Professional Documents

Culture Documents

190326quadax Valves Coating Specifications

190326quadax Valves Coating Specifications

Uploaded by

S MhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

190326quadax Valves Coating Specifications

190326quadax Valves Coating Specifications

Uploaded by

S MhCopyright:

Available Formats

Coating Specifications

Quadax Series Butterfly Valves

Version November 2013

müller co-ax ag

Gottfried-Müller-Str. 1

74670 Forchtenberg

Germany

Tel. +49 7947 828-0

Fax +49 7947 828-11

E-Mail info@co-ax.com

Internet www.co-ax.com

Coating Specifications

Table of Contents

1 Scope 3

2 Applicable standards 3

3 Preparation 3

4 Covering 4

5 Coating preparation 4

6 Coating 4

7 Protection of non-coated surfaces 4

8 Final inspection 5

Version November 2013 Page 2/5

Coating Specifications

1 Scope

These specifications describe the passive corrosion protection through the external coating

of housing elements of QUADAX butterfly valves that do not come into contact with medium.

These specifications do not apply to butterfly valves made of rust-resistant materials that are

not coated in the standard configuration.

2 Applicable standards

Standards

Preparation of steel substrates before application of

paints and related products – Visual assessment of

EN ISO 8501-1,2 ,4 surface cleanliness

Preparation of steel substrates before application of

paints and related products – Surface roughness

EN ISO 8503 characteristics of blast-cleaned steel substrates

Paints and varnishes – Corrosion protection of steel

EN ISO 12944 structures by protective paint systems

Preparation of steel substrates before application of

EN ISO 11124 paints and related products

EN ISO 2808 Paints and varnishes – Determination of film thickness

DIN EN 10204 Iron ores - types of test coatings

Non-conductive coatings on non-magnetic electrically

conductive basis materials – Measurement of coating

EN ISO 2360 thickness – Amplitude-sensitive eddy-current method

Paints and varnishes – Evaluation of degradation of

coatings – Designation of quantity and size of defects,

EN ISO 4628 and of intensity of uniform changes in appearance

DIN EN 13463 Non-electrical devices for use in explosive areas

RAL National Committee for Delivery Conditions Color-Coding

DIN color cards, DIN color card for the 2° standard

DIN 6164 observer

3 Preparation

‐ All soil and loose particles must be removed from the surfaces to be coated.

‐ The surfaces to be coated must be free from oil and grease.

‐ If necessary, roughen or blast the surfaces to be coated.

‐ Components requiring coating are painted on the fully assembled valve.

Version November 2013 Page 3/5

Coating Specifications

4 Covering

The following parts of the valve are coated:

‐ Body (partially)

‐ Cover plate incl. screws

‐ gland follower incl. screws

The following need to be covered:

‐ Flange sealing surfaces on body

‐ Welding stubs of housing (welding version)

‐ Shaft incl. key

Any actuators mounted to the valve are not coated.

5 Coating preparation

‐ The parts to be coated must be at least 5° above the dew point

‐ Relative humidity must be below 80%

‐ The temperature of the parts to be coated must be between10°C and 35°C.

6 Coating

‐ One-component silicone resin varnish (cover coating material) and conventional

atomizing spray are applied to the surface.

‐ The varnish has a single-layer structure and a minimum dry film thickness of

50 µm.

7 Protection of non-coated surfaces

‐ The coverings of non-coated surfaces must be removed

‐ Any adhesive residues must be removed

‐ Non-coated surfaces such as flange sealing surfaces must be protected against

corrosion with suitable measures (e.g. greasing) prior to installation.

Version November 2013 Page 4/5

Coating Specifications

8 Final inspection

‐ A final inspection of the coating of the valves is to be performed on a random-basis.

‐ The total thickness is to be inspected in line with DIN ISO 2808

‐ The total thickness may not be less than 80% of the specified coat thickness at any

point

‐ The total thickness may not exceed 250% of the specified coat thickness at any point

‐ The quality of the surface is to be inspected in line with EN ISO 4628

‐ The color must be inspected in line with RAL or DIN 6164

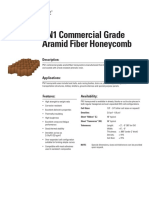

The coating is designed for corrosion protection for warm and

hot steel surfaces, for interior area as sole coating as well as

Description

for outdoor weathering in rural, urban and industrial

atmospheres.

Minimum permissible

-20°C

duration - temperature

Maximum permissible

+500°C

duration - temperature

Maximum temporary

+600°C

permissible temperature

Corrosion class No official corrosion class

Expected duration of

5 years (no liability)

corrosion protection

Materials for coating Ferrous materials such as steel and cast steel

Pretreatment of surface See specification

Topcoat 1-component silicon-resin varnish

Topcoat color Silver ( Alu ) matt

Topcoat dry film thickness 50 µm

EN ISO 8501-1, 2 ,4 / EN ISO 8503 / EN ISO 12944 / EN

Applicable standards ISO 11124 / EN ISO 2808 / DIN EN 10204 / EN ISO 2360 /

EN ISO 4628 / DIN EN 13463 / RAL / DIN 6164

Version November 2013 Page 5/5

You might also like

- TL 256 en 2022Document8 pagesTL 256 en 2022Michal BílekNo ratings yet

- Design of An Industrial TrussDocument15 pagesDesign of An Industrial Trussammarsteel68No ratings yet

- Painting Scheme StructureDocument10 pagesPainting Scheme StructureVeerapandianNo ratings yet

- Aquatherm Training Manual 2011Document48 pagesAquatherm Training Manual 2011Dana LoreNo ratings yet

- Engineering Materials Note by Me For Ctevt-1Document20 pagesEngineering Materials Note by Me For Ctevt-1VedhPrakas Gupta71% (7)

- Significant Changes in AWWA D100-11Document6 pagesSignificant Changes in AWWA D100-11Leslie Scott100% (4)

- Coating Spec 01 PDFDocument5 pagesCoating Spec 01 PDFWINNo ratings yet

- 111011quadax Spezifikation Beschichtung enDocument5 pages111011quadax Spezifikation Beschichtung enjkhgvdj mnhsnjkhgNo ratings yet

- TL 262 EnglischDocument4 pagesTL 262 Englischjsantos_865904No ratings yet

- 03 - Paint Spec - Added - FDC 25KDocument15 pages03 - Paint Spec - Added - FDC 25KJIM CAMPBELLNo ratings yet

- Barrier: Technical Data Sheet Application GuideDocument8 pagesBarrier: Technical Data Sheet Application GuideNurmalinda SihombingNo ratings yet

- G16S-0205-01 - Repair Hot Drip Galv SurfaceDocument5 pagesG16S-0205-01 - Repair Hot Drip Galv Surfacepuwarin naja100% (1)

- Barrier 77: Technical Data Sheet Application GuideDocument8 pagesBarrier 77: Technical Data Sheet Application GuideNurmalinda SihombingNo ratings yet

- Attachment: Painting ProcedureDocument79 pagesAttachment: Painting ProcedureOmar Wardeh100% (2)

- Barrier: Technical Data Sheet Application GuideDocument8 pagesBarrier: Technical Data Sheet Application GuideANIBALLOPEZVEGANo ratings yet

- Barrier 80: Technical Data Sheet Application GuideDocument8 pagesBarrier 80: Technical Data Sheet Application GuideAyman JadNo ratings yet

- Resist 78: Technical Data Sheet Application GuideDocument7 pagesResist 78: Technical Data Sheet Application GuideMohd YusriNo ratings yet

- 8474l-000-Jsd-2310-001-2-Protective CoatingDocument31 pages8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- AG 7740 Tankguard SF Euk GBDocument11 pagesAG 7740 Tankguard SF Euk GBChandran NairNo ratings yet

- Surface Protection External Coating of Claas ProductsDocument1 pageSurface Protection External Coating of Claas ProductsTomaszNo ratings yet

- Rukovodstvo Po NaneseniyuDocument11 pagesRukovodstvo Po NaneseniyugustinugrahaNo ratings yet

- Tankguard Zinc AGDocument10 pagesTankguard Zinc AGKev RushNo ratings yet

- AG 2521 Barrier Euk GBDocument9 pagesAG 2521 Barrier Euk GBDoni RandanuNo ratings yet

- Barrier 77 PDFDocument8 pagesBarrier 77 PDFRizki AhmadNo ratings yet

- 8474L-000-JSD-2310-001-4-Protective Coatings PDFDocument31 pages8474L-000-JSD-2310-001-4-Protective Coatings PDFDo Quynh100% (2)

- Coating Specification: 1. ScopeDocument4 pagesCoating Specification: 1. ScopeThaiminh Vo100% (2)

- Barrier 65: Technical Data Sheet Application GuideDocument8 pagesBarrier 65: Technical Data Sheet Application Guidesabari ramasamyNo ratings yet

- Solvalitt Alu: Technical Data Sheet Application GuideDocument9 pagesSolvalitt Alu: Technical Data Sheet Application GuideEngTamerNo ratings yet

- Working Procedure For Coating Repair C4Document7 pagesWorking Procedure For Coating Repair C4tuyen nguyenNo ratings yet

- Screenshot 2023-05-20 at 14.51.58Document8 pagesScreenshot 2023-05-20 at 14.51.58morisNo ratings yet

- Barrier - 80 - Product - Description - Technicad HL PDFDocument8 pagesBarrier - 80 - Product - Description - Technicad HL PDFDimas BatamNo ratings yet

- Material SpecificationDocument10 pagesMaterial SpecificationMuthu GaneshNo ratings yet

- Chemflake Special AGDocument9 pagesChemflake Special AGAnantha PadmanabhanNo ratings yet

- 20 Korrosionsschutz enDocument4 pages20 Korrosionsschutz enNenad DeusicNo ratings yet

- 02-02 - Paint and Protective CoatingsDocument43 pages02-02 - Paint and Protective CoatingsFolayemiNo ratings yet

- Application Guide Barrier 80Document8 pagesApplication Guide Barrier 80adeoye_okunoyeNo ratings yet

- Penguard Express Application GuideDocument10 pagesPenguard Express Application GuidenizamuddinNo ratings yet

- Barrier ZEP: Technical Data Sheet Application GuideDocument7 pagesBarrier ZEP: Technical Data Sheet Application GuideNurmalinda SihombingNo ratings yet

- Chemflake Special Application GuideDocument10 pagesChemflake Special Application GuideMohanadNo ratings yet

- Standard Specification For Hot Dip GalvanizingDocument6 pagesStandard Specification For Hot Dip GalvanizingKrunal PanchalNo ratings yet

- Exico Paint SpecificationDocument5 pagesExico Paint SpecificationFredy Xavier DomínguezNo ratings yet

- Tender Specification Trimdec - Coastel (Ultra)Document1 pageTender Specification Trimdec - Coastel (Ultra)Dushan Lalithya Gamaethige100% (1)

- AG Penguard Universal GB English ProtectiveDocument14 pagesAG Penguard Universal GB English ProtectiveajuhaseenNo ratings yet

- Tankguard Storage: Technical Data Sheet Application GuideDocument14 pagesTankguard Storage: Technical Data Sheet Application GuideEngTamerNo ratings yet

- Iso 08502-4Document24 pagesIso 08502-4Akram DriraNo ratings yet

- Painting SpecDocument10 pagesPainting SpecTroy HooperNo ratings yet

- Data Ketebalan Cat JotunDocument13 pagesData Ketebalan Cat JotunDeniNo ratings yet

- G16S-0205-04 - Shop Coat Galv Surf (Duplex)Document3 pagesG16S-0205-04 - Shop Coat Galv Surf (Duplex)puwarin naja100% (1)

- Section 942-BR Area Coating GIIDocument31 pagesSection 942-BR Area Coating GIIchristian gordonNo ratings yet

- Application Jotamastic 90 AlDocument13 pagesApplication Jotamastic 90 Aladitya kristantoNo ratings yet

- Jotun Resist 86 Data SheetDocument7 pagesJotun Resist 86 Data SheetKunal AjgaonkarNo ratings yet

- Jotachar JF750Document17 pagesJotachar JF750samet çelikNo ratings yet

- SP-93-1 Paint and Coatings PDFDocument12 pagesSP-93-1 Paint and Coatings PDFMahmoud Al HomranNo ratings yet

- 222-307-012K EMD 30 Grau TRDocument2 pages222-307-012K EMD 30 Grau TRszafakNo ratings yet

- Jotamastic 80 AG NewDocument10 pagesJotamastic 80 AG NewMuthu Sivarama Krishnan NallaiahNo ratings yet

- Iso 08504-2Document16 pagesIso 08504-2Akram DriraNo ratings yet

- PPG Touch Up PaintDocument10 pagesPPG Touch Up PaintTheAnh TranNo ratings yet

- Alkydprimer AGDocument8 pagesAlkydprimer AGangelito bernalNo ratings yet

- Mar Painting 2Document24 pagesMar Painting 2Teguh IndrawanNo ratings yet

- NORSOK M-501 Rev 5 2004Document20 pagesNORSOK M-501 Rev 5 2004Col TennantNo ratings yet

- Standard Specification For Hot Dip GalvanizingDocument4 pagesStandard Specification For Hot Dip GalvanizingNuzul Furqony100% (1)

- Jotun Galvanite - AgDocument7 pagesJotun Galvanite - AgAvinash LalNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Water-based Acrylic Dispersions: Applications in Architectural CoatingsFrom EverandWater-based Acrylic Dispersions: Applications in Architectural CoatingsNo ratings yet

- Mathcad - AISC 8th and 9th Edition Tubing Bending AnalysisDocument5 pagesMathcad - AISC 8th and 9th Edition Tubing Bending AnalysisFabio OkamotoNo ratings yet

- Manning EquationDocument4 pagesManning Equationsevero97No ratings yet

- Total Materia - Chemical CompositionDocument1 pageTotal Materia - Chemical CompositionMinh LeNo ratings yet

- SVWRF 2 5Document4 pagesSVWRF 2 5邱瑋No ratings yet

- PRES-M-09 Rotating Equipment - Gas TurbinesDocument2 pagesPRES-M-09 Rotating Equipment - Gas Turbinessalamlin100% (1)

- Maintenance, Inspection and Rehabilitation of Bridges: by Sri A.Nagendra Joint Secretary (RTD) Karnataka PWD BangaloreDocument145 pagesMaintenance, Inspection and Rehabilitation of Bridges: by Sri A.Nagendra Joint Secretary (RTD) Karnataka PWD Bangalorevj8584100% (1)

- HAGS UniPlay 205 PDFDocument116 pagesHAGS UniPlay 205 PDFKostas PapadopoulosNo ratings yet

- PTS 15.13.01 - Thermal AmmendmendDocument40 pagesPTS 15.13.01 - Thermal AmmendmendJustin LowNo ratings yet

- FWG TroubleshootingDocument7 pagesFWG TroubleshootingMariappan Na100% (5)

- Api-650-Tank DesignDocument29 pagesApi-650-Tank DesignJoeNo ratings yet

- SuhnerBollardsHandrailsTubeCatalogue FINALDocument20 pagesSuhnerBollardsHandrailsTubeCatalogue FINALLee NagleNo ratings yet

- Beijing CAAS Presentation With ChineseDocument33 pagesBeijing CAAS Presentation With ChineseXuan Phuong HuynhNo ratings yet

- N-17765-STANTEC-SEDE-CS-0101 - Wall Thickness Calc-Mtr Fttngs - R.0Document8 pagesN-17765-STANTEC-SEDE-CS-0101 - Wall Thickness Calc-Mtr Fttngs - R.0Noor AnterNo ratings yet

- Example To EN 1991 Part 1-2: Compartment Fire: P. Schaumann, T. TrautmannDocument11 pagesExample To EN 1991 Part 1-2: Compartment Fire: P. Schaumann, T. TrautmannSerbanDragosNo ratings yet

- Sandwich Panels en Lo RUUKKIDocument8 pagesSandwich Panels en Lo RUUKKIszeestherNo ratings yet

- Inspection Test Plan ITP Painting WorksDocument4 pagesInspection Test Plan ITP Painting WorksMichael AntipuestoNo ratings yet

- Typenreihe NE enDocument6 pagesTypenreihe NE encspivetta6095No ratings yet

- Viking Johnson Dismantling Joint+BrochureDocument13 pagesViking Johnson Dismantling Joint+BrochureecocadecNo ratings yet

- Atkins Chapter02.Lect01Document19 pagesAtkins Chapter02.Lect01Ivy JoyceNo ratings yet

- Bearings: Products CatalogueDocument73 pagesBearings: Products CatalogueTamaduianu IoanNo ratings yet

- TANKING SLURRY-UserGuide PDFDocument4 pagesTANKING SLURRY-UserGuide PDFIan MitchellNo ratings yet

- Surface Repair Using Form-and-Pour Techniques: Reported by ACI Committee E 706Document7 pagesSurface Repair Using Form-and-Pour Techniques: Reported by ACI Committee E 706Carlos Gonzalez100% (1)

- Plascore - PN1 - Honeycomb PDFDocument2 pagesPlascore - PN1 - Honeycomb PDFIverton FariasNo ratings yet

- 2ND Floor Beam DesignDocument14 pages2ND Floor Beam DesignJustinNo ratings yet

- Problems With FEM Solution: Heat TransferDocument34 pagesProblems With FEM Solution: Heat Transfermailsk123No ratings yet

- Calculations Summary Sheet: PD SE Py PD C SE P y PD SE CDocument2 pagesCalculations Summary Sheet: PD SE Py PD C SE P y PD SE CcrackrojoNo ratings yet