Professional Documents

Culture Documents

Quick Reference Guide To ASME Section VIII, Div 1 - 230626 - 014213

Quick Reference Guide To ASME Section VIII, Div 1 - 230626 - 014213

Uploaded by

Said FerdjallahCopyright:

Available Formats

You might also like

- Impact Test Exemptions PEDDocument7 pagesImpact Test Exemptions PEDoberaiNo ratings yet

- 5.case ToolsDocument16 pages5.case ToolsﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞNo ratings yet

- Owners N Operators Guide ErjDocument21 pagesOwners N Operators Guide Erjcjtrybiec75% (4)

- Cs & Las Impact Req - Asme Sec Viii Div 2Document16 pagesCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareNo ratings yet

- Excel PV 2016 Demo VersionDocument6 pagesExcel PV 2016 Demo Versionahmadlie0% (1)

- Pressure Vessel Fabrication & Inspection: Poyyara ConsultantsDocument137 pagesPressure Vessel Fabrication & Inspection: Poyyara ConsultantsPratik VashiNo ratings yet

- PV Elite Transport A Vertical Vessel in The Horizontal Position PDFDocument3 pagesPV Elite Transport A Vertical Vessel in The Horizontal Position PDFnodyyy100% (1)

- Electrode Selection As Per Base Metal With Preheat, Postheat and Hardness DetailsDocument1 pageElectrode Selection As Per Base Metal With Preheat, Postheat and Hardness DetailsJlkKumar100% (1)

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)Ricardo Paz SoldanNo ratings yet

- Guide To ASME Code VIII Division 1 Pressure VesselsDocument16 pagesGuide To ASME Code VIII Division 1 Pressure VesselsSaâd Eddine Atif0% (1)

- Advanced User Guide For Free McBoot 1.8Document35 pagesAdvanced User Guide For Free McBoot 1.8Anzac Matt100% (2)

- Maximum Allowable Stress: Mechanical Design of Pressure VesselsDocument17 pagesMaximum Allowable Stress: Mechanical Design of Pressure Vesselsfauzi100% (2)

- Bolt TighteningDocument13 pagesBolt Tighteningwali banNo ratings yet

- Sa 387Document29 pagesSa 387Ali VarmazyarNo ratings yet

- Heat TreatmentDocument5 pagesHeat TreatmentsheikmoinNo ratings yet

- ASME DIV 2 Class 1 Vs Class 2Document3 pagesASME DIV 2 Class 1 Vs Class 2Idris SiddiquiNo ratings yet

- Check List For Design of Pressure VesselsDocument2 pagesCheck List For Design of Pressure Vesselssuresh_vikiNo ratings yet

- ASME Section VIII-Division 1 - Pressure Vessels - CASTI GuidebookDocument1 pageASME Section VIII-Division 1 - Pressure Vessels - CASTI GuidebookcristinelbNo ratings yet

- Flange Bolt Torque Sequence and Torque Table - A Complete Bolt Tightening ProcedureDocument16 pagesFlange Bolt Torque Sequence and Torque Table - A Complete Bolt Tightening Procedureal arabiNo ratings yet

- Shell and Tube Heat Exchangers (API 660 vsTEMA)Document3 pagesShell and Tube Heat Exchangers (API 660 vsTEMA)Aravind MadhuNo ratings yet

- Conversion ASME Unit ConversionDocument3 pagesConversion ASME Unit ConversionMohdBadruddinKarimNo ratings yet

- Equivalent ASME en MaterialsDocument3 pagesEquivalent ASME en MaterialsChee WeiNo ratings yet

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyNo ratings yet

- Weld End Preparation at Unequal Wall ThicknessesDocument4 pagesWeld End Preparation at Unequal Wall ThicknessesDesmond ChangNo ratings yet

- Manual Design Validation CalculationDocument21 pagesManual Design Validation CalculationToniNo ratings yet

- Tube To Tube Sheet WeldingDocument5 pagesTube To Tube Sheet WeldingGowrish Kumar100% (2)

- 6-12-0031 - Standard Specification For Storage Tanks For Package Items PDFDocument13 pages6-12-0031 - Standard Specification For Storage Tanks For Package Items PDFpl_arunachalam79No ratings yet

- Welding SymbolsDocument21 pagesWelding Symbolstuna61No ratings yet

- Pressure Vessel - Columns - AnimateDocument16 pagesPressure Vessel - Columns - AnimateSamir ChaudharyNo ratings yet

- Heat Treatment After Forming Review Head: (A) - % Extreme Fiber Elongation CalculationDocument2 pagesHeat Treatment After Forming Review Head: (A) - % Extreme Fiber Elongation CalculationvpjagannaathNo ratings yet

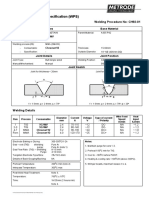

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- Wps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Document4 pagesWps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Nilotpal Kumar RaiNo ratings yet

- Hydrostatic Test Pressure CalculationDocument1 pageHydrostatic Test Pressure Calculationmohd as shahiddin jafriNo ratings yet

- Mandatory Appendix 26Document28 pagesMandatory Appendix 26Sushil WadiyeNo ratings yet

- ASME 9 - CalculatorDocument2 pagesASME 9 - CalculatorEmel Besir100% (1)

- Fatigue Analysis in PV EliteDocument3 pagesFatigue Analysis in PV EliteCostynhaNo ratings yet

- Blind Thickness CalculatorDocument2 pagesBlind Thickness CalculatorTejas Patel100% (1)

- Asme Form U-1. v-11201 ADocument3 pagesAsme Form U-1. v-11201 ASalman KhanNo ratings yet

- Using s275jr For Asme Div1 Vessel-UnassignedDocument6 pagesUsing s275jr For Asme Div1 Vessel-UnassignedNasrul AdliNo ratings yet

- Nozzle CheckDocument11 pagesNozzle CheckincaurcoNo ratings yet

- Asme WPS Demo PWHT PDFDocument3 pagesAsme WPS Demo PWHT PDFGanesh rohitNo ratings yet

- Tema Asme Section Viii Div1 Section Uhx PDFDocument20 pagesTema Asme Section Viii Div1 Section Uhx PDFAdrian StoicescuNo ratings yet

- 8-12 X 3000 M Spherical LPG Storage TankDocument1 page8-12 X 3000 M Spherical LPG Storage Tankevrim77100% (1)

- WELDING SUMMARY SHEET (Syu DTD 17 04 19)Document12 pagesWELDING SUMMARY SHEET (Syu DTD 17 04 19)Kushal PraviraNo ratings yet

- Girth Flange Load Calculation Using by FEA TechniquesDocument12 pagesGirth Flange Load Calculation Using by FEA TechniqueskingstonNo ratings yet

- WRC, PV Elite, NozzlePro Sign ConventionsDocument13 pagesWRC, PV Elite, NozzlePro Sign ConventionsADHIRAJ KOLINo ratings yet

- Acceptance Criteria Asme B31.3 PDFDocument1 pageAcceptance Criteria Asme B31.3 PDFAhmad RizkiNo ratings yet

- Pressure Vessel Dimension InspectionDocument10 pagesPressure Vessel Dimension InspectionYetkin ErdoğanNo ratings yet

- Univeral WPS For Pipe To Plate Fillet Welding (6800009)Document1 pageUniveral WPS For Pipe To Plate Fillet Welding (6800009)Ibrahim shaikNo ratings yet

- Lloyd's Register's Guide To Understanding Ibr-1950 - inDocument12 pagesLloyd's Register's Guide To Understanding Ibr-1950 - inthehindu100% (1)

- Pressure Vessel Design Training - Course ContentDocument13 pagesPressure Vessel Design Training - Course Contentamol shindeNo ratings yet

- Asme Viii - QDocument431 pagesAsme Viii - Qmajdi jerbi100% (1)

- Tube-To-Tube Sheet Joint RequirementsDocument2 pagesTube-To-Tube Sheet Joint RequirementsWaqas WaqasNo ratings yet

- Asme Section I: Section - Iii Code ExtractionDocument3 pagesAsme Section I: Section - Iii Code ExtractionReadersmo100% (1)

- ASME Impact Test RequirementDocument15 pagesASME Impact Test Requirementumar_hazrad8219100% (1)

- Elliptical Head Design ToolDocument1 pageElliptical Head Design Toolnaveen_86No ratings yet

- Pressure Vessel Interview QuestionsDocument1 pagePressure Vessel Interview Questionsdh6802No ratings yet

- 3.3 Piping Design Criteria Rev 2Document15 pages3.3 Piping Design Criteria Rev 2Maheswaran KurusamyNo ratings yet

- 12.15.1 Plano de Red de Distribucion-Ap-01Document1 page12.15.1 Plano de Red de Distribucion-Ap-01Dick GuiliansNo ratings yet

- Tupi BV: Cosco (Dalian)Document4 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- Pipe Ring Product Selector: Light-Duty Galvanized Pipe RingsDocument1 pagePipe Ring Product Selector: Light-Duty Galvanized Pipe RingsReem Ahmed KhalilNo ratings yet

- Urea Granul: No Kode Alat Nama Alat Jumlah No Kode Alat Nama Alat JumlahDocument1 pageUrea Granul: No Kode Alat Nama Alat Jumlah No Kode Alat Nama Alat JumlahFarhan MuhamadNo ratings yet

- 4020-186-M-018 - 3 Cyanide Stripping Column General Arrangement 1Document1 page4020-186-M-018 - 3 Cyanide Stripping Column General Arrangement 1thoriq ikhwanNo ratings yet

- CP-X980: DP-6860 Users ManualDocument40 pagesCP-X980: DP-6860 Users ManualRichard HollidayNo ratings yet

- Digam SeriesDocument14 pagesDigam SeriesNguyễn Quang TrânNo ratings yet

- GATE 2015 Information BrochureDocument34 pagesGATE 2015 Information BrochureAdam BlanchardNo ratings yet

- Repair ManualDocument31 pagesRepair Manualzye88593No ratings yet

- Skinner CNA130 Syllabus Winter10Document5 pagesSkinner CNA130 Syllabus Winter10osalazardebreauxNo ratings yet

- Pulse-Width Modulation (PWM) TechniquesDocument14 pagesPulse-Width Modulation (PWM) TechniquesMohamed SalahNo ratings yet

- 1 - 117 - FOX505 NL PDFDocument2 pages1 - 117 - FOX505 NL PDFpriyanka236No ratings yet

- Manual Compresor HuskyDocument88 pagesManual Compresor HuskyShakty Iglesias100% (1)

- Resume - John e Driscoll 11-5-14Document1 pageResume - John e Driscoll 11-5-14api-271060247No ratings yet

- Ons Kerk Se MenseDocument4 pagesOns Kerk Se MensetoypomNo ratings yet

- PULSE V2.0 - New Features: Cyber Security Protection Enhancements UAG (Unity Application Generator)Document2 pagesPULSE V2.0 - New Features: Cyber Security Protection Enhancements UAG (Unity Application Generator)cyrus6_997303No ratings yet

- Energy Performance Assessment of Hvac SystemsDocument4 pagesEnergy Performance Assessment of Hvac SystemsBudihardjo Sarwo SastrosudiroNo ratings yet

- Tutorial For Cadence SOC Encounter Place & RouteDocument28 pagesTutorial For Cadence SOC Encounter Place & Routeanon_248257978No ratings yet

- Ds Erhard Roco WaveDocument27 pagesDs Erhard Roco Wavekad-7No ratings yet

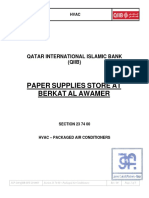

- Paper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Document5 pagesPaper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Congson JeffNo ratings yet

- RSM72-6-320P-340P/5BB 72 Cell 320-340Wp 1500VDC 17.5%: High Performance Polycrystalline ModuleDocument2 pagesRSM72-6-320P-340P/5BB 72 Cell 320-340Wp 1500VDC 17.5%: High Performance Polycrystalline ModuleTiago MottaNo ratings yet

- XDM 100 SDH System en 1Document0 pagesXDM 100 SDH System en 1swartsenburgNo ratings yet

- Electromechanical Boq ForensicDocument31 pagesElectromechanical Boq ForensicDesigner ForeverNo ratings yet

- Click Fraud Detection: Adversarial Pattern Recognition Over 5 Years at MicrosoftDocument21 pagesClick Fraud Detection: Adversarial Pattern Recognition Over 5 Years at MicrosoftBhakti RaneNo ratings yet

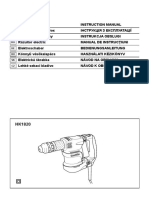

- Bor MasinaDocument28 pagesBor MasinaLohon TatianaNo ratings yet

- Rishi Kushwaha Resume MSC DA EPITA EngDocument1 pageRishi Kushwaha Resume MSC DA EPITA EngRishi KushwahaNo ratings yet

- Switchgear Vs SwitchboardDocument20 pagesSwitchgear Vs SwitchboardJuan MoralesNo ratings yet

- Ba Battery Tester MBT 101 enDocument8 pagesBa Battery Tester MBT 101 enDamian FediukNo ratings yet

- Industrial Training Report Final 38Document120 pagesIndustrial Training Report Final 38Sifat RaihanNo ratings yet

- Azimuth Co OrdinatorDocument2 pagesAzimuth Co OrdinatorGlen DonnellyNo ratings yet

- Attachment To SDO Memo No 96 S. 2024Document2 pagesAttachment To SDO Memo No 96 S. 2024LoidaCarameNo ratings yet

- User Manual710Document19 pagesUser Manual710Pedro AlmeidaNo ratings yet

Quick Reference Guide To ASME Section VIII, Div 1 - 230626 - 014213

Quick Reference Guide To ASME Section VIII, Div 1 - 230626 - 014213

Uploaded by

Said FerdjallahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quick Reference Guide To ASME Section VIII, Div 1 - 230626 - 014213

Quick Reference Guide To ASME Section VIII, Div 1 - 230626 - 014213

Uploaded by

Said FerdjallahCopyright:

Available Formats

A SM E BOILE R & P R ESSURE VESSEL COD E (BP VC )

Quick Reference Guide to ASME Section VIII, Div. 1

3 to 1 Tapers Loading and Nozzle Flange Design

Minimum Nozzle Neck UW-9(c) Lifting Lugs Reinforcement Appendix 2

Formed Head Thickness Nozzle Joint UW-42 UG-22 & UG-55 UG-37

Tolerances N4

UG-45 & Table UG-45 Design

UG-79 UW-16

UG-81

Exempting from

Reinforcement

UG-36(c)(3)(a)

Vent Holes Material

Nozzles in UG-37(g) Identification

Weld Seams

3 to 1 Taper Crosses UG-77

UW-14

UW-9(d)

UG-36

Spin Holes

UW-34

Hemi Head

Mandatory

Section VIII Div 1

Inspection

Threaded Scope Boundary

Openings Saddles and Supports

Connections U-1(e)(3)

UG-46 Appendix G

UG-43(e)

UG-54

Efficiency and Joint

Categorization

UG-32

UCS-57 THICKNESS ABOVE WHICH FULL WALL THICKNESS CHART/PIPE SCHEDULE - IN. (MM)

UW-35 MAXIMUM WELD REINFORCEMENT UW-33 ALIGNMENT TOLERANCE QW-461.9 PERFORMANCE QUALIFICATION

RADIOGRAPHIC EXAMINATION OF BUTT-WELDED

POSITION AND DIAMETER LIMITATIONS NOMINAL

JOINTS IS MANDATORY PIPE O.D. 10 10S 20 30 STD 40 60 XH 80 100 120 140 160 XXH

PIPE SIZE

Customary Units Customary Units Qualification Position & Type Weld

Nominal Thickness Above Which Test Qualified 1/2 (15) 0.840 (21.3) --- --- --- .109 (2.769) .109 (2.769) --- .147 (3.734) .147 (.3734) --- --- --- .188 (4.775) .294 (7.467)

P-No. & Group No.

Maximum Reinforcement (in.) Joint Categories Butt-Welded Joints Shall be Fully

Material Nominal Section Thickness Classification of

Radiographed 3/4 (20) 1.050 (26.7) .083 (2.108) .083 (2.108) --- --- .113 (2.870) .113 (2.870) --- .154 (3.912) .154 (3.912) --- --- --- .218 (5.537) .308 (7.823)

Thickness (in.) Categories B and C (in.) Material (1) Plate Plat and Pipe

Other Welds A B, C, & D in. (mm)

Butt Welds 1 (25) 1.315 (33.4) .109 (2.769) .109 (2.769) --- --- .133 (3.378) .133 (3.378) --- .179 (4.547) .179 (4.547) --- --- --- .250 (6.350) .358 (9.093)

Less than 3/32 3/32 1/32 Up to 1/2, incl. 1/4t 1/4t 1 Gr. 1, 2, 3 1-1/4 (32) Weld Position Groove Fillet or Tack 1-1/4 (35) 1.660 (42.2) .109 (2.769) .109 (2.769) --- --- .140 (3.556) .140 (3.556) --- .191 (4.851) .191 (4.851) --- --- --- .250 (6.350) .382 (9.703)

3/32 to 3/16, incl. 1/8 1/16 Over 1/2 to 3/4, incl. 1/8 in. 1/4t

3 Gr. 1, 2, 3 3/4 (19) 1G F* F

Over 3/16 to 1/2, incl. 5/32 3/32 1-1/2 (40) 1.900 (48.3) .109 (2.769) .109 (2.769) --- --- .145 (3.683) .145 (3.683) --- .200 (5.080) .200 (5.080) --- --- --- .281 (7.137) .400 (10.160)

Over 3/4 to 1-1/2, incl. 1/8 in. 3/16 in.

4 Gr. 1, 2 5/8 (16) 2G F,H* F,H

Over 1/2 to 1, incl. 3/16 3/32 Over 1-1/2 to 2, incl. 1/8 in. 1/8t 2 (50) 2.375 (60.3) .109 (2.769) .109 (2.769) --- --- .154 (3.912) .154 (3.912) --- .218 (5.537) .218 (5.537) --- --- --- .344 (8.738) .436 (11.074)

3G F,V* F,H,V

Over 1 to 2, incl. 1/4 1/8 Lesser of 1/16t Lesser of 1/8t 5A Gr. 1, 2 0 (0) Groove

Over 2 2-1/2 (65) 2.875 (73.0) .120 (3.048) .120 (3.048) --- --- .203 (5.156) .203 (5.156) --- .276 (7.010) .276 (7.010) --- --- --- .375 (9.525) .552 (14.021)

or 3/8 in. or 3/4 in. Weld 4G F,O* F,H,O

Over 2 to 3, incl. 1/4 5/32 5B Gr. 1 0 (0)

SI Units 3G & 4G F,V,O* ALL 3 (80) 3.500 (88.9) .120 (3.048) .120 (3.048) --- --- .216 (5.486) .216 (5.486) --- .300 (7.620) .300 (7.620) --- --- --- .438 (11.125) .600 (15.240)

Over 3 to 4, incl. 1/4 7/32

5C Gr. 1 0 (0)

Over 4 to 5, incl. 1/4 1/4 Joint Categories 2G, 3G & 4G ALL* ALL 3-1/2 (90) 4.000 (101.6) .120 (3.048) .120 (3.048) --- --- .226 (5.740) .226 (5.740) --- .318 (8.077) .318 (8.077) --- --- --- --- .646 (16.154)

Section Thickness

Over 5 5/16 5/16 (mm) 15E, Gr.1 0 (0)

A B, C, & D (2) Pipe Groove Fillet 4 (100) 4.500 (114.3) .120 (3.048) .120 (3.048) --- --- .237 (6.020) .237 (6.020) --- .337 (8.560) .337 (8.560) --- .438 (11.125) --- .531 (13.487) .674 (17.120)

SI Units 9A Gr. 1 5/8 (16)

Up to 13, incl. 1/4t 1/4t 5 (125) 5.563 (141.3) .134 (3.404) .134 (3.404) --- --- .258 (6.553) .258 (6.553) --- .375 (9.525) .375 (9.525) --- .500 (12.700) --- .625 (15.875) .750 (19.050)

Maximum Reinforcement (mm) 1G F F

Material Nominal Over 13 to 19, incl. 3 mm 1/4t 9B Gr. 1 5/8 (16)

Categories B and C 2G F,H F,H 6 (150) 6.625 (168.3) .134 (3.404) .134 (3.404) --- --- .280 (7.112) .280 (7.112) --- .432 (10.073) .432 (10.073) --- .562 (14.275) --- .719(18.263) .864 (21.050)

Thickness (mm) Other Welds

Butt Welds Over 19 to 38, incl. 3 mm 5 mm 10A Gr. 1 3/4 (19) Groove 5G F,V,O ALL 8 (200) 8.625 (219.1) .148 (3.759) .148 (3.759) .250 (6.350) .277 (7.036) .322 (8.179) .322 (8.179) .406 (10.312) .500 (12.700) .500 (12.700) .594 (15.088) .719 (18.263) .812 (20.625) .906 (23.012) .875 (22.275)

Less than 2.4 2.5 0.8 Over 38 to 51, incl. 3 mm 1/8t Weld

10B Gr. 1 5/8 (16) 6G ALL ALL

10 (250) 10.750 (273.1) .165 (4.191) .165 (4.191) .250 (6.350) .307 (7.798) .365 (9.271) .365 (9.271) .500 (12.700) .500 (12.700) .594 (15.090) .719 (18.263) .844 (21.438) 1.000 (25.400) 1.125 (28.575) 1.000 (25.400)

2.4 to 4.8, incl. 3 1.5 Lesser of 1/16t Lesser of 1/8t ALL ALL

Over 51 10C Gr. 1 5/8 (16) 2G & 5G

or 10 mm or 19 mm 12 (300) 12.750 (323.9) .180 (4.572) .180 (4.572) .250 (6.350) .330 (8.382) .375 (9.525) .406 (10.312) .562 (14.275) .500 (12.700) .688 (17.475) .844 (21.438) 1.000 (25.400) 1.125 (28.575) 1.312 (33.325) 1.000 (25.400)

Over 4.8 to 13, incl. 4 2.5

Over 13 to 25, incl. 5 2.5 QW-452.3 GROOVE-WELD DIAMETER LIMITS QW-452.4 SMALL DIAMETER FILLET-WELD TEST NOTES: 14 (350) 14.000 (355.6) .210 (5.334) .188 (4.775) .312 (7.925) .375 (9.525) .375 (9.525) .375 (9.525) .594 (15.088) .500 (12.700) .750 (19.050) .938 (23.825) 1.094 (27.788) 1.250 (31.750) 1.406 (35.712) ---

Over 25 to 51, incl 6 3 O.D. of Test Coupon, O.D. Qualified, in. (mm) • (1) Plate - Qualification on plate qualified for pipe diameter

O.D. of Test Coupon, Minimum O.D., Qualified 16 (400) 16.000 (406.4) .250 (6.350) .188 (4.775) .312 (7.925) .375 (9.525) .375 (9.525) .500 (12.700) .656 (16.662) .500 (12.700) .844 (21.438) 1.031 (26.187) 1.219 (30.963) 1.438 (36.525) 1.594 (40.488) ---

in. (mm) down to 2-7/8”

Over 51 to 76, incl. 6 4 Minimum Maximum in. (mm) Qualified, in. (mm) Thickness

• (*) 1G,3G, & 4G - Qualification restricts pipe groove welds to 18 (450) 18.000 (457.2) .250 (6.350) .188 (4.775) .312 (7.925) .438 (11.125) .375 (9.525) .562 (14.275) .750 (19.050) .500 (12.700) .9.38 (23.825) 1.156 (29.362) 1.375 (34.930) 1.562 (39.675) 1.781 (45.237) ---

Over 76 to 102, incl. 6 5.5 Less than 1 (25) Size Welded Unlimited Less than 1 (25) Size Welded All flat only on pipe diameter of 24” & less (See QW-161.9)

20 (500) 20.000 (508.0) .250 (6.350) .218 (5.537) .375 (9.525) .500 (12.700) .375 (9.525) .594 (15.088) .812 (20.625) .500 (12.700) 1.031 (26.187) 1.281 (32.537) 1.500 (38.100) 1.750 (44.450) 1.969 (50.013) ---

Over 102 to 127, incl. 6 6 1 (25) to 2-7/8 (73) 1 (25) Unlimited 1 to 2-7/8 (73) 1 (25) All • (2) Pipe - Qualification on 2-7/8” and over qualifies 2-7/8”

and over 24 (600) 24.000 (609.6) .250 (6.350) .250 (6.350) .375 (9.525) .562 (14.275) .375 (9.525) .688 (17.475) .969 (24.613) .500 (12.700) 1.219 (30.963) 1.531 (38.887) 1.812 (46.025) 2.062 (52.375) 2.344 (59.538) ---

Over 127 8 8 Over 2-7/8 (73) 2-7/8 (73) Unlimited Over 2-7/8 (73) 2-7/8 (73) All

NOTE: The above thicknesses are nominal and under tolerance as permitted in the material specifications to be considered for evaluation.

To find out more about how Lloyd’s Register can help you, email inspection@lr.org or visit www.lr.org

Lloyd’s Register assumes no responsibility and shall not be liable to any person for any loss, damage or

expense caused by reliance on the information or advice in this document or howsoever provided.

Lloyd’s Register, LR and any variants are trading names of Lloyd’s Register Group Limited, its subsidiaries and affiliates.

© Lloyd’s Register Group Limited 2019

You might also like

- Impact Test Exemptions PEDDocument7 pagesImpact Test Exemptions PEDoberaiNo ratings yet

- 5.case ToolsDocument16 pages5.case ToolsﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞﱞNo ratings yet

- Owners N Operators Guide ErjDocument21 pagesOwners N Operators Guide Erjcjtrybiec75% (4)

- Cs & Las Impact Req - Asme Sec Viii Div 2Document16 pagesCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareNo ratings yet

- Excel PV 2016 Demo VersionDocument6 pagesExcel PV 2016 Demo Versionahmadlie0% (1)

- Pressure Vessel Fabrication & Inspection: Poyyara ConsultantsDocument137 pagesPressure Vessel Fabrication & Inspection: Poyyara ConsultantsPratik VashiNo ratings yet

- PV Elite Transport A Vertical Vessel in The Horizontal Position PDFDocument3 pagesPV Elite Transport A Vertical Vessel in The Horizontal Position PDFnodyyy100% (1)

- Electrode Selection As Per Base Metal With Preheat, Postheat and Hardness DetailsDocument1 pageElectrode Selection As Per Base Metal With Preheat, Postheat and Hardness DetailsJlkKumar100% (1)

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)Ricardo Paz SoldanNo ratings yet

- Guide To ASME Code VIII Division 1 Pressure VesselsDocument16 pagesGuide To ASME Code VIII Division 1 Pressure VesselsSaâd Eddine Atif0% (1)

- Advanced User Guide For Free McBoot 1.8Document35 pagesAdvanced User Guide For Free McBoot 1.8Anzac Matt100% (2)

- Maximum Allowable Stress: Mechanical Design of Pressure VesselsDocument17 pagesMaximum Allowable Stress: Mechanical Design of Pressure Vesselsfauzi100% (2)

- Bolt TighteningDocument13 pagesBolt Tighteningwali banNo ratings yet

- Sa 387Document29 pagesSa 387Ali VarmazyarNo ratings yet

- Heat TreatmentDocument5 pagesHeat TreatmentsheikmoinNo ratings yet

- ASME DIV 2 Class 1 Vs Class 2Document3 pagesASME DIV 2 Class 1 Vs Class 2Idris SiddiquiNo ratings yet

- Check List For Design of Pressure VesselsDocument2 pagesCheck List For Design of Pressure Vesselssuresh_vikiNo ratings yet

- ASME Section VIII-Division 1 - Pressure Vessels - CASTI GuidebookDocument1 pageASME Section VIII-Division 1 - Pressure Vessels - CASTI GuidebookcristinelbNo ratings yet

- Flange Bolt Torque Sequence and Torque Table - A Complete Bolt Tightening ProcedureDocument16 pagesFlange Bolt Torque Sequence and Torque Table - A Complete Bolt Tightening Procedureal arabiNo ratings yet

- Shell and Tube Heat Exchangers (API 660 vsTEMA)Document3 pagesShell and Tube Heat Exchangers (API 660 vsTEMA)Aravind MadhuNo ratings yet

- Conversion ASME Unit ConversionDocument3 pagesConversion ASME Unit ConversionMohdBadruddinKarimNo ratings yet

- Equivalent ASME en MaterialsDocument3 pagesEquivalent ASME en MaterialsChee WeiNo ratings yet

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyNo ratings yet

- Weld End Preparation at Unequal Wall ThicknessesDocument4 pagesWeld End Preparation at Unequal Wall ThicknessesDesmond ChangNo ratings yet

- Manual Design Validation CalculationDocument21 pagesManual Design Validation CalculationToniNo ratings yet

- Tube To Tube Sheet WeldingDocument5 pagesTube To Tube Sheet WeldingGowrish Kumar100% (2)

- 6-12-0031 - Standard Specification For Storage Tanks For Package Items PDFDocument13 pages6-12-0031 - Standard Specification For Storage Tanks For Package Items PDFpl_arunachalam79No ratings yet

- Welding SymbolsDocument21 pagesWelding Symbolstuna61No ratings yet

- Pressure Vessel - Columns - AnimateDocument16 pagesPressure Vessel - Columns - AnimateSamir ChaudharyNo ratings yet

- Heat Treatment After Forming Review Head: (A) - % Extreme Fiber Elongation CalculationDocument2 pagesHeat Treatment After Forming Review Head: (A) - % Extreme Fiber Elongation CalculationvpjagannaathNo ratings yet

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- Wps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Document4 pagesWps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Nilotpal Kumar RaiNo ratings yet

- Hydrostatic Test Pressure CalculationDocument1 pageHydrostatic Test Pressure Calculationmohd as shahiddin jafriNo ratings yet

- Mandatory Appendix 26Document28 pagesMandatory Appendix 26Sushil WadiyeNo ratings yet

- ASME 9 - CalculatorDocument2 pagesASME 9 - CalculatorEmel Besir100% (1)

- Fatigue Analysis in PV EliteDocument3 pagesFatigue Analysis in PV EliteCostynhaNo ratings yet

- Blind Thickness CalculatorDocument2 pagesBlind Thickness CalculatorTejas Patel100% (1)

- Asme Form U-1. v-11201 ADocument3 pagesAsme Form U-1. v-11201 ASalman KhanNo ratings yet

- Using s275jr For Asme Div1 Vessel-UnassignedDocument6 pagesUsing s275jr For Asme Div1 Vessel-UnassignedNasrul AdliNo ratings yet

- Nozzle CheckDocument11 pagesNozzle CheckincaurcoNo ratings yet

- Asme WPS Demo PWHT PDFDocument3 pagesAsme WPS Demo PWHT PDFGanesh rohitNo ratings yet

- Tema Asme Section Viii Div1 Section Uhx PDFDocument20 pagesTema Asme Section Viii Div1 Section Uhx PDFAdrian StoicescuNo ratings yet

- 8-12 X 3000 M Spherical LPG Storage TankDocument1 page8-12 X 3000 M Spherical LPG Storage Tankevrim77100% (1)

- WELDING SUMMARY SHEET (Syu DTD 17 04 19)Document12 pagesWELDING SUMMARY SHEET (Syu DTD 17 04 19)Kushal PraviraNo ratings yet

- Girth Flange Load Calculation Using by FEA TechniquesDocument12 pagesGirth Flange Load Calculation Using by FEA TechniqueskingstonNo ratings yet

- WRC, PV Elite, NozzlePro Sign ConventionsDocument13 pagesWRC, PV Elite, NozzlePro Sign ConventionsADHIRAJ KOLINo ratings yet

- Acceptance Criteria Asme B31.3 PDFDocument1 pageAcceptance Criteria Asme B31.3 PDFAhmad RizkiNo ratings yet

- Pressure Vessel Dimension InspectionDocument10 pagesPressure Vessel Dimension InspectionYetkin ErdoğanNo ratings yet

- Univeral WPS For Pipe To Plate Fillet Welding (6800009)Document1 pageUniveral WPS For Pipe To Plate Fillet Welding (6800009)Ibrahim shaikNo ratings yet

- Lloyd's Register's Guide To Understanding Ibr-1950 - inDocument12 pagesLloyd's Register's Guide To Understanding Ibr-1950 - inthehindu100% (1)

- Pressure Vessel Design Training - Course ContentDocument13 pagesPressure Vessel Design Training - Course Contentamol shindeNo ratings yet

- Asme Viii - QDocument431 pagesAsme Viii - Qmajdi jerbi100% (1)

- Tube-To-Tube Sheet Joint RequirementsDocument2 pagesTube-To-Tube Sheet Joint RequirementsWaqas WaqasNo ratings yet

- Asme Section I: Section - Iii Code ExtractionDocument3 pagesAsme Section I: Section - Iii Code ExtractionReadersmo100% (1)

- ASME Impact Test RequirementDocument15 pagesASME Impact Test Requirementumar_hazrad8219100% (1)

- Elliptical Head Design ToolDocument1 pageElliptical Head Design Toolnaveen_86No ratings yet

- Pressure Vessel Interview QuestionsDocument1 pagePressure Vessel Interview Questionsdh6802No ratings yet

- 3.3 Piping Design Criteria Rev 2Document15 pages3.3 Piping Design Criteria Rev 2Maheswaran KurusamyNo ratings yet

- 12.15.1 Plano de Red de Distribucion-Ap-01Document1 page12.15.1 Plano de Red de Distribucion-Ap-01Dick GuiliansNo ratings yet

- Tupi BV: Cosco (Dalian)Document4 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- Pipe Ring Product Selector: Light-Duty Galvanized Pipe RingsDocument1 pagePipe Ring Product Selector: Light-Duty Galvanized Pipe RingsReem Ahmed KhalilNo ratings yet

- Urea Granul: No Kode Alat Nama Alat Jumlah No Kode Alat Nama Alat JumlahDocument1 pageUrea Granul: No Kode Alat Nama Alat Jumlah No Kode Alat Nama Alat JumlahFarhan MuhamadNo ratings yet

- 4020-186-M-018 - 3 Cyanide Stripping Column General Arrangement 1Document1 page4020-186-M-018 - 3 Cyanide Stripping Column General Arrangement 1thoriq ikhwanNo ratings yet

- CP-X980: DP-6860 Users ManualDocument40 pagesCP-X980: DP-6860 Users ManualRichard HollidayNo ratings yet

- Digam SeriesDocument14 pagesDigam SeriesNguyễn Quang TrânNo ratings yet

- GATE 2015 Information BrochureDocument34 pagesGATE 2015 Information BrochureAdam BlanchardNo ratings yet

- Repair ManualDocument31 pagesRepair Manualzye88593No ratings yet

- Skinner CNA130 Syllabus Winter10Document5 pagesSkinner CNA130 Syllabus Winter10osalazardebreauxNo ratings yet

- Pulse-Width Modulation (PWM) TechniquesDocument14 pagesPulse-Width Modulation (PWM) TechniquesMohamed SalahNo ratings yet

- 1 - 117 - FOX505 NL PDFDocument2 pages1 - 117 - FOX505 NL PDFpriyanka236No ratings yet

- Manual Compresor HuskyDocument88 pagesManual Compresor HuskyShakty Iglesias100% (1)

- Resume - John e Driscoll 11-5-14Document1 pageResume - John e Driscoll 11-5-14api-271060247No ratings yet

- Ons Kerk Se MenseDocument4 pagesOns Kerk Se MensetoypomNo ratings yet

- PULSE V2.0 - New Features: Cyber Security Protection Enhancements UAG (Unity Application Generator)Document2 pagesPULSE V2.0 - New Features: Cyber Security Protection Enhancements UAG (Unity Application Generator)cyrus6_997303No ratings yet

- Energy Performance Assessment of Hvac SystemsDocument4 pagesEnergy Performance Assessment of Hvac SystemsBudihardjo Sarwo SastrosudiroNo ratings yet

- Tutorial For Cadence SOC Encounter Place & RouteDocument28 pagesTutorial For Cadence SOC Encounter Place & Routeanon_248257978No ratings yet

- Ds Erhard Roco WaveDocument27 pagesDs Erhard Roco Wavekad-7No ratings yet

- Paper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Document5 pagesPaper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Congson JeffNo ratings yet

- RSM72-6-320P-340P/5BB 72 Cell 320-340Wp 1500VDC 17.5%: High Performance Polycrystalline ModuleDocument2 pagesRSM72-6-320P-340P/5BB 72 Cell 320-340Wp 1500VDC 17.5%: High Performance Polycrystalline ModuleTiago MottaNo ratings yet

- XDM 100 SDH System en 1Document0 pagesXDM 100 SDH System en 1swartsenburgNo ratings yet

- Electromechanical Boq ForensicDocument31 pagesElectromechanical Boq ForensicDesigner ForeverNo ratings yet

- Click Fraud Detection: Adversarial Pattern Recognition Over 5 Years at MicrosoftDocument21 pagesClick Fraud Detection: Adversarial Pattern Recognition Over 5 Years at MicrosoftBhakti RaneNo ratings yet

- Bor MasinaDocument28 pagesBor MasinaLohon TatianaNo ratings yet

- Rishi Kushwaha Resume MSC DA EPITA EngDocument1 pageRishi Kushwaha Resume MSC DA EPITA EngRishi KushwahaNo ratings yet

- Switchgear Vs SwitchboardDocument20 pagesSwitchgear Vs SwitchboardJuan MoralesNo ratings yet

- Ba Battery Tester MBT 101 enDocument8 pagesBa Battery Tester MBT 101 enDamian FediukNo ratings yet

- Industrial Training Report Final 38Document120 pagesIndustrial Training Report Final 38Sifat RaihanNo ratings yet

- Azimuth Co OrdinatorDocument2 pagesAzimuth Co OrdinatorGlen DonnellyNo ratings yet

- Attachment To SDO Memo No 96 S. 2024Document2 pagesAttachment To SDO Memo No 96 S. 2024LoidaCarameNo ratings yet

- User Manual710Document19 pagesUser Manual710Pedro AlmeidaNo ratings yet