Professional Documents

Culture Documents

Fertewitjg J

Fertewitjg J

Uploaded by

aleksovOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fertewitjg J

Fertewitjg J

Uploaded by

aleksovCopyright:

Available Formats

®

Desmodur IL 1451 BA

Characterization Desmodur IL 1451 BA is an aromatic polyisocyanate based on toluene

diisocyanate.

It is suitable as a hardener component for fast drying, two-component

polyurethane coatings.

Form supplied Form supplied is approximately 51% in butyl acetate.

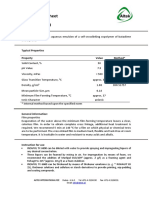

Characteristic data

Property Value Unit of measurement Method

NCO content 7.4 ± 0.2 %

Non-volatile content 51.0 ± 2.0 %

o

(0.2 g / 60 min / 120 C)

O

Viscosity (23 C) 250 ± 75 mPa∙s

Color value (Iodine) ≤ 1.0

Monomer content < 0.50 %

Other data*

Property Value Unit of measurement Method

Equivalent weight approx. 570

Flash point approx. 26 °C

Density at 20 C

o approx. 1.07 g/ml

*These values provide general information and are not part of the product specification.

page 1 of 3

Document contains important information and must be read in its entirety.

Edition 2017-07-14 Product Datasheet

®

Desmodur IL 1451 BA

Solubility / thinnability Generally speaking, Desmodur IL 1451 BA is well suited to thinning with esters

such as ethyl acetate, butyl acetate, 1-methoxyproplyacetate-2 and aromatic

®

hydrocarbons such as toluene, xylene, Solvesso 100 and

™

ShellSol A. The solutions formed must be tested for their storage stability. In

particular, prolonged storage of a solution with low binder content may result in

turbidity and sedimentation. The product cannot be reduced with mineral spirit.

Alcohols react with Desmodur IL 1451 BA and therefore may not be used. Only

PU grade solvents (< 0.05 % water, free of other reactive impurities) may be

used.

Compatibility ®

Desmodur IL 1451 BA is compatible with Desmophen A 450 polyacrylate,

®

many polyester-based Desmophen grades and with alkyd resin, including

combinations with nitrocellulose. In the critical combinations, Desmodur IL

1451 BA exhibits better compatibility than the standard products based on TDI

isocyanurates. Desmodur IL 1451 BA can be combined with Desmodur L and

also with Desmodur HL and Desmodur N. The compatibility of Desmodur IL

1451 BA with the other formulation components must be tested in advance.

Properties / Applications The two-component polyurethane systems formulated with Desmodur IL 1451

BA are characterized by their very rapid initial drying and early sandability,

making them ideal for the industrial coating of wood and furniture. An NCO/OH

ratio of approximately 0.5 - 0.7 is recommended as a function of the reactivity

and hardness of the polyol. With an NCO/OH ratio of 1:1, the Desmodur IL

1451 BA must be combined with Desmodur L. In this case, the optimal ratio

of the Desmodur L / IL 1451 is a function of polyol hardness and the required

drying time. The low viscosity and high reactivity of the Desmodur IL 1451 BA

enables the formulation of clear and colored coatings with high solids contents.

These can be applied quickly and only a few coats are required.

As with any product, use of Desmodur IL 1451 BA in a given application must

be tested (including but not limited to field testing) in advance by the user to

determine suitability.

Handling information The product is used mainly as a hardener in coating materials or

adhesives. The handling of coating materials or adhesives containing reactive

polyisocyanates and residual monomeric TDI requires appropriate protective

measures referred to in the safety data sheet. These products may therefore

be used only in industrial or trade applications. They are not suitable for use

in homeworker (DIY) applications.

page 2 of 3

Document contains important information and must be read in its entirety.

Edition 2017-07-14 Product Datasheet

®

Desmodur IL 1451 BA

Storage Desmodur IL 1451 BA should be stored in tightly sealed original containers and

protected from moisture, heat, and foreign materials. The product is sensitive

to moisture. Storage at higher temperatures may result in increased viscosity.

Recommended storage temperature is 0º-30ºC.

Storage time Desmodur IL 1451 BA has a shelf life of nine months from date of receipt at

customer, provided the material is stored in sealed original containers at the

recommended storage temperature.

Other information ® ®

Desmodur and Desmophen are registered trademarks of Covestro AG.

®

Solvesso is a registered trademark of Exxon.

™

ShellSol is a trademark of Shell.Handling instructions

Health and Safety Information Appropriate literature has been assembled which provides information

concerning the health and safety precautions that must be observed when

handling this product. Before working with this product, you must read

and become familiar with the available information on its risks, proper

use, and handling. This cannot be overemphasized. Information is available

in several forms, e.g., safety data sheets and product labels. For further

information contact your Covestro LLC representative or the Product Safety

and Regulatory Affairs Department in Pittsburgh, PA.

The manner in which you use and the purpose to which you put and utilize our products, technical assistance and information (whether verbal, written

or by way of production evaluations), including any suggested formulations and recommendations, are beyond our control. Therefore, it is imperative

that you test our products, technical assistance and information to determine to your own satisfaction whether our products, technical assistance and

information are suitable for your intended uses and applications. This application-specific analysis must at least include testing to determine suitability

from a technical as well as health, safety, and environmental standpoint. Such testing has not necessarily been done by us. Unless we otherwise agree

in writing, all products are sold strictly pursuant to the terms of our standard conditions of sale which are available upon request. All information and

technical assistance is given without warranty or guarantee and is subject to change without notice. It is expressly understood and agreed that you

assume and hereby expressly release us from all liability, in tort, contract or otherwise, incurred in connection with the use of our products, technical

assistance, and information. Any statement or recommendation not contained herein is unauthorized and shall not bind us. Nothing herein shall be

construed as a recommendation to use any product in conflict with any claim of any patent relative to any material or its use. No license is implied

or in fact granted under the claims of any patent.

Editor: Covestro LLC

1 Covestro Circle

Pittsburgh, Pennsylvania 15205 Contact:

United States CA Single Point of Contact Office

www.covestro.com Tel. 412-413-3983

page 3 of 3

Document contains important information and must be read in its entirety.

Edition 2017-07-14 Product Datasheet

You might also like

- Deurheo 2810Document1 pageDeurheo 2810omerNo ratings yet

- Chapter 12 AnswersDocument2 pagesChapter 12 AnswersMatt Wong100% (2)

- Chemical Health Risk Assessment (CHRA) - Draft Final PDFDocument31 pagesChemical Health Risk Assessment (CHRA) - Draft Final PDFPriyo Djatmiko100% (1)

- The Truth About Fermented Cod Liver OilDocument111 pagesThe Truth About Fermented Cod Liver OildonexcelNo ratings yet

- Desmodur Z 4470 BA - en - 04465350 12978466 13462745Document3 pagesDesmodur Z 4470 BA - en - 04465350 12978466 13462745shikaru7114No ratings yet

- Desmodur Z 4470 BA - en - 04465350 12978466 13462745Document3 pagesDesmodur Z 4470 BA - en - 04465350 12978466 13462745RICHNo ratings yet

- Desmodur HL BA - en - 00130850 12978366 13422252Document3 pagesDesmodur HL BA - en - 00130850 12978366 13422252naosopresNo ratings yet

- Desmodur N 75 BA - en - 04132289 12978409 13434689Document3 pagesDesmodur N 75 BA - en - 04132289 12978409 13434689bitisa5368No ratings yet

- Desmodur N 75 BADocument4 pagesDesmodur N 75 BASergiu Tarala100% (1)

- Desmodur Z 4470 BA: Type Form Supplied UsesDocument4 pagesDesmodur Z 4470 BA: Type Form Supplied Usessriatul2006No ratings yet

- Desmodur N 3400 - en - 00072044 12978399 13434739Document3 pagesDesmodur N 3400 - en - 00072044 12978399 13434739SAURAVENDRA TOMARNo ratings yet

- Desmodur L 75 - en - 82358391 12978387 13422316Document3 pagesDesmodur L 75 - en - 82358391 12978387 13422316Aditya NarainNo ratings yet

- Desmodur L 75 - en - 82358391 12978387 13422316Document3 pagesDesmodur L 75 - en - 82358391 12978387 13422316Long An DoNo ratings yet

- Desmodur N 3390 BA: Characterization Form SuppliedDocument4 pagesDesmodur N 3390 BA: Characterization Form Suppliedbuzas94No ratings yet

- Desmodur N 3200Document4 pagesDesmodur N 3200محمد مقلدNo ratings yet

- Setalux® D A 870 BaDocument2 pagesSetalux® D A 870 Baسلطان ابوالعلاNo ratings yet

- Desmodur Ultra N 3390 BA - en - 86223279 20818211 20818688Document4 pagesDesmodur Ultra N 3390 BA - en - 86223279 20818211 20818688majidhajnasrNo ratings yet

- Desmodur VP LS 2394 - en - 05573580 17844557 19844485Document4 pagesDesmodur VP LS 2394 - en - 05573580 17844557 19844485gUiLhErMe fAnTiNiNo ratings yet

- Desmodur L75: CharacterizationDocument4 pagesDesmodur L75: CharacterizationasmaraputriNo ratings yet

- Tds Lurapret Dispersion D 2337 EngDocument4 pagesTds Lurapret Dispersion D 2337 EngRoking KumarNo ratings yet

- Desmodur N 75 MPA - en - 00832197 00009989 00054371Document4 pagesDesmodur N 75 MPA - en - 00832197 00009989 00054371VeliYunusKavalciNo ratings yet

- COVESTRO Desmodur BL 3272 MPA - en - 04109147 12978291 13410124Document3 pagesCOVESTRO Desmodur BL 3272 MPA - en - 04109147 12978291 13410124massimodinelliNo ratings yet

- Desmophen A 160 SN: Type Characterization Form Supplied UsesDocument2 pagesDesmophen A 160 SN: Type Characterization Form Supplied UsesFadi MagdyNo ratings yet

- Bayhydur XP 2655 - en - 06756239 17854696 21037056Document4 pagesBayhydur XP 2655 - en - 06756239 17854696 21037056trường phạmNo ratings yet

- Desmophen 650 MPADocument3 pagesDesmophen 650 MPAさいとはちこNo ratings yet

- Loctite Liofol HS 59-670-EnDocument2 pagesLoctite Liofol HS 59-670-EnCharly DtNo ratings yet

- Emulsogen LCN 070 (TDS)Document1 pageEmulsogen LCN 070 (TDS)Joyce yychongNo ratings yet

- Desmodur N 75 BA/X: Aliphatic PolyisocyanateDocument2 pagesDesmodur N 75 BA/X: Aliphatic PolyisocyanateLê TiếnNo ratings yet

- TDS Hostapur OS LiqDocument2 pagesTDS Hostapur OS LiqRabah ABBASNo ratings yet

- Loctite Liofol Op 1450-EnDocument2 pagesLoctite Liofol Op 1450-EnCharly DtNo ratings yet

- Tds Acronaleco702ap enDocument3 pagesTds Acronaleco702ap enShreyashi MukhopadhayNo ratings yet

- Desmodur N 75 MPAX - en - 00832200 17844451 19840310Document4 pagesDesmodur N 75 MPAX - en - 00832200 17844451 19840310rkapadia505No ratings yet

- Desmophen VP LS 22491 - en - 04896483 13042682 13540223Document3 pagesDesmophen VP LS 22491 - en - 04896483 13042682 135402234dlem0nheadNo ratings yet

- Product Datasheet DESMODUR REDocument3 pagesProduct Datasheet DESMODUR RECristianNo ratings yet

- Desmodur N 75 MPAX - en - 00832200 00009990 00034502Document4 pagesDesmodur N 75 MPAX - en - 00832200 00009990 00034502feby nurvinandaNo ratings yet

- Product Bulletin Id-Bond L: Typical Physical PropertiesDocument1 pageProduct Bulletin Id-Bond L: Typical Physical PropertiesBaher SaidNo ratings yet

- Agitan 731Document1 pageAgitan 731ahmed ahmedNo ratings yet

- Robond L-330 TDSDocument2 pagesRobond L-330 TDSSebastian Camilo SalazarNo ratings yet

- Poligen WE1: Technical InformationDocument4 pagesPoligen WE1: Technical InformationCarlotta C.No ratings yet

- Data Sheet of FloccCare 6050Document1 pageData Sheet of FloccCare 6050Osama AhmedNo ratings yet

- Desmodur E21: Type Form Supplied UsesDocument3 pagesDesmodur E21: Type Form Supplied UsesRajuNSanaboinaNo ratings yet

- Technical Data Sheet Defoam RI 100Document2 pagesTechnical Data Sheet Defoam RI 100KETAN SHAHNo ratings yet

- Desmodure-Rfe-Tds CROSSLİNKİNG AGENTDocument2 pagesDesmodure-Rfe-Tds CROSSLİNKİNG AGENTGİZEM DEMİRNo ratings yet

- Silco Af 838: Product Description: Special NotesDocument1 pageSilco Af 838: Product Description: Special NotesrosarioNo ratings yet

- Loctite Liofol BC 1580-EnDocument3 pagesLoctite Liofol BC 1580-EnCharly DtNo ratings yet

- Desmodur BL 3175 SN - en - 00831484 17778921 19840234Document4 pagesDesmodur BL 3175 SN - en - 00831484 17778921 19840234I Love MusicNo ratings yet

- Genapol PF 10Document2 pagesGenapol PF 10Mohamed HalemNo ratings yet

- Antifoulant: DescriptionDocument2 pagesAntifoulant: DescriptionAbhishek GuddadNo ratings yet

- 15885Document1 page158858612106535No ratings yet

- Desmodur Ultra E 15 - en - 86620634 23266676 23505085Document3 pagesDesmodur Ultra E 15 - en - 86620634 23266676 23505085محمد مقلدNo ratings yet

- Desmophen 1200 - en - 00134597 17947398 20766463Document3 pagesDesmophen 1200 - en - 00134597 17947398 20766463Sabri AeroChemNo ratings yet

- Bpxe B9JPDQDocument2 pagesBpxe B9JPDQTanguy FloryNo ratings yet

- Rheobuild 6601Document2 pagesRheobuild 6601Rohil JulaniyaNo ratings yet

- Acronal ECO 702 AP TI EDA Nov 07Document3 pagesAcronal ECO 702 AP TI EDA Nov 07nanoNo ratings yet

- Anti Mus Sol UDF Liq - eDocument3 pagesAnti Mus Sol UDF Liq - esuvrodev812100% (1)

- Bayhydrol A 2695 - en - 80628498 12942229 13229734Document3 pagesBayhydrol A 2695 - en - 80628498 12942229 13229734FilemonDimasAdityaNo ratings yet

- Rocol Dry Moly SprayDocument9 pagesRocol Dry Moly SpraysubodhasinghNo ratings yet

- Inzapol TX 6600Document2 pagesInzapol TX 6600New EmailNo ratings yet

- TDS Celvolit 1326 (SG)Document2 pagesTDS Celvolit 1326 (SG)Duc Nguyen100% (1)

- Bonderite C-Ne 6771: Known As P3-Emulpon 6771 2014Document2 pagesBonderite C-Ne 6771: Known As P3-Emulpon 6771 2014RakshasuduNo ratings yet

- SF 7647-EnDocument2 pagesSF 7647-EnRonald Mario Quiroz SerrateNo ratings yet

- Thioplast G4: Liquid Polysulfide Polymer With Thiol End Groups (MW 1800)Document3 pagesThioplast G4: Liquid Polysulfide Polymer With Thiol End Groups (MW 1800)kebenshanNo ratings yet

- Alginate RemoverDocument4 pagesAlginate RemoveraleksovNo ratings yet

- 26 1986 Dowsil FBL 0563 Formulated BlendDocument3 pages26 1986 Dowsil FBL 0563 Formulated BlendaleksovNo ratings yet

- Acs Langmuir 9b03908Document56 pagesAcs Langmuir 9b03908aleksovNo ratings yet

- Finntalc M30Sl: Functional ExtenderDocument2 pagesFinntalc M30Sl: Functional ExtenderaleksovNo ratings yet

- Ruukki 41338 Instructiuni de Montaj Placarea Fatadei Peste PanouriDocument12 pagesRuukki 41338 Instructiuni de Montaj Placarea Fatadei Peste PanouriGhenoiu PaulNo ratings yet

- Cooling Tower ChlorinationDocument1 pageCooling Tower ChlorinationdeejayroxNo ratings yet

- Instructions For Students: Indian National Chemistry Olympiad Theory 2010Document53 pagesInstructions For Students: Indian National Chemistry Olympiad Theory 2010Anubhuti GhaiNo ratings yet

- Titremetriic Analysis 2Document23 pagesTitremetriic Analysis 2nagito komaedaNo ratings yet

- Aquaponics: From Wikipedia, The Free EncyclopediaDocument11 pagesAquaponics: From Wikipedia, The Free Encyclopediahossamh3No ratings yet

- CV-DR - Adel SalemSultan - EGYPT-PHARMACEUTICAL PLANT MANAGERDocument7 pagesCV-DR - Adel SalemSultan - EGYPT-PHARMACEUTICAL PLANT MANAGERDr.Adel Salem SultanNo ratings yet

- Titanium Setting Coil BestDocument25 pagesTitanium Setting Coil BestLukman HakimNo ratings yet

- Formaldehyde Test: 1. MethodDocument1 pageFormaldehyde Test: 1. MethodElin KarlinaNo ratings yet

- PultusionDocument5 pagesPultusionvinaykumaryadavNo ratings yet

- Entech ControlsDocument12 pagesEntech Controlsmanmohansingh1999No ratings yet

- Iso 13507 2012Document9 pagesIso 13507 2012Logan KNo ratings yet

- Experiment 6 Colorimetric Analysis For Reducing SugarDocument3 pagesExperiment 6 Colorimetric Analysis For Reducing SugarMsfaeza HanafiNo ratings yet

- Horse ChestnutDocument12 pagesHorse ChestnutBilal MasoodNo ratings yet

- Analisa Jurnal Spektrofluorometri - AnfiskimDocument13 pagesAnalisa Jurnal Spektrofluorometri - AnfiskimWira Wahyudi NandayasaNo ratings yet

- 4-7ts - General Welding Requierments - KBRDocument11 pages4-7ts - General Welding Requierments - KBRKunal SrivastavaNo ratings yet

- Experiment On Hydrogen Ion ConcentrationDocument15 pagesExperiment On Hydrogen Ion ConcentrationAnsell EwemeNo ratings yet

- Designing With BerylliaDocument25 pagesDesigning With BerylliaXidornNo ratings yet

- Cyclen Based GD ComplexesDocument22 pagesCyclen Based GD ComplexesHaroon Ur RashidNo ratings yet

- LG - Refrigerador Gc-p207, Gc-l207, Gc-c207, Gc-b207Document145 pagesLG - Refrigerador Gc-p207, Gc-l207, Gc-c207, Gc-b207pasantito50% (2)

- Drug Education and Vice Control: Reviewer Notes inDocument10 pagesDrug Education and Vice Control: Reviewer Notes inJolly BelleNo ratings yet

- PDS Milk of LimeDocument2 pagesPDS Milk of Limenachiappan_rameshNo ratings yet

- Unique Mixproof ValveDocument8 pagesUnique Mixproof ValveyapwaieeNo ratings yet

- Granular Fertilizer Drying and Agglomeration in StorageDocument10 pagesGranular Fertilizer Drying and Agglomeration in StoragevzgscribdNo ratings yet

- SAE J1392-2001 Stabilized 2017Document10 pagesSAE J1392-2001 Stabilized 2017ALEX MURPHYNo ratings yet

- Thermolatent Curing Agents For Low Temperature 1K Epoxy Adhesive ApplicationsDocument27 pagesThermolatent Curing Agents For Low Temperature 1K Epoxy Adhesive Applicationss0n1907No ratings yet

- 2.2.2. Briggs-Haldane Approach: ES ES P SDocument8 pages2.2.2. Briggs-Haldane Approach: ES ES P SMugdha Dabir-PathakNo ratings yet

- Nylon Sleeve CouplingDocument3 pagesNylon Sleeve CouplingHudiNo ratings yet