Professional Documents

Culture Documents

ITC April 2021 Paper 1 Question 1 Kubanda

ITC April 2021 Paper 1 Question 1 Kubanda

Uploaded by

Kambi OfficialOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ITC April 2021 Paper 1 Question 1 Kubanda

ITC April 2021 Paper 1 Question 1 Kubanda

Uploaded by

Kambi OfficialCopyright:

Available Formats

QUESTION 1 50 marks

Ignore value-added tax.

Assume that all persons are South African residents for taxation purposes, unless

indicated otherwise.

1 Background

Kubanda (Pty) Ltd (‘Kubanda’) was formed five years ago by a group of South African

entrepreneurs who wanted to manufacture local appliances that were affordable to the broader

population of South Africa. Kubanda produces domestic fridges, called Solarcold; this is the

only product produced by the company. Kubanda sells the Solarcold fridges to retail

distributers at R4 000 per fridge. Solarcold is labelled a ‘proudly South African product’. The

company has a 30 June financial year end.

2 Production inputs and materials

The production process of the Solarcold fridges consists of a number of integrated steps that

require various materials and inputs:

2.1 The external shell of the fridge is made from inexpensive steel sheeting that currently

costs R20 per square metre (m2) and which can be cut and shaped in five minutes. The

external shell of a Solarcold fridge uses 5 m2 of steel sheeting. Kubanda had 500 m2 of

steel sheeting on hand on 30 June 2020 and it has ordered another 1 000 m2 from a

supplier. This has not yet been delivered and Kubanda has not yet paid for it either. All

orders can be cancelled at a cancellation fee of 10% of the purchase price.

2.2 The inner cabinet is made from high-quality thin stainless steel and each fridge uses

4,5 m2 of stainless steel. The cost of stainless steel is currently R40 per m2. Kubanda

had 2 000 m2 of stainless steel on hand on 30 June 2020 that could be resold at only

60% of its original cost as there is little demand for this material in the external market.

2.3 Both the inner cabinets and the external shells are sprayed with a white, quick-drying

paint. Paint, sufficient to meet one month’s production requirements, is purchased from

Cha Paints, a Durban-based paint manufacturer, at R40 470 per month. After spraying,

the inner cabinet is placed in the external shell and low-density foam is sprayed into the

gap between the cabinet and the shell to bind them together, thus forming the fridge

case.

2.4 A cooling system with a high energy-efficiency rating is installed in the fridge. This

feature makes Solarcold a unique domestic fridge. Kubanda did not have the funds to

patent the design of the cooling system and therefore sources these systems from a

local manufacturer, CS Ltd (‘CS’). In terms of the agreement between Kubanda and CS,

the system is specially designed to Kubanda’s specifications and CS may not share the

design or produce the systems for any other customers.

2.5 A Solarcold fridge is powered by solar energy and hence each fridge has two solar

panels, an inverter and batteries. The batteries can power the fridge for four hours once

fully charged. SolarSA (Pty) Ltd supplies the solar panels, batteries and inverters as a

‘solar set’ at a cost of R1 650 per set per fridge, which includes a delivery cost of R10

per solar set. The minimum order is a batch of 500 solar sets. Kubanda does not

currently have any solar sets on hand.

ITC April 2021 1 © SAICA 2021

Paper 1 question 1

2.6 The last step in the process consists of the addition of accessories (e.g. shelves and ice

trays), after which the fridge goes through a testing process. Accessories are bought

from a local plastics producer at R100 per set per fridge.

3 Production process and costs

Kubanda operates from a factory that is located in a business park in Durban. It is divided into

two separate sections: one section is used as a metal processing plant and the other section

is used for the assembly of the solar set and accessories of the fridge. The metal processing

plant comprises metal shaping and cutting as well as paint-spraying machinery. A new and

unused metal processing plant was purchased on 1 December 2018 for an amount of

R2,5 million and was brought into use on the same day. The plant has a useful life of five years

and a residual value of R100 000.

Normal production in the factory is 2 850 Solarcold units per month and the monthly costs of

running the factory amount to R343 030. The breakdown of the monthly costs are as follows:

Cost description Note R

Supervisor salary 1 30 000

Plant operating staff salaries 1 120 000

Assembly staff wages 1 25 000

Maintenance and consumables 2 17 980

Rent 3 50 000

Electricity 4 100 050

Notes

1 There is one supervisor who oversees the production process and six staff members

who operate the machinery at the metal processing plant. There are two unsupervised

staff members who assemble all the components (e.g. the cooling system, solar sets

and accessories) of the fridges. The employment conditions of all the staff members

provide that, if a staff member is retrenched, he or she must receive a minimum

retrenchment payment of six months’ salary.

2 The machinery in the metal processing plant requires regular maintenance checks; if its

parts are not placed correctly, or cutting edges are not sharp, there is a risk that a whole

batch of materials may be wasted. Consumables relate to welding, pop rivets and screws

used in the metal processing plant only.

3 The factory rent amounts to R50 000 per month and is allocated equally to each of the

plant and assembly sections. The lease agreement is flexible and can be altered to suit

the needs of Kubanda.

4 Each of the two factory sections uses a fixed amount of R3 000 in electricity per month

and in addition thereto, on average the manufacturing of each Solarcold unit consumes

20 kiloWatt hours (kWh) at R1,65 per kWh.

4 Business operations

Kubanda was unable to manufacture any fridges during the full lockdown period resulting from

the Covid-19 pandemic, because fridges were classified as non-essential products. While

Kubanda was able to negotiate extended payment terms from 20 to 40 days with its suppliers,

ITC April 2021 2 © SAICA 2021

Paper 1 question 1

orders from customers were being cancelled because of the economic downturn. This had a

negative effect on the company’s liquidity.

CS, Kubanda’s supplier of cooling systems, was also struggling with low margins on other

products because of competition from foreign suppliers. On 30 April 2020, CS notified

Kubanda it was shutting down its company because of financial difficulties and that it had

1 500 cooling systems available, which it was willing to sell at R708 each. This amount was

equal to 80% of the retail price at that time. CS also told a Kubanda representative that it would

need cash funding or a cash guarantee of R5 million to settle its creditors if it were to wind

down its other operations and produce cooling systems only.

As a result, Kubanda started searching for alternative sources of cooling systems. It

approached foreign companies. One of these was Leng, a company based in China that

manufactures fridge cooling systems for the Chinese market. Leng is not a resident for tax

purposes. Leng offered to supply Kubanda with cooling systems at R799 each, provided that

Kubanda agreed to purchase a minimum of 2 850 cooling systems per month.

5 Sources of funding and restructure

Kubanda desperately needed cash to alleviate its liquidity challenges and started investigating

possible sources of funding. It managed to conclude the following transactions:

5.1 A revolving credit facility with Green Bank of up to R300 000 at the prime lending rate.

5.2 The sale of shares Kubanda owned in Avion Ltd (‘Avion’), a company listed on the

Johannesburg Stock Exchange, for R240 000 on 1 May 2020. The share price had

declined significantly in the first quarter of the 2020 financial year (FY2020).

Kubanda had acquired these shares on 1 September 2019 as a long-term investment.

The purchase price of R1 million had been funded with a loan that was obtained from

Medupi (Pty) Ltd (‘Medupi’), a connected person in relation to Kubanda. The loan bore

interest at 7% per annum and the interest was payable annually in arrears.

After the sale of the shares in Avion, Kubanda and Medupi reached an agreement on

1 May 2020 that Kubanda would settle the outstanding loan and interest by transferring

ownership of its delivery truck to Medupi. On 1 May 2020, the truck’s market value was

R1,1 million. Kubanda had purchased the truck five years earlier for R4 million and it

had been fully written off for tax purposes. Medupi, which does not lend money as its

core business, has a 30 June year end.

5.3 Kubanda reached an agreement with Kusile (Pty) Ltd (‘Kusile’) relating to a subordinated

loan.

Kubanda and Kusile, which is a connected person in relation to Kubanda, had entered

into a loan agreement on 1 July 2018. The entities agreed at the time that interest and

the capital portion of a loan of R5 million would be subordinated until the market value

of Kubanda’s assets exceeded the market value of its liabilities. The loan was used to

fund the purchase of a piece of land intended for future expansion. The loan had an

interest rate of 6% per annum, which was payable quarterly in arrears.

Although the original repayment terms were five annual instalments, no payments of any

amount had been made in respect of this loan. Kusile’s board took a commercial

decision to write off 60% of the original loan capital on 30 June 2020. The remainder of

the debt is still outstanding. Kusile has a 30 June year end.

ITC April 2021 3 © SAICA 2021

Paper 1 question 1

6 Alternative outsourcing options

Kubanda also considered the possibility of selling its plant on 30 June 2020 for a cash injection

into the company. It could outsource parts of its production process to Metalwork AG

(‘Metalwork’). Metalwork, not a resident for tax purposes, is based in Germany and

manufactures metal formworks for several industries and companies across the world.

Metalwork quoted Kubanda R350 per fridge case. It would in addition charge delivery costs of

R3 000 per batch of 1 000 fridge cases. The minimum order size would be 1 000 fridge cases

and Metalwork would be able to supply up to 15 000 fridge cases per month. Time from order

to arrival would be three weeks. Kubanda would have to pay for orders upfront.

If Kubanda outsourced the metal processes of the Solarcold fridges to Metalwork, it would be

able to sell its plant for R1 740 000.

ITC April 2021 4 © SAICA 2021

Paper 1 question 1

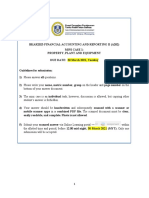

INITIAL TEST OF COMPETENCE, APRIL 2021

PROFESSIONAL PAPER 1

Marks

PAPER 1 QUESTION 1 – REQUIRED Sub-

Total

total

(a) Discuss, with calculations where relevant –

(i) the income tax consequences of the sale of shares in Avion for 4

Kubanda; and

(ii) the impact of the settlement of the loan from Medupi on 3

Kubanda’s taxable income

for the 2020 year of assessment. 7

(b) Discuss, with calculations where relevant, the income tax

consequences for Medupi of the loan settlement (including any

interest owing) with Kubanda for the 2020 year of assessment. 8

Communication skills – presentation 1 9

(c) Discuss the income tax consequences for Kusile with regard to the

loan advanced to Kubanda as well as its partial write-off during its

2020 year of assessment. 5 5

(d) Evaluate Kubanda’s opportunity to purchase cooling systems from

Leng, if Kubanda is no longer able to purchase these systems from

CS. 9

Communication skills – logical argument 1 10

(e) Determine, with supporting calculations, whether the production of

fridge cases should be outsourced to Metalwork for financial year

ending 30 June 2021. 18

Communication skills – presentation 1 19

Total 50

ITC April 2021 1 © SAICA 2021

Paper 1 question 1 required

You might also like

- Iibf & Nism Adda: Certified Treasury ProfessionalsDocument365 pagesIibf & Nism Adda: Certified Treasury Professionalsnageswara kuchipudi0% (1)

- Nickel Ore 2%-Contract-Draft-FOB MV-100% LCfinal 20121101Document9 pagesNickel Ore 2%-Contract-Draft-FOB MV-100% LCfinal 20121101Aszland Prince II100% (3)

- Sample Final Exam FINA 521Document4 pagesSample Final Exam FINA 521khalidhamdanNo ratings yet

- Aluminum Household Utensil Making PlantDocument26 pagesAluminum Household Utensil Making PlantYohannes Woldekidan100% (2)

- MC 1-PPE (Students) - A202Document5 pagesMC 1-PPE (Students) - A202lim qsNo ratings yet

- Energy Storage: Legal and Regulatory Challenges and OpportunitiesFrom EverandEnergy Storage: Legal and Regulatory Challenges and OpportunitiesNo ratings yet

- Pathways to Low-Carbon Development for the PhilippinesFrom EverandPathways to Low-Carbon Development for the PhilippinesNo ratings yet

- Business Model Canvas (BMC)Document21 pagesBusiness Model Canvas (BMC)Eva FadillahNo ratings yet

- Director Financial Planning Analysis in New York NY Resume Howard SchierDocument2 pagesDirector Financial Planning Analysis in New York NY Resume Howard SchierHowardSchierNo ratings yet

- ITC June 2022 Paper 3 Question 1 IntellectDocument5 pagesITC June 2022 Paper 3 Question 1 Intellectdjbongz777No ratings yet

- Cost Accounting: T I C A PDocument6 pagesCost Accounting: T I C A PShehrozSTNo ratings yet

- AlumiuniumCasting Furniture-100 Set Per MonthDocument9 pagesAlumiuniumCasting Furniture-100 Set Per Monthpm37506No ratings yet

- Kuken Kogyo Co - LTD - Presentation Export G of CT Industrial Use - 20201028Document35 pagesKuken Kogyo Co - LTD - Presentation Export G of CT Industrial Use - 20201028saqib hashmiNo ratings yet

- Practice Set 2Document6 pagesPractice Set 2Marielle CastañedaNo ratings yet

- Revival ProjectDocument22 pagesRevival ProjectNIYAS NICHUNo ratings yet

- London Examinations GCE: Accounting (Modular Syllabus) Advanced Subsidiary/Advanced LevelDocument16 pagesLondon Examinations GCE: Accounting (Modular Syllabus) Advanced Subsidiary/Advanced LevelSadman DibboNo ratings yet

- Managerial Finance: Professional 1 Examination - August 2009Document19 pagesManagerial Finance: Professional 1 Examination - August 2009Jocy ReisNo ratings yet

- Project Proposal BriefDocument7 pagesProject Proposal BriefRama KrishnaNo ratings yet

- Task 2 Final Report PDFDocument94 pagesTask 2 Final Report PDFcarzanteNo ratings yet

- ITC June 2019 Paper 1 Question 1 SolarDocument8 pagesITC June 2019 Paper 1 Question 1 SolarKoti KatishiNo ratings yet

- Question Bank Disclosure - 2023Document23 pagesQuestion Bank Disclosure - 2023thamsanqamanciNo ratings yet

- Accounting For BanksDocument4 pagesAccounting For BanksBrenda audrey SonfackNo ratings yet

- 2010 Jan AS SBDocument2 pages2010 Jan AS SBMuhtasim RosulNo ratings yet

- Friend Ice FactoryDocument25 pagesFriend Ice FactoryHafizAhmadNo ratings yet

- Assessment Opportunity 3 - 2023Document8 pagesAssessment Opportunity 3 - 2023Johannes MoyoNo ratings yet

- GI Sheet ProductsDocument23 pagesGI Sheet Productsbirukbrook2No ratings yet

- This Paper Is Not To Be Removed From The Examination HallsDocument56 pagesThis Paper Is Not To Be Removed From The Examination HallsDương DươngNo ratings yet

- 6.revised Galvanized Iron Sheet Product Producing PlantDocument23 pages6.revised Galvanized Iron Sheet Product Producing PlantFekadie TesfaNo ratings yet

- 2019 Exam QuestionDocument6 pages2019 Exam QuestionInsaaf RashidNo ratings yet

- Solar CookerDocument25 pagesSolar CookerTm De100% (1)

- Iceplantanitamujalda 150421081258 Conversion Gate02 PDFDocument20 pagesIceplantanitamujalda 150421081258 Conversion Gate02 PDFavipat74No ratings yet

- Air Condition Refrigeration Installation RepairDocument6 pagesAir Condition Refrigeration Installation RepairshsggNo ratings yet

- A8 Audit of Prepayments, Ip and Other NciDocument7 pagesA8 Audit of Prepayments, Ip and Other NciKezNo ratings yet

- Assignment ProblemsDocument3 pagesAssignment ProblemsCertified Public AccountantNo ratings yet

- AAM3781-Test 1 06 March 2017 1 Hour 15 Minutes: 40 Marks Examiner: FM KapepisoDocument2 pagesAAM3781-Test 1 06 March 2017 1 Hour 15 Minutes: 40 Marks Examiner: FM KapepisosimsonNo ratings yet

- FA3 Block 1 Tut Pack PrintingDocument165 pagesFA3 Block 1 Tut Pack Printingkatelynnewson07No ratings yet

- Bcom Y3 Acc3 12 August 2021 s1Document4 pagesBcom Y3 Acc3 12 August 2021 s1Ntokozo Siphiwo Collin DlaminiNo ratings yet

- Relevant Cost Cases and QuestionsDocument8 pagesRelevant Cost Cases and Questionskert1234No ratings yet

- Assessment 5Document6 pagesAssessment 5Mmaleema LedwabaNo ratings yet

- Tam Plate Solar CookerDocument24 pagesTam Plate Solar CookerAhmad Daood0% (1)

- Electrical Project1Document12 pagesElectrical Project1Lokanath ChoudhuryNo ratings yet

- Grey Iron Castings: Profile No.: 219 NIC Code: 24319Document11 pagesGrey Iron Castings: Profile No.: 219 NIC Code: 24319Sanyam BugateNo ratings yet

- PPE IllustrationsDocument3 pagesPPE Illustrationsprlu1No ratings yet

- Cyanoacrylate AdhesiveDocument4 pagesCyanoacrylate AdhesivePathan Sameer KhanNo ratings yet

- RELEVANT COST CASES and QuestionsDocument21 pagesRELEVANT COST CASES and QuestionsBijay AgrawalNo ratings yet

- Aluminium Shots and Knotched BarsDocument4 pagesAluminium Shots and Knotched Bars124swadeshiNo ratings yet

- Bolt Project ProfileDocument6 pagesBolt Project ProfileRaviNo ratings yet

- Plastic Water Storage TankDocument7 pagesPlastic Water Storage TankRachit GoyalNo ratings yet

- ICAB - IAS 36 - QuestionsDocument3 pagesICAB - IAS 36 - QuestionsMonirul Islam MoniirrNo ratings yet

- Lecture 18Document30 pagesLecture 18Riaz Baloch NotezaiNo ratings yet

- 6.revised Galvanized Iron Sheet Product Producing PlantDocument23 pages6.revised Galvanized Iron Sheet Product Producing PlantaschalewNo ratings yet

- Non-Routine DecisionsDocument5 pagesNon-Routine DecisionsVincent Lazaro0% (1)

- FIAC6211 EaDocument13 pagesFIAC6211 EaPanashe SimbiNo ratings yet

- Audit PpeDocument4 pagesAudit Ppenicole bancoroNo ratings yet

- Domestic LPG Stove (Project Report)Document6 pagesDomestic LPG Stove (Project Report)Prashant KhaireNo ratings yet

- Assessment TasksDocument5 pagesAssessment TasksLDB Ashley Jeremiah Magsino - ABMNo ratings yet

- Auto Pistons and Piston RingsDocument11 pagesAuto Pistons and Piston RingsSabhaya ChiragNo ratings yet

- Plumbing&Servicing of Electrical AppliancesDocument8 pagesPlumbing&Servicing of Electrical AppliancesGopi BaboolNo ratings yet

- Caf 3 Cma Spring 2022Document6 pagesCaf 3 Cma Spring 2022Dua FarmoodNo ratings yet

- Project Profile On Air Filters For Two WheelsDocument10 pagesProject Profile On Air Filters For Two WheelsFahimNo ratings yet

- Fin2bsat Quiz1 InvProperty Fund PpeDocument5 pagesFin2bsat Quiz1 InvProperty Fund PpeMarvin San JuanNo ratings yet

- BCOM - Accounting 3Document6 pagesBCOM - Accounting 3Ntokozo Siphiwo Collin DlaminiNo ratings yet

- University of London Preliminary Exam 2017Document11 pagesUniversity of London Preliminary Exam 2017Pei TingNo ratings yet

- Fly Ash BricksDocument8 pagesFly Ash BricksSabhaya ChiragNo ratings yet

- CPA Official IAS 16 Possible QNDocument2 pagesCPA Official IAS 16 Possible QNKambi OfficialNo ratings yet

- CPA Official IAS 37 PSSBL QNDocument1 pageCPA Official IAS 37 PSSBL QNKambi OfficialNo ratings yet

- CPA Official CGU & IFRS Possble9Document2 pagesCPA Official CGU & IFRS Possble9Kambi OfficialNo ratings yet

- CPA Official IFRS 9& CGU AnsDocument2 pagesCPA Official IFRS 9& CGU AnsKambi OfficialNo ratings yet

- CPA Official IAS 40 AnsDocument3 pagesCPA Official IAS 40 AnsKambi OfficialNo ratings yet

- CPA Official Ifrs 9 AnsDocument2 pagesCPA Official Ifrs 9 AnsKambi OfficialNo ratings yet

- CPA Official CVP QN 2 BackupDocument1 pageCPA Official CVP QN 2 BackupKambi OfficialNo ratings yet

- (Backup) P1 CIMA VPI Set IDocument1 page(Backup) P1 CIMA VPI Set IKambi OfficialNo ratings yet

- QN 2 (STD Cost & Variance)Document2 pagesQN 2 (STD Cost & Variance)Kambi OfficialNo ratings yet

- f9 2006 Dec PPQDocument17 pagesf9 2006 Dec PPQMuhammad Kamran KhanNo ratings yet

- Tax AssessmentDocument1 pageTax AssessmentKambi OfficialNo ratings yet

- Removal of A Member From WhatsApp Group Violates The Right To Freedom of Association - MD, MendezDocument1 pageRemoval of A Member From WhatsApp Group Violates The Right To Freedom of Association - MD, MendezKambi OfficialNo ratings yet

- Chapter 2 (Tan&Lee)Document47 pagesChapter 2 (Tan&Lee)desy nataNo ratings yet

- Dashboard Template: Business Unit Revenue ($000) Profit Margin ($000)Document1 pageDashboard Template: Business Unit Revenue ($000) Profit Margin ($000)GolamMostafaNo ratings yet

- Afar Midterms Reviewer - PracticeDocument10 pagesAfar Midterms Reviewer - PracticeAlmira Bulilan TanNo ratings yet

- Sample Exam QuestionsDocument8 pagesSample Exam QuestionsEmmanuel MbonaNo ratings yet

- B LawDocument240 pagesB LawShaheer MalikNo ratings yet

- Order in The Matter of Exelon Infrastructure LimitedDocument22 pagesOrder in The Matter of Exelon Infrastructure LimitedShyam SunderNo ratings yet

- Valuation-Deal Making PDFDocument17 pagesValuation-Deal Making PDFSandeep KumarNo ratings yet

- Ratio AnalysisDocument50 pagesRatio AnalysissshreyasNo ratings yet

- Finance Applications and Theory 4th Edition Cornett Test Bank 1Document23 pagesFinance Applications and Theory 4th Edition Cornett Test Bank 1harry100% (50)

- Sarfaesi ActDocument68 pagesSarfaesi ActkarteekjrNo ratings yet

- Shri Bhausaheb Vartak College of Arts, Commerce and Science, Borivali (West) Program: - TYBBI Sem: - VDocument10 pagesShri Bhausaheb Vartak College of Arts, Commerce and Science, Borivali (West) Program: - TYBBI Sem: - VAniket KawadeNo ratings yet

- Accounting C2 Lesson 1 PDFDocument5 pagesAccounting C2 Lesson 1 PDFJake ShimNo ratings yet

- SWR RatesDocument1 pageSWR RatesAadaesh VermaNo ratings yet

- Cost of Capital - The Effect To The Firm Value and Profitability Empirical Evidences in Case of Personal Goods (Textile) Sector of KSE 100 IndexDocument7 pagesCost of Capital - The Effect To The Firm Value and Profitability Empirical Evidences in Case of Personal Goods (Textile) Sector of KSE 100 IndexKanganFatimaNo ratings yet

- Bay' Al TawarruqDocument1 pageBay' Al TawarruqAriff MustafaNo ratings yet

- Performance Analysis of HDFC and Axis Bank: Marketing Performance Metrics (MSM-6421)Document11 pagesPerformance Analysis of HDFC and Axis Bank: Marketing Performance Metrics (MSM-6421)samiksha agarwalNo ratings yet

- Sub Order LabelsDocument2 pagesSub Order LabelsJaai ArigathoNo ratings yet

- Swing Trading Recommendation by Stock Axis For Last 6 Months-300620Document6 pagesSwing Trading Recommendation by Stock Axis For Last 6 Months-300620Anupam DasNo ratings yet

- Financial Risk Management - WikipediaDocument4 pagesFinancial Risk Management - WikipediaPranay JaipuriaNo ratings yet

- Bullet Form ReviewerDocument10 pagesBullet Form ReviewerKlerkxzNo ratings yet

- Business Studies NotesDocument80 pagesBusiness Studies NoteszacksNo ratings yet

- Arab Sudanese Bank: Sudanese Private Ccompany LTDDocument30 pagesArab Sudanese Bank: Sudanese Private Ccompany LTDShadow PrinceNo ratings yet

- Long Examination in Mathematics in The Modern World (Finals) Name: SectionDocument3 pagesLong Examination in Mathematics in The Modern World (Finals) Name: SectionACE BRIANNo ratings yet

- Marion BoatsDocument3 pagesMarion Boatser.ruchira671No ratings yet

- MBA711 - Answers To Book - Chapter 4Document16 pagesMBA711 - Answers To Book - Chapter 4Hạng VũNo ratings yet