Professional Documents

Culture Documents

Result N Discussion Exp3 Sku - PDF

Result N Discussion Exp3 Sku - PDF

Uploaded by

Fadila AbdulnurCopyright:

Available Formats

You might also like

- Yardline ASTON 10 X 7-6 Manual enDocument60 pagesYardline ASTON 10 X 7-6 Manual enJimmy Zettenberg75% (4)

- BOQ Bathroom RenovationDocument9 pagesBOQ Bathroom RenovationKevin Marc Babate100% (1)

- Manufacturing of PU FoamsDocument36 pagesManufacturing of PU FoamsDIPAK VINAYAK SHIRBHATE100% (5)

- Experiment 4Document5 pagesExperiment 4Anonymous 6ZljVVvETNo ratings yet

- Water Based Surface Coatings FormulationDocument34 pagesWater Based Surface Coatings Formulationchayanun82% (11)

- Windows & Window TreatmentsDocument51 pagesWindows & Window TreatmentsRajat KatiyarNo ratings yet

- Elastomeric Impression MaterialsDocument89 pagesElastomeric Impression MaterialsDr Anand RajapurNo ratings yet

- Poly BD Resins in Construction ApplicationsDocument6 pagesPoly BD Resins in Construction ApplicationsJOSEANTONIO2001No ratings yet

- Impression MaterialsDocument75 pagesImpression MaterialsDapinder Brar67% (3)

- Polybutadiene Rubber Project ReviewDocument20 pagesPolybutadiene Rubber Project ReviewJaveed Ali100% (1)

- Water Treatment ChemicalsDocument9 pagesWater Treatment Chemicalsjidi125737No ratings yet

- Furnace PDFDocument9 pagesFurnace PDFBilalNo ratings yet

- 14 Design of Bolted JointsDocument13 pages14 Design of Bolted JointsPRASAD32675% (4)

- PVC - Polyvinyl ChlorideDocument13 pagesPVC - Polyvinyl ChloridejbertralNo ratings yet

- Chap12 PDFDocument44 pagesChap12 PDFYassine OuakkiNo ratings yet

- Brochure Coating Raw Materials For Building Protection 14-06-2011 EDocument32 pagesBrochure Coating Raw Materials For Building Protection 14-06-2011 EΣταύρος ΒουγιουκλίδηςNo ratings yet

- Poly Sulphide Silicone RubberDocument22 pagesPoly Sulphide Silicone RubberSuyash TrivediNo ratings yet

- PolyethyleneDocument38 pagesPolyethyleneTej Pratap SinghNo ratings yet

- Industrial ResinsDocument13 pagesIndustrial ResinsGideon PaulNo ratings yet

- Polyvinyl Chloride (PVC)Document23 pagesPolyvinyl Chloride (PVC)Rajat Agarwal100% (1)

- CHAPTER 2 SPONGE AND MICROCELLULAR RUBBER LecturerDocument41 pagesCHAPTER 2 SPONGE AND MICROCELLULAR RUBBER LecturerMuhd BazliNo ratings yet

- Polyvinylchloride (PVC) : Eco-Profiles of The European Plastics IndustryDocument15 pagesPolyvinylchloride (PVC) : Eco-Profiles of The European Plastics IndustryGuillianNo ratings yet

- Butyl Rubber IIRDocument3 pagesButyl Rubber IIRbentmoltheringerNo ratings yet

- CH CH CH - CH CL CL N N: PolymerizationDocument40 pagesCH CH CH - CH CL CL N N: PolymerizationAkash YadavNo ratings yet

- Manufacturing Process of Polyvinyl ChlorDocument6 pagesManufacturing Process of Polyvinyl ChlorMaulik KotadiyaNo ratings yet

- Aditivos ClariantDocument36 pagesAditivos ClariantandrefaccindasilvaNo ratings yet

- Polivinyl Chloride: Maharani Suci 1306370846 Pratiwi Rostiningtyas 1306370833Document19 pagesPolivinyl Chloride: Maharani Suci 1306370846 Pratiwi Rostiningtyas 1306370833HaniNo ratings yet

- Polyurethane FoamsDocument4 pagesPolyurethane FoamsAshokkumar ParthipanNo ratings yet

- Butyle RubberDocument5 pagesButyle RubberADITYA_PATHAKNo ratings yet

- C1-Bin Rasheed-Polyurethane & Polyurea Coatings (Mr. M. Shafiq Randhawa)Document66 pagesC1-Bin Rasheed-Polyurethane & Polyurea Coatings (Mr. M. Shafiq Randhawa)AllanNo ratings yet

- Search P "Polyether+polyol"&prssweb Search&ei UTF-8&fl 0 PDFDocument15 pagesSearch P "Polyether+polyol"&prssweb Search&ei UTF-8&fl 0 PDFA MahmoodNo ratings yet

- Ethio Plastic Industry (Epi) : Jimma University Jimma Institute of Technology School of Chemical EngineeringDocument11 pagesEthio Plastic Industry (Epi) : Jimma University Jimma Institute of Technology School of Chemical EngineeringHiwot Wubetu100% (1)

- Solvent Cast Technology - A Versatile ToolDocument14 pagesSolvent Cast Technology - A Versatile ToolsggdgdNo ratings yet

- Elastomeric Impression MaterialsDocument67 pagesElastomeric Impression Materialsمحمود ألاهدلNo ratings yet

- CN1454945A - Environmental-Protection Type Gypsum-Based Putty Powder For Building - Google PatentsDocument23 pagesCN1454945A - Environmental-Protection Type Gypsum-Based Putty Powder For Building - Google PatentsniteshacharyaNo ratings yet

- BC Luwax PVC Evd409eDocument20 pagesBC Luwax PVC Evd409eHikmet İŞLERNo ratings yet

- WUHAN DICT TECH Sodium LignosulfonateDocument3 pagesWUHAN DICT TECH Sodium LignosulfonatejimmyNo ratings yet

- Tejas Kush Investigatory Hard Plastic ExperimentDocument18 pagesTejas Kush Investigatory Hard Plastic ExperimentTejas KushNo ratings yet

- Process Department: MOHAMMAD SHUJJAT ABBAS (Trainee Engineer M&U) - Orientation ReportDocument4 pagesProcess Department: MOHAMMAD SHUJJAT ABBAS (Trainee Engineer M&U) - Orientation ReportShujjat AbbasNo ratings yet

- Brochure Hardeners For WaterglassDocument18 pagesBrochure Hardeners For WaterglassAlejandro LozanoNo ratings yet

- Impression Material 2Document104 pagesImpression Material 2Manjulika Tysgi100% (1)

- CH CH CH - CH CL CL N N: PolymerizationDocument34 pagesCH CH CH - CH CL CL N N: PolymerizationBagoes Rebel CrewNo ratings yet

- Elastomeric Impression MaterialsDocument6 pagesElastomeric Impression MaterialsMarlene CasayuranNo ratings yet

- PVC Compound Ingredients IdentificationsDocument9 pagesPVC Compound Ingredients IdentificationsAhmed RaafatNo ratings yet

- Calculos de Poliuretano RigidoDocument46 pagesCalculos de Poliuretano Rigidosescobar86100% (1)

- PVC Compounding1-NSA WITH DIAGRAMS & FORMULATIONS-1Document21 pagesPVC Compounding1-NSA WITH DIAGRAMS & FORMULATIONS-1Mahesh GiriNo ratings yet

- Flexidone™ - A New Class of Innovative PVC Plasticizers: Martin Bonnet and Hasan KaytanDocument19 pagesFlexidone™ - A New Class of Innovative PVC Plasticizers: Martin Bonnet and Hasan KaytanBenpetro ChaichuaNo ratings yet

- Polyvinyl Chloride - Wikipedia PDFDocument105 pagesPolyvinyl Chloride - Wikipedia PDFJesly JosephNo ratings yet

- Mowilith LDM 7255 For Film Print LaminationDocument8 pagesMowilith LDM 7255 For Film Print LaminationchayanunNo ratings yet

- XPU Flooring Balcony Case StudyDocument12 pagesXPU Flooring Balcony Case StudyyasafyNo ratings yet

- Polymer FoamsDocument17 pagesPolymer FoamsSachin PatilNo ratings yet

- PolyolyfinsDocument40 pagesPolyolyfinsManikiranSai100% (1)

- Chemoxy International LTD Coalescing RangeDocument8 pagesChemoxy International LTD Coalescing RangeIliass MeskiNo ratings yet

- AdmixtureDocument35 pagesAdmixtureSasanka AyinaparthiNo ratings yet

- LLDPE ProjectDocument86 pagesLLDPE Projectbhagwat2680% (5)

- Butyl & Chloroprene 2003Document16 pagesButyl & Chloroprene 2003Suyash TrivediNo ratings yet

- Polyvinyl ChlorideDocument14 pagesPolyvinyl ChlorideSerkan GecimNo ratings yet

- MSF 846 690-2Document8 pagesMSF 846 690-2Maurice ABOURIDANo ratings yet

- Roll-to-Roll Manufacturing: Process Elements and Recent AdvancesFrom EverandRoll-to-Roll Manufacturing: Process Elements and Recent AdvancesJehuda GreenerNo ratings yet

- Polyurethanes: Science, Technology, Markets, and TrendsFrom EverandPolyurethanes: Science, Technology, Markets, and TrendsRating: 1 out of 5 stars1/5 (1)

- Membrane Gas SeparationFrom EverandMembrane Gas SeparationBenny FreemanNo ratings yet

- Draf (Model Keseimbangan Minyak Kelapa SawitDocument4 pagesDraf (Model Keseimbangan Minyak Kelapa SawitFadila AbdulnurNo ratings yet

- Exit TicketDocument1 pageExit TicketFadila AbdulnurNo ratings yet

- Key Point PartDocument5 pagesKey Point PartFadila AbdulnurNo ratings yet

- Skema Japan KPD Part DilaDocument3 pagesSkema Japan KPD Part DilaFadila AbdulnurNo ratings yet

- CISPLATINDocument3 pagesCISPLATINFadila AbdulnurNo ratings yet

- Astronomy Assigment 3Document6 pagesAstronomy Assigment 3Fadila AbdulnurNo ratings yet

- TRIGONOMETRY (Distance and Height Measurement)Document4 pagesTRIGONOMETRY (Distance and Height Measurement)Fadila AbdulnurNo ratings yet

- Laboratory Assignment Report: Skf3023: Kimia Fizik (B) Semester 03 Session 2021/2022Document5 pagesLaboratory Assignment Report: Skf3023: Kimia Fizik (B) Semester 03 Session 2021/2022Fadila AbdulnurNo ratings yet

- Experiment Astronomy SundialDocument3 pagesExperiment Astronomy SundialFadila AbdulnurNo ratings yet

- Ga Marta ViewDocument188 pagesGa Marta ViewAndes PutraNo ratings yet

- PEC-En-GDE-L-10028 - Design Guidelines For Jacketed PipingDocument9 pagesPEC-En-GDE-L-10028 - Design Guidelines For Jacketed PipingAkshay DesaiNo ratings yet

- CAISSON - Tolinggula 2Document1 pageCAISSON - Tolinggula 2Bamz ImpazztNo ratings yet

- Reinforced Elastomeric Bearing Table Type BDocument9 pagesReinforced Elastomeric Bearing Table Type BAy ChNo ratings yet

- Section D - Proposed Methodology: Request For Proposal - Civil & Structural Consultancy ServicesDocument46 pagesSection D - Proposed Methodology: Request For Proposal - Civil & Structural Consultancy Servicesdak comeiNo ratings yet

- "Why Are My Stainless Steel Filters Getting Pin-Hole Leaks?Document2 pages"Why Are My Stainless Steel Filters Getting Pin-Hole Leaks?Tahseen ShNo ratings yet

- Daftar Harga Upah Dan Bahan / MaterialDocument24 pagesDaftar Harga Upah Dan Bahan / MaterialOkta RizalNo ratings yet

- WirebondingDocument9 pagesWirebondingElvis NgNo ratings yet

- ECEG-3205 - Chapter 2 Second PartDocument37 pagesECEG-3205 - Chapter 2 Second PartYohanes FisehaNo ratings yet

- SSAB Trailer Design GuidelineDocument28 pagesSSAB Trailer Design GuidelineGerard Piedra García100% (1)

- Liebert Refrigerant SizingDocument2 pagesLiebert Refrigerant Sizingcoolth2No ratings yet

- Existing Chandmari Rob (Dismantling Scheme) : 5. Jacking Arrangement Required For Lift The Existing StructureDocument24 pagesExisting Chandmari Rob (Dismantling Scheme) : 5. Jacking Arrangement Required For Lift The Existing StructureAnkitaNo ratings yet

- IMEC Quick Start Guide V1.0 SPDocument4 pagesIMEC Quick Start Guide V1.0 SPJose Ivan Carvajal CortizosNo ratings yet

- Types of Roof Trusses: King Post TrussDocument3 pagesTypes of Roof Trusses: King Post TrussjashndeepNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document8 pagesRCC91 One-Way Solid Slabs (Tables)Mohd Said Mohd ZakariaNo ratings yet

- Aluminum Extrusions (HFS6 Series) Aluminum Extrusions (HFS6 Series)Document1 pageAluminum Extrusions (HFS6 Series) Aluminum Extrusions (HFS6 Series)Jesus ValenciaNo ratings yet

- Part B-Arch ExreciseDocument2 pagesPart B-Arch Exrecisestudio surfaceNo ratings yet

- Finite Element Modeling of Rutting For Flexible PaDocument14 pagesFinite Element Modeling of Rutting For Flexible PaZainab A. AbdulstaarNo ratings yet

- Technical - STWS-ECS-FCU-103 AND 104Document1 pageTechnical - STWS-ECS-FCU-103 AND 104Prakash RaoNo ratings yet

- Mastertop 1332: Polyurethane, Waterproofing and Protective Traffic-Deck Coating SystemDocument3 pagesMastertop 1332: Polyurethane, Waterproofing and Protective Traffic-Deck Coating SystemFrancois-No ratings yet

- Valqua CatalogDocument44 pagesValqua CatalogzatenneNo ratings yet

- BT5 SpecsDocument6 pagesBT5 SpecsJustine Rose AngolluanNo ratings yet

- Design For Wind Loads - SampleDocument6 pagesDesign For Wind Loads - SampleLouie PachecoNo ratings yet

- Format - CISDocument8 pagesFormat - CISgopichandallakaNo ratings yet

- Din 6914Document2 pagesDin 6914vpjagannaathNo ratings yet

Result N Discussion Exp3 Sku - PDF

Result N Discussion Exp3 Sku - PDF

Uploaded by

Fadila AbdulnurOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Result N Discussion Exp3 Sku - PDF

Result N Discussion Exp3 Sku - PDF

Uploaded by

Fadila AbdulnurCopyright:

Available Formats

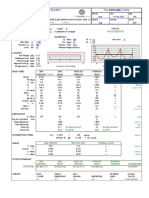

RESULT

Mass of polysulfide rubber formed = 15.0248 g

Time (minutes) Observation

0 minute No precipitate

After 30 minutes Yellow-colored precipitate started to form

After 45 minutes Yellow-colored precipitate formed

DISCUSSION

1. Describe any observations or changes from the beginning to the end of the reaction.

There is no change from the original solution, which is a colorless solution, at the

commencement of the reaction, which is at 0 minutes. The yellow precipitate starts to appear

after 30 minutes. The yellow precipitate that results from the reaction is known as polysulfide

rubber. The resultant (S-CH2CH2OCH2CH2-S2)n polymer precipitates in the presence of the

right dispersants but is insoluble in the reaction media.

2. Why the polymer produced in this experiment must be kept in water?

It is thus necessary to maintain the polysulfide rubber submerged in water to prevent

coagulation and serve as a cooling mechanism. The polymerization process results in the

production of water as a by-product. The process of producing a by-product during

polymerization is referred to as condensation polymerization. Due to the presence of water

inside the polysulfide structure, the impression will fade as water evaporates from it.

3. What are the uses of polysulfide rubber?

In the building and construction, aerospace, and automotive industries, polysulfides are

frequently used as the primary polymer in sealants, caulks, and adhesives. Other industrial

uses include concrete coatings, moulding or potting compounds, and highway sealants. This is

as a result of polysulfides' great swelling resistance. Additionally, it offers solvent and oil

resistance, thermal stability, and weatherability.

4. Write the equation for the polymerization reaction.

2CH2Cl + 2NaS2 ( CH2CH2S4 )n

CONCLUSION

Condensation polymerization can be used in this experiment to create polysulfide rubber.

15.0248 g of polysulfide rubber were produced. In the building and construction, aerospace,

and automotive industries, polysulfides are frequently used as the primary polymer in

sealants, caulks, and adhesives. This is as a result of polysulfides' great swelling resistance.

Additionally, it has oil and solvent resistance, thermal stability, and weatherability.

REFERENCES

Kalaee, M. R., Famili, M. H. N., & Mahdavi, H. (2009, February). Synthesis and

characterization of polysulfide rubber using phase transfer catalyst. In

Macromolecular symposia (Vol. 277, No. 1, pp. 81-86). Weinheim: WILEY‐VCH

Verlag.

Pirayesh, A., Salami-Kalajahi, M., Roghani-Mamaqani, H., & Najafi, F. (2019). Polysulfide

polymers: synthesis, blending, nanocomposites, and applications. Polymer Reviews,

59(1), 124-148.

You might also like

- Yardline ASTON 10 X 7-6 Manual enDocument60 pagesYardline ASTON 10 X 7-6 Manual enJimmy Zettenberg75% (4)

- BOQ Bathroom RenovationDocument9 pagesBOQ Bathroom RenovationKevin Marc Babate100% (1)

- Manufacturing of PU FoamsDocument36 pagesManufacturing of PU FoamsDIPAK VINAYAK SHIRBHATE100% (5)

- Experiment 4Document5 pagesExperiment 4Anonymous 6ZljVVvETNo ratings yet

- Water Based Surface Coatings FormulationDocument34 pagesWater Based Surface Coatings Formulationchayanun82% (11)

- Windows & Window TreatmentsDocument51 pagesWindows & Window TreatmentsRajat KatiyarNo ratings yet

- Elastomeric Impression MaterialsDocument89 pagesElastomeric Impression MaterialsDr Anand RajapurNo ratings yet

- Poly BD Resins in Construction ApplicationsDocument6 pagesPoly BD Resins in Construction ApplicationsJOSEANTONIO2001No ratings yet

- Impression MaterialsDocument75 pagesImpression MaterialsDapinder Brar67% (3)

- Polybutadiene Rubber Project ReviewDocument20 pagesPolybutadiene Rubber Project ReviewJaveed Ali100% (1)

- Water Treatment ChemicalsDocument9 pagesWater Treatment Chemicalsjidi125737No ratings yet

- Furnace PDFDocument9 pagesFurnace PDFBilalNo ratings yet

- 14 Design of Bolted JointsDocument13 pages14 Design of Bolted JointsPRASAD32675% (4)

- PVC - Polyvinyl ChlorideDocument13 pagesPVC - Polyvinyl ChloridejbertralNo ratings yet

- Chap12 PDFDocument44 pagesChap12 PDFYassine OuakkiNo ratings yet

- Brochure Coating Raw Materials For Building Protection 14-06-2011 EDocument32 pagesBrochure Coating Raw Materials For Building Protection 14-06-2011 EΣταύρος ΒουγιουκλίδηςNo ratings yet

- Poly Sulphide Silicone RubberDocument22 pagesPoly Sulphide Silicone RubberSuyash TrivediNo ratings yet

- PolyethyleneDocument38 pagesPolyethyleneTej Pratap SinghNo ratings yet

- Industrial ResinsDocument13 pagesIndustrial ResinsGideon PaulNo ratings yet

- Polyvinyl Chloride (PVC)Document23 pagesPolyvinyl Chloride (PVC)Rajat Agarwal100% (1)

- CHAPTER 2 SPONGE AND MICROCELLULAR RUBBER LecturerDocument41 pagesCHAPTER 2 SPONGE AND MICROCELLULAR RUBBER LecturerMuhd BazliNo ratings yet

- Polyvinylchloride (PVC) : Eco-Profiles of The European Plastics IndustryDocument15 pagesPolyvinylchloride (PVC) : Eco-Profiles of The European Plastics IndustryGuillianNo ratings yet

- Butyl Rubber IIRDocument3 pagesButyl Rubber IIRbentmoltheringerNo ratings yet

- CH CH CH - CH CL CL N N: PolymerizationDocument40 pagesCH CH CH - CH CL CL N N: PolymerizationAkash YadavNo ratings yet

- Manufacturing Process of Polyvinyl ChlorDocument6 pagesManufacturing Process of Polyvinyl ChlorMaulik KotadiyaNo ratings yet

- Aditivos ClariantDocument36 pagesAditivos ClariantandrefaccindasilvaNo ratings yet

- Polivinyl Chloride: Maharani Suci 1306370846 Pratiwi Rostiningtyas 1306370833Document19 pagesPolivinyl Chloride: Maharani Suci 1306370846 Pratiwi Rostiningtyas 1306370833HaniNo ratings yet

- Polyurethane FoamsDocument4 pagesPolyurethane FoamsAshokkumar ParthipanNo ratings yet

- Butyle RubberDocument5 pagesButyle RubberADITYA_PATHAKNo ratings yet

- C1-Bin Rasheed-Polyurethane & Polyurea Coatings (Mr. M. Shafiq Randhawa)Document66 pagesC1-Bin Rasheed-Polyurethane & Polyurea Coatings (Mr. M. Shafiq Randhawa)AllanNo ratings yet

- Search P "Polyether+polyol"&prssweb Search&ei UTF-8&fl 0 PDFDocument15 pagesSearch P "Polyether+polyol"&prssweb Search&ei UTF-8&fl 0 PDFA MahmoodNo ratings yet

- Ethio Plastic Industry (Epi) : Jimma University Jimma Institute of Technology School of Chemical EngineeringDocument11 pagesEthio Plastic Industry (Epi) : Jimma University Jimma Institute of Technology School of Chemical EngineeringHiwot Wubetu100% (1)

- Solvent Cast Technology - A Versatile ToolDocument14 pagesSolvent Cast Technology - A Versatile ToolsggdgdNo ratings yet

- Elastomeric Impression MaterialsDocument67 pagesElastomeric Impression Materialsمحمود ألاهدلNo ratings yet

- CN1454945A - Environmental-Protection Type Gypsum-Based Putty Powder For Building - Google PatentsDocument23 pagesCN1454945A - Environmental-Protection Type Gypsum-Based Putty Powder For Building - Google PatentsniteshacharyaNo ratings yet

- BC Luwax PVC Evd409eDocument20 pagesBC Luwax PVC Evd409eHikmet İŞLERNo ratings yet

- WUHAN DICT TECH Sodium LignosulfonateDocument3 pagesWUHAN DICT TECH Sodium LignosulfonatejimmyNo ratings yet

- Tejas Kush Investigatory Hard Plastic ExperimentDocument18 pagesTejas Kush Investigatory Hard Plastic ExperimentTejas KushNo ratings yet

- Process Department: MOHAMMAD SHUJJAT ABBAS (Trainee Engineer M&U) - Orientation ReportDocument4 pagesProcess Department: MOHAMMAD SHUJJAT ABBAS (Trainee Engineer M&U) - Orientation ReportShujjat AbbasNo ratings yet

- Brochure Hardeners For WaterglassDocument18 pagesBrochure Hardeners For WaterglassAlejandro LozanoNo ratings yet

- Impression Material 2Document104 pagesImpression Material 2Manjulika Tysgi100% (1)

- CH CH CH - CH CL CL N N: PolymerizationDocument34 pagesCH CH CH - CH CL CL N N: PolymerizationBagoes Rebel CrewNo ratings yet

- Elastomeric Impression MaterialsDocument6 pagesElastomeric Impression MaterialsMarlene CasayuranNo ratings yet

- PVC Compound Ingredients IdentificationsDocument9 pagesPVC Compound Ingredients IdentificationsAhmed RaafatNo ratings yet

- Calculos de Poliuretano RigidoDocument46 pagesCalculos de Poliuretano Rigidosescobar86100% (1)

- PVC Compounding1-NSA WITH DIAGRAMS & FORMULATIONS-1Document21 pagesPVC Compounding1-NSA WITH DIAGRAMS & FORMULATIONS-1Mahesh GiriNo ratings yet

- Flexidone™ - A New Class of Innovative PVC Plasticizers: Martin Bonnet and Hasan KaytanDocument19 pagesFlexidone™ - A New Class of Innovative PVC Plasticizers: Martin Bonnet and Hasan KaytanBenpetro ChaichuaNo ratings yet

- Polyvinyl Chloride - Wikipedia PDFDocument105 pagesPolyvinyl Chloride - Wikipedia PDFJesly JosephNo ratings yet

- Mowilith LDM 7255 For Film Print LaminationDocument8 pagesMowilith LDM 7255 For Film Print LaminationchayanunNo ratings yet

- XPU Flooring Balcony Case StudyDocument12 pagesXPU Flooring Balcony Case StudyyasafyNo ratings yet

- Polymer FoamsDocument17 pagesPolymer FoamsSachin PatilNo ratings yet

- PolyolyfinsDocument40 pagesPolyolyfinsManikiranSai100% (1)

- Chemoxy International LTD Coalescing RangeDocument8 pagesChemoxy International LTD Coalescing RangeIliass MeskiNo ratings yet

- AdmixtureDocument35 pagesAdmixtureSasanka AyinaparthiNo ratings yet

- LLDPE ProjectDocument86 pagesLLDPE Projectbhagwat2680% (5)

- Butyl & Chloroprene 2003Document16 pagesButyl & Chloroprene 2003Suyash TrivediNo ratings yet

- Polyvinyl ChlorideDocument14 pagesPolyvinyl ChlorideSerkan GecimNo ratings yet

- MSF 846 690-2Document8 pagesMSF 846 690-2Maurice ABOURIDANo ratings yet

- Roll-to-Roll Manufacturing: Process Elements and Recent AdvancesFrom EverandRoll-to-Roll Manufacturing: Process Elements and Recent AdvancesJehuda GreenerNo ratings yet

- Polyurethanes: Science, Technology, Markets, and TrendsFrom EverandPolyurethanes: Science, Technology, Markets, and TrendsRating: 1 out of 5 stars1/5 (1)

- Membrane Gas SeparationFrom EverandMembrane Gas SeparationBenny FreemanNo ratings yet

- Draf (Model Keseimbangan Minyak Kelapa SawitDocument4 pagesDraf (Model Keseimbangan Minyak Kelapa SawitFadila AbdulnurNo ratings yet

- Exit TicketDocument1 pageExit TicketFadila AbdulnurNo ratings yet

- Key Point PartDocument5 pagesKey Point PartFadila AbdulnurNo ratings yet

- Skema Japan KPD Part DilaDocument3 pagesSkema Japan KPD Part DilaFadila AbdulnurNo ratings yet

- CISPLATINDocument3 pagesCISPLATINFadila AbdulnurNo ratings yet

- Astronomy Assigment 3Document6 pagesAstronomy Assigment 3Fadila AbdulnurNo ratings yet

- TRIGONOMETRY (Distance and Height Measurement)Document4 pagesTRIGONOMETRY (Distance and Height Measurement)Fadila AbdulnurNo ratings yet

- Laboratory Assignment Report: Skf3023: Kimia Fizik (B) Semester 03 Session 2021/2022Document5 pagesLaboratory Assignment Report: Skf3023: Kimia Fizik (B) Semester 03 Session 2021/2022Fadila AbdulnurNo ratings yet

- Experiment Astronomy SundialDocument3 pagesExperiment Astronomy SundialFadila AbdulnurNo ratings yet

- Ga Marta ViewDocument188 pagesGa Marta ViewAndes PutraNo ratings yet

- PEC-En-GDE-L-10028 - Design Guidelines For Jacketed PipingDocument9 pagesPEC-En-GDE-L-10028 - Design Guidelines For Jacketed PipingAkshay DesaiNo ratings yet

- CAISSON - Tolinggula 2Document1 pageCAISSON - Tolinggula 2Bamz ImpazztNo ratings yet

- Reinforced Elastomeric Bearing Table Type BDocument9 pagesReinforced Elastomeric Bearing Table Type BAy ChNo ratings yet

- Section D - Proposed Methodology: Request For Proposal - Civil & Structural Consultancy ServicesDocument46 pagesSection D - Proposed Methodology: Request For Proposal - Civil & Structural Consultancy Servicesdak comeiNo ratings yet

- "Why Are My Stainless Steel Filters Getting Pin-Hole Leaks?Document2 pages"Why Are My Stainless Steel Filters Getting Pin-Hole Leaks?Tahseen ShNo ratings yet

- Daftar Harga Upah Dan Bahan / MaterialDocument24 pagesDaftar Harga Upah Dan Bahan / MaterialOkta RizalNo ratings yet

- WirebondingDocument9 pagesWirebondingElvis NgNo ratings yet

- ECEG-3205 - Chapter 2 Second PartDocument37 pagesECEG-3205 - Chapter 2 Second PartYohanes FisehaNo ratings yet

- SSAB Trailer Design GuidelineDocument28 pagesSSAB Trailer Design GuidelineGerard Piedra García100% (1)

- Liebert Refrigerant SizingDocument2 pagesLiebert Refrigerant Sizingcoolth2No ratings yet

- Existing Chandmari Rob (Dismantling Scheme) : 5. Jacking Arrangement Required For Lift The Existing StructureDocument24 pagesExisting Chandmari Rob (Dismantling Scheme) : 5. Jacking Arrangement Required For Lift The Existing StructureAnkitaNo ratings yet

- IMEC Quick Start Guide V1.0 SPDocument4 pagesIMEC Quick Start Guide V1.0 SPJose Ivan Carvajal CortizosNo ratings yet

- Types of Roof Trusses: King Post TrussDocument3 pagesTypes of Roof Trusses: King Post TrussjashndeepNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document8 pagesRCC91 One-Way Solid Slabs (Tables)Mohd Said Mohd ZakariaNo ratings yet

- Aluminum Extrusions (HFS6 Series) Aluminum Extrusions (HFS6 Series)Document1 pageAluminum Extrusions (HFS6 Series) Aluminum Extrusions (HFS6 Series)Jesus ValenciaNo ratings yet

- Part B-Arch ExreciseDocument2 pagesPart B-Arch Exrecisestudio surfaceNo ratings yet

- Finite Element Modeling of Rutting For Flexible PaDocument14 pagesFinite Element Modeling of Rutting For Flexible PaZainab A. AbdulstaarNo ratings yet

- Technical - STWS-ECS-FCU-103 AND 104Document1 pageTechnical - STWS-ECS-FCU-103 AND 104Prakash RaoNo ratings yet

- Mastertop 1332: Polyurethane, Waterproofing and Protective Traffic-Deck Coating SystemDocument3 pagesMastertop 1332: Polyurethane, Waterproofing and Protective Traffic-Deck Coating SystemFrancois-No ratings yet

- Valqua CatalogDocument44 pagesValqua CatalogzatenneNo ratings yet

- BT5 SpecsDocument6 pagesBT5 SpecsJustine Rose AngolluanNo ratings yet

- Design For Wind Loads - SampleDocument6 pagesDesign For Wind Loads - SampleLouie PachecoNo ratings yet

- Format - CISDocument8 pagesFormat - CISgopichandallakaNo ratings yet

- Din 6914Document2 pagesDin 6914vpjagannaathNo ratings yet