Professional Documents

Culture Documents

Galvilite Aug2019

Galvilite Aug2019

Uploaded by

Dhanush santhoshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Galvilite Aug2019

Galvilite Aug2019

Uploaded by

Dhanush santhoshCopyright:

Available Formats

www.zrcworldwide.

com

ZRC Galvilite® Galvanizing Repair Compound

ZRC’s Galvilite provides all the corrosion protection you’ve come to expect from the world’s most specified

galvanizing repair compound—in a silvery finish that closely matches the color of galvanized metal.

Enjoy the following great benefits with ZRC’s Galvilite:

• 95% zinc in the dry film using only Type III “ultra pure” ASTM-D-520 zinc

(lead and cadmium free)

• Recognized under the Component Program of Underwriters Laboratories,

Inc. as equivalent to hot dip galvanizing

• Meets and exceeds Fed. Spec. DOD-P-21035A (Galvanizing Repair Spec);

MIL-P-26915A (USAF Zinc Dust Primer); ASTM Des. A-780 (Standard

Practice for Repair of Damaged Hot-Dip Galvanized Coatings; SSPC-Paint

20 (Specification for Zinc-Rich Primer)

• Passes 3,000 hours salt spray testing without failure (ASTM Des. B117)

• Passes 9-year subtropical testing

• Low VOC approved in all 50 states

• ISO 9001 registration assures the highest quality consistently

For specification assistance, application assistance, test reports and product

selection please contact our customer support at (800) 831-3275 or our APPLICATIONS

website www.zrcworldwide.com.

Repairing hot-dip galvanizing

Field applied galvanizing

Rust proofing welds

Repairing inorganic zinc

THE ZRC GALVILITE DIFFERENCE Regalvanizing of worn hot-dip

The ZRC Galvilite difference is made possible by Galvilites’s high zinc content (95% by Metal fabrication

weight in the dried film) of “ultra pure” (ASTM D 520 Type III) zinc dust, ensuring that Construction

more metallic zinc is available for superior galvanic protection against corrosion. This high Manufacturing/OEM

purity zinc dust is compounded with a tenacious non-encapsulating binder using a highly

Antenna Towers

controlled trade secret process in our state-of-the-art manufacturing facility.

Petrochemical Plants

Competitor

The result is a self-healing galvanic film that does not require sand- Roads & Bridges

blasting for most applications, providing both up-front labor savings Tanks

and extended longevity of corrosion protection. We offer a Certifi-

Industrial Maintenance

cate of Compliance to these exacting material standards and a

copy of our most recent ISO Registration Certificate. Water Treatment

Marine & Offshore

The Proof is in the Photos Cooling Towers

These scanning electron microscope photos

illustrate the difference between the true galvanic

Hundreds more!

protection of ZRC Galvilite and a competitor’s low

ZRC

percentage zinc coating.

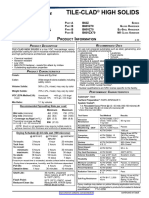

TESTING & SPECIFICATION CONFORMANCE DATA Technical Data

• Meets and exceeds Fed. Spec. DOD-P-21035A,

TYPE Single pack, premixed, ready to apply,

formerly MIL-P-21035 (Galvanizing Repair Spec.)

liquid organic zinc compound

• Meets and exceeds Fed. Spec. MIL-P-26915A

(USAD Zinc Dust Primer) THEORETICAL COVERAGE 400 ft²/gal @ 1.5 mil dry film thickness

• Passes 3,000 hours salt spray testing without failure** METALLIC ZINC CONTENT 95% by weight in dry film

(ASTM Des. B117)

FLASH POINT 111°F (44°C) (SETA method, ASTM D3278)

• Passes Preece Test (ASTM Des. A239) for hot-dip galvanizing

• Resists intermittent dry-heat temperatures up to 750°F VOC CONTENT 3.3 lbs/gal (385 gms/ltr) (ASTM D3960)

• Meets and exceeds ASTM Des. A-780 (Standard Practice for WEIGHT PER GALLON 24 lbs. (ASTM D1475)

Repair of Damaged Hot-Dip Galvanized Coatings)

• Meets and exceeds SSPC-Paint 20 (Specification for Zinc-Rich SOLIDS CONTENT 86% (by weight)/52% (by volume)

Primer), Type II (organic), Level I, Type III zinc dust VISCOSITY 2500 cps. Brookfield spindle #5 @ 100 RPM, @ 25°C

MAXIMUM SERVICE TEMP - Intermittent 750°F (399)°C

AVAILABILITY/COST

Immediately available off the shelf, Galvilite Galvanizing Compound MAXIMUM SERVICE TEMP - Constant 350°F (177)°C

is offered directly from the manufacturer, or through a worldwide ELECTRICAL CONDUCTIVITY 73 million ohms per square @ 3 mils dry (resistivity)

distribution network. The initial cost of Galvilite is more than offset

IMPACT RESISTANCE Greater than 30 inch-lbs. (extrusion) per ASTM-D2794

by substantial maintenance savings and the increased service life

of protected surfaces. Galvilite is available in 3.5 gallon pails, gallon ABRASION RESISTANCE 11.5 liters per dry mil (tested @ 3 dry mils) per ASTM-D98-51

cans, quart cans, and a convenient 12 oz. aerosol spray. Contact ZRC At least 24 hrs. @ 77°F (25°C)

POT LIFE

Worldwide for current pricing and further information.

PACKAGING 3.5 gallon pails, gallon, quart, half-pint and aerosol cans

MATERIALS/FINISHES DRY TIME Set to touch. When ambient air dried, 20-30 minutes

A unique formulation of 95% pure zinc metal as a liquid coating, ZRC (Second coat) After 12 hrs.

RECOAT TIME

Galvanizing Compound and Galvilite are manufactured to exacting

standards in our own state-of-the-art manufacturing facility. Galivite’s

silvery metallic finish closely approximates the look of new hot-dip TOPCOATING After 24-48 hrs., topcoat with acrylic, epoxy, urethane or vinyl

galvanizing. Standard ZRC Galvanizing Compound is light matte gray type products. DO NOT USE alkyd, alkyd-modified acrylic, or

in color. lacquer type products. Consult our Guide to Topcoating

for detailed instructions.

SUGGESTED SPECIFICATION Surface Preparation

Silvery-finish Galvanic Zinc-Rich coating containing 95% metallic

zinc, by weight in the dried film; recognized under the Component Dependant upon surface condition and intended service. Typical examples include:

Program of Underwriters Laboratories, Inc. as an equivalent to hot- GREASE & OILS Solvent clean to SSPC-SP1

dip galvanizing; as manufactured by ZRC Worldwide, Marshfield, MA

RUST SCALE Power tool clean to SSPC-SP11

(www.zrcworldwide.com) or other facility having been registered to

the International Organization for Standardization ISO 9001 standard MILL SCALE Sandblast to SSPC-SP6 (commercial)

for quality. (100°F maximum) Sandblast to SSPC-SP10 (near-white)

WATER IMMERSION

For areas and industries with more stringent VOC restrictions specify Application

ZRC 221.

BRUSH/ROLLER/AEROSOL Apply as received in container. For Brush Application, use 100%

** Copy of reports available upon request Natural 100% Chinese bristle brushes. For Roller Application,

use 3/8" nap rollers, made of mohair or lambs wool (sheepskin).

SPRAY (low pressure compressor type)

Atomized air pressure 50 lbs/in² = 3.5 kg/cm²

Fluid pressure 15-20 lbs/in² = 1.1-1.4 kg/cm²

Orifice of tip 0.080 inches (0.20 cm)

Viscosity reduction 4:1 GALVILITE:Mineral Spirits -OR- 16:1 GALVILITE:Xylene

SPRAY (airless type)

Pump 30:1

Hose 1/2” (1.3 cm) (I.D.)

Orifice of tip 60°-0.026 inches (0.07 cm)

Type of tip Tungsten carbide, reversing

Filter screens Complete removal is recommended.

However, if screens are employed, use no less than 30 mesh.

Viscosity No reduction required

Recommended procedure Connect hose directly to pump, without filter assembly,

ensuring a hose length of 50 ft. max. Use in-pot agitator or

continuous recycling. Use least pressure possible. Start at

1500 lbs/in² = 105 kg/cm² and increase

as required for good spraying.

CLEAN UP Mineral spirits solvent or Xylene

ZRC Worldwide has been registered to the International Organization for Standardization

ISO 9000 Series Standards for Quality. The fact that ZRC is registered to ISO 9001 as-

145 Enterprise Drive, Marshfield, MA 02050-2132 sures our customers that the zinc-rich coatings manufactured in our facility are designed

Tel: 800.831.3275 or 781.319.0400 • Fax: 781.319.0404 and manufactured according to the most stringent quality control standards, so you can

www.zrcworldwide.com • E-mail: info@zrcworldwide.com rely on their consistency.

© 2019 ZRC Worldwide. All rights reserved

You might also like

- Fabrication Procedure Steel Structure TSEDocument21 pagesFabrication Procedure Steel Structure TSEspazzbgt67% (6)

- Galvanizing Repair Compound: The ZRC DifferenceDocument2 pagesGalvanizing Repair Compound: The ZRC DifferenceJosé SermeñoNo ratings yet

- ZRC GALVILITE Galvanizing Repair CompoundDocument2 pagesZRC GALVILITE Galvanizing Repair CompoundRaymond LalumiereNo ratings yet

- ZRC 3 07Document2 pagesZRC 3 07groelzjNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Carboguard 1207 PDSDocument4 pagesCarboguard 1207 PDSmartinbeyerNo ratings yet

- PDS - GacoFlex S20 Series - Silicone CoatingDocument3 pagesPDS - GacoFlex S20 Series - Silicone Coatingwassaadi95No ratings yet

- Polibrid 705: Technical DataDocument2 pagesPolibrid 705: Technical DataSky MoonNo ratings yet

- Polyclad 777 PL PDSDocument4 pagesPolyclad 777 PL PDShakkianilNo ratings yet

- 3750-3752 Product InfoDocument2 pages3750-3752 Product InfoVendy KurniawanNo ratings yet

- Carboguard 890N PDSDocument5 pagesCarboguard 890N PDScorey jacobsNo ratings yet

- Carboguard 893 PDSDocument2 pagesCarboguard 893 PDSNguyễn Thị Châu TâyNo ratings yet

- Sigma Coatings Is A Brand of The Sigmakalon GroupDocument8 pagesSigma Coatings Is A Brand of The Sigmakalon Groupmedkom2000No ratings yet

- VRC Product SheetDocument2 pagesVRC Product SheetKaran LANo ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- Sellos Cilindros y VariosDocument4 pagesSellos Cilindros y VariosJuan Gabriel Galvis ZuluagaNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDScrisNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- PolykenYG IIIDocument2 pagesPolykenYG IIISenthilkumar NarayananNo ratings yet

- PDS GacoFlexS2100 SiliconeCoating 1Document2 pagesPDS GacoFlexS2100 SiliconeCoating 1wassaadi95No ratings yet

- Delta Protekt KL120Document1 pageDelta Protekt KL120GavinNo ratings yet

- FG HLB 800 Pdsusa110117Document2 pagesFG HLB 800 Pdsusa110117DarkedgeNo ratings yet

- TOPROCK DD Flat Roof Insulation TechdataDocument2 pagesTOPROCK DD Flat Roof Insulation TechdataCONSTRUTAINER MÉXICONo ratings yet

- ALPHA CVP-520 Solder Paste EN 25nov19 TBDocument6 pagesALPHA CVP-520 Solder Paste EN 25nov19 TBDeep SharmaNo ratings yet

- Amphenol 62GB Series: Mil-Dtl-26482 Performance Without Mis-MatingDocument3 pagesAmphenol 62GB Series: Mil-Dtl-26482 Performance Without Mis-MatingOsamaAliBangashNo ratings yet

- CUI Corrosion PDFDocument39 pagesCUI Corrosion PDFLâm Thanh100% (1)

- 147-168 62gb Series 62GB-57A14-15SNDocument22 pages147-168 62gb Series 62GB-57A14-15SNwiradesNo ratings yet

- Ip67 Profile Catalogue 2023Document31 pagesIp67 Profile Catalogue 2023Rohit MEPNo ratings yet

- Carboguard 890: Selection & Specification DataDocument5 pagesCarboguard 890: Selection & Specification DataMuthazhagan SaravananNo ratings yet

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 pagesPintura Epoxica Sherwin Willians Hoja Seguridad1No ratings yet

- 147-168 62gb SeriesDocument22 pages147-168 62gb SeriesJdhdkdidbdjdubdnjfbebeirhrbNo ratings yet

- FT Grease 22Document2 pagesFT Grease 22Edgar Leonel CortésNo ratings yet

- 1233-1235 Product InfoDocument2 pages1233-1235 Product InfoJeisson HolguinNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDSAchraf BoudayaNo ratings yet

- Hmled4: LED High Mast LightingDocument6 pagesHmled4: LED High Mast LightingEduardo AvalosNo ratings yet

- WBEpoxyCoating Data SheetDocument2 pagesWBEpoxyCoating Data SheetkaleshNo ratings yet

- Shell Diala S3 ZX-IG DriedDocument2 pagesShell Diala S3 ZX-IG DriedAnonymous oAbjbl4HNo ratings yet

- Transformer Oil Shell DIALA-S4-ZX-IGDocument3 pagesTransformer Oil Shell DIALA-S4-ZX-IGAsim IbrahimNo ratings yet

- Mineral Wool Pipe InsulationDocument4 pagesMineral Wool Pipe InsulationMiguel Martinez GuerreroNo ratings yet

- 07 Tiger Drylac R Primer 0973841 Zinc Free Ogf TDC en Aug 09 2016 FinalDocument3 pages07 Tiger Drylac R Primer 0973841 Zinc Free Ogf TDC en Aug 09 2016 FinalErikas KulpinasNo ratings yet

- 4622 Product InfoDocument4 pages4622 Product InfoVendy KurniawanNo ratings yet

- Corothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsDocument4 pagesCorothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsScott NorrisNo ratings yet

- Hempadur Zinc SeriesDocument2 pagesHempadur Zinc SerieskylegazeNo ratings yet

- SW13494 - Heat-Flex - 3500. Loai Thay The Bao On PDFDocument2 pagesSW13494 - Heat-Flex - 3500. Loai Thay The Bao On PDFtienNo ratings yet

- THE Tri-Con SeriesDocument6 pagesTHE Tri-Con Seriespablopasqualini18No ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Alpha Om-338-T CNP TB SM871-20 English 20190604Document6 pagesAlpha Om-338-T CNP TB SM871-20 English 20190604Красимир КостадиновNo ratings yet

- DacrometDocument6 pagesDacrometPeter MangalukiNo ratings yet

- Fiberglass Reinforced Polyester (FRP) Link Boxes: DescriptionDocument2 pagesFiberglass Reinforced Polyester (FRP) Link Boxes: DescriptionlatifNo ratings yet

- Sikalastic®-8800: Product Data SheetDocument4 pagesSikalastic®-8800: Product Data SheetshahoorhussainNo ratings yet

- Jax Magna-Plate 1100: High-Performance, Corrosion-Control H2 GreaseDocument2 pagesJax Magna-Plate 1100: High-Performance, Corrosion-Control H2 GreaseEmerson 21400% (1)

- Sikaplan®-1652 Bonded VOC Gas Barrier: Product Data SheetDocument3 pagesSikaplan®-1652 Bonded VOC Gas Barrier: Product Data SheetKhin Sandi KoNo ratings yet

- Shell Diala S4 ZX IG BrochureDocument6 pagesShell Diala S4 ZX IG Brochurekihewiy675No ratings yet

- Workshop 2 - Zinc Clad III PDSDocument4 pagesWorkshop 2 - Zinc Clad III PDSbuitems11No ratings yet

- Battery Range Summary: Safe SafeDocument2 pagesBattery Range Summary: Safe SaferadikahendryNo ratings yet

- Jet-Lube Marine Grade Anti-SeizeDocument1 pageJet-Lube Marine Grade Anti-SeizeDon HowardNo ratings yet

- Ficha Tecnicas Royal Hammer Paste PDS XDocument2 pagesFicha Tecnicas Royal Hammer Paste PDS XAndres AgudeloNo ratings yet

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Section 077100 - Roof SpecialtiesDocument6 pagesSection 077100 - Roof SpecialtiesWENDING HUNo ratings yet

- Full Locked Coil (FLC) Galvanised: Breaking Load TableDocument2 pagesFull Locked Coil (FLC) Galvanised: Breaking Load TableajdhNo ratings yet

- Sustainability in Steel ConstructionDocument5 pagesSustainability in Steel ConstructionIshwarya SrikanthNo ratings yet

- Niedax USA KatalogDocument250 pagesNiedax USA Katalogmahesh_sali2003No ratings yet

- Cook PW CatalogDocument54 pagesCook PW CatalogLuis DomdNo ratings yet

- Brochure Cathelain GBDocument28 pagesBrochure Cathelain GBFg FgNo ratings yet

- Annexure IIIDocument674 pagesAnnexure IIItakari divisionNo ratings yet

- The Fast Track: Systems in Cable ManagementDocument6 pagesThe Fast Track: Systems in Cable ManagementMiguel GarzaNo ratings yet

- Ebook Corrosion Atlas 3Rd Edition A Collection of Illustrated Case Histories PDF Full Chapter PDFDocument67 pagesEbook Corrosion Atlas 3Rd Edition A Collection of Illustrated Case Histories PDF Full Chapter PDFmyrtle.sampson431100% (37)

- Corrosion Protection: General Information: Industry AirDocument1 pageCorrosion Protection: General Information: Industry AirMAI_QualityNo ratings yet

- En 12944Document11 pagesEn 12944scribd99190100% (1)

- Technical IndexDocument4 pagesTechnical IndexNgân LêNo ratings yet

- K-Line Complete CatalogueDocument55 pagesK-Line Complete Cataloguekaisersv75No ratings yet

- Ties Straps SimpsonDocument12 pagesTies Straps SimpsonmurdicksNo ratings yet

- Catalogo Mclean Lineas Subtransmision PDFDocument258 pagesCatalogo Mclean Lineas Subtransmision PDFArmando Estrada MendezNo ratings yet

- JO-AM-MGC-SP-203 (Rev. A1) Painting and Coating of Metal Surfaces SSDocument43 pagesJO-AM-MGC-SP-203 (Rev. A1) Painting and Coating of Metal Surfaces SSpetronashscribdid100% (1)

- Pricing For Al Qattara - 116Document34 pagesPricing For Al Qattara - 116Amro HarasisNo ratings yet

- Cable TrayDocument14 pagesCable TrayCareer_001No ratings yet

- Copie de Price Sheet - Structural Steel Frame - 24.05.2023 - 2 FRDocument2 pagesCopie de Price Sheet - Structural Steel Frame - 24.05.2023 - 2 FRmezouedNo ratings yet

- Structural Coils (SS) : International StandardsDocument2 pagesStructural Coils (SS) : International StandardsVengatesh HariNo ratings yet

- DRP001-OUF-SPE-W-000-008-B4 (Painting of New Equipment & Piping)Document37 pagesDRP001-OUF-SPE-W-000-008-B4 (Painting of New Equipment & Piping)Kannan MurugesanNo ratings yet

- Lecture 2 - Steel SectionsDocument45 pagesLecture 2 - Steel Sectionsayoub aliousalahNo ratings yet

- ArcelorMittal Fact SheetDocument3 pagesArcelorMittal Fact SheetrcgfNo ratings yet

- 32 Samss 009Document14 pages32 Samss 009naruto256No ratings yet

- Ms 966 Part 1 2001 Playground Equipment Part 1 Specifications For Materials First Revision PDFDocument17 pagesMs 966 Part 1 2001 Playground Equipment Part 1 Specifications For Materials First Revision PDFAhmad HafizNo ratings yet

- BS 1245 - 1975Document20 pagesBS 1245 - 1975Khairul Azwan Mohad LasimNo ratings yet

- Aiditec Systems Lightning Protection SystemsDocument64 pagesAiditec Systems Lightning Protection SystemsRogério BorgesNo ratings yet

- C1 To C5 Environment Application MatrixDocument1 pageC1 To C5 Environment Application MatrixakmlogaNo ratings yet

- TDS Jotamastic 90Document7 pagesTDS Jotamastic 90Syamsul MaripNo ratings yet