Professional Documents

Culture Documents

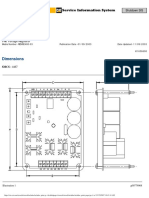

42,0426,0038, Ea

42,0426,0038, Ea

Uploaded by

dilipOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

42,0426,0038, Ea

42,0426,0038, Ea

Uploaded by

dilipCopyright:

Available Formats

TransPuls Synergic

TransSynergic Comfort Quick Reference: English

1 Setting the wire diameter 6 Correcting parameters 5 Setting the welding power

Special diameter - select desired parameter - select desired parameter

- correct desired parameter - set desired parameter

Arc length correction Specify sheet thickness

Arc-force dynamic correction / pulse

correction / arc-force dynamic Specify welding current

Arc voltage

Specify wire feed speed

2 Specifying the filler metal and Important! In synergic mode, all the remaining

parameters are set automatically.

shielding gas

Special setting Note! If external system components are

connected, some parameters can be modified

on those components. The power source

control panel is only for display purposes.

3 Setting the mode 1 - 6 Commissioning sequence 4 Selecting the process

Follow operating instructions MIG/MAG pulse synergic

2-step mode MIG/MAG standard synergic

4-step mode MIG/MAG standard manual

Special 4-step mode Feeder inching Job mode

(Aluminium welding start-up) TIG

Spot welding Gas test Rod electrode (MMA)

Special function

Setup/store

42,0426,0038,EA 01/2007 Fronius International GmbH, www.fronius.com

Text and illustrations were accurate at the time of printing. We reserve the right to make amendments.

TransPuls Synergic

TransSynergic Comfort Quick Reference: English

MIG/MAG setup MIG/MAG setup TIG - setup Electrode - setup

2-step mode Procedure

+ +

+ + or

2nd menu level Hotstart current

Gas pre-flow time Cooling unit control Hotstart time

Starting current

Gas post-flow time Cooling unit watchdog 2nd menu level

Slope

Wire feeder creep Comfort stop sensitivity Welding cct resistance

final current

Feeder inching speed Welding cct resistance Welding cct inductivity

time - starting current

Burn back correction Welding cct inductivity Charactaristic selection

time - end current

Hotstart current * Anti-stick

Hotstart time * Break voltage

Gas setup +

MIG/MAG setup Frequency **

Special 4-step mode Wirefeed deviation ** Gas pre-flow time Exit setup

Arc length correction Gas post-flow time

Return to factory setting Gas flushing Exit setup

2nd menu level Gas flow rate *** Save job

Select push-pull unit

Cooling unit control

correction, see operating instructions

For details of Job mode and Job

Cooling unit watchdog

+ Ignition timeout

Arc-break watchdog

Starting current Wire-end settings

Slope Country setting

final current Special 2-step variants

Job correction

Special 4-step variants

JobMaster mode select.

+

MIG/MAG setup

Welding cct resistance

Spot welding

Welding cct inductivity

Gas correction ***

* ... only for standard

synergic process

+

** ... only with SynchroPuls option Display firmware versions

+ Power source firmware e.g. Welding database e.g.

*** ... only with digital gas

Spot-welding time control option Wirefeeder firmware e.g. Total welding time e.g.

You might also like

- Filing # 120208791 E-Filed 01/25/2021 07:26:55 PMDocument67 pagesFiling # 120208791 E-Filed 01/25/2021 07:26:55 PMthe next miami100% (1)

- SafeScan 7 ManualDocument75 pagesSafeScan 7 Manualdilip100% (1)

- Project Proposal On Dairy FarmDocument26 pagesProject Proposal On Dairy Farmvector dairy88% (8)

- Radio Parameter Reference GSMDocument658 pagesRadio Parameter Reference GSMCamilo Bazan HerediaNo ratings yet

- HMX Fundamentals Public Application - April - May - June 2019 - Personal InformationDocument6 pagesHMX Fundamentals Public Application - April - May - June 2019 - Personal InformationMichaelJonatanNo ratings yet

- Mitsubishi Triton l200 Specifications Specs PDFDocument28 pagesMitsubishi Triton l200 Specifications Specs PDFngulumi82100% (2)

- Origo Mig 4004i - 5004iDocument4 pagesOrigo Mig 4004i - 5004icarlosNo ratings yet

- Mta1, M1 10prog, AT1, AT1, M1, AT1, AT1, RA 12, RA 23, RA T1, FS 002, FS 002Document16 pagesMta1, M1 10prog, AT1, AT1, M1, AT1, AT1, RA 12, RA 23, RA T1, FS 002, FS 002kismikloshun55No ratings yet

- Vacuum Stepper Motors: Arun Microelectronics LimitedDocument3 pagesVacuum Stepper Motors: Arun Microelectronics LimitedMuraleetharan BoopathiNo ratings yet

- Katalogovy List 1726Document2 pagesKatalogovy List 1726Mohamed lamine AssaslaNo ratings yet

- Mta1, M1 10prog, AT1, AT1, M1, AT1, AT1, RA 12, RA 23, FS 002, FS 002Document16 pagesMta1, M1 10prog, AT1, AT1, M1, AT1, AT1, RA 12, RA 23, FS 002, FS 002kismikloshun55No ratings yet

- Seco BroncoDocument6 pagesSeco BroncoAlberto SánchezNo ratings yet

- Kap05 FI01 eDocument34 pagesKap05 FI01 echochoroyNo ratings yet

- Master Slave SwitchoverDocument18 pagesMaster Slave Switchoversanjaya srivastavaNo ratings yet

- GVM CatalogDocument56 pagesGVM CatalogGuilherme Leite JSNo ratings yet

- Release 4 - 0 Overview - ENDocument24 pagesRelease 4 - 0 Overview - ENvitor17050137No ratings yet

- Balun MBAL-1440 MMIC 14-40GHz Isolation BalunDocument7 pagesBalun MBAL-1440 MMIC 14-40GHz Isolation BalunDukSoo KwonNo ratings yet

- Compact Pressure SwitchDocument4 pagesCompact Pressure SwitchPablo Gerardo Gil CocaNo ratings yet

- MT3D-0113LSM-2-GaAs MMIC T3 Mixer With Differential IFDocument18 pagesMT3D-0113LSM-2-GaAs MMIC T3 Mixer With Differential IF2022ht80586No ratings yet

- AGC 200 Automatic Gen-Set Controller Data Sheet AGC 200 Advanced Gen-Set Controller Data SheetDocument13 pagesAGC 200 Automatic Gen-Set Controller Data Sheet AGC 200 Advanced Gen-Set Controller Data SheetlucasNo ratings yet

- LS Training ManualDocument29 pagesLS Training ManualMuhammad Haris Baig100% (6)

- STRAINER MEE Cooling Water PumpDocument2 pagesSTRAINER MEE Cooling Water PumpBhaumikNo ratings yet

- STRAINER - MEE - Cooling Water PumpDocument2 pagesSTRAINER - MEE - Cooling Water PumpBhaumik BhuvaNo ratings yet

- Sony wm-fx193 fx195 Ver1.1Document19 pagesSony wm-fx193 fx195 Ver1.1Chef KaiserNo ratings yet

- Motorized Torque Stand MTS SeriesDocument6 pagesMotorized Torque Stand MTS Seriesadi cahya saputraNo ratings yet

- Programming Guide - Power Navigator Power Navigator / EnavigatorDocument14 pagesProgramming Guide - Power Navigator Power Navigator / EnavigatorPandu BirumakovelaNo ratings yet

- Gefran GTF ManualDocument37 pagesGefran GTF ManualLavanyaNo ratings yet

- Device Overview: Gaas Mmic Double Balanced Mixer Mm1-0222HsmDocument13 pagesDevice Overview: Gaas Mmic Double Balanced Mixer Mm1-0222HsmRAMAVATH RAJKUMARNo ratings yet

- Magic Weld 250 (07-22) - enDocument3 pagesMagic Weld 250 (07-22) - enmeryem sıla özdemirNo ratings yet

- Acon-C/Cg, Pcon-C/Cg/Cf First Step Guide: Tenth EditionDocument5 pagesAcon-C/Cg, Pcon-C/Cg/Cf First Step Guide: Tenth EditionÁron SzárazNo ratings yet

- Smootharc Elite Iseries BrochureDocument8 pagesSmootharc Elite Iseries BrochureRiaan De BeerNo ratings yet

- Electrod 5Document3 pagesElectrod 5RAMESH PANDARINo ratings yet

- 80960F MHW GTF 04-2016 EngDocument39 pages80960F MHW GTF 04-2016 EngDipen PatelNo ratings yet

- Manual FlowDocument37 pagesManual Flowmahevi27No ratings yet

- Ca EMPR Eng PDFDocument44 pagesCa EMPR Eng PDFdaniel2rialNo ratings yet

- Torque-Angle Measurement System TAA SeriesDocument10 pagesTorque-Angle Measurement System TAA SeriesSharan DaraindharaneNo ratings yet

- ST 730Document22 pagesST 730bigm94iNo ratings yet

- VF-S15 Toshiba DriveDocument13 pagesVF-S15 Toshiba DriveRebecca DangNo ratings yet

- 07-02-2018 12-59-46 - etaSMART APFC Relay - Catalogue PDFDocument5 pages07-02-2018 12-59-46 - etaSMART APFC Relay - Catalogue PDFIshwar ranawatNo ratings yet

- SEL-387A Current Differential and Overcurrent Protection RelayDocument20 pagesSEL-387A Current Differential and Overcurrent Protection RelayAlan YairNo ratings yet

- MAE Stepper MotorsDocument28 pagesMAE Stepper MotorssbgrimssonNo ratings yet

- KINGgates Linear EN3Document6 pagesKINGgates Linear EN3Catalin IrimiaNo ratings yet

- DownloadDocument5 pagesDownloadVVan TanNo ratings yet

- LEITWIND Technical Data Sheet LTW42 250Document2 pagesLEITWIND Technical Data Sheet LTW42 250James MartinNo ratings yet

- Tosvert Vf-S15 Parameter ListDocument47 pagesTosvert Vf-S15 Parameter ListΑντώνης ΣπυρόπουλοςNo ratings yet

- VR6 - Nenr2480-03Document75 pagesVR6 - Nenr2480-03PhamVan CaNo ratings yet

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Document2 pagesPrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorldNo ratings yet

- High Efficiency Amplifiers For EDGE Applications Based On Enhancement-Mode Junction PHEMTDocument19 pagesHigh Efficiency Amplifiers For EDGE Applications Based On Enhancement-Mode Junction PHEMTChelva SelvaNo ratings yet

- DDR4 8Gb C Die Unbuffered SODIMM Rev1.5 Apr.18Document83 pagesDDR4 8Gb C Die Unbuffered SODIMM Rev1.5 Apr.18jagadees21No ratings yet

- MRG 2Document20 pagesMRG 2Prasenjit MaityNo ratings yet

- Tornatech JockeypumpDocument2 pagesTornatech Jockeypumpsafetyjulz14No ratings yet

- Information: Smart Positioner (Rotary Type)Document2 pagesInformation: Smart Positioner (Rotary Type)Hamed YadegariNo ratings yet

- Circutor Energy Meter ManualDocument12 pagesCircutor Energy Meter Manualtayyab1965No ratings yet

- HMC 213 ADocument9 pagesHMC 213 ARamadan AlhalabiNo ratings yet

- Main Features: Advanced Power ControllerDocument18 pagesMain Features: Advanced Power ControllerGopal HegdeNo ratings yet

- A1102 34708Document9 pagesA1102 34708Adán Cogley CantoNo ratings yet

- Lorad - Miv - Full (Service Manuals)Document183 pagesLorad - Miv - Full (Service Manuals)fragmentos100% (1)

- KRP928 ManualDocument4 pagesKRP928 ManualWahyu pramonoNo ratings yet

- Non-Inverting Amplifier OPAmp Freq Ug-EDocument4 pagesNon-Inverting Amplifier OPAmp Freq Ug-EYousif AlaaNo ratings yet

- Genset Control For Auto Start and Transfer Switch Operation (Model "320/350")Document4 pagesGenset Control For Auto Start and Transfer Switch Operation (Model "320/350")mohammad javad golNo ratings yet

- FT-22300500MP (Smart 500 MP) - enDocument2 pagesFT-22300500MP (Smart 500 MP) - enArahman RamadhanNo ratings yet

- SM 2035 ADocument5 pagesSM 2035 Aajc2_1984No ratings yet

- ZXWR RNC (V3.11.10) Radio Network Controller Radio Parameter Reference - 604911Document1,096 pagesZXWR RNC (V3.11.10) Radio Network Controller Radio Parameter Reference - 604911Kamlesh MehtaNo ratings yet

- Woodward ATS Module Spec Easy Gen 350Document4 pagesWoodward ATS Module Spec Easy Gen 350nooruddinkhan1No ratings yet

- Touch Sensing vs. Seam Tracking V1.1Document15 pagesTouch Sensing vs. Seam Tracking V1.1dilipNo ratings yet

- Procedure To Copy Software Between LR MatesDocument2 pagesProcedure To Copy Software Between LR MatesdilipNo ratings yet

- Littelfuse Powr-BloksDocument8 pagesLittelfuse Powr-BloksdilipNo ratings yet

- User Manual 1756-It6iDocument31 pagesUser Manual 1756-It6idilipNo ratings yet

- Quick Start Guide For The Remote Access Dial-In Multiport Ethernet ModemDocument16 pagesQuick Start Guide For The Remote Access Dial-In Multiport Ethernet ModemdilipNo ratings yet

- Panelview Plus PDFDocument244 pagesPanelview Plus PDFdilipNo ratings yet

- Power Supply Specifications (1746-P1, - P2, - P3, and - P4) : Description: Specification: 1746-P1 P2 P3 P4Document2 pagesPower Supply Specifications (1746-P1, - P2, - P3, and - P4) : Description: Specification: 1746-P1 P2 P3 P4dilipNo ratings yet

- C Controller Ops and Programming PDFDocument564 pagesC Controller Ops and Programming PDFdilipNo ratings yet

- Fanuc Rj3ib Controller ManualDocument5 pagesFanuc Rj3ib Controller ManualdilipNo ratings yet

- 80 3689 01 Threaded ConnectionsDocument12 pages80 3689 01 Threaded ConnectionsMiguel Alfonso Ruiz MendezNo ratings yet

- Anthropometrics ErgonomicsDocument78 pagesAnthropometrics ErgonomicsashokdinoNo ratings yet

- Construction of A 170m Long Cripple Sided Tunnel Using Variable Geometry Hydraulic Formwork in DTL 3, C927Document16 pagesConstruction of A 170m Long Cripple Sided Tunnel Using Variable Geometry Hydraulic Formwork in DTL 3, C927Batu GajahNo ratings yet

- Bpacr FinalDocument7 pagesBpacr FinalNivedita CharanNo ratings yet

- Fruit Processing: Ömer Utku Çopur and Canan Ece TamerDocument28 pagesFruit Processing: Ömer Utku Çopur and Canan Ece TamerTan Hau VoNo ratings yet

- ABE 30 Lab Exercise 6 Operation and Performance of A Laboratory Scale Paddy DehuskerDocument7 pagesABE 30 Lab Exercise 6 Operation and Performance of A Laboratory Scale Paddy DehuskerBryan Buno100% (1)

- On Linguistic Politeness Theory: Robin Lakoff's Theory of Politeness, Brown and Levinson's Theory of Politeness, Geoffrey Leech's Theory of PolitenessDocument9 pagesOn Linguistic Politeness Theory: Robin Lakoff's Theory of Politeness, Brown and Levinson's Theory of Politeness, Geoffrey Leech's Theory of PolitenessCentral Asian StudiesNo ratings yet

- Ict Dos and DontsDocument5 pagesIct Dos and DontsLouwellaEredianoIbabaoNo ratings yet

- Perbandingan Jumlah Eritrosit Pada Sampel Darah 3, 2 Dan 1 ML Dengan Antikoagulan K2EdtaDocument6 pagesPerbandingan Jumlah Eritrosit Pada Sampel Darah 3, 2 Dan 1 ML Dengan Antikoagulan K2EdtaNia AzNo ratings yet

- Research & Innovation: The EuDocument42 pagesResearch & Innovation: The EurubenpeNo ratings yet

- Construct The Relational Model of The Following Scenario. (6 MARKS) System DescriptionDocument2 pagesConstruct The Relational Model of The Following Scenario. (6 MARKS) System DescriptionBushra ShahzadNo ratings yet

- American School: International LagosDocument32 pagesAmerican School: International LagosGozie obiNo ratings yet

- Nail Care Lesson 2Document5 pagesNail Care Lesson 2Tin TinNo ratings yet

- Birla Power - MBA ProjectDocument23 pagesBirla Power - MBA ProjectBibhu Prasad SahooNo ratings yet

- Pasolink NEO Version Up Procedure - Ver3.1.7 - by PNMXJDocument15 pagesPasolink NEO Version Up Procedure - Ver3.1.7 - by PNMXJdlgt63No ratings yet

- Name of Customer - Name of Project - TE-112045 - WFC - Print - OutDocument1 pageName of Customer - Name of Project - TE-112045 - WFC - Print - OutJavier EspinosaNo ratings yet

- Free Iptv Ex - Yu Streams 11.07.14Document51 pagesFree Iptv Ex - Yu Streams 11.07.14bajra123No ratings yet

- Data Mining: BooksDocument14 pagesData Mining: BooksGonzales BlesNo ratings yet

- Practical File AI - Class 10Document3 pagesPractical File AI - Class 10pawankvs2008No ratings yet

- Angew,. Chem. Int. Ed. Engl. 1993, 32, No. 9, 1306Document3 pagesAngew,. Chem. Int. Ed. Engl. 1993, 32, No. 9, 1306elderwanNo ratings yet

- PHD Pharma 23 IdDocument1 pagePHD Pharma 23 Idos krishnaNo ratings yet

- International Tropical Timber Organization: (ITTO) Fellowship Application FormDocument11 pagesInternational Tropical Timber Organization: (ITTO) Fellowship Application FormKhoza RaNo ratings yet

- Nami Solar Company Profile Aug 2020 ENGDocument13 pagesNami Solar Company Profile Aug 2020 ENGKien Trung Nguyen100% (1)

- Fundamentals of Thermal Sensors: Thu HuynhDocument39 pagesFundamentals of Thermal Sensors: Thu HuynhsamcaridoNo ratings yet

- Complete Guide For Growing Plants Hydroponically by J Benton Jones JR B00hznqitmDocument5 pagesComplete Guide For Growing Plants Hydroponically by J Benton Jones JR B00hznqitmnagesh dolasNo ratings yet

- PragmaticsDocument10 pagesPragmaticsDisya RusmadinantiNo ratings yet