Professional Documents

Culture Documents

2436

2436

Uploaded by

Preety sharmaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2436

2436

Uploaded by

Preety sharmaCopyright:

Available Formats

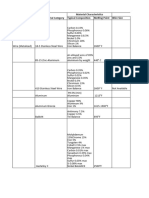

Laboratory MICROLAB, SP.

101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 1 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

CHEMICAL TESTING

I. METAL & ALLOYS

1. Alloy Steels Aluminium IS 8811-1998 (RA 2012)/ 0.001 % to 0.15%

Arsenic ASTME 415 - 2017 0.001 % to 0.010%

Boron ML/VAL/Fe/2013-2014 dt 0.001 % to 0.010%

Carbon Apr 2013By OES 0.001 % to 2.0%

Chromium 0.001 % to 8.00%

Cobalt 0.001 % to 0.050%

Copper 0.001 % to 0.500%

Lead 0.001 % to 0.40%

Manganese 0.001 % to 2.00%

Molybdenum 0.001 % to 1.50%

Nickel 0.001 % to 5.00%

Niobium/Columbium 0.001 % to 0.050%

Nitrogen 0.001 % to 0.040%

Phosphorus 0.001 % to 0.100%

Silicon 0.001 % to 2.00%

Sulphur 0.001 % to 0.300%

Tin 0.001 % to 0.050%

Titanium 0.001 % to 0.010%

Tungsten 0.001 % to 1.10%

Vanadium 0.001 % to 1.00%

Zirconium 0.001 % to 0.050%

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 2 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

2. Stainless Steel Aluminium ASTM E1086-2014 0.001 % to 0.150%

Boron IS 9879 – 1998 (RA 2015) 0.001 % to 0.010%

Carbon ML/VAL/Fe/013-014 0.001 % to 1.5%

Chromium dt Apr 2013By OES 8.00 % to 24.0%

Cobalt 0.001 % to 0.5%

Copper 0.001 % to 5.00%

Manganese 0.001 % to11.00%

Molybdenum 0.001 % to 6.00%

Nickel 0.001% to 25.0%

Niobium 0.001 % to 0.70%

Nitrogen 0.005 % to 0.600%

Phosphorus 0.001 % to 0.080%

Silicon 0.100 % to 4.00 %

Sulphur 0.001 % to 0.35%

Tantulam 0.001 % to 0.06%

Titanium 0.001 % to 0.7%

Tungsten 0.010 %to 2.5%

Vanadium 0.001 % to 2.50%

Zirconium 0.001 % to 0.050%

3. Cast Iron / SG Carbon ASTM E1999-2011 1.90 % to 3.80%

Iron Chromium By OES 0.025 % to 2.00%

Copper 0.015 % to 0.750%

Magnesium 0.01 % to 0.09%

Manganese 0.001% to 2.00%

Molybdenum 0.010 % to 2.00%

Nickel 0.020 % to 2.00%

Phosphorus 0.005 % to 0.400%

Silicon 0.150 % to 2.50%

Sulphur 0.010 % to 0.080%

Tin 0.004 % to 0.140%

Titanium 0.003 % to 0.120%

Vanadium 0.008 % to 0.220

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 3 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

4. Tool Steel Carbon ML/VAL/HSS/2011-2012 0.5 % to 1.5%

Silicon dt Apr 2011By OES 0.2 % to 0.7%

Manganese 0.4 % to 0.8%

Sulphur 0.01 % to 0.04%

Phosporus 0.01 % to 0.03%

Chromium 4.0 % to 17.0%

Molybdenum 1.0 % to 1.7%

Vanadium 1.0 % to 1.7%

Tungsten 15.0 % to 22.0%

Cobalt 8.0 % to 12.0%

5. Aluminium & its Beryllium ASTM E1251 – 2011 0.001 % to 0.100%

Alloys Bismuth 0.001 % to 0.100%

Chromium 0.010 % to 0.20%

Copper 0.020 % to 5.50%

Iron 0.100 % to 1.50%

Lead 0.005 % to 0.06%

Magnesium 0.010 % to 5.00%

Manganese 0.010 % to 1.20%

Nickel 0.010 % to 2.00%

Silicon 0.100 % to 15.00%

Tin 0.010 % to 0.500%

Titanium 0.010 % to 0.300%

Vanadium 0.001 % to 0.025%

Zinc 0.07 % to 5.00%

Zirconium 0.001 % to 0.15%

6. Copper & its Tin BS EN 15079-2015 0.005 % to 10.00%

Alloys Lead ML/VAL/Cu/2011-2012 0.005 % to 10.00%

Zinc dt Sep 2011 by OES 0.005 % to 40.00%

Iron 0.005 %to 4.50%

Nickel 0.005 % to 35.00%

Manganese 0.005 % to 3.00%

Sulphur 0.001 % to 0.050%

Phosporus 0.001 % to 0.200%

Aluminium 0.005 % to 11.00%

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 4 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

Silicon 0.002 % to 3.50%

Antimony 0.002 % to 0.500%

Arsenic 0.005 % to 0.100%

Chromium 0.002 % to 0.020%

Cobalt 0.005 % to 0.250%

Bismuth 0.001 % to 0.100%

7. Nickel & its Alloys Carbon ASTM E-3047-2016 0.005 % to 0.300%

Silicon ML/VAL/Ni/2011-2012 0.010 % to 2.00%

Manganese dt Sep 2011 by OES 0.010 % to 2.00%

Sulphur 0.002 % to 0.040%

Phosporus 0.002 % to 0.040%

Iron 0.100 % to 41.00%

Molybdenum 0.020 % to 27.00%

Vanadium 0.002 % to 0.600%

Copper 0.001 % to 34.00%

Niobium 0.002 % to 6.00%

Cobalt 0.005% to17.50%

Tungsten 0.010% to 20.0%

Titanium 0.005 % to 3.00%

Aluminium 0.050 %to 3.00%

Chromium 0.005 % to 30.00%

Tantalum 0.010 % to 0.050%

8. Titanium & Aluminium ASTM E-2994-2016 0.006 % to 9.00%

Titanium Alloys Iron ML/VAL/Ti/2011-2012 0.025 % to 0.250%

Molybdenum dt Oct 2011By OES 0.005 % to 2.00%

Vanadium 0.005 % to 3.00%

Zirconium 1.00 % to 4.50%

Tin 0.005 % to 2.50%

Carbon 0.010 % to 0.050%

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 5 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

9. Cobalt & its Aluminium ML/VAL/Co/2013 dt Apr 0.025 % to 0.25%

Alloys Boron 2013By OES 0.001 % to 0.005%

Chromium 15.0 % to 28.0%

Carbon 0.100 % to 0.300%

Copper 0.02 % to 0.06%

Iron 2.00 % to 3.00%

Manganese 0.20 % to 2.00%

Molybdenum 0.50 % to 2.00%

Nickel 8.0 % to 25.0%

Silicon 0.10 % to 0.60%

Vanadium 0.005 % to 0.050%

Sulphur 0.0005 % to 0.005%

Phosphorus 0.005 % to 0.020%

Tungsten 10.0 % to 16.0%

Titanium 0.005 % to 0.015%

Niobium/Columbium 0.02 % to 0.05%

Tantalum 0.02 % to 0.05%

10. Cast Iron, SG Iron Carbon IS 12308 Part 11-1991 0.01% to 4.50%

Silicon (RA 2012) 0.10% to 5.00 %

Sulphur 0.005% to 0.25%

Manganese IS 12308 Part 6-1991 0.001% to 3.0 %

Phosphorus (RA 2012) 0.001% to 0.5%

Copper 0.001% to 2.5 %

Chromium IS 12308 Part 2-1987 0.001 % to 6.00%

Nickel (RA 2012) 0.001 % to 5.00%

Molybdenum 0.001% to 0.30 %

Lead ML/Val/ST-Fe-01/13/ICP 0.001% to 0.03 %

Tin OES dt 08.10.2013 0.001% to 0.050%

Vanadium 0.001% to 0.050%

Magnesium 0.001% to 0.10 %

11. Carbon steel Carbon IS 228 Part 1-1987 0.05 % to 2.50 %

(RA 2012)

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 6 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

Silicon IS 228 Part 8-1989 0.10 %to 2.50%

(RA 2014)

Sulphur IS 12308 Part 2-1987 0.002% to 0.25%

(RA 2012)

Chromium IS 228 Part 6-1987 3.00% to 25.00 %

(RA 2014) 0.001 % to 3.00%

ML/Val/ST-Fe-01/13/ICP

OES dt 08.10.2013

Nickel IS 228 Part 5-1987 3.00% to 15.00 %

(RA 2014) 0.001 % to 3.00 %

ML/Val/ST-Fe-01/13/ICP

OES dt 08.10.2013

Manganese ML/Val/ST-Fe-01/13/ICP 0.001% to 3.00%

Phosphorus OES dt 08.10.2013 0.001 % to 2.50%

Copper 0.001 % to 3.00 %

Molybdenum 0.001% to 4.00 %

Aluminium 0.001% to 2.50 %

Lead 0.001% to 4.00%

Tin 0.001% to 2.50 %

Titanium 0.001% to 2.50 %

Vanadium 0.001% to 2.50 %

Cobalt 0.001% to 2.50%

12. Stainless Steel Carbon IS 228 Part 1-1987 0.01 % to 0.15%

Silicon (RA 2012) 0.01 % to 1.50 %

Sulphur IS 228 Part 8-1989 0.001 % to 3.00 %

Chromium (RA 2014) 3.00% to 25.00 %

Nickel IS 12308 Part 2-1987 3.00% to 15.00%

Manganese (RA 2012) 0.10 %to 2.00%

Phosphorus IS 228 Part 6-1987 0.001% to 0.10%

Copper (RA 2014) 0.002% to 0.10%

Molybdenum IS 228 Part 5-1987 0.001% to 4.00 %

Aluminium (RA 2014) 0.001% to 2.50 %

Titanium ML/Val/ST-Fe-01/13/ICP 0.001% to 2.50 %

Vanadium OES dt 08.10.2013 0.001% to 2.50 %

Cobalt 0.001% to 2.50 %

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 7 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

13. Copper & its Copper IS 4027 Part1-1987 30% to 99%

Alloys (RA 2012) 95.0 %to 99.9%

Lead ASTM E53:2007(RA2013) 0.50% to 10.00%

IS 4027 Part1-1987 0.001% to 3.00 %

Carbon (RA 2012) 0.10% to 3.00%

ML/NF-Cu-01/15/ICP OES

IS 228 (Part1):1987

(RA 2012)

Sulphur IS 12308 (Part2):1987 0.002% to 0.50%

(RA 2012)

Nickel ML/NF-Cu-01/15/ICP OES 0.001% to 1.50 %

dt 08.10.2015

Tin ML/NF-Cu-01/15/ICP OES 0.001% to 0.500%

dt 08.10.2015 0.50% to 15.00 %

IS 4667 Part 2-1969

(RA 2012)

Zinc ML/NF-Cu-01/15/ICP OES 0.001% to 4.00 %

dt 08.10.2015 25.0% to 45.0%

IS 4027 Part 6-1987

(RA 2012)

Iron IS 4027 (Part8): 1991 0.001% to 4.00 %

(RA 2012)

Aluminium ML/NF-Cu-01/15/ICP OES 0.001% to 8.00%

dt 08.10.2015

ML/NF-Cu-01/15/ICP OES

dt 08.10.2015

Silver ML/NF-Cu-01/15/ICP OES 0.001% to 0.02%

dt 08.10.2015

Bismuth ML/NF-Cu-01/15/ICP OES 0.001% to 1.00%

dt 08.10.2015

Antimony ML/NF-Cu-01/15/ICP OES 0.001% to 2.50%

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 8 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

dt 08.10.2015

14. Aluminium & its Silicon IS 504-1963 (RA 2014) 0.10% to 15.00 %

Alloys Nickel ML/NF-Al-01/15/ICP OES 0.001% to 4.00%

Copper dt 08.10.2015 0.001% to 8.00 %

Zinc 0.001% to 4.00 %

Lead 0.001% to 4.00 %

Iron 0.001% to 4.00 %

Tin 0.001% to 2.00 %

Manganese 0.001% to 4.00v

Magnesium 0.001% to 7.00%

Titanium 0.001% to 2.00%

Vanadium 0.001% to 2.00 v

Zirconium 0.001% to 2.50 %

15. Zinc & Zinc Alloys Zinc IS 4611:1991(RA 2015) 1.00% to 99.00%

Nickel Annexure A 0.001% to 3.00%

Lead ML/NF-Zn-01/17/ICP OES 0.001% to 4.00%

Copper dt 23.10.2017 0.001% to 4.00%

Tin 0.001% to 4.00%

Iron 0.001% to 4.00%

Aluminium 0.001% to 8.00%

Chromium 0.001% to 4.00%

Manganese 0.001% to 4.00%

Magnesium 0.001% to 4.00%

Titanium 0.001% to 4.00%

16. Heavy Metal on Lead BS EN 62321-Part 5-2017 1.0 mg/kg to 2500 mg/kg

Metals, Alloys & Cadmium BS EN 62321-Part 5-2017 1.0 mg/kg to 300 mg/kg

Semi Conductor Mercury BS EN 62321-Part 5-2017 1.0 mg/kg to 2500 mg/kg

Hexavalent Cr6+ IEC-62321-Part 2-2017 1.0 mg/kg to 1000 mg/kg

17. Carbon Steel & Oxygen ASTM E1019-2011 0.0030 % to 0.0150%

Stainless Steel Nitrogen ASTM E1019-2011 0.0050 % to 0.0600%

Hydrogen ML/VAL/ST-H2-2017-18 dt 0.0002 % to 0.0010%

29.09.2017

18. Titanium & Oxygen ASTM E1409-2013 0.0040 % to 0.200%

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 9 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

Titanium Alloys Nitrogen ASTM E1409-2013 0.001 % to 0.020%

Hydrogen ASTM E1447-2016 0.0010 % to 0.0200%

II. PAINT & SURFACE COATING

1. Enamel Paints Flexibility and IS 101 – Part 5-Sec 2-1988 Qualitative

(Finishing/ Adhersion - Scratch (RA 2014)

Under Hardness

coating) Mass in kg/10 Litres IS 101 – Part 1-Sec 7-1987 (1kg to 20 kg)/10L

(RA 2014)

Drying time IS 101 – Part 3-Sec 1-1986 10 minutes Hrs to 72 Hrs

(RA 2012) (Qualitative)

Finish IS 101 – Part 3-Sec 4-1987 Qualitative

(RA 2014)

Gloss 60° IS 101 – Part 4-Sec 4-1988 5 to 99

(RA 2012)

Fineness of Grind IS 101 – Part 3-Sec 5-1987 10 Microns to 100 Microns

(RA 2014)

Colour IS 101 – Part 4-Sec 2-1989 Qualitative

(RA 2014)

IS 5-2007-2007 (RA 2012)

Water Content IS 101 – Part 2-Sec 1-1988 0 to 5 ml

(RA 2014)

Consistency-Flow Cup IS 101 – Part 1-Sec 5-1989 10 Sec to 250 Sec

(RA 2014)

Flexibility and IS 101 – Part 5-Sec 2-1988 Qualitative

Adhersion-Bend Test (RA 2014)

Flash Point IS 101 – Part 1-Sec 6-1987 30°C to 70°C

(RA 2014)

Volume Solids IS 101 – Part 8-Sec 6-1993 5.0 % to 80%

(RA 2014)

Phthalic Anhydride IS 101 – Part 8-Sec 4-2015 8 % to 30%

content

Accelerated Storage IS 8662-2004(RA 2014) Qualitative

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 10 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

Stability Test Annexure F

IS 2932-2003(RA 2013)

Annexure G

IS 133-2004 (RA 2013)

Annexure E

Resistance to Acid IS 8662-2004 (RA 2014) Qualitative

Annexure D

IS 2932-2003 (RA 2013)

Annexure E

Resistance to Alkali IS 8662-2004 (RA 2014) Qualitative

Annexure E

IS 2932-2003 (RA 2013)

Annexure F

Volatile Matter IS 101 – Part 2-Sec 2-1986 10 % to 95%

(RA 2012)

Pressure Test IS 101 – Part 5-Sec 1-1988 Qualitative

(RA 2014)

Wet opacity IS 101 – Part 4-Sec 1-1988 80 m2/10L to 300 m2/10L

(RA 2014)

Resistance to Water IS 133 -2004 (RA 2013) Qualitative

Annexure D

Film Thickness – IS 101 – Part 3-Sec 2-1989 5 Microns to 250 Microns

Method - 5 (RA 2014)

2. Ready Mixed Accelerated Storage IS 2074-1992 (RA 2014) Qualitative

Paints Stability Test Annexure E

(Zinc Chrome pigment content IS 101 – Part 8-Sec 2-1989 10 % to 60%

Primer) (RA 2014)

Protection Against IS 101 – Part 6-Sec 1-1988 Qualitative

Corrosion under (RA 2015)

condition of

condensation

Resistance to Neutral IS 101 – Part 6-Sec 1-1988 Qualitative

Salt Spray (RA 2015)

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 11 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

Resistance to Artificial IS 2074-1992(RA 2014) Qualitative

sea water Annexure C

Chromic Anhydride IS 2074-1992(RA 2014) 2 % to 25 %

Annexure B

Zinc oxide IS 2074-1992(RA 2014) 2 % to 25 %

Annexure B

3. Varnish Acid Value IS 101 – Part 9-Sec 1-1993 2 mg of KOH/g to 50 mg of

(RA 2014) KOH/g

Resistance to Water IS 101 – Part 7-Sec 1-1989 Qualitative

(RA 2014)

4. Ready Mixed Resistance to Acid & IS 158- 2015 Qualitative

Paint Bituminous Alkali IS 9862- 1981-(RA 2014)

Brushing, Black

japan, Exterior,

petrol resisting,

stoving

Resistance to Heat IS 158- 2015 Qualitative

Resistance to Chlorine IS 9862- 1981,(RA 2014) Qualitative

Protection Against IS 101 – Part 6-Sec 1-1988 Qualitative

Corrosion under (RA 2015)

condition of

condensation

Lead Restriction test- IS 101 – Part 8-Sec 5-1993 upto 1.0 %

Electrolysis Method (RA 2014)

Ash content IS 341-2016 1 % to 10 %

Residue on sieve IS 101 – Part 8-Sec 1-1989 upto 5.0 %

(RA 2014)

Resistance to Petrol & IS 142-1980-(RA 2015) Qualitative

Lubricating oil

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 12 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

III. WATER

1. Water

for Drinking

Purpose Odour IS 3025 Part 5-1983 Qualitative

(RA2012)

Taste IS 3025 Part 7,8-1984 Qualitative

(RA2012)

pH at 25°C IS 3025 Part 11-1983 1.0 to 14.0

(RA 2012)

Total Dissolved Solids IS 3025 Part 16-1984 10 mg/l to 5000 mg/l

at 180°C (RA 2012)

Total Hardness as IS 3025 Part 21- 2009 2.0 mg/l to 2000 mg/l

CaCO3 (RA 2014)

Total Alkalinity as IS 3025 Part 23-1986 5 mg/l to 2000 mg/l

CaCO3 (RA2014)

Chlorides as Cl IS 3025 Part 32-1988 1.0 mg/l to 2000 mg/l

(RA2014)

Sulphate as SO4 IS 3025 Part 24-1986 10 mg/l to 2000 mg/l

(RA2014)

Calcium as Ca IS 3025 Part 40-1991 2.0 mg/l to 1000 mg/l

(RA2014)

Magnesium as Mg IS 3025 Part 46-1994 2.0 mg/l to 1000 mg/l

(RA2014)

Silica as SiO2 IS 3025 Part 35-1988 1.0 mg/l to 100 mg/l

(RA2014)

Iron as Fe IS 3025 Part 2 - 2004 0.01 mg/l to 40 mg/l

(RA2014)by ICP OES

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 13 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

Copper as Cu IS 3025 Part 2 - 2004 (RA 0.01 mg/l to 40 mg/l

2014) by ICP OES

Zinc as Zn 0.01 mg/l to 40 mg/l

Lead as Pb 0.01 mg/l to 40 mg/l

Cadmium as Cd 0.001 mg/l to 10 mg/l

Manganese as 0.01 mg/l to 40 mg/l

Mn

Aluminium as Al 0.01 mg/l to 40 mg/l

Barium as Ba 0.01 mg/l to 40 mg/l

Molybdenum as Mo 0.01 mg/l to 40 mg/l

Nickel as Ni 0.01 mg/l to 40 mg/l

Total Chromium as Cr 0.01 mg/l to 40 mg/l

2. Water for To Neutralize 100ml IS 3025 (Part 22): 1986 0.1 ml to 50 ml

Construction sample of water using (RA 2014)

Purpose phenolphthalein as an

indicator

To Neutralize 100ml IS 3025 (Part 23): 1986 0.1 ml to 50 ml

sample of water using (RA 2014)

mixed indicator

pH at 25°C IS 3025 Part 11-1983 1.0 to 14.0

(RA 2012)

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 14 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

Inorganic Solids IS 3025 Part 18-1984 10 mg/l to 5000 mg/l

(RA2012)

Organic Solids IS 3025 Part 18-1984 10 mg/l to 1000 mg/l

(RA2012)

Suspended Solids IS 3025 Part 15-1984 10 mg/l to 3000 mg/l

(RA2014)

Chloride as Cl IS 3025 Part 32-1988 1.0 mg/l to 2000 mg/l

(RA2014)

Sulphate as SO3 IS 3025 Part 24-1986 10 mg/l to 2000 mg/l

(RA2014)

IV. ORES & MINERALS

1. Lime Stone Loss on Ignition IS 1760 Part 1-1991 1.0 % to 44 %

(RA 2017)

Silica IS 1760 Part 2-1991 0.50% to 10 %

(RA 2017)

CaO IS 1760 Part 3-1991 1.0% to 56.0 %

(RA 2017)

MgO IS 1760 Part 3-1991 0.10% to 5.00 %

(RA 2017)

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 15 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

MECHANICAL TESTING

I. MECHANICAL PROPERTIES OF

METALS

1. Ferrous & Non Tensile Test

Ferrous Metals Tensile Strength IS 1608 - 2005 (RA 2011) 1 to 950 kN

Including Weld ASTM A370 - 2017

Metals ASTM E8/E8M - 2016a

ISO 6892-1 : 2016

ASME SEC IX - 2017

EN ISO 15614-1:2017

EN ISO 4136-2012

EN 13458-2:2002

IS 7307-1:1974 (RA

2013)

AWS D 1.1 - 2015

IS 2825 – 1969 (RA2017)

AWS D1.6-2007

API 1104-2013

Elevated Tensile Test ASTM E21 - 2009

ISO 6892-2 : 2011

IS 1367 Part 3 - 2017

100 °C to 900 °C

Axial Tensile Test

Wedge Tensile Test EN ISO 898-1 : 2013

ASTM F606/F606M-

Yield Strength/0.2&, 2016

0.5% & 1% Proof

Strength 1 to 950 kN

% of Elongation

% Reduction in area 1% to 75%

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 16 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

5% to 80%

Bend Test

IS 1599 – 2012(RA2017)

ASTM A370 - 2017 Mandrel Dia

ISO 7438-2016 2mm to 200mm

Bend Test

Face/Root/Side bend Qualitative

ASME SEC IX - 2017

EN ISO 15614-1:2017

EN 13458-2:2002 Qualitative

ISO 5173-2009

IS 7307-1:1974 (RA2013)

IS 2825 – 1969 (RA2017)

AWS D1.6 – 2007

AWS D1.1-2015

API 1104-2013

Rebend Test IS 1786-2008 (RA 2013) Mandrel Dia

2 mm to 200 mm

Nick Break Test API 1104-2013 Qualitative

IS 2825 – 1969 (RA2017)

Compression Test

ASTM A370-2017 Qualitative

Fracture Test

ASME SEC IX-2017 Qualitative

AWS D1.1-2015

AWS D1.6-2007

IS 7307-1:1974 (RA2013)

ISO 9017-2001

Hardness Test

Rockwell Hardness

HRA ASTM A370-2017

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 17 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

HRB IS 1586 Part- 20 to 88 HRA

HRC 12012(RA2017) 45 to 100 HRB

Superficial Rockwell ASTM E18-2017e1 20 to 70 HRC

Hardness ISO 6508-1:2016

HR15T

HR30T

HR45T IS 1586 Part-1 2012 (RA

HR15N 2017) 67 to 93 HR15T

HR30N ASTM E18-2017e1 29 to 82 HR30T

HR45N ISO 6508-1:2016 30 to 70 HR45T

70 to 94 HR 15N

Vickers Hardness 42 to 86 HR30N

IS 1501 Part 1-2013 20 to 77 HR45N

ASTM E384-2016

ISO 6507-1:2005 100 to 800 HV

Micro Vickers ASTM E92-2017

Hardness IS 1501 Part 1-2013

(1kg to 50kg)

ASTM E384-2016

ASTM E92-2017

ISO 9015-1:2001 100 to 1000 HV

Brinell Hardness ISO 6507-1:2005 (200gf to 1000gf)

IS 1500 Part1:2013

ASTM E10-2017

ISO 6506-1:2014

100 to 600 BHN

(187.5 to 3000kgs)

(2.5,5.0.10.0 mm

diameter ball)

2. Ferrous & Non Charpy Impact Test IS 1757-Part 1-2014 4-300 Joules

Ferrous Metals IS 1499-1977 (RA 2015) (RT to -196 °C)

(Including weld ASTM A370-2017

metals &all weld ASTM E23 – 2016B

ASME Sec IX-2017

metals like

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 18 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

Plates, rods, EN ISO 15614-1:2017

pipes etc) ISO 9016-2012

ISO 148-1:2016

Izod Impact Test IS 1598-1977 (RA 2015) 5 to 164 Joules

Flattening Test ASTM A370- 2017

3. IS 2328-2005 (RA 2017) Qualitative

Ferrous & Non ASTM A530/A530M-2012

Ferrous Pipes &

Tubes (Including Flaring (Flange) Test IS 2330-2011

Welded Pipes) ASTM A370-2017 Qualitative

ASTM A450/A450M-2015

Crush Test ASTM A370-2017

Drift Expanding Test IS 2335-2005 (RA 2017) Qualitative

Pull out/Push out Test ASME SEC IX-2017 Qualitative

ASME SEC VIII DIV 1-2015

Qualitative

Embrittlement Test ASTM F606/F606M-2016

Proof Load for Bolts, IS 1367 Part 3-2017,

4. Screws & Studs ISO 898-1-2013 Qualitative

Fasteners ASTM F606/F606M-2016

(External & Proof Load for Nuts IS 1367 Part6-1994 (RA Qualitative

Internal 2015)

Threaded) ISO 898-2:2012

Macro Examination/ ASTM E340-2015 Qualitative

Visual Examination ASTM E381-2017

IS 11371 -1985 (RA 2012)

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 19 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

5. ASM Metal Hand Book 1X,10X,20X

vol.9-2004 (Qualitative)

ASME SEC IX - 2017

Ferrous & Non

ISO 17639-2013

Ferrous Billets, IS 7307 Part1-1974

Blooms, (RA 2013)

Hotrolled

products,

Forgings,

Extrusion,

Sheets, Plates,

Weldments,

Castings

Machined and

Ground Parts

6. Metals and Alloys Micro Structural ASTM E3- 50X to 1500X

Characterization 2011(Reapproved 2017) (Qualitative)

ASTM E407-07

(Reapproved2015)E1

ASM Metals Hand Book

Vol-9-2004

Steel & Stainless Inclusion Rating IS 4163-2004 (RA2010) 100X

7. Steels ASTM E45-2013 (Qualitative)

Grain Size ASTM E112-2013 Grain size No 1 to 10

Measurements by IS 4748-2009 (Qualitative)

comparison method EN ISO 643-2012

Decarburization Depth ASTM E1077-2014 20 microns to 1mm

IS 6396-2000 (RA

2012)

Grey Cast Iron Micro Examination IS 7754 - 1975 (RA 50X,100X,200X,

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 20 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

and S.G. Iron Graphite Flakes/ 2012) 250X,400X,500X, 800X,

8. Products Nodules type and size, ASM metals hand book 1000X,1500X

distribution vol.9 2004 (Qualitative)

characteristics and ASTM A247-2017

matrix analysis ISO 945-1:2008

ISO 1083-2004

Duplex Stainless Determination of ASTM E562-2011 5% to 95%

Steel Volume fraction of (Qualitative)

phase

9.

Case Hardened Case depth by IS 6416-1988 (RA 2012) 0.05mm to 10mm

Steels & Hardness Traverse IS 13691-1993 (RA 2012)

Nitrided Steels method & ISO 18203-2016 (200gf to 1000gf)

10. Metallography ASTM B487-85 (RA-13)

20 mm to 0.3mm

Metallic and Measurement of ISO 1463-2003

Oxide coating on Metal and oxide 0.01 mm to 0.3mm

Metals coating thickness by 0.01 mm to 0.3mm

Microscopic method IS 3203-1982

11. Measurement of (Reaffirmed 2016)

thickness of Electro 0.01 mm to 0.3mm

plated Coatings

12. Carbon & Carbon Jominy End Quench ASTM A255-10 30 HRC to 60 HRC

Alloy Steels Test (Reapproved 2014)

IS 3848-1981 (RA

2009)

ISO 642-1999

Stainless Steel Intergranular-corrosion ASTM A262 - 2015

13. wrought /cast Test Qualitative

products Practice-A 0.001 g to 220g

Practice-B 0.001 g to 220g

Practice-C Qualitative

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 21 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

Practice-E 0.001 g to 220g

Practice-F

Austenitic & Intergranular corrosion ISO 3651-1:1998

Duplex Stainless of stainless steels

14. 0.001 g to 220g

Steel (Huey Test)

Ferritic, Intergranular corrosion ISO 3651-2:1998

Austenitic & of stainless steels

15. Duplex Stainless Qualitative

Steel

Intergranular-corrosion ASTM G28-2002

Wrought Nickel Test (RA 2015)

16. Rich Chromium Method A 0.001 g to 220g

Bearing Alloys

Intergranular-corrosion ASTM A923-2014

Duplex Stainless Test

Steel Method A

17. Method C Qualitative

0.001 g to 220g

Pitting Corrosion Test ASTM G48-2011

Stainless steels Method A (RA 2015)

Duplex Stainless Method B

18. Steel Method C 0.001 g to 220g

Method D

Method E

Method F

Stress Corrosion ASTM G36 – 1994

Stainless steels cracking test in boiling (RA 2013)

Duplex Stainless Magnesium/Calcium

Steel Chloride Solution

19. (CSCC) Qualitative

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 22 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

20. Stainless steels Test for Resistance to NACE TM 0177-2016 Qualitative

Duplex Stainless Sulphide Stress

Steel& Carbon Corrosion

Steels Cracking

(SSCC at RT,

90 & 120 °C)

Steel Pipes & Test for Resistance to NACE TM 0284 – 2016 Qualitative

21. Pressure Hydrogen Induced

Vessel Plates Cracking (HIC)

Inorganic & Neutral Salt Spray ASTM B117 2016 Qualitative

22. Organic Coating Testing ISO 9227 - 2012

(Plated &

Painted)Material

Copper / Copper - Accelerated ASTM B368-2009 Qualitative

Nickel/Chromium Acetic Acid Salt Spray (RA 2014)

23. Coatings on steel, Test (CASS Test) ISO 9227 - 2012

zinc Alloys,

Aluminum

Alloys& Plastics

and on Aluminum

Anodized

Samples

Ferrous & Non Acetic Acid Salt ASTM G85 - 2011 Qualitative

Ferrous Spray Test IS 9227 - 2012

Material (ASS Test)

24. (Inorganic &

Organic

Coatings)

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

Laboratory MICROLAB, SP. 101, 2nd Main Road, Ambattur Industrial Estate,

Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number TC-6815 (in lieu of T-0774, T-0775) Page 23 of 23

Validity 21.12.2017 to 20.12.2019 Last Amended on 18.01.2018

Sl. Product / Material Specific Test Test Method Specification RAnge of Testing /

of Test Performed against which tests are Limits of Detection

performed

Copper Base Mercurrous Nitrate IS 2305 - 1988 (RA 2005) Qualitative

Alloys Test Procedure A ASTM B154 - 2016

25.

Zinc Coating on Mass of Zinc Coating IS 6745-1972 (RA 2016) 0.001 g to 220g

Ferrous Metals ASTM A90/A90M-2013

IS 3618-1966

26. Ferritic Stainless Intergranular Attack in ASTM A763-2015 Qualitative

Steel Ferritic Steel

27.

Anand Deep Gupta N. Venkateswaran

Convenor Program Director

You might also like

- PM-3000 Section 1 To 7 ManualDocument52 pagesPM-3000 Section 1 To 7 Manualpablo100% (1)

- Homework 1Document3 pagesHomework 1Hussain Ali MurtazaNo ratings yet

- Comunicaciones Digitales Avanzadas DEBER 1 (Select Max. 10 Problems and Answer The Two Questions)Document3 pagesComunicaciones Digitales Avanzadas DEBER 1 (Select Max. 10 Problems and Answer The Two Questions)Cristian Sancho LopezNo ratings yet

- T 0774Document10 pagesT 0774Preety sharmaNo ratings yet

- Urja Lab1Document3 pagesUrja Lab1WasimMogalNo ratings yet

- E 1898 - 97 - Rte4otgtukveDocument7 pagesE 1898 - 97 - Rte4otgtukveDamen JohnsonNo ratings yet

- In Lieu of T-1800, T-1801, T-3484 & T-4240Document46 pagesIn Lieu of T-1800, T-1801, T-3484 & T-4240Pramukh Test houseNo ratings yet

- TMP 2 1Document2 pagesTMP 2 1mj03127477706No ratings yet

- TMP 10Document2 pagesTMP 10mj03127477706No ratings yet

- TMP 12Document2 pagesTMP 12mj03127477706No ratings yet

- 2nd Match: 4130 3rd Match: 4150: Main Store Sample 4140 Test #7598 09:01:23 Saturday February 17 2024Document2 pages2nd Match: 4130 3rd Match: 4150: Main Store Sample 4140 Test #7598 09:01:23 Saturday February 17 2024mj03127477706No ratings yet

- Chemical Analysis of Nickel, Cobalt, and High-Temperature AlloysDocument38 pagesChemical Analysis of Nickel, Cobalt, and High-Temperature AlloysLuigi HernándezNo ratings yet

- G1 E 1473 - 03 Co Titulacion PotenciometricaDocument38 pagesG1 E 1473 - 03 Co Titulacion PotenciometricaDANIELA ANDREA RIEGA AGUIRRENo ratings yet

- TMP 77Document2 pagesTMP 77ZubairNo ratings yet

- 4 Year Ilc Plan 2019Document63 pages4 Year Ilc Plan 2019earth metallurgical services pvt.ltd.No ratings yet

- Astm E1473 22Document12 pagesAstm E1473 22Dip MNo ratings yet

- TMP 22Document2 pagesTMP 22Avijit DebnathNo ratings yet

- TMP 133Document2 pagesTMP 133ZubairNo ratings yet

- TMP 27Document2 pagesTMP 27Avijit DebnathNo ratings yet

- ASTM E351-13 (Test Methods For Chemical Analysis of Cast Iron)Document55 pagesASTM E351-13 (Test Methods For Chemical Analysis of Cast Iron)Said MohamedNo ratings yet

- TMP 82Document2 pagesTMP 82ZubairNo ratings yet

- TMP 1Document2 pagesTMP 1mj03127477706No ratings yet

- TMP 85Document2 pagesTMP 85ZubairNo ratings yet

- TMP 37Document2 pagesTMP 37Avijit DebnathNo ratings yet

- TMP 83Document2 pagesTMP 83ZubairNo ratings yet

- Laboratory ELCA Laboratories, Plot No. A-444, Road No. 37, Ram Nagar, Wagle Industrial Estate, Thane, MaharashtraDocument56 pagesLaboratory ELCA Laboratories, Plot No. A-444, Road No. 37, Ram Nagar, Wagle Industrial Estate, Thane, MaharashtraProsenjit RoyNo ratings yet

- Chemical Content of SSDocument4 pagesChemical Content of SSAnonymous TK7b87faNo ratings yet

- TMP 1 2Document2 pagesTMP 1 2mj03127477706No ratings yet

- Chemical Analysis of Cast Iron-All Types: Standard Test Methods ForDocument57 pagesChemical Analysis of Cast Iron-All Types: Standard Test Methods Forparag.dip1424No ratings yet

- ASTM453Document1 pageASTM453EderNo ratings yet

- ASTM A449 Tech InfoDocument2 pagesASTM A449 Tech InfoBoz Van DuynNo ratings yet

- E 351 Â " 93 R00 RTM1MQDocument48 pagesE 351 Â " 93 R00 RTM1MQmario valenzuelaNo ratings yet

- Astm E350-12Document65 pagesAstm E350-12Norman ricardo RojoNo ratings yet

- TMP 24Document2 pagesTMP 24Avijit DebnathNo ratings yet

- Test Report: Equipment: Q4 TASMAN/ 214435Document1 pageTest Report: Equipment: Q4 TASMAN/ 214435test qtesNo ratings yet

- TMP 6Document2 pagesTMP 6mj03127477706No ratings yet

- TMP 19Document2 pagesTMP 19Avijit DebnathNo ratings yet

- TMP 1 1Document2 pagesTMP 1 1mj03127477706No ratings yet

- E350-18 Standard Test Methods For Chemical Analysis of Carbon Steel, Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and Wrought IronDocument64 pagesE350-18 Standard Test Methods For Chemical Analysis of Carbon Steel, Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and Wrought IronEda VergiliNo ratings yet

- Aluminum LM5 As Manufactured - Gravity Die CastDocument1 pageAluminum LM5 As Manufactured - Gravity Die CastdolincastingNo ratings yet

- TMP 32Document2 pagesTMP 32Avijit DebnathNo ratings yet

- TMP 4Document2 pagesTMP 4mj03127477706No ratings yet

- E 353 - 93 R00 - RTM1MW - PDFDocument33 pagesE 353 - 93 R00 - RTM1MW - PDFDavid AriasNo ratings yet

- Aluminum LM5 As Manufactured - Sand CastDocument1 pageAluminum LM5 As Manufactured - Sand CastdolincastingNo ratings yet

- Raw MaterialDocument14 pagesRaw MaterialAbhijeet AnkushNo ratings yet

- Sae-J403-2001 - TolDocument2 pagesSae-J403-2001 - TolNorberto A. GhiggiNo ratings yet

- Nickel Spec 230329Document1 pageNickel Spec 230329MajidNo ratings yet

- E1019-11Document24 pagesE1019-11ALEXANDER FRANCO CASTRILLONNo ratings yet

- Material Data Sheet Thermally Broken Steel USADocument2 pagesMaterial Data Sheet Thermally Broken Steel USAYungfang HuangNo ratings yet

- Dialysis Water Parameters - MDocument1 pageDialysis Water Parameters - MMohamed ShokryNo ratings yet

- Tek Bahan 'Baja Karbon'Document2 pagesTek Bahan 'Baja Karbon'Maulana PutraNo ratings yet

- ASTM E1898-2013 Standard Test Method For Determination of Silver in Copper Concentrates by Flame Atomic Absorption SpectrometryDocument5 pagesASTM E1898-2013 Standard Test Method For Determination of Silver in Copper Concentrates by Flame Atomic Absorption Spectrometryxiujia LongNo ratings yet

- Astm E353 19Document46 pagesAstm E353 19Abner CamposNo ratings yet

- 2 HBI in EAF Fact Sheet Rev3 PDFDocument2 pages2 HBI in EAF Fact Sheet Rev3 PDFAaquil RaziNo ratings yet

- Si PB MN Fe Cu Mo Ti W Al Ni NB CR V: 2nd Match: CDA 151 3rd Match: CDA 174xx Low Be CuDocument2 pagesSi PB MN Fe Cu Mo Ti W Al Ni NB CR V: 2nd Match: CDA 151 3rd Match: CDA 174xx Low Be CuRahmat FadhilaNo ratings yet

- Redmond Clay® Elemental Analysis: Element PPM % Element PPM %Document1 pageRedmond Clay® Elemental Analysis: Element PPM % Element PPM %kiyasudeena4283No ratings yet

- Henson White Paper SeawaterDocument11 pagesHenson White Paper SeawaterHưng Đặng ThếNo ratings yet

- Astm E353Document33 pagesAstm E353Naufal Ghifari Rahmat88% (8)

- Certificate of Analysis: MethanolDocument1 pageCertificate of Analysis: MethanolPervaz AnwerNo ratings yet

- Astm A514Document5 pagesAstm A514FYNo ratings yet

- Sodium Perchlorate 1-Hydrate (Reag. USP) For Analysis, ACSDocument1 pageSodium Perchlorate 1-Hydrate (Reag. USP) For Analysis, ACSTANIA MARGARITA ANGEL GALINDONo ratings yet

- List SuperpowerDocument20 pagesList SuperpowerRezaNo ratings yet

- Weather Symbolism in Macbeth For IOCDocument3 pagesWeather Symbolism in Macbeth For IOCGeorgie HancockNo ratings yet

- 2bhk Sell in Casa Rio Palava City 909sqf PDFDocument54 pages2bhk Sell in Casa Rio Palava City 909sqf PDFDailydiegestNo ratings yet

- JTEC Manuscript Template v5Document3 pagesJTEC Manuscript Template v5علي عدنانNo ratings yet

- Thalassemias Ali T Taher, David J Weatherall, Maria Domenica Cappellini 2018Document13 pagesThalassemias Ali T Taher, David J Weatherall, Maria Domenica Cappellini 2018Malika MohNo ratings yet

- DD Soft Copy and Hard Copy Recieved Details Journal Review Process 21 April 2014 8 PM1Document34 pagesDD Soft Copy and Hard Copy Recieved Details Journal Review Process 21 April 2014 8 PM1Puneet AjalNo ratings yet

- Lecture-5 - Classification of Process Variables - Control StrategiesDocument18 pagesLecture-5 - Classification of Process Variables - Control StrategiesKshitij SoniNo ratings yet

- Department of Education: Daily Lesson PlanDocument14 pagesDepartment of Education: Daily Lesson PlanSharlene Jane Roque AporboNo ratings yet

- Alternador AVK - DSG DIG Instalacion Servicio y MantenimientoDocument595 pagesAlternador AVK - DSG DIG Instalacion Servicio y MantenimientoMartin FloresNo ratings yet

- Engr Imtiaz Ahmad CP2 & SCTDocument7 pagesEngr Imtiaz Ahmad CP2 & SCTMuhammad Nasir SiddiqueNo ratings yet

- Class Notes, Trajectory Planning, COMS4733: 1 TrajectoriesDocument11 pagesClass Notes, Trajectory Planning, COMS4733: 1 TrajectoriesAustin Tyson DsouzaNo ratings yet

- Conductive Polymer Based On Polyaniline-Eggshell Powder (PANI-ESP) CompositesDocument17 pagesConductive Polymer Based On Polyaniline-Eggshell Powder (PANI-ESP) CompositesSergioNo ratings yet

- TAD531GE: Volvo Penta Genset EngineDocument2 pagesTAD531GE: Volvo Penta Genset EngineMATS DIVISIONNo ratings yet

- Photoelastic Coatings PDFDocument2 pagesPhotoelastic Coatings PDFAnia Jeune AviatriceNo ratings yet

- 00-30juni 2023 Data Stok FLDocument98 pages00-30juni 2023 Data Stok FLSunaryo AryandaNo ratings yet

- Controller BrochureDocument4 pagesController BrochureShomasy Shomasy100% (2)

- Fuzzy SystemsDocument226 pagesFuzzy SystemsZelalem GirmaNo ratings yet

- Entropy: New Insights Into The Fractional Order Diffusion Equation Using Entropy and KurtosisDocument15 pagesEntropy: New Insights Into The Fractional Order Diffusion Equation Using Entropy and KurtosisBibin FrancisNo ratings yet

- Polaris Battery Labs: Case SummaryDocument2 pagesPolaris Battery Labs: Case SummaryHassanNo ratings yet

- Mercedes Actros Head FAHES - Vehicle Inspection Result 25-02-24Document1 pageMercedes Actros Head FAHES - Vehicle Inspection Result 25-02-24Sreeja LinNo ratings yet

- Quanta G31a Dag31amb6d0 Y61x-6l Rev 1aDocument49 pagesQuanta G31a Dag31amb6d0 Y61x-6l Rev 1aKrystian PalaciosNo ratings yet

- Structure AhmedabadDocument87 pagesStructure AhmedabadNandpal Prashant100% (1)

- Federal Register / Vol. 88, No. 81 / Thursday, April 27, 2023 / Proposed RulesDocument236 pagesFederal Register / Vol. 88, No. 81 / Thursday, April 27, 2023 / Proposed RulesSimon AlvarezNo ratings yet

- Precor 723e Manual-EnglishDocument28 pagesPrecor 723e Manual-EnglishGabriel SuarezNo ratings yet

- Alg 1 HWPDocument184 pagesAlg 1 HWPHaad MahmoodNo ratings yet

- A Study On Customer Satisfaction of Honda Activa In: ChennaiDocument65 pagesA Study On Customer Satisfaction of Honda Activa In: ChennaiSampath Bengalooru HudugaNo ratings yet

- Beating The Bonk QuestionsDocument1 pageBeating The Bonk Questionst3xxaNo ratings yet

- Fitgurlmel's 365 Food Guide by Melissa AlcantaraDocument27 pagesFitgurlmel's 365 Food Guide by Melissa AlcantaraSinem YukselNo ratings yet