Professional Documents

Culture Documents

Vlsi Process Technology

Vlsi Process Technology

Uploaded by

shivaspyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vlsi Process Technology

Vlsi Process Technology

Uploaded by

shivaspyCopyright:

Available Formats

VLSI PROCESS TECHNOLOGY

PROFESSIONAL ELECTIVES IV

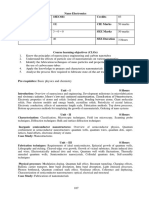

Course Code Category Hours / Week Credits Maximum Marks

L T P C CIA SEE Tota

17CD04209 Core

4 0 - 4 40 60 100

l

Contact Classes: Tutorial Classes: Nil Practical Classes: Nil Total Classes: 60

OBJECTIVES:

60

To introduce the fundamentals of multi rate signal processing and cognitive

Radio.

To provide rigorous foundation in MOS and CMOS fabrication process.

OUTCOMES:

Able to understand various techniques involved in the VLSI fabrication process.

Able to understand the different lithography methods and etching process

Analyze the deposition and diffusion mechanisms.

Analyze the fabrication of NMOS, CMOS memory and bipolar devices

Understand the nuances of assembly and packaging of VLSI devices.

UNIT - I ELECTRON GRADE SILICON Classes: 15

Crystal growth. Wafer preparation. Vapour phase and molecular beam epitaxy. SOI. Epitaxial

evaluation. Oxidation techniques, systems and properties. Oxidation defects. Ch 1, 2, 3

UNIT - II LITHOGRAPHY Classes: 10

Optical, electron, X-ray and ion lithography methods. Plasma properties, size, control, etch

mechanism, etch techniques and equipments ch 4, 5

UNIT - III DEPOSITION PROCESS AND METHODS Classes: 10

Diffusion in solids. Diffusion equation and diffusion mechanisms ch 7

UNIT-IV ION IMPLANTATION AND METALLIZATION Classes: 15

Process simulation of ion implementation, diffusion, oxidation, epitaxy, lithography, etching and

deposition. NMOS, CMOS, MOS memory and bipolar IC technologies. IC fabrication ch 10, 11

UNIT-V ANALYTICAL AND ASSEMBLY TECHNIQUES Classes: 10

Packaging of VLSI devices ch 13

Text Books:

1. S.M.Sze, “VLSI Technology (2/e)” , McGraw Hill, 1988

Reference Books:

1. W. Wolf, “Modern VLSI Design”, (3/e), Pearson,2002

You might also like

- Embedded Systems by Rajkamal 2nd PDFDocument557 pagesEmbedded Systems by Rajkamal 2nd PDFshivaspy72% (18)

- Microwave Engineering and Antenna Measurement Lab ManualDocument165 pagesMicrowave Engineering and Antenna Measurement Lab ManualsaisuneelademNo ratings yet

- VLSI Test Principles and Architectures: Design for TestabilityFrom EverandVLSI Test Principles and Architectures: Design for TestabilityRating: 4.5 out of 5 stars4.5/5 (4)

- Introduction To Flight Control SystemsDocument34 pagesIntroduction To Flight Control SystemsshivaspyNo ratings yet

- Birla Institute of Technology & Science, Pilani Work Integrated Learning Programmes Digital Learning Part A: Content DesignDocument5 pagesBirla Institute of Technology & Science, Pilani Work Integrated Learning Programmes Digital Learning Part A: Content Designkansal611No ratings yet

- Vlsi Technology Lesson PlanDocument4 pagesVlsi Technology Lesson PlanMahendra BabuNo ratings yet

- Icft Mel ZG611 Course HandoutDocument4 pagesIcft Mel ZG611 Course Handoutsaireddykakumanu97No ratings yet

- Mel ZG611Document5 pagesMel ZG611jitendraNo ratings yet

- Semester: VII: A. Theory PapersDocument4 pagesSemester: VII: A. Theory PapersAkhil KhandelwalNo ratings yet

- Course No. Course Title Teaching Schedule Allotment of Marks Duration of Exam (HRS.) L T P EL-303N Course Outcomes (CO) CO-1Document2 pagesCourse No. Course Title Teaching Schedule Allotment of Marks Duration of Exam (HRS.) L T P EL-303N Course Outcomes (CO) CO-1GauravNo ratings yet

- IC Fabrication TechnologyDocument5 pagesIC Fabrication TechnologyEldo N BabyNo ratings yet

- 18-M.Tech (VLSI Design and Embedded System) PDFDocument31 pages18-M.Tech (VLSI Design and Embedded System) PDFAhilan AppathuraiNo ratings yet

- Micro Course FileDocument47 pagesMicro Course FileRatish DhimanNo ratings yet

- Ic Technology CourseDocument2 pagesIc Technology CourseTara GonzalesNo ratings yet

- Course Structure & Syllabus of M. Tech. Programme In: Vlsi Signal ProcessingDocument29 pagesCourse Structure & Syllabus of M. Tech. Programme In: Vlsi Signal Processingmaheepa pavuluriNo ratings yet

- M.Tech. ETC VSP PDFDocument29 pagesM.Tech. ETC VSP PDFmaheepa pavuluriNo ratings yet

- VLSI Design Course OutlineDocument3 pagesVLSI Design Course OutlineSoftware EngineerNo ratings yet

- Assignment 2: Assignments#1 For Vlsi TechnologyDocument5 pagesAssignment 2: Assignments#1 For Vlsi TechnologyRajesh BathijaNo ratings yet

- Department of Computer Science and EngineeringDocument24 pagesDepartment of Computer Science and EngineeringSunita MauryaNo ratings yet

- HICET - Department of Electronics and Communication EngineeringDocument1 pageHICET - Department of Electronics and Communication EngineeringK.KALAISELVI HICET STAFF ECENo ratings yet

- 14 MT Ec WC 2021Document132 pages14 MT Ec WC 2021KRISHNALAKSHMI ANo ratings yet

- SyllabusDocument15 pagesSyllabusRushabh ShahNo ratings yet

- 5th Sem QBDocument378 pages5th Sem QBmenakadevieceNo ratings yet

- Vision: To Become A Centre of Excellence in Teaching and Research in The Field of Computer Science and EngineeringDocument6 pagesVision: To Become A Centre of Excellence in Teaching and Research in The Field of Computer Science and EngineeringkingraajaNo ratings yet

- 8th Sem QBDocument255 pages8th Sem QBMohana KrishnanNo ratings yet

- VTU Advanced Communication LAB Manual 2020 - KLS VDIT HaliyalDocument69 pagesVTU Advanced Communication LAB Manual 2020 - KLS VDIT Haliyalkartik balojiNo ratings yet

- Ece Iboc Technology ReportDocument26 pagesEce Iboc Technology ReportSandhya0% (1)

- Fabrication Course OutlineDocument4 pagesFabrication Course OutlineOmarNo ratings yet

- PG CO Second Semester PDFDocument9 pagesPG CO Second Semester PDFMaxuell SmashNo ratings yet

- MVLD507L - Ic-Technology - TH - 1.0 - 73 - MVLD507L - 67 AcpDocument2 pagesMVLD507L - Ic-Technology - TH - 1.0 - 73 - MVLD507L - 67 AcpMahesh N 22MVD0090No ratings yet

- Vlsi SyllabusDocument1 pageVlsi SyllabusrekhayadavNo ratings yet

- Architectures For Ripple Carry Adders, Carry Look Ahead Adders, High Speed Adders, Accumulators, MultipliersDocument3 pagesArchitectures For Ripple Carry Adders, Carry Look Ahead Adders, High Speed Adders, Accumulators, MultipliersK.KALAISELVI HICET STAFF ECENo ratings yet

- VLSIDESIGNDocument2 pagesVLSIDESIGNRaghu RamNo ratings yet

- Ece MT SylDocument79 pagesEce MT Sylpermiable permissionNo ratings yet

- Course Information SheetDocument3 pagesCourse Information SheetKameshSontiNo ratings yet

- VLSI Objectives Outline 2019Document3 pagesVLSI Objectives Outline 2019waseem cryptoNo ratings yet

- File 1704210712 0006745 IntroductoryCNDocument18 pagesFile 1704210712 0006745 IntroductoryCNcutiemegha512No ratings yet

- 6th Sem SyllabusDocument13 pages6th Sem SyllabusAbhishek GuptaNo ratings yet

- Vlsi DesignDocument2 pagesVlsi DesignsruchakradarNo ratings yet

- Cybersecurity Lab MaualDocument66 pagesCybersecurity Lab Maualharendra tomarNo ratings yet

- EC8095-VLSI Design - 01 - by WWW - LearnEngineering.inDocument134 pagesEC8095-VLSI Design - 01 - by WWW - LearnEngineering.inDelphin ShibinNo ratings yet

- 15.09.2023 Physics For Information Sciences Syllabus 2023 - V1 - TDocument3 pages15.09.2023 Physics For Information Sciences Syllabus 2023 - V1 - TaberrationchromaticNo ratings yet

- Nanoelectronics 18EC661 SyllabusDocument3 pagesNanoelectronics 18EC661 SyllabussmkeshkamatNo ratings yet

- Vlsi CoursefileDocument124 pagesVlsi CoursefileanithaNo ratings yet

- Microwave Engineering and Antenna Measurement Lab ManualDocument166 pagesMicrowave Engineering and Antenna Measurement Lab ManualsaisuneelademNo ratings yet

- Semester V: 1. Explain What Is CMOS VLSI? and Current and Future Trends in VLSIDocument3 pagesSemester V: 1. Explain What Is CMOS VLSI? and Current and Future Trends in VLSIlokeahaNo ratings yet

- 10Lvs1 2 10ec12 9 Soc Design: PracticalDocument8 pages10Lvs1 2 10ec12 9 Soc Design: PracticalroshanuchilsterNo ratings yet

- Eee590 Ic-Technology SyllabusDocument2 pagesEee590 Ic-Technology SyllabusKeerthiKalyanNo ratings yet

- 4th YEARDocument47 pages4th YEARAD THE GR8No ratings yet

- Cybersecurity Lab MaualDocument66 pagesCybersecurity Lab MaualJatin PrajapatNo ratings yet

- All SemDocument14 pagesAll SemSamaira Shahnoor ParvinNo ratings yet

- ACA-2 DCN ECE 221 - HO - VijayDocument14 pagesACA-2 DCN ECE 221 - HO - VijayAkshay kumar Akshay kumarNo ratings yet

- Course Module & Course Outline - Computer NetworksDocument7 pagesCourse Module & Course Outline - Computer NetworksSAMEER AHMADNo ratings yet

- Course Hand Out s7Document58 pagesCourse Hand Out s7Deepak TiwariNo ratings yet

- Me Gtu CurriculumDocument47 pagesMe Gtu CurriculumAnupam DevaniNo ratings yet

- 4-4 Autonomous Syllabus R-15 250418Document44 pages4-4 Autonomous Syllabus R-15 250418Srinivasa DumpaNo ratings yet

- Design of LCOS Microdisplay BackplanesDocument250 pagesDesign of LCOS Microdisplay BackplanesA. VillaNo ratings yet

- JNTUA B.tech 4-1 ECE R13 Syllabus BookDocument23 pagesJNTUA B.tech 4-1 ECE R13 Syllabus BookReddy Kiran KDNo ratings yet

- Department of Computer Science and EngineeringDocument22 pagesDepartment of Computer Science and EngineeringNishitha PriyankaNo ratings yet

- Vlsi DesignDocument3 pagesVlsi Designkumarrajivranjan440No ratings yet

- Vlsi TechDocument1 pageVlsi TechPraveen Kumar0% (1)

- M. Tech. (Electronics and Telecommunication) Curriculum StructureDocument30 pagesM. Tech. (Electronics and Telecommunication) Curriculum StructureAnet AugustinNo ratings yet

- CH 14Document12 pagesCH 14shivaspyNo ratings yet

- Basic Electrical EngineeringDocument625 pagesBasic Electrical EngineeringshivaspyNo ratings yet

- CH 11Document20 pagesCH 11shivaspyNo ratings yet

- CH 02Document31 pagesCH 02shivaspyNo ratings yet

- Notes of History Chapter-2Document7 pagesNotes of History Chapter-2shivaspyNo ratings yet

- Civics - Chapter - 2 NotesDocument4 pagesCivics - Chapter - 2 NotesshivaspyNo ratings yet

- Tutorial: Introduction To DSP Using Sysgen and Introductory AssignmentDocument11 pagesTutorial: Introduction To DSP Using Sysgen and Introductory AssignmentshivaspyNo ratings yet

- 1 - BW NavIC Technology BrochureDocument2 pages1 - BW NavIC Technology BrochureshivaspyNo ratings yet

- 05 Expression SOULDocument7 pages05 Expression SOULshivaspyNo ratings yet

- (Lecture Notes in Mathematics - 644-645) Aron R. M. (Ed) - Vector Space Measures and Applications I (1978, Springer-Verlag)Document458 pages(Lecture Notes in Mathematics - 644-645) Aron R. M. (Ed) - Vector Space Measures and Applications I (1978, Springer-Verlag)shivaspyNo ratings yet

- EE 445L - Embedded System Design Lab: Interrupts Software Style Guidelines DebuggingDocument44 pagesEE 445L - Embedded System Design Lab: Interrupts Software Style Guidelines DebuggingshivaspyNo ratings yet

- Chap 5 Ed 2 July 02Document143 pagesChap 5 Ed 2 July 02shivaspyNo ratings yet

- Exp# 6 Ethernet CSMA/CD Protocol: CS2307 - Network Lab Simulator ProgramsDocument4 pagesExp# 6 Ethernet CSMA/CD Protocol: CS2307 - Network Lab Simulator ProgramsshivaspyNo ratings yet

- EEE Lecture Notes-1Document118 pagesEEE Lecture Notes-1shivaspyNo ratings yet

- KPRay LecDocument45 pagesKPRay LecshivaspyNo ratings yet

- EE 445L - Embedded System Design Lab: Architecture Interfaces Data Flow Graphs Flowcharts Fixed-Point NumbersDocument29 pagesEE 445L - Embedded System Design Lab: Architecture Interfaces Data Flow Graphs Flowcharts Fixed-Point NumbersshivaspyNo ratings yet

- 2BA5 Telecommunications: Error Detection and CorrectionDocument40 pages2BA5 Telecommunications: Error Detection and CorrectionshivaspyNo ratings yet

- 10csl77 Network LabDocument39 pages10csl77 Network LabshivaspyNo ratings yet

- Wireless Sensor Networks For Smart Grid Applications: Melike Erol-Kantarci, Hussein T. MouftahDocument6 pagesWireless Sensor Networks For Smart Grid Applications: Melike Erol-Kantarci, Hussein T. MouftahshivaspyNo ratings yet

- Efficient WirelessDocument9 pagesEfficient WirelessshivaspyNo ratings yet

- Smart: Courtesy of Fatemeh Saremi, Poliang Wu, and Heechul Yun From Illinois UnivDocument40 pagesSmart: Courtesy of Fatemeh Saremi, Poliang Wu, and Heechul Yun From Illinois UnivshivaspyNo ratings yet