Driver Assistance (ADAS) Solutions GuideDocument29 pagesAdvanced Driver Assistance (ADAS) Solutions GuideDharmody0% (1)

- End-SemEC101 22Document4 pagesEnd-SemEC101 22PLAY LYRICSNo ratings yet

- Bit 101 Reviewer Group 1-5Document10 pagesBit 101 Reviewer Group 1-5Cleofe Jane PatnubayNo ratings yet

- Solution MT 2 April 16 Spring 2022 NSUDocument13 pagesSolution MT 2 April 16 Spring 2022 NSUziniaafrin1988No ratings yet

- Wp406 DSP Design ProductivityDocument14 pagesWp406 DSP Design ProductivityStar LiNo ratings yet

- Silver Oak College of Engineering and Technology: Computer Organization Module Solution - 4Document11 pagesSilver Oak College of Engineering and Technology: Computer Organization Module Solution - 4sodutuNo ratings yet

- 4x4 Matrix Membrane Keypad v1.2Document5 pages4x4 Matrix Membrane Keypad v1.2pierdonneNo ratings yet

- Lab 1: Introduction To Combinational Design: EquipmentsDocument42 pagesLab 1: Introduction To Combinational Design: EquipmentsnarpatzaNo ratings yet

- CY7C63000 CY7C63001 CY7C63100 CY7C63101 CY7C63200 CY7C63201 Universal Serial Bus MicrocontrollerDocument28 pagesCY7C63000 CY7C63001 CY7C63100 CY7C63101 CY7C63200 CY7C63201 Universal Serial Bus MicrocontrollerMarcelo PerezNo ratings yet

- VLSI& Embedded - MCQ's - 21 - 30Document5 pagesVLSI& Embedded - MCQ's - 21 - 30rohi89No ratings yet

- Various Addressing Modes of 8086 - 8088Document3 pagesVarious Addressing Modes of 8086 - 8088NeelmaniNo ratings yet

- RD2kit Examples enDocument14 pagesRD2kit Examples enLim Yoon-hwanNo ratings yet

- CH - 14 - Instruction Level Parallelism and Superscalar ProcessorsDocument42 pagesCH - 14 - Instruction Level Parallelism and Superscalar ProcessorsGita RamdhaniNo ratings yet

- Design of Very Large Scale Integration CircuitsDocument22 pagesDesign of Very Large Scale Integration CircuitsStudentNo ratings yet

- Direct Addressing PDFDocument8 pagesDirect Addressing PDFSiamNo ratings yet

- Week 7 - Direct-Current Bridge PDFDocument43 pagesWeek 7 - Direct-Current Bridge PDFWeng YeeNo ratings yet

- ADC0809 With CKT, Flow CodeDocument8 pagesADC0809 With CKT, Flow CodeBhaskar Rao PNo ratings yet

- Peripheral DevicesDocument6 pagesPeripheral DevicesRuth MootooNo ratings yet

- 8251 USART: Universal Synchronous and Asyhnchrous Receiver and TransmitterDocument20 pages8251 USART: Universal Synchronous and Asyhnchrous Receiver and TransmitterIlan KumarNo ratings yet

- PCB Component MBI ICDocument22 pagesPCB Component MBI ICAmit BhatiaNo ratings yet

- Question of Unit 3 and 4Document3 pagesQuestion of Unit 3 and 4Ritesh Kumar100% (1)

- 9300-USBS User's Manual (English)Document13 pages9300-USBS User's Manual (English)Rodrigo Eduardo Rosales Rivera0% (1)

- DSD Module 1 - Notes 1Document95 pagesDSD Module 1 - Notes 1Abinesh RNo ratings yet