Professional Documents

Culture Documents

FC4500

FC4500

Uploaded by

hugoamendozaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FC4500

FC4500

Uploaded by

hugoamendozaCopyright:

Available Formats

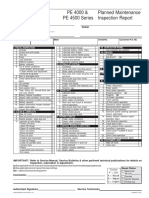

C FC 4500 Series Planned Maintenance

Inspection Report

Customer Dealer

Date Hr. Meter Reading Make Serial No. Customer P.O. No.

I. VISUAL INSPECTION V. POWER CABLES & CONTROL XI. MAST ASSEMBLY & MISC.

1. Oil Leaks 1. Power Cable Conditions 1. Roller & Tracking - Wear or Damage

2. Overhead Guard 2. Power Cable Connections Secure 2. Lift Chains Condition - Wear

3. Mast Assembly 3. Wiring Conditions 3. Lift Chains Adjustment

4. Tire & Wheel Conditions 4. Wiring Connections Secure 4. Lift & Tilt Cylinder & Mount Condition

• Drive Tire, LH & RH VI. CONTACTOR PANEL & POWER 5. Mounting Bolts to Power Unit Secure

• Steer Tire, LH & RH 1. Line Tip Condition 6. Control Cables & Hoses

5. Lift Chains & Mounts 2. S Tip Condition 7. Limit Switch

6. Limit Switch Operation (Tilt Interlock) 3. P Tip Condition DC Lift (Option) 8. Load Backrest Secure

7. Seat Belt VII. BRAKES 9. Overhead Guard Bolts Tight

8. Bent or Damaged Parts 1. Service Brake Pedal Operation 10. Tilt Cylinder Adjustment

9. Forks & Latches 2. Service Brake Switch Adjustment XII. FREEZERCONDITIONTRUCKS

10. Load Backrest 3. Service Brake Piston Leaks 1. Heater Operation

11. Safety Decals & Capacity Plates 4. Brake Lines 2. Wiring Operation

in Place 5. Brake Pads XII. OPERATIONAL CHECKS &

12. Seat Deck Latch, Gas Struts, Hinges 6. Brake, LH & RH Rotors TEST DRIVE

and Mount Condition 7. Parking Brake Switch Operation 1. Horn

13. Battery Connector (Truck Side) 8. Parking Brake Linkage Adjustment 2. Manual Emergency Battery Disconnect

14. Battery Cable (Truck Side) 9. Service Brake Valve Leaks 3. Power Steering Operation

15. Battery Retainer 10. Accumulator Charge & Warning 4. Verify Service & Parking Brake

16. Battery Rollers (Option) System Operation Operation (a)

II. CLEAN & LUBRICATE VII. STEERING 5. Forward/Reverse Travel

1. Blow Off Truck 1. Power Steering Operation 6. Plugging

2. Blow Low Pressure Over All 2. Steering Unit 7. Creep Speed

Electrical Panels 3. Pump & Motor Secure 8. Lift/Tilt & Aux. Operation

3. Lubricate All Zerk Fittings 4. Brush & Armature Condition 9. Lift/Tilt & Aux. Switch Operation

4. Blow Off Brake Linkage 5. Steer Cylinder Secure 10. Directional Control Operation

5. Lubricate Steering Bottom (8 Zerks) 6. Steer Cylinder Condition 11. Directional Switches

6. Lubricate Mast & RollerAssemblies 7. Leaks in Steering Hydraulic Lines 12. Rated Capacity

7. Lubricate Lift Chains 8. Steering Links 13. Stopping Distance

8. Lubricate Miscellaneous Linkages 9. Spindle Assemblies & Fasteners 14. Travel Alarm

9. Battery Rollers 10. Steering Column 15. Park Brake Alarm Operation

10. Lubricate Tilt Cylinder Mounts 11. Steering Column Position Lock 16. Work Lights

11. Lift/Tilt/Aux. Lever Asm. IX. ACCELERATOR PEDAL 17. Display

III. HYDRAULIC PUMP & MOTOR 1. Pedal Operation 18. Operator Fan

1. Mounting Secure 2. Switch Adjustment 19. Compartment Fan

2. Hose & Fitting Conditions X. HYDRAULIC SYSTEM 20. Brake, Strobe & Backup Lights

3. Leaks 1. Oil Level & Condition 21. Battery Retainer Switches (Opt.)

4. Brush & Armature Conditions 2. Leaks XIV. ATTACHMENTS

DC Lift (Option) 3. Breather Cap 1. Operation

5. Blow Brush Dust From Motor 4. Hoses & Fittings 2. Leaks

DC Lift (Option) 5. Filter 3. Condition

6. Cable Connections 6. Dip Stick/Fill Port Cap XV. CUSTOMER CARE

7. Pump Operation 1. Wipe Off Truck

IV. DRIVE UNIT 2. Clean Area

1. Fluid Level

2. Leaks

3. Secure Motor Mountings

4. Wheel Lug Bolts

IMPORTANT: Refer to Service Manual for details on inspection, lubrication & adjustment.

(a) See applicable service manual for brake adjustment procedures and recommended operation.

Repair Status

Codes

Approved

= O.K. W.O.#

Comments: A = Adjust Denied

R = Repair Quote Repairs

U = Urgent Follow-Up

Authorized Signature Serviceman

Crown 2007 PF15705 D Rev. 4/11 Printed in U.S.A.

You might also like

- Normas NES M1019Document12 pagesNormas NES M1019Margarita Torres FloresNo ratings yet

- Service Manual: WarningDocument77 pagesService Manual: Warningpeter panNo ratings yet

- Hyster J40xnt Parts and Service Periodic Maintenance 1689720 8000SRM1339 (02 2012) US ENDocument80 pagesHyster J40xnt Parts and Service Periodic Maintenance 1689720 8000SRM1339 (02 2012) US ENJahir FrutosNo ratings yet

- Sensor de Compartimento Del Operador ReachDocument20 pagesSensor de Compartimento Del Operador ReachDetodito VentasNo ratings yet

- Operator Manual For Yale Order Picker Forklifts PDFDocument1 pageOperator Manual For Yale Order Picker Forklifts PDFluis4caballero-14No ratings yet

- Caterpillar NR4500Document112 pagesCaterpillar NR4500Christian Bedoya0% (1)

- Pallet Truck Pth50 Brochure GBDocument3 pagesPallet Truck Pth50 Brochure GBGhufran AhmedNo ratings yet

- Lab2 PDFDocument3 pagesLab2 PDFMd.Arifur RahmanNo ratings yet

- The Soul of An Octopus - Favorite QuotesDocument7 pagesThe Soul of An Octopus - Favorite QuotesTanya RodmanNo ratings yet

- Pe4000 4500Document1 pagePe4000 4500hugoamendozaNo ratings yet

- Please Contact: Some of The Photos May Include Optional EquipmentDocument7 pagesPlease Contact: Some of The Photos May Include Optional EquipmentАлександр ОлейникNo ratings yet

- F-12 Preventive Maintenance For 3 TonsDocument4 pagesF-12 Preventive Maintenance For 3 TonsPyae Phyoe AungNo ratings yet

- RD5200SDocument80 pagesRD5200SMiguel Angel Rodriguez Catro100% (2)

- Especificaciones Roller ClampDocument4 pagesEspecificaciones Roller ClampBersanz SrlNo ratings yet

- 2-Stage Mast: MaintenanceDocument80 pages2-Stage Mast: MaintenanceRex PereiraNo ratings yet

- 78 Sec Operator S ManualDocument96 pages78 Sec Operator S ManualDiego Salazar JarrínNo ratings yet

- Brake SystemDocument14 pagesBrake SystemLinde Forklift100% (2)

- Manual de Servicio Hyster N40xtaDocument15 pagesManual de Servicio Hyster N40xtaMONTACARGAS AVSNo ratings yet

- Cooling System: Safety Precautions Maintenance and RepairDocument13 pagesCooling System: Safety Precautions Maintenance and RepairKiều Văn TrungNo ratings yet

- Hyster 897800 11 02 srm0590Document48 pagesHyster 897800 11 02 srm0590Miguel Angel Velazquez Mercado100% (1)

- Manual de Servicio 1930ESDocument218 pagesManual de Servicio 1930ESfernandoNo ratings yet

- JLG 10MSP Service EnglishDocument178 pagesJLG 10MSP Service Englishspamrql2No ratings yet

- LiteEdit 4.6 Reference Guide r1Document52 pagesLiteEdit 4.6 Reference Guide r1Елена Ахметзянова0% (1)

- SX125 CompleteDocument109 pagesSX125 CompleteMuhamad KarisNo ratings yet

- SC6200Document50 pagesSC6200Migue Angel Rodríguez CastroNo ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0496Document2 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0496PeterNo ratings yet

- TSP 6000 InstallationDocument19 pagesTSP 6000 InstallationSteNo ratings yet

- Hyster B257, B60ZHD, B80ZHD Service & Repair ManualDocument26 pagesHyster B257, B60ZHD, B80ZHD Service & Repair ManualBruno Ferreira SilvaNo ratings yet

- TSS DDocument17 pagesTSS Dfrancisco uribeNo ratings yet

- Event Code Group 500 (GPC3020 Up To 08/2012) : Lectrical YstemDocument7 pagesEvent Code Group 500 (GPC3020 Up To 08/2012) : Lectrical Ystemmarceloo1993No ratings yet

- Steering System PDFDocument24 pagesSteering System PDFamine100% (1)

- Master Drive Unit - Mpb040-E (B827)Document14 pagesMaster Drive Unit - Mpb040-E (B827)Juan Esteban AgudeloNo ratings yet

- Bendi - B3-30 - AC - Maintenance - Check Lists PDFDocument9 pagesBendi - B3-30 - AC - Maintenance - Check Lists PDFChristian BedoyaNo ratings yet

- Hydraulic Cleanliness Procedures: MaintenanceDocument24 pagesHydraulic Cleanliness Procedures: MaintenanceEsjo100% (1)

- Electrical System/Lights: H36.00-48.00E (H800-1050E) (D117)Document20 pagesElectrical System/Lights: H36.00-48.00E (H800-1050E) (D117)Nguyễn Văn Hùng0% (1)

- Toyota Forklifts Spec Ae484dDocument8 pagesToyota Forklifts Spec Ae484dEmadNo ratings yet

- Capacities and SpecificationsDocument10 pagesCapacities and SpecificationsamineNo ratings yet

- Hyster 299YDocument44 pagesHyster 299YraquelestevezNo ratings yet

- Secador Parker PDFDocument68 pagesSecador Parker PDFArmandoOlivaresNo ratings yet

- ForewordDocument423 pagesForewordRicardo VieiraNo ratings yet

- FB 20 NTKDocument21 pagesFB 20 NTKAnderson BriedaNo ratings yet

- Tilt CylindersDocument14 pagesTilt CylindersJuan Carlos Sanchez Gomez100% (1)

- Awp 05-50000Document144 pagesAwp 05-50000Jhon Hever BenitezNo ratings yet

- Kalmar Montacargas DCE 90-180, DCE 70-32E3-70-35E Workshop Manual (PDF - Io)Document151 pagesKalmar Montacargas DCE 90-180, DCE 70-32E3-70-35E Workshop Manual (PDF - Io)ValeriNo ratings yet

- 45F Paper Roll ClampDocument2 pages45F Paper Roll ClampAnonymous MdXQ2V9xNo ratings yet

- JLG Lift E 300 A, AJ y AJP (Ingles 2009) PDFDocument174 pagesJLG Lift E 300 A, AJ y AJP (Ingles 2009) PDFJuan Carlos Rubio FrescoNo ratings yet

- Podem - Spare Parts - Electric Wire Rope Hoists, T Series (EN)Document24 pagesPodem - Spare Parts - Electric Wire Rope Hoists, T Series (EN)Luka BornaNo ratings yet

- AF-3100 Series: General-Purpose High-Performance Inverter Maintenance ManualDocument88 pagesAF-3100 Series: General-Purpose High-Performance Inverter Maintenance Manualhoang dungNo ratings yet

- GTZZ14EJ 16EJ Maintenance Manual1Document90 pagesGTZZ14EJ 16EJ Maintenance Manual1Kris topher100% (1)

- Etr345 Junghenrich TranspalletDocument13 pagesEtr345 Junghenrich TranspalletLuis ArcudiaNo ratings yet

- Installation & Ops Manual - Smart Start M and D Models 7-2009Document24 pagesInstallation & Ops Manual - Smart Start M and D Models 7-2009Yang GomezNo ratings yet

- Bil-Jax 3522A Operator Manual PDFDocument54 pagesBil-Jax 3522A Operator Manual PDFLynn WardleNo ratings yet

- Diagramas Hyster H55FT 2,5 TonDocument72 pagesDiagramas Hyster H55FT 2,5 TonRherisson ModulosNo ratings yet

- Century Fuel Products On Material Handling Network MagazineDocument56 pagesCentury Fuel Products On Material Handling Network MagazineSeth priceNo ratings yet

- Codigos de Fallas 8fg Toyota 8fgcu15 8fgcu25Document552 pagesCodigos de Fallas 8fg Toyota 8fgcu15 8fgcu25Cesar MendozaNo ratings yet

- Adjusments With PC Ev 100 and Sem - (08-2003) - Us-EnDocument38 pagesAdjusments With PC Ev 100 and Sem - (08-2003) - Us-EnChristian BedoyaNo ratings yet

- 4 Stage Mast - (04-2005) - Us-EnDocument48 pages4 Stage Mast - (04-2005) - Us-EnChristian BedoyaNo ratings yet

- Periodic MaintenanceDocument26 pagesPeriodic MaintenanceHector Puac100% (1)

- AHQ 76 Nos - Hulift Semi Electric Manual Godrej NosDocument22 pagesAHQ 76 Nos - Hulift Semi Electric Manual Godrej NosAnup Kumar singhNo ratings yet

- HeinWerner - HW93642 Service JackDocument8 pagesHeinWerner - HW93642 Service JackmoquitiNo ratings yet

- Air Series: Part D: Receiving Unit G ACRS13-G DCRS13Document8 pagesAir Series: Part D: Receiving Unit G ACRS13-G DCRS13ajamyuyaNo ratings yet

- Pauta RMD6000Document1 pagePauta RMD6000hugoamendozaNo ratings yet

- MP Misc 255 April 10 Emd CommissioningDocument6 pagesMP Misc 255 April 10 Emd CommissioningmailbkraoNo ratings yet

- Unit - 2 Sensor Networks - Introduction & ArchitecturesDocument32 pagesUnit - 2 Sensor Networks - Introduction & Architecturesmurlak37No ratings yet

- Process of Concept Formation: ReferencesDocument1 pageProcess of Concept Formation: ReferencesRamani SwarnaNo ratings yet

- Free Online Course On PLS-SEM Using SmartPLS 3.0 - Moderator and MGADocument31 pagesFree Online Course On PLS-SEM Using SmartPLS 3.0 - Moderator and MGAAmit AgrawalNo ratings yet

- William Angelo - Week-7.AssessmentDocument2 pagesWilliam Angelo - Week-7.Assessmentsup shawtyNo ratings yet

- Annual Return For A Company Limited by GuaranteeDocument4 pagesAnnual Return For A Company Limited by GuaranteeAtisang Tonny SethNo ratings yet

- Notes On HAMDocument89 pagesNotes On HAMCletus Paul100% (1)

- English Curriculum Reforminthe PhilippinesDocument18 pagesEnglish Curriculum Reforminthe PhilippinesLanping FuNo ratings yet

- A Biblical Philosophy of MinistryDocument11 pagesA Biblical Philosophy of MinistryDavid Salazar100% (4)

- Homework Helper FreeDocument8 pagesHomework Helper Freeh48gh6sy100% (1)

- HNDIT 1022 Web Design - New-PaperDocument6 pagesHNDIT 1022 Web Design - New-Paperravinduashan66No ratings yet

- The Quiescent Benefits and Drawbacks of Coffee IntakeDocument6 pagesThe Quiescent Benefits and Drawbacks of Coffee IntakeVikram Singh ChauhanNo ratings yet

- NT Organic FarmingDocument17 pagesNT Organic FarmingSai Punith Reddy100% (1)

- Pengkarya Muda - Aliah BiDocument7 pagesPengkarya Muda - Aliah BiNORHASLIZA BINTI MOHAMAD MoeNo ratings yet

- M HealthDocument81 pagesM HealthAbebe ChekolNo ratings yet

- Greece Education Foundation Courses and Gces 10 2010Document6 pagesGreece Education Foundation Courses and Gces 10 2010Stamatios KarapournosNo ratings yet

- RecipesDocument7 pagesRecipesIndira UmareddyNo ratings yet

- Metaverse Report - Thought Leadership 1Document17 pagesMetaverse Report - Thought Leadership 1Tejas KNo ratings yet

- DMPB 9015 e Rev4Document109 pagesDMPB 9015 e Rev4mohammad hazbehzadNo ratings yet

- p-37 Recovery of Gold From Its OresDocument33 pagesp-37 Recovery of Gold From Its OresRussell Hartill100% (6)

- Realme Buds Q2s With AI ENC & Fast Charging Bluetooth HeadsetDocument2 pagesRealme Buds Q2s With AI ENC & Fast Charging Bluetooth HeadsetKhuni FreefireNo ratings yet

- User Manual of CUBOIDDocument50 pagesUser Manual of CUBOIDshahinur rahmanNo ratings yet

- DoomsdayDocument29 pagesDoomsdayAsmita RoyNo ratings yet

- Teacher Learning Walk Templates - 2017 - 1Document13 pagesTeacher Learning Walk Templates - 2017 - 1Zakaria Md SaadNo ratings yet

- Female Genital Organ AnomaliesDocument83 pagesFemale Genital Organ AnomalieszulinassirNo ratings yet

- DO - 159 - S2015 Duration of SchoolDocument2 pagesDO - 159 - S2015 Duration of SchoolAnonymous qg3W2rsRcGNo ratings yet

- CAD1501 Notes: Unit 1: What You Can Expect To See in The Summary/Notes For This UnitDocument9 pagesCAD1501 Notes: Unit 1: What You Can Expect To See in The Summary/Notes For This UnitSimone BreetNo ratings yet

- List Peserta Swab Antigen - 5 Juni 2021Document11 pagesList Peserta Swab Antigen - 5 Juni 2021minhyun hwangNo ratings yet