Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

6 viewsLiquid Filling Systems

Liquid Filling Systems

Uploaded by

Arun UThis document summarizes liquid filling systems that can fill a variety of containers with different types of liquids. It describes key features such as weighmetric filling for accuracy, filling speed options, and data recording capabilities. Various filling methods and optional features are also outlined, along with safety features to prevent spills and ensure proper filling. Different display and controller options allow for flexible operation in safe or hazardous areas.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Saej1469v003 Air Brake Actuator Test ProcedureDocument22 pagesSaej1469v003 Air Brake Actuator Test ProcedureDaniel Farfan100% (1)

- Auto Guide w-25600 - W-17800 - WEINGRILL - GUIDE-7Document1 pageAuto Guide w-25600 - W-17800 - WEINGRILL - GUIDE-7Ambar Jati WaluyoNo ratings yet

- Price List FM200 CFSDocument38 pagesPrice List FM200 CFSdanielmq100% (1)

- Sieme 02089 200424082235Document3 pagesSieme 02089 200424082235Bruce CoxNo ratings yet

- MAK WATER - PDS Brackish Water Reverse Osmosis (BWRO)Document2 pagesMAK WATER - PDS Brackish Water Reverse Osmosis (BWRO)efendyandraNo ratings yet

- Catalogo Durometro Electrolab PDFDocument8 pagesCatalogo Durometro Electrolab PDFWilber RodriguezNo ratings yet

- Bermad: Electro-Pneumatically Controlled Deluge Valve With Local Reset Model FP 400Y - 6MDocument4 pagesBermad: Electro-Pneumatically Controlled Deluge Valve With Local Reset Model FP 400Y - 6MLuis GonzalezNo ratings yet

- LH 10 Golden Rules For SEEC Mastery - Main FileDocument39 pagesLH 10 Golden Rules For SEEC Mastery - Main FileTarek Fenniche100% (1)

- Model: 4TT: World's Best 4x4 Concrete MixersDocument5 pagesModel: 4TT: World's Best 4x4 Concrete MixersSenthilKumarNo ratings yet

- 5.19 JSP Power Transformer High Voltage TestDocument4 pages5.19 JSP Power Transformer High Voltage Testmuhammad.younisNo ratings yet

- Brcthtincna 0220Document20 pagesBrcthtincna 0220LEO AROKYA DASS ANo ratings yet

- Check Valve SelectionDocument1 pageCheck Valve SelectionramkikkdNo ratings yet

- Truck-Mounted Cranes: HB-R Series, The Perfect Solution For Applications With Large VehiclesDocument4 pagesTruck-Mounted Cranes: HB-R Series, The Perfect Solution For Applications With Large VehiclesRodrigo LealNo ratings yet

- BaurDocument3 pagesBaurmunggangNo ratings yet

- DS - Oil Breakdown Voltage Tester - DPA 75 C - BAUR - En-GbDocument3 pagesDS - Oil Breakdown Voltage Tester - DPA 75 C - BAUR - En-GbNOVASKY De Paula e CarvalhoNo ratings yet

- Production Logging Interpretation Logging Interpretation Production Logging FundamentalsDocument37 pagesProduction Logging Interpretation Logging Interpretation Production Logging FundamentalsShereef ElsawyNo ratings yet

- Electrically Controlled Deluge Valve With Remote Reset Model FP 400Y - 3UDocument4 pagesElectrically Controlled Deluge Valve With Remote Reset Model FP 400Y - 3Upedro torresNo ratings yet

- Back Connect Bimetal Thermometer PTC 0320Document4 pagesBack Connect Bimetal Thermometer PTC 0320Frank RondonNo ratings yet

- 7 Interpretation MethodologyDocument13 pages7 Interpretation MethodologyErnesto de la CarcovaNo ratings yet

- W-Palm Weingrill Guide-6Document1 pageW-Palm Weingrill Guide-6Jesid ApraezNo ratings yet

- Asphalt Plant Inspection ItemDocument2 pagesAsphalt Plant Inspection ItemsacsewNo ratings yet

- EBT Sand Filling NEWDocument2 pagesEBT Sand Filling NEWDebora ChavezNo ratings yet

- Tappi Controle de ConsitenciaDocument16 pagesTappi Controle de ConsitenciaFelipe WatanabeNo ratings yet

- Roller ChecklistDocument1 pageRoller ChecklistArsalan AhmadNo ratings yet

- Manual BRIODocument2 pagesManual BRIOrifki wahyudiNo ratings yet

- Ispe Fab Isolateur LocauxDocument22 pagesIspe Fab Isolateur LocauxAzzedine hammadiNo ratings yet

- Modulate Action Catalog EN 01 2020Document60 pagesModulate Action Catalog EN 01 2020AMIRNo ratings yet

- Weatherford Artificial Lifts Progressing Cavity Pumping Systems PDFDocument12 pagesWeatherford Artificial Lifts Progressing Cavity Pumping Systems PDFFan JackNo ratings yet

- Model Series S, Din: Sempell Safety ValveDocument17 pagesModel Series S, Din: Sempell Safety ValveKiattisak JaemjunNo ratings yet

- Brookfield Choices For InstrumentationDocument1 pageBrookfield Choices For InstrumentationRS RetheeshNo ratings yet

- Sany SLB3000C8 Asphalt Batching Plant-084006Document2 pagesSany SLB3000C8 Asphalt Batching Plant-084006wasco plantNo ratings yet

- Technical Data Sheet: Zwaluw Fix-O-Chem (Styrene Free)Document2 pagesTechnical Data Sheet: Zwaluw Fix-O-Chem (Styrene Free)Tudor GolbanNo ratings yet

- Data Sheets Safety Valve Api 526 Model Series S Sempell en en 5378736Document2 pagesData Sheets Safety Valve Api 526 Model Series S Sempell en en 5378736Braulio AhumadaNo ratings yet

- TB Fenner Y54 PDFDocument30 pagesTB Fenner Y54 PDF'viki ArtNo ratings yet

- DS - Oil Breakdown Voltage Tester - DPA 75 C - BAUR - En-GbDocument3 pagesDS - Oil Breakdown Voltage Tester - DPA 75 C - BAUR - En-Gbkavish malakaNo ratings yet

- Product Presentation Axial Piston Variable Pump A4VG Series 32Document9 pagesProduct Presentation Axial Piston Variable Pump A4VG Series 32Sameh MohamedNo ratings yet

- Data Sheets Steam Safety Valve Sapag en en 5195198Document18 pagesData Sheets Steam Safety Valve Sapag en en 5195198tinasheNo ratings yet

- Presented by Presented By: Sajad Falah Radhi Mustafa Nawfal Abdulameer Hussain Musa JaffarDocument25 pagesPresented by Presented By: Sajad Falah Radhi Mustafa Nawfal Abdulameer Hussain Musa JaffarSajad FalahNo ratings yet

- Pictus 700 Biochemistry AnalyzerDocument2 pagesPictus 700 Biochemistry AnalyzerHA FidNo ratings yet

- 35423-10 Eco Testr Ph2Document2 pages35423-10 Eco Testr Ph2Sally Salina FarahNo ratings yet

- Folleto NovalumDocument4 pagesFolleto Novalumapi-3697331No ratings yet

- Rotating Equipment & Pump Testing SystemsDocument4 pagesRotating Equipment & Pump Testing SystemsAakash PandyaNo ratings yet

- Operation and Maintenance: 5. Trouble Shooting GuideDocument3 pagesOperation and Maintenance: 5. Trouble Shooting Guidezerocool86No ratings yet

- 06 - Valve and Meters V216 - Uk - 4-4Document1 page06 - Valve and Meters V216 - Uk - 4-4fajri asyukronNo ratings yet

- Remmers Kiesol C - Horizontal Barrier: Quick and Easy Injection Due To Its Cream ConsistenceDocument4 pagesRemmers Kiesol C - Horizontal Barrier: Quick and Easy Injection Due To Its Cream ConsistenceAjayNo ratings yet

- AutoTrak Service LevelsDocument2 pagesAutoTrak Service LevelspendexxNo ratings yet

- Line Trial FormatDocument3 pagesLine Trial FormatShubham SrivastavaNo ratings yet

- INV Trouble Shootguide (Engver.)Document108 pagesINV Trouble Shootguide (Engver.)Yohanes Triatmojo100% (1)

- Jacobi Ab Resinex Softening A4 Eng A0613Document2 pagesJacobi Ab Resinex Softening A4 Eng A0613Dzulkifli MuhamadNo ratings yet

- WHM Ecotex BrochureDocument4 pagesWHM Ecotex BrochureVirendra ChhasatiyaNo ratings yet

- Brochure - Slide Stainer DP360 - EN V2.1Document3 pagesBrochure - Slide Stainer DP360 - EN V2.1quankddNo ratings yet

- Bermad - Deluge Valve - FP-400Y-2M - VU05 PDFDocument4 pagesBermad - Deluge Valve - FP-400Y-2M - VU05 PDFJESUS HUAMANINo ratings yet

- 2/2-Way Diaphragm Valve, Air Piloted: Type 174Document4 pages2/2-Way Diaphragm Valve, Air Piloted: Type 174Francisco Mones RuizNo ratings yet

- Xamine OA FlyerDocument2 pagesXamine OA FlyerJeisson HolguinNo ratings yet

- Cardiothoracic Products CatalogDocument24 pagesCardiothoracic Products Catalogmihalcea alinNo ratings yet

- Cat EP13 20TCB Electric Forklift BrochureDocument6 pagesCat EP13 20TCB Electric Forklift BrochureAbdul WaheedNo ratings yet

- Temperature Control UnitDocument2 pagesTemperature Control UnitMIGUEL GONZALEZNo ratings yet

- NETZSCH-Abwasser 0419 ENDocument12 pagesNETZSCH-Abwasser 0419 ENArieWahyuWidodoNo ratings yet

- Belt Conveyor RT45-BDocument2 pagesBelt Conveyor RT45-BMahmoud HanafyNo ratings yet

- Desalter Trouble Shooting Guide: Baker PetroliteDocument2 pagesDesalter Trouble Shooting Guide: Baker PetroliteuripssNo ratings yet

- 7642v1.0 (G52 76421X3) (890GXM G65) ASIA PDFDocument191 pages7642v1.0 (G52 76421X3) (890GXM G65) ASIA PDFКирилл КошкинNo ratings yet

- Cheat SheetDocument1 pageCheat Sheetkeng3915100% (4)

- Basic Electronics Lab Exp 4-6-pdf Ayush Anshuman Supakar (118MN0579)Document10 pagesBasic Electronics Lab Exp 4-6-pdf Ayush Anshuman Supakar (118MN0579)Ayush Anshuman SupakarNo ratings yet

- Introduction To In-Circuit TestingDocument123 pagesIntroduction To In-Circuit TestingMed Medy Fehem100% (1)

- LT-1083RCU FX-3500RCU Installation ManualDocument116 pagesLT-1083RCU FX-3500RCU Installation ManualErick CastilloNo ratings yet

- Project SolenoidDocument14 pagesProject SolenoidPradip IndraNo ratings yet

- SRV02 Rotary Pendulum User ManualDocument11 pagesSRV02 Rotary Pendulum User ManualRoby NicaNo ratings yet

- Blue Ray DiskDocument6 pagesBlue Ray DiskManpreet SachdevaNo ratings yet

- AC Current Transducer AP-B10 I 10 .. 400 A: Electrical Data FeaturesDocument2 pagesAC Current Transducer AP-B10 I 10 .. 400 A: Electrical Data FeaturesCESAR BARROSO NO HAY QUE SER UN EXPERTO.No ratings yet

- Belt (Mechanical)Document54 pagesBelt (Mechanical)stallone21No ratings yet

- CATALOG Honeywell Q340A1074-UDocument2 pagesCATALOG Honeywell Q340A1074-UAmir QayyumNo ratings yet

- Centrala Za Dojavu Pozara-Cad-150-2Document2 pagesCentrala Za Dojavu Pozara-Cad-150-2Milorad PantelinacNo ratings yet

- Automotive Transmission - 2Document9 pagesAutomotive Transmission - 2Pradeep SudhanNo ratings yet

- Matlab/Simulink Models For Typical Soft Starting Means For A DC MotorDocument6 pagesMatlab/Simulink Models For Typical Soft Starting Means For A DC MotorkensesanNo ratings yet

- Drill Class 1 DeskDocument19 pagesDrill Class 1 DeskomkardashetwarNo ratings yet

- Auto Chassis and Trnasmission System by Srinath GhodkeDocument246 pagesAuto Chassis and Trnasmission System by Srinath Ghodkesrinath ghodkeNo ratings yet

- Valvetronic Engine Technology PDF FreeDocument15 pagesValvetronic Engine Technology PDF FreeAnexmechNo ratings yet

- Overcurrent Protection NEC Article 240 and Beyond by Bierals, Gregory PDocument110 pagesOvercurrent Protection NEC Article 240 and Beyond by Bierals, Gregory PFE-ZAMARRON100% (2)

- Data Collector With M-Bus and RS-485 Protocol Conversion Reference DesignDocument27 pagesData Collector With M-Bus and RS-485 Protocol Conversion Reference DesigndbmNo ratings yet

- Hammer Mill: Multimill 630B-1000BDocument43 pagesHammer Mill: Multimill 630B-1000Bsarah ahmedNo ratings yet

- Y 0720Document260 pagesY 0720Oscar Gálvez IglesiasNo ratings yet

- Ms 3500Document2 pagesMs 3500antonioNo ratings yet

- GFK 2741DDocument32 pagesGFK 2741DMohammad Nabeel SarwarNo ratings yet

- Sr30je E01Document3 pagesSr30je E01freddy1115No ratings yet

- 130nm Techbrief01Document3 pages130nm Techbrief01Gilang Mardian KNo ratings yet

- FS CellD-DPS300C-48-4 en Rev 00Document2 pagesFS CellD-DPS300C-48-4 en Rev 00kubikNo ratings yet

- ALUMINIUM Import Tariff RateDocument4 pagesALUMINIUM Import Tariff RateSamwovenNo ratings yet

Liquid Filling Systems

Liquid Filling Systems

Uploaded by

Arun U0 ratings0% found this document useful (0 votes)

6 views3 pagesThis document summarizes liquid filling systems that can fill a variety of containers with different types of liquids. It describes key features such as weighmetric filling for accuracy, filling speed options, and data recording capabilities. Various filling methods and optional features are also outlined, along with safety features to prevent spills and ensure proper filling. Different display and controller options allow for flexible operation in safe or hazardous areas.

Original Description:

Original Title

Liquid Filling Systems__

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes liquid filling systems that can fill a variety of containers with different types of liquids. It describes key features such as weighmetric filling for accuracy, filling speed options, and data recording capabilities. Various filling methods and optional features are also outlined, along with safety features to prevent spills and ensure proper filling. Different display and controller options allow for flexible operation in safe or hazardous areas.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

6 views3 pagesLiquid Filling Systems

Liquid Filling Systems

Uploaded by

Arun UThis document summarizes liquid filling systems that can fill a variety of containers with different types of liquids. It describes key features such as weighmetric filling for accuracy, filling speed options, and data recording capabilities. Various filling methods and optional features are also outlined, along with safety features to prevent spills and ensure proper filling. Different display and controller options allow for flexible operation in safe or hazardous areas.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

LIQUID FILLING SYSTEMS

Ÿ Chemicals Ÿ Pastes & Slurries

Ÿ Solvents Ÿ Grease

Ÿ Resins Ÿ Oils

Ÿ Paints Ÿ Food Products

Ÿ Pesticides Ÿ Inks

Ÿ Adhesives Ÿ Honey

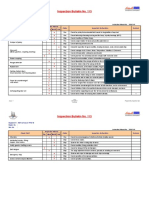

Key Features Single Drum Single Drum Carboy Filling System Carboy Filling System

Filling System (Top) Filling System (Bottom) (Top) Lance (Bottom) Lance Benets

Ÿ Weighmetric lling solutions

Ÿ Increase in productivity

Ÿ 3 speed lling for greater accuracy and higher

speed Ÿ No spillage

Ÿ Standard wetted parts : SS316 with Ÿ Accurate lling

PTFE seals*. Custom MOC possible Ÿ Safe operation

Ÿ Capable to store different recipes Ÿ Recording of data

Ÿ Totalizer for containers lled and total weight Ÿ Early payback

Ÿ Built-in RTC (real-time clock) Ÿ Stop leakage of prot

Ÿ Standard RS232/422 communication interface

In-ight Correction

Ÿ Operation in auto/manual mode

Ÿ Resumption of lling from same point in case of Ÿ Static - user dened x value

power failure Ÿ Percentage step correction - automatic

Palletized Drum Palletized Drum correction by error percentage

Ÿ Height adjustment for lling different height of Filling System (Top) Filling System (Bottom) Bucket/ Pail Filling System Tin / Can / Pail Filling System

containers on same system Ÿ Dynamic auto-correction based on ow

Ÿ Customize solutions as per requirement rate of liquid

Ÿ Available in weather proof & ame proof

execution

Safety Features

Ÿ Checks empty drum presence before lling

Filling Methods Ÿ Checks insertion of lling nozzle in

bunghole

Ÿ Above bunghole - non foaming liquid Ÿ Checks material ow in specied time

Ÿ Below bunghole - non foaming liquid Ÿ Filling stops during accidental failure of

Ÿ Subsurface - foaming or charged liquid electrical or pneumatic supply

Ÿ One touch home position

IBC Filling System Ÿ Hazardous area operation (optional)

For Safe Area

Optional Features Filling Controllers

Ÿ Nitrogen blanketing / purging Ÿ Selection of display

Ÿ Fume hood with outlet (LED/LCD, Backlit LCD or Touchpad)

Ÿ Earth fault interrupt Ÿ Error message

LED and LCD display Graphical LCD display Touch Key display Ÿ Set point

Ÿ Heat jacketing

Ÿ In-feed and out-feed conveyor Ÿ Number of drums lled

For Hazardous Area

Ÿ Drum movement arrester for single lling Ÿ Total net quantity

Ÿ Drip tray

Platform Options

Ÿ Pneumatically operated capping and

sealing tools

Square Type E Type U Type

LED and LCD display Graphical LCD display Touch Key display

Automatic Filling System Ÿ Twin- Head Automatic Filling System with motorized

turn table for auto-feeding of containers and collection

of lled containers

Ÿ Filling, lid dispensing and lid pressing all in one system

Ÿ Ideal solution for lling open mouth containers ranging

from 500ml to 4ltr.

Ÿ Options: Systems can be provided with higher

capacity of lling open mouth containers

Auger Filling System Multi-head Filling System

Pneumatic Motorized Lid Press Systems

Ÿ Height adjustment for lid pressing different

height of containers on same system

Ÿ Pneumatically operated for single round

plate or double half round plate design

Ÿ Motorized System for automatic lid pressing

Ÿ Available in weather proof & ame proof

execution

JAY INSTRUMENTS AND SYSTEMS PRIVATE LIMITED

Head Office : Navi Mumbai Office :

E-16, Everest, Tardeo Road, C-64, TTC - Industrial Area,Turbhe,

Mumbai - 400 034. Navi Mumbai - 400 703.

sales@jayinst.com Tel. : +91-22-2352 6207 / 8, Tel. : +91-22-2767 2955 / 0092

www.jayinst.com Fax. : +91-22-2352 6210

Branches : Ahmedabad, Baroda, Bengaluru, Chennai, Delhi, Hubballi, Hyderabad,Tiruppur.

You might also like

- Saej1469v003 Air Brake Actuator Test ProcedureDocument22 pagesSaej1469v003 Air Brake Actuator Test ProcedureDaniel Farfan100% (1)

- Auto Guide w-25600 - W-17800 - WEINGRILL - GUIDE-7Document1 pageAuto Guide w-25600 - W-17800 - WEINGRILL - GUIDE-7Ambar Jati WaluyoNo ratings yet

- Price List FM200 CFSDocument38 pagesPrice List FM200 CFSdanielmq100% (1)

- Sieme 02089 200424082235Document3 pagesSieme 02089 200424082235Bruce CoxNo ratings yet

- MAK WATER - PDS Brackish Water Reverse Osmosis (BWRO)Document2 pagesMAK WATER - PDS Brackish Water Reverse Osmosis (BWRO)efendyandraNo ratings yet

- Catalogo Durometro Electrolab PDFDocument8 pagesCatalogo Durometro Electrolab PDFWilber RodriguezNo ratings yet

- Bermad: Electro-Pneumatically Controlled Deluge Valve With Local Reset Model FP 400Y - 6MDocument4 pagesBermad: Electro-Pneumatically Controlled Deluge Valve With Local Reset Model FP 400Y - 6MLuis GonzalezNo ratings yet

- LH 10 Golden Rules For SEEC Mastery - Main FileDocument39 pagesLH 10 Golden Rules For SEEC Mastery - Main FileTarek Fenniche100% (1)

- Model: 4TT: World's Best 4x4 Concrete MixersDocument5 pagesModel: 4TT: World's Best 4x4 Concrete MixersSenthilKumarNo ratings yet

- 5.19 JSP Power Transformer High Voltage TestDocument4 pages5.19 JSP Power Transformer High Voltage Testmuhammad.younisNo ratings yet

- Brcthtincna 0220Document20 pagesBrcthtincna 0220LEO AROKYA DASS ANo ratings yet

- Check Valve SelectionDocument1 pageCheck Valve SelectionramkikkdNo ratings yet

- Truck-Mounted Cranes: HB-R Series, The Perfect Solution For Applications With Large VehiclesDocument4 pagesTruck-Mounted Cranes: HB-R Series, The Perfect Solution For Applications With Large VehiclesRodrigo LealNo ratings yet

- BaurDocument3 pagesBaurmunggangNo ratings yet

- DS - Oil Breakdown Voltage Tester - DPA 75 C - BAUR - En-GbDocument3 pagesDS - Oil Breakdown Voltage Tester - DPA 75 C - BAUR - En-GbNOVASKY De Paula e CarvalhoNo ratings yet

- Production Logging Interpretation Logging Interpretation Production Logging FundamentalsDocument37 pagesProduction Logging Interpretation Logging Interpretation Production Logging FundamentalsShereef ElsawyNo ratings yet

- Electrically Controlled Deluge Valve With Remote Reset Model FP 400Y - 3UDocument4 pagesElectrically Controlled Deluge Valve With Remote Reset Model FP 400Y - 3Upedro torresNo ratings yet

- Back Connect Bimetal Thermometer PTC 0320Document4 pagesBack Connect Bimetal Thermometer PTC 0320Frank RondonNo ratings yet

- 7 Interpretation MethodologyDocument13 pages7 Interpretation MethodologyErnesto de la CarcovaNo ratings yet

- W-Palm Weingrill Guide-6Document1 pageW-Palm Weingrill Guide-6Jesid ApraezNo ratings yet

- Asphalt Plant Inspection ItemDocument2 pagesAsphalt Plant Inspection ItemsacsewNo ratings yet

- EBT Sand Filling NEWDocument2 pagesEBT Sand Filling NEWDebora ChavezNo ratings yet

- Tappi Controle de ConsitenciaDocument16 pagesTappi Controle de ConsitenciaFelipe WatanabeNo ratings yet

- Roller ChecklistDocument1 pageRoller ChecklistArsalan AhmadNo ratings yet

- Manual BRIODocument2 pagesManual BRIOrifki wahyudiNo ratings yet

- Ispe Fab Isolateur LocauxDocument22 pagesIspe Fab Isolateur LocauxAzzedine hammadiNo ratings yet

- Modulate Action Catalog EN 01 2020Document60 pagesModulate Action Catalog EN 01 2020AMIRNo ratings yet

- Weatherford Artificial Lifts Progressing Cavity Pumping Systems PDFDocument12 pagesWeatherford Artificial Lifts Progressing Cavity Pumping Systems PDFFan JackNo ratings yet

- Model Series S, Din: Sempell Safety ValveDocument17 pagesModel Series S, Din: Sempell Safety ValveKiattisak JaemjunNo ratings yet

- Brookfield Choices For InstrumentationDocument1 pageBrookfield Choices For InstrumentationRS RetheeshNo ratings yet

- Sany SLB3000C8 Asphalt Batching Plant-084006Document2 pagesSany SLB3000C8 Asphalt Batching Plant-084006wasco plantNo ratings yet

- Technical Data Sheet: Zwaluw Fix-O-Chem (Styrene Free)Document2 pagesTechnical Data Sheet: Zwaluw Fix-O-Chem (Styrene Free)Tudor GolbanNo ratings yet

- Data Sheets Safety Valve Api 526 Model Series S Sempell en en 5378736Document2 pagesData Sheets Safety Valve Api 526 Model Series S Sempell en en 5378736Braulio AhumadaNo ratings yet

- TB Fenner Y54 PDFDocument30 pagesTB Fenner Y54 PDF'viki ArtNo ratings yet

- DS - Oil Breakdown Voltage Tester - DPA 75 C - BAUR - En-GbDocument3 pagesDS - Oil Breakdown Voltage Tester - DPA 75 C - BAUR - En-Gbkavish malakaNo ratings yet

- Product Presentation Axial Piston Variable Pump A4VG Series 32Document9 pagesProduct Presentation Axial Piston Variable Pump A4VG Series 32Sameh MohamedNo ratings yet

- Data Sheets Steam Safety Valve Sapag en en 5195198Document18 pagesData Sheets Steam Safety Valve Sapag en en 5195198tinasheNo ratings yet

- Presented by Presented By: Sajad Falah Radhi Mustafa Nawfal Abdulameer Hussain Musa JaffarDocument25 pagesPresented by Presented By: Sajad Falah Radhi Mustafa Nawfal Abdulameer Hussain Musa JaffarSajad FalahNo ratings yet

- Pictus 700 Biochemistry AnalyzerDocument2 pagesPictus 700 Biochemistry AnalyzerHA FidNo ratings yet

- 35423-10 Eco Testr Ph2Document2 pages35423-10 Eco Testr Ph2Sally Salina FarahNo ratings yet

- Folleto NovalumDocument4 pagesFolleto Novalumapi-3697331No ratings yet

- Rotating Equipment & Pump Testing SystemsDocument4 pagesRotating Equipment & Pump Testing SystemsAakash PandyaNo ratings yet

- Operation and Maintenance: 5. Trouble Shooting GuideDocument3 pagesOperation and Maintenance: 5. Trouble Shooting Guidezerocool86No ratings yet

- 06 - Valve and Meters V216 - Uk - 4-4Document1 page06 - Valve and Meters V216 - Uk - 4-4fajri asyukronNo ratings yet

- Remmers Kiesol C - Horizontal Barrier: Quick and Easy Injection Due To Its Cream ConsistenceDocument4 pagesRemmers Kiesol C - Horizontal Barrier: Quick and Easy Injection Due To Its Cream ConsistenceAjayNo ratings yet

- AutoTrak Service LevelsDocument2 pagesAutoTrak Service LevelspendexxNo ratings yet

- Line Trial FormatDocument3 pagesLine Trial FormatShubham SrivastavaNo ratings yet

- INV Trouble Shootguide (Engver.)Document108 pagesINV Trouble Shootguide (Engver.)Yohanes Triatmojo100% (1)

- Jacobi Ab Resinex Softening A4 Eng A0613Document2 pagesJacobi Ab Resinex Softening A4 Eng A0613Dzulkifli MuhamadNo ratings yet

- WHM Ecotex BrochureDocument4 pagesWHM Ecotex BrochureVirendra ChhasatiyaNo ratings yet

- Brochure - Slide Stainer DP360 - EN V2.1Document3 pagesBrochure - Slide Stainer DP360 - EN V2.1quankddNo ratings yet

- Bermad - Deluge Valve - FP-400Y-2M - VU05 PDFDocument4 pagesBermad - Deluge Valve - FP-400Y-2M - VU05 PDFJESUS HUAMANINo ratings yet

- 2/2-Way Diaphragm Valve, Air Piloted: Type 174Document4 pages2/2-Way Diaphragm Valve, Air Piloted: Type 174Francisco Mones RuizNo ratings yet

- Xamine OA FlyerDocument2 pagesXamine OA FlyerJeisson HolguinNo ratings yet

- Cardiothoracic Products CatalogDocument24 pagesCardiothoracic Products Catalogmihalcea alinNo ratings yet

- Cat EP13 20TCB Electric Forklift BrochureDocument6 pagesCat EP13 20TCB Electric Forklift BrochureAbdul WaheedNo ratings yet

- Temperature Control UnitDocument2 pagesTemperature Control UnitMIGUEL GONZALEZNo ratings yet

- NETZSCH-Abwasser 0419 ENDocument12 pagesNETZSCH-Abwasser 0419 ENArieWahyuWidodoNo ratings yet

- Belt Conveyor RT45-BDocument2 pagesBelt Conveyor RT45-BMahmoud HanafyNo ratings yet

- Desalter Trouble Shooting Guide: Baker PetroliteDocument2 pagesDesalter Trouble Shooting Guide: Baker PetroliteuripssNo ratings yet

- 7642v1.0 (G52 76421X3) (890GXM G65) ASIA PDFDocument191 pages7642v1.0 (G52 76421X3) (890GXM G65) ASIA PDFКирилл КошкинNo ratings yet

- Cheat SheetDocument1 pageCheat Sheetkeng3915100% (4)

- Basic Electronics Lab Exp 4-6-pdf Ayush Anshuman Supakar (118MN0579)Document10 pagesBasic Electronics Lab Exp 4-6-pdf Ayush Anshuman Supakar (118MN0579)Ayush Anshuman SupakarNo ratings yet

- Introduction To In-Circuit TestingDocument123 pagesIntroduction To In-Circuit TestingMed Medy Fehem100% (1)

- LT-1083RCU FX-3500RCU Installation ManualDocument116 pagesLT-1083RCU FX-3500RCU Installation ManualErick CastilloNo ratings yet

- Project SolenoidDocument14 pagesProject SolenoidPradip IndraNo ratings yet

- SRV02 Rotary Pendulum User ManualDocument11 pagesSRV02 Rotary Pendulum User ManualRoby NicaNo ratings yet

- Blue Ray DiskDocument6 pagesBlue Ray DiskManpreet SachdevaNo ratings yet

- AC Current Transducer AP-B10 I 10 .. 400 A: Electrical Data FeaturesDocument2 pagesAC Current Transducer AP-B10 I 10 .. 400 A: Electrical Data FeaturesCESAR BARROSO NO HAY QUE SER UN EXPERTO.No ratings yet

- Belt (Mechanical)Document54 pagesBelt (Mechanical)stallone21No ratings yet

- CATALOG Honeywell Q340A1074-UDocument2 pagesCATALOG Honeywell Q340A1074-UAmir QayyumNo ratings yet

- Centrala Za Dojavu Pozara-Cad-150-2Document2 pagesCentrala Za Dojavu Pozara-Cad-150-2Milorad PantelinacNo ratings yet

- Automotive Transmission - 2Document9 pagesAutomotive Transmission - 2Pradeep SudhanNo ratings yet

- Matlab/Simulink Models For Typical Soft Starting Means For A DC MotorDocument6 pagesMatlab/Simulink Models For Typical Soft Starting Means For A DC MotorkensesanNo ratings yet

- Drill Class 1 DeskDocument19 pagesDrill Class 1 DeskomkardashetwarNo ratings yet

- Auto Chassis and Trnasmission System by Srinath GhodkeDocument246 pagesAuto Chassis and Trnasmission System by Srinath Ghodkesrinath ghodkeNo ratings yet

- Valvetronic Engine Technology PDF FreeDocument15 pagesValvetronic Engine Technology PDF FreeAnexmechNo ratings yet

- Overcurrent Protection NEC Article 240 and Beyond by Bierals, Gregory PDocument110 pagesOvercurrent Protection NEC Article 240 and Beyond by Bierals, Gregory PFE-ZAMARRON100% (2)

- Data Collector With M-Bus and RS-485 Protocol Conversion Reference DesignDocument27 pagesData Collector With M-Bus and RS-485 Protocol Conversion Reference DesigndbmNo ratings yet

- Hammer Mill: Multimill 630B-1000BDocument43 pagesHammer Mill: Multimill 630B-1000Bsarah ahmedNo ratings yet

- Y 0720Document260 pagesY 0720Oscar Gálvez IglesiasNo ratings yet

- Ms 3500Document2 pagesMs 3500antonioNo ratings yet

- GFK 2741DDocument32 pagesGFK 2741DMohammad Nabeel SarwarNo ratings yet

- Sr30je E01Document3 pagesSr30je E01freddy1115No ratings yet

- 130nm Techbrief01Document3 pages130nm Techbrief01Gilang Mardian KNo ratings yet

- FS CellD-DPS300C-48-4 en Rev 00Document2 pagesFS CellD-DPS300C-48-4 en Rev 00kubikNo ratings yet

- ALUMINIUM Import Tariff RateDocument4 pagesALUMINIUM Import Tariff RateSamwovenNo ratings yet