Professional Documents

Culture Documents

Steam Turbine Inspection Schedule Maintenance

Steam Turbine Inspection Schedule Maintenance

Uploaded by

MELCO JITPLOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steam Turbine Inspection Schedule Maintenance

Steam Turbine Inspection Schedule Maintenance

Uploaded by

MELCO JITPLCopyright:

Available Formats

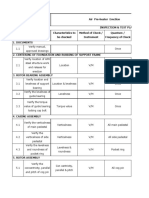

Steam Turbine Inspection Schedule

Maintenance

Frequency

h = hourly

Parameter

d = daily

Activity Work to be performed measured Remarks

w = weekly

No. or tested

m = monthly

y = yearly

1.0 Testing of Tests according to:

1.1 Controllers Functioning Ref. 6.2-0021 6.3-0030

& setting 6.3-0035

1.2 Automatic Turbine Tester Functioning Ref. 6.2-0022 6.3-0060

& 6.2-0023 6.3-0061

1.3 Protective devices Functioning Ref.6.2-0024 during start up,

& setting power operation,

1.4 Safety devices Functioning Ref. 6.2-0025 shut down & stand

& setting still

1.5 Valves Functioning Ref. 6.2-0026

free movement

leak tightness

1.6 Monitoring devices Functioning Ref. 6.2-0027

setting and

accuracy

2.0 Recording and Comparison Ref. 6.2-0028 Also ref. 6.3-0037

documentation of of specified and for long term

operational parameters actual data monitoring

and conditions

2.1 Steady state operation h

2.2 Non-steady state operation every start-up

2.3 Faults every occurrence

2.4 Analysis of steam Purity d Ref. 6.3-0050

2.5 Measurement of internal Internal 3m

efficiency condition of

turbine

3.0 Inspection of LP turbine During Ref Tech. Circular

free standing blades intermediate No. X-68

3.1 Visual inspection Erosion, and major

looseness inspections,

every 50,000

3.2 Blade profile and root Crack

hrs. of

crack examination

operation

3.3 Cleanliness of blade root Cleanliness

and groove

3.4 Blade natural frequency Natural freq.

test

BHEL, Hardwar 6.3-0010-04/1

Frequency

Parameter h = hourly

Activity Work to be performed measured d = daily Remarks

No. or tested w = weekly

m = monthly

y = yearly

4.0 Inspection of accessible During minor, during shut down

expansion joints in cross intermediate

around and extraction lines and major

4.1 Visual inspection Damages inspections

4.2 Surface crack examination Crack

5.0 Inspection of casing

guides and supports

5.1 Seating of casing on w

support elements

5.2 Cleanliness w

5.3 Integrity of keys & packers Damage During During shut down

5.4 Thermal clearances as per Clearances intermediate

drawing and major

inspections

6.0 Visual inspection for Leakage d

steam-tightness noise

6.1 Casing joints

6.2 Flanges

6.3 Shaft seals

6.4 Valve stems

6.5 Instrument connections

7.0 Inspection of drains

7.1 Internal leak-tightness w

7.2 External leak-tightness w

8.0 Inspection of pumps,

motors and other drives in

continuous operation

8.1 Vibration behaviour d

8.2 Head d

8.3 Bearing temperatures d

8.4 Thrust d

8.5 Leak-tightness d

9.0 Visual inspection of piping

9.1 Leak-tightness d

9.2 Vibration d

9.3 Hangers w

9.4 Expansion w

9.5 Vibration dampers 3m

BHEL, Hardwar 6.3-0010-04/2

Frequency

Parameter h = hourly

Activity Work to be performed measured d = daily Remarks

No. or tested w = weekly

m = monthly

y = yearly

10.0 Inspection of hydraulic

accumulator

10.1 Check charge pressure 2w

11.0 Inspection of Main oil tank

11.1 Level check d

11.2 Foaming characteristics w

11.3 Water collection on bottom 2w

of oil tank

11.4 Level check in bucket filter w

to assess filter chocking

11.5 Water content of oil d

11.6 Solid particle content of oil d

11.7 Analysis of properties Ref. 6.1-0130 Ref. 6.3-0080

12.0 Inspection of FRF tank

12.1 Level check d

12.2 Level check in bucket filter w

to access filter chocking

12.3 Foaming characteristics of w

FRF

12.4 Analysis of fluid properties Ref. 6.1-0140 Ref. 6.3-0082

13.0 Oil / FRF filter

13.1 Check differential pressure d

reading

13.2 Check venting d

14.0 Inspection of TG-deck

springs

14.1 Reference spring heights Ref. Technical After first year

14.2 Alignment check circular No. X-85 of operation

14.3 Catenary check

BHEL, Hardwar 6.3-0010-04/3

You might also like

- Sartorius Sigma CentrifugeDocument172 pagesSartorius Sigma CentrifugeFedor78% (9)

- Test Bank For The Legal Environment of Business Text and Cases 11th Edition CrossDocument11 pagesTest Bank For The Legal Environment of Business Text and Cases 11th Edition CrossMatthew Adams100% (35)

- Sbi Mains Admit CardDocument2 pagesSbi Mains Admit CardnavneetNo ratings yet

- Day 7.5 - BGCO Basic Call FlowDocument4 pagesDay 7.5 - BGCO Basic Call FlowStephanie Park100% (1)

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- Machine Learning - Multi Linear Regression AnalysisDocument29 pagesMachine Learning - Multi Linear Regression AnalysisAdnan KhanNo ratings yet

- NATA Calibration Reference Equipment TableDocument25 pagesNATA Calibration Reference Equipment TableAdmer Rey C. DablioNo ratings yet

- 2012140409-MD-04-MT-RSELC-PD-018 Rev.01 Maintenance Procedure For Cathodic Protection SystemDocument28 pages2012140409-MD-04-MT-RSELC-PD-018 Rev.01 Maintenance Procedure For Cathodic Protection SystemHuy Thieu BuiNo ratings yet

- Vista 120 V3SFA0032Document1 pageVista 120 V3SFA0032rubyhall bio-medicalNo ratings yet

- FRM QUA 506 Process Audit Sheet 1Document2 pagesFRM QUA 506 Process Audit Sheet 1Ravi javaliNo ratings yet

- Field Quality Plan: BusbarsDocument3 pagesField Quality Plan: BusbarsSourav RanaNo ratings yet

- Steam Turbine Maintenance Schedule Maintenance TurbineDocument1 pageSteam Turbine Maintenance Schedule Maintenance TurbineMELCO JITPLNo ratings yet

- TJB-BM-XXXX-XX-WIXXX Work Instruction Turbine CV Disassembly and InspectionDocument6 pagesTJB-BM-XXXX-XX-WIXXX Work Instruction Turbine CV Disassembly and InspectiondikiNo ratings yet

- MK Tron Auto Part: Procedure of Leak TestingDocument1 pageMK Tron Auto Part: Procedure of Leak Testingsachin kadamNo ratings yet

- Preventative Maintenance Agreement: Extending Equipment LifeDocument8 pagesPreventative Maintenance Agreement: Extending Equipment LifeJo Ziza SugihartoNo ratings yet

- Transformer TestingDocument37 pagesTransformer TestingVinodNo ratings yet

- Automated Weather Observing System (AWOS) : Purposed Periodic Check SheetDocument6 pagesAutomated Weather Observing System (AWOS) : Purposed Periodic Check SheetGautambuddha AirportNo ratings yet

- ASSIGNMENTDocument5 pagesASSIGNMENTPanchdev KumarNo ratings yet

- dm68 PDFDocument17 pagesdm68 PDFKALILNo ratings yet

- Oxygen Concentrator Service Manual: For Visionaire, Visionaire 2 & Visionaire 3 ModelsDocument37 pagesOxygen Concentrator Service Manual: For Visionaire, Visionaire 2 & Visionaire 3 ModelsSadegh ShebaniNo ratings yet

- Ngome ReportDocument4 pagesNgome ReportmrlaeluNo ratings yet

- WP Moisture RoutineTesting ENDocument16 pagesWP Moisture RoutineTesting ENMadeNo ratings yet

- Elec. AMNDocument63 pagesElec. AMNAiman Al ArabNo ratings yet

- Art Evo Service M503-E342Document30 pagesArt Evo Service M503-E342Shahmir ShahidNo ratings yet

- pg0409 PDFDocument42 pagespg0409 PDFInstalatiiGeneraleNo ratings yet

- LG (67) - G3-1007 Fan (Propeller) G v.2Document10 pagesLG (67) - G3-1007 Fan (Propeller) G v.2Anonymous Lta32Ta9No ratings yet

- 06、轻型冷水机组出厂试验大纲(中英文)Document24 pages06、轻型冷水机组出厂试验大纲(中英文)nur hasanNo ratings yet

- 7SR1587 Voltage and Frequency RelayDocument4 pages7SR1587 Voltage and Frequency RelayAnonymous dH3DIEtzNo ratings yet

- Samson 373X 5Document8 pagesSamson 373X 5Arun KumarNo ratings yet

- 3 WH Drum Process ProjectDocument28 pages3 WH Drum Process ProjectBrandvision AdvertisementNo ratings yet

- C92IQ003EN-J MCRxx2 Maintenance Record FormDocument11 pagesC92IQ003EN-J MCRxx2 Maintenance Record FormdiegobouNo ratings yet

- 20-7 Commissioning of SystemsDocument7 pages20-7 Commissioning of Systemsmohammad AdnanNo ratings yet

- Substation Equipment MaintenanceDocument15 pagesSubstation Equipment MaintenanceDr. R. SharmaNo ratings yet

- A8Ponetics: Series SystemsDocument86 pagesA8Ponetics: Series SystemsdmitroivanenkoNo ratings yet

- NDT-SA-SATORP-UT-60, Rev00, Date 15 Aug-2023Document20 pagesNDT-SA-SATORP-UT-60, Rev00, Date 15 Aug-2023Md Abu Hanif RajuNo ratings yet

- Inolab Ph/Cond 720: Operating ManualDocument70 pagesInolab Ph/Cond 720: Operating ManualArdo IsküllNo ratings yet

- Inspection Task Report No. - 1 - : Rev.01 1 Inspection Activity Hydrotest of FlowlineDocument17 pagesInspection Task Report No. - 1 - : Rev.01 1 Inspection Activity Hydrotest of FlowlinehilalNo ratings yet

- QY360 Blasting Wheel Operation ManualDocument15 pagesQY360 Blasting Wheel Operation ManualDecho KrachevNo ratings yet

- 54 57 Service Manual en v12p 30585778aDocument35 pages54 57 Service Manual en v12p 30585778acarlcox45No ratings yet

- HT-400 Fluid End Onshore, Facility and Offshore InspectionDocument21 pagesHT-400 Fluid End Onshore, Facility and Offshore InspectionFrancisco javierNo ratings yet

- 7100 Series 101Document67 pages7100 Series 101Marlene SalazarNo ratings yet

- CRS SEC - 10632 - Warranty Inspection Procedure For TransformersDocument2 pagesCRS SEC - 10632 - Warranty Inspection Procedure For TransformersKhaja SayeedNo ratings yet

- JG-SC-003 NDTDocument10 pagesJG-SC-003 NDTarsil5840No ratings yet

- Calibration Non-Self-Indicating Weighing InstrumentDocument10 pagesCalibration Non-Self-Indicating Weighing InstrumentVikram BillalNo ratings yet

- Pipe Fabrication - Es-32Document2 pagesPipe Fabrication - Es-32My one onlyNo ratings yet

- AI-VO-PRC-004 R1 Procedure For Inspection DefermentDocument14 pagesAI-VO-PRC-004 R1 Procedure For Inspection Defermentkhairie rahimNo ratings yet

- Anicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateDocument9 pagesAnicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateAnicon Flowcontols llpNo ratings yet

- Itp For AphDocument4 pagesItp For Aphmohan babuNo ratings yet

- Low Voltage Testing Manual SM4613 PDFDocument83 pagesLow Voltage Testing Manual SM4613 PDFLaurence CastilloNo ratings yet

- 7.6 02 12Document11 pages7.6 02 12ilansakthiNo ratings yet

- ITTC - Recommended Procedures: Sample Work Instructions Calibration of A Liquid-in-Glass ThermometerDocument12 pagesITTC - Recommended Procedures: Sample Work Instructions Calibration of A Liquid-in-Glass ThermometertungluongNo ratings yet

- NATA - Revised General Accreditation GuidanceDocument16 pagesNATA - Revised General Accreditation Guidancesiham bedierNo ratings yet

- Construction Leak Test ProcedureDocument6 pagesConstruction Leak Test Procedurezack zeeartNo ratings yet

- VDA - New MSA - VDA - QMC - YPrint - 2024Document45 pagesVDA - New MSA - VDA - QMC - YPrint - 2024Quality System SMGNo ratings yet

- Amca 220-91Document17 pagesAmca 220-91Chakkrit TipasriNo ratings yet

- Pfi Es 32Document2 pagesPfi Es 32My one onlyNo ratings yet

- General Equipment TableDocument16 pagesGeneral Equipment Tablearli krisnandikaNo ratings yet

- At1 - ExcavadoraDocument14 pagesAt1 - ExcavadoraFREDDY NICOLAS ESCOBEDO LOZANONo ratings yet

- (Gensets Close Inspection Checklist) D00-ELED012-01Document1 page(Gensets Close Inspection Checklist) D00-ELED012-01Noman AliNo ratings yet

- Table 1 Inspection and Testing Summary Work Stage Assessment Assessment Method Test Equipment NotesDocument6 pagesTable 1 Inspection and Testing Summary Work Stage Assessment Assessment Method Test Equipment Notesvijay rajputNo ratings yet

- Induction Cap Sealing Machine Performance Qualification Report - Pharmaceutical UpdatesDocument5 pagesInduction Cap Sealing Machine Performance Qualification Report - Pharmaceutical UpdatesChetan Ganesh RautNo ratings yet

- 关键设施设备自检自查整改跟踪表 CtuDocument21 pages关键设施设备自检自查整改跟踪表 Ctu池边树No ratings yet

- Vacutron Suction Regulators Vacuum Regulators For Continuous or Intermittent Drainage Operation and Maintenance ManualDocument16 pagesVacutron Suction Regulators Vacuum Regulators For Continuous or Intermittent Drainage Operation and Maintenance ManualAnne Stephany ZambranoNo ratings yet

- HIRA - Hopper SealingDocument3 pagesHIRA - Hopper SealingMELCO JITPLNo ratings yet

- Spare Consumption May 2024Document1 pageSpare Consumption May 2024MELCO JITPLNo ratings yet

- HIRA - Insulation WorkDocument3 pagesHIRA - Insulation WorkMELCO JITPLNo ratings yet

- BTG AlarmDocument7 pagesBTG AlarmMELCO JITPLNo ratings yet

- HIRA - RT & SR WorkDocument9 pagesHIRA - RT & SR WorkMELCO JITPLNo ratings yet

- HIRA - Refractory WorkDocument3 pagesHIRA - Refractory WorkMELCO JITPLNo ratings yet

- WBDocument2 pagesWBMELCO JITPLNo ratings yet

- Mill Cag PassingDocument2 pagesMill Cag PassingMELCO JITPLNo ratings yet

- Bik VaccumDocument2 pagesBik VaccumMELCO JITPLNo ratings yet

- Block Diagram Local Mode HMQ-F - 250-2000 5800029 - BHELDocument1 pageBlock Diagram Local Mode HMQ-F - 250-2000 5800029 - BHELMELCO JITPLNo ratings yet

- Description Electr. Drawing 5800029 - BHELDocument2 pagesDescription Electr. Drawing 5800029 - BHELMELCO JITPLNo ratings yet

- Block Diagram Automatic Remote Mode - BHELDocument1 pageBlock Diagram Automatic Remote Mode - BHELMELCO JITPLNo ratings yet

- S7-5800029-02 - Doku - en - BHEL BoilerDocument54 pagesS7-5800029-02 - Doku - en - BHEL BoilerMELCO JITPLNo ratings yet

- Signal List 5800029 Doc.005 2revDocument1 pageSignal List 5800029 Doc.005 2revMELCO JITPLNo ratings yet

- RMC Online Washing System Industrial Gas TurbineDocument3 pagesRMC Online Washing System Industrial Gas TurbinepayamzarNo ratings yet

- AssessmentDocument4 pagesAssessmentapi-243749103No ratings yet

- 50 Percentage Problems With SolutionsDocument31 pages50 Percentage Problems With SolutionsAbhilash LoveNo ratings yet

- Article Climate Change From Sharm El Sheikh COP 27 To Dubai COP 28 by Nabeel MunirDocument7 pagesArticle Climate Change From Sharm El Sheikh COP 27 To Dubai COP 28 by Nabeel MunirMaham SajjadNo ratings yet

- Operator E-Jets News Rel 040Document12 pagesOperator E-Jets News Rel 040jivomirNo ratings yet

- Technical Training of Draft Animals Sheet LineDocument8 pagesTechnical Training of Draft Animals Sheet LineEvans Katuta Mpundu Jr.No ratings yet

- Partnership Memory Aid AteneoDocument13 pagesPartnership Memory Aid AteneoLucioJr AvergonzadoNo ratings yet

- Navin Fluorine International LTD 532504 March 2002Document21 pagesNavin Fluorine International LTD 532504 March 2002Sanjeev Kumar SinghNo ratings yet

- EPM Model5014i ManualDocument352 pagesEPM Model5014i ManualJorgeLuisUriarteNo ratings yet

- Carver Nash Spss ProblemDocument6 pagesCarver Nash Spss ProblemNitish SenNo ratings yet

- IR7243 en ModuloDocument2 pagesIR7243 en ModuloAitor Tapia SaavedraNo ratings yet

- 7227 Strongandweek-Lstplus213Document8 pages7227 Strongandweek-Lstplus213fbmd4ysszbNo ratings yet

- Load Line and Q-PointDocument3 pagesLoad Line and Q-PointRavi Kanth M NNo ratings yet

- Configuring Intergraph Smart 3D Application Servers and Databases CreationsDocument20 pagesConfiguring Intergraph Smart 3D Application Servers and Databases CreationsAnonymous WCG2HjPybJNo ratings yet

- Devoir N° 1 - AlloSchoolDocument2 pagesDevoir N° 1 - AlloSchoolHalas MaitNo ratings yet

- Businessmath Lesson1 Quarter2Document18 pagesBusinessmath Lesson1 Quarter2Lynn DomingoNo ratings yet

- Irrigation Engineering: Course Instructor: Engr. Arif Asghar GopangDocument22 pagesIrrigation Engineering: Course Instructor: Engr. Arif Asghar GopangArif AsgharNo ratings yet

- Taut Wire Bandak MK 15 B PDFDocument26 pagesTaut Wire Bandak MK 15 B PDFGonzalo Villalobos Sanchez100% (1)

- Costly Mistake Zik MadeDocument7 pagesCostly Mistake Zik MadeBenNo ratings yet

- S16r-Pta (T13-0311-E)Document4 pagesS16r-Pta (T13-0311-E)Dikdik Sidqi100% (1)

- EPA Cadmium Techical FACT SHEETDocument4 pagesEPA Cadmium Techical FACT SHEETEric CheahNo ratings yet

- AE23 Capital BudgetingDocument4 pagesAE23 Capital BudgetingCheska AgrabioNo ratings yet

- DDD 3360Document23 pagesDDD 3360Rixall Jun SanchezNo ratings yet

- Human Resource Management Gaining A Competitive AdvantageDocument22 pagesHuman Resource Management Gaining A Competitive AdvantagelinhNo ratings yet

- Jurnal Syafri AntoniDocument11 pagesJurnal Syafri Antoni170462201014 Syafri AntoniNo ratings yet

- Ed 00 (EN-NL-FR-DE-ES-SV-IT-RUS)Document42 pagesEd 00 (EN-NL-FR-DE-ES-SV-IT-RUS)Mesafint kassieNo ratings yet