Professional Documents

Culture Documents

Opticline CS Technical Data 2019 04 en

Opticline CS Technical Data 2019 04 en

Uploaded by

Doanh NguyenCopyright:

Available Formats

You might also like

- Opticline C Technical Data 2019 04 enDocument1 pageOpticline C Technical Data 2019 04 enDoanh NguyenNo ratings yet

- 180307-Prodcut Leafelt For NMD500 Series Metal Detector (Fat Man)Document2 pages180307-Prodcut Leafelt For NMD500 Series Metal Detector (Fat Man)Prima AdyNo ratings yet

- Strenx Tube 700QLH: General Product DescriptionDocument2 pagesStrenx Tube 700QLH: General Product Descriptionflastrico832No ratings yet

- Stainless Steel 1.4401 316Document3 pagesStainless Steel 1.4401 316Luis LoayzaNo ratings yet

- Data Sheet Raex 450Document3 pagesData Sheet Raex 450Amit GauravNo ratings yet

- Datasheet TBUT000400 enDocument2 pagesDatasheet TBUT000400 enpetkoNo ratings yet

- TDB-E-CM 725-Technisches DatenblattDocument2 pagesTDB-E-CM 725-Technisches DatenblattNarimane Benty100% (1)

- Large Exhaust FanDocument12 pagesLarge Exhaust Fanskarun500No ratings yet

- Waw 1000e 111Document18 pagesWaw 1000e 111ShemelsNo ratings yet

- Datasheet Robocut A C400ic ENDocument2 pagesDatasheet Robocut A C400ic ENbureau d'études techniques et méthodesNo ratings yet

- CHM 300 DTDocument2 pagesCHM 300 DTDaniel AceitunoNo ratings yet

- ROP-N3-C-065-W-G-L-B-B-B-NA: Product FeaturesDocument2 pagesROP-N3-C-065-W-G-L-B-B-B-NA: Product FeaturesChín Hồng NguyễnNo ratings yet

- Factors That Influence - PDF - XX PDFDocument43 pagesFactors That Influence - PDF - XX PDFharmlesdragonNo ratings yet

- RTL Series Linear Motion PotentiometerDocument2 pagesRTL Series Linear Motion Potentiometeralireza.str1995No ratings yet

- Fisa Tehnica Pentur Cablu Anti Incendiu JHSTH-2x2x0.8x500MDocument2 pagesFisa Tehnica Pentur Cablu Anti Incendiu JHSTH-2x2x0.8x500MSava SergiuNo ratings yet

- Torsion Testing MachineDocument5 pagesTorsion Testing Machinegosaye desalegnNo ratings yet

- Triple RRU SupportDocument2 pagesTriple RRU SupportVitalii LukianchikovNo ratings yet

- WP Dynamic Data-Sheet200925Document4 pagesWP Dynamic Data-Sheet200925Tan VuNo ratings yet

- HTM SeriesDocument6 pagesHTM Seriesys710924No ratings yet

- DA-acr-15D Directriz para El Muestreo de ProductosDocument1 pageDA-acr-15D Directriz para El Muestreo de Productossadit mayorcaNo ratings yet

- Product Specifications: CNT-300-300MDocument3 pagesProduct Specifications: CNT-300-300MsysloNo ratings yet

- CTS 30Document1 pageCTS 30Maria T YateNo ratings yet

- DS MMS33 enDocument5 pagesDS MMS33 engezhoubapichanakiNo ratings yet

- Arad Multi Jet Water MeterDocument2 pagesArad Multi Jet Water MeterJullian Gomez GregorioNo ratings yet

- Datasheet TBPU000083 enDocument2 pagesDatasheet TBPU000083 enzuda.ahamdNo ratings yet

- Technical Data S3Document2 pagesTechnical Data S3Mario AlejandroNo ratings yet

- Ds Lc15dx enDocument3 pagesDs Lc15dx enradule021No ratings yet

- Accutom10 100 Tech EnglishDocument2 pagesAccutom10 100 Tech EnglishDaniel CNo ratings yet

- TEST-E Series Computer Controlled Electro-Hydraulic Servo Universal Testing MachineDocument3 pagesTEST-E Series Computer Controlled Electro-Hydraulic Servo Universal Testing MachineCirclesOnSandNo ratings yet

- Model: TTE: Electronic Control Panel (Series: 9901)Document2 pagesModel: TTE: Electronic Control Panel (Series: 9901)poongodiskNo ratings yet

- Ultrasonic Thickness GaugeDocument5 pagesUltrasonic Thickness GaugecarlosNo ratings yet

- Ti64 PDFDocument5 pagesTi64 PDFqualityfreekNo ratings yet

- VM-3B ManualDocument2 pagesVM-3B ManualBHAART PANCHALNo ratings yet

- PALM Flat Scanner: For General Weld InspectionDocument4 pagesPALM Flat Scanner: For General Weld InspectionYoucef ChorfaNo ratings yet

- H 1000 2124 01 B - SP80 - DatasheetDocument4 pagesH 1000 2124 01 B - SP80 - DatasheetDarko MemarovicNo ratings yet

- Specialty Turbine Flowmeters: NufloDocument2 pagesSpecialty Turbine Flowmeters: NufloJose CameloNo ratings yet

- Strenx 700MC Plus: General Product DescriptionDocument1 pageStrenx 700MC Plus: General Product DescriptionMircea FloreaNo ratings yet

- BTU - LandisGyr-Ultraheat-Ultracold-T550-UH50Document6 pagesBTU - LandisGyr-Ultraheat-Ultracold-T550-UH50ahmed abdellahNo ratings yet

- Trigear Brochure - 2121 PDFDocument5 pagesTrigear Brochure - 2121 PDFDeep PatelNo ratings yet

- ROE-05-C-100-W-G-R-B-R-B-B-NA: Product FeaturesDocument2 pagesROE-05-C-100-W-G-R-B-R-B-B-NA: Product FeaturesChín Hồng NguyễnNo ratings yet

- Sefar Spécification: SEFAR TETEX MONO 03-1010-K 056 140 CM Numéro D' Article: 3B03-1000-140-00Document1 pageSefar Spécification: SEFAR TETEX MONO 03-1010-K 056 140 CM Numéro D' Article: 3B03-1000-140-00Bkiri AbderrahimNo ratings yet

- Drilling Machine TR40Document1 pageDrilling Machine TR40عمر عمرNo ratings yet

- MAG-DS-00508-EN ModMAG M7600 Electromagnetic Flow Meters Product Data SheetDocument4 pagesMAG-DS-00508-EN ModMAG M7600 Electromagnetic Flow Meters Product Data SheetPhilippe jean-louisNo ratings yet

- CMM Coordinate Measuring MachinesDocument16 pagesCMM Coordinate Measuring MachinesDoanh NguyenNo ratings yet

- WMTCNC CNC Lathe Machines (Slant Bed & Flat Bed Lathe)Document118 pagesWMTCNC CNC Lathe Machines (Slant Bed & Flat Bed Lathe)walid ben khedherNo ratings yet

- Liebherr Measuring Instruments WGT 280 1200Document8 pagesLiebherr Measuring Instruments WGT 280 1200CAT MINING SHOVELNo ratings yet

- 1.4401 EnglDocument4 pages1.4401 EnglpdmsNo ratings yet

- Detection Distance of 100 MM For Both Ferrous and Non-Ferrous SubstancesDocument6 pagesDetection Distance of 100 MM For Both Ferrous and Non-Ferrous SubstancesSebastian-Ionut ValacheNo ratings yet

- MP 35Document9 pagesMP 35jailsonNo ratings yet

- Suzhou Hanxin Machinery CatalogueDocument19 pagesSuzhou Hanxin Machinery CatalogueKhaled BOUALINo ratings yet

- Features: Advantages:: Semi-Automatic Balancing MachineDocument2 pagesFeatures: Advantages:: Semi-Automatic Balancing Machinelipeng828No ratings yet

- CMC mvm001 Vibration Sensor Ds Rev A00Document2 pagesCMC mvm001 Vibration Sensor Ds Rev A00bianhuiNo ratings yet

- TDC 09 - R1 - S690 QL & Weldox 700Document2 pagesTDC 09 - R1 - S690 QL & Weldox 700Thennarasu VelloreNo ratings yet

- Automatic Compression Testers For Cylinders: SeriesDocument4 pagesAutomatic Compression Testers For Cylinders: SeriesJosé Fco. Cerda M.No ratings yet

- Stainless Steel 1.4404 316lDocument3 pagesStainless Steel 1.4404 316lDilipSinghNo ratings yet

- Stainless Steel 1.4404 316lDocument3 pagesStainless Steel 1.4404 316lDilipSinghNo ratings yet

- Now IP 66: Krautkramer USM 32XDocument2 pagesNow IP 66: Krautkramer USM 32XZouhair BenmabroukNo ratings yet

- Datasheet Strenx 700E - en - 2016Document3 pagesDatasheet Strenx 700E - en - 2016peterNo ratings yet

- Brochuresmx 1000 SMX 1000 LC 251 e 023 ADocument18 pagesBrochuresmx 1000 SMX 1000 LC 251 e 023 ADoanh NguyenNo ratings yet

- Xslicer-SMX 160 KVDocument16 pagesXslicer-SMX 160 KVDoanh NguyenNo ratings yet

- TA7000series ProductGuide Eng Mar2016 SDocument44 pagesTA7000series ProductGuide Eng Mar2016 SDoanh NguyenNo ratings yet

- Powertrain REVO RetrofitDocument4 pagesPowertrain REVO RetrofitDoanh NguyenNo ratings yet

- CMM Coordinate Measuring MachinesDocument16 pagesCMM Coordinate Measuring MachinesDoanh NguyenNo ratings yet

- PSS-40 Solution Rev 2Document20 pagesPSS-40 Solution Rev 2Doanh NguyenNo ratings yet

- Industrial X-Ray and CTDocument7 pagesIndustrial X-Ray and CTDoanh NguyenNo ratings yet

- Altera - ENDocument8 pagesAltera - ENDoanh NguyenNo ratings yet

- Nikon Solutions enDocument21 pagesNikon Solutions enDoanh NguyenNo ratings yet

- 2ce Iwhh 10Document7 pages2ce Iwhh 10Doanh NguyenNo ratings yet

- L300L200 FinalDocument5 pagesL300L200 FinalDoanh NguyenNo ratings yet

- Nexiv VMZ H en - NewDocument3 pagesNexiv VMZ H en - NewDoanh NguyenNo ratings yet

- ByprovinceDocument128 pagesByprovinceLun Do100% (1)

- Design and Develoment of Vertical Lifting Bridge Ijariie14643Document8 pagesDesign and Develoment of Vertical Lifting Bridge Ijariie14643Anshika MendheNo ratings yet

- Fabrication & Certification LPG Tank:: 0: 10-Feb-20:::: Field Inspection & Test Plan (Itp)Document3 pagesFabrication & Certification LPG Tank:: 0: 10-Feb-20:::: Field Inspection & Test Plan (Itp)Rifki HasyaNo ratings yet

- Effect of Resonance Frequency, Power Input, and Saturation Gas Type On The Oxidation Efficiency of An Ultrasound HornDocument7 pagesEffect of Resonance Frequency, Power Input, and Saturation Gas Type On The Oxidation Efficiency of An Ultrasound HornHamza FerkousNo ratings yet

- Fot Sing 2005Document4 pagesFot Sing 2005DieseNo ratings yet

- Universal Manuscript Template For Optica Publishing Group JournalsDocument6 pagesUniversal Manuscript Template For Optica Publishing Group JournalsFresh Prince Of NigeriaNo ratings yet

- CE70-Structural Theory: Analysis of Statically Determinate StructuresDocument12 pagesCE70-Structural Theory: Analysis of Statically Determinate StructuresJaymark S. GicaleNo ratings yet

- Beta Monic Ai-MonicaiDocument2 pagesBeta Monic Ai-MonicaiJAYAKUMARNo ratings yet

- (Asce) 1090-0241 (2006) 132 6Document10 pages(Asce) 1090-0241 (2006) 132 6Tarek KhallafNo ratings yet

- Assess Your Understanding: Are You Prepared?Document5 pagesAssess Your Understanding: Are You Prepared?GoldNo ratings yet

- Stergianos Calibration 2022Document292 pagesStergianos Calibration 2022laronasaboneNo ratings yet

- BS 8110-2 Structural Use Of...Document93 pagesBS 8110-2 Structural Use Of...ndesigngmail50% (2)

- Nonlinear Static Seismic Performance Assessment of Plan-Irregular Steel StructuresDocument29 pagesNonlinear Static Seismic Performance Assessment of Plan-Irregular Steel Structuresrithy khouyNo ratings yet

- Soil Comp Action Test Report by Yasas89Document6 pagesSoil Comp Action Test Report by Yasas89yasas8991% (11)

- Force and Laws of Motion Chapter 2 Notes Part2Document4 pagesForce and Laws of Motion Chapter 2 Notes Part2A48 SHAIKH WAJIDNo ratings yet

- Emd Part1Document414 pagesEmd Part1kgrhoads100% (3)

- Penentuan Uji Kelarutan KTI ParacetamolDocument6 pagesPenentuan Uji Kelarutan KTI ParacetamolMinul1412No ratings yet

- Sample QP 1 - 12th Maths - Pre Board Feb 2023 - 2024Document6 pagesSample QP 1 - 12th Maths - Pre Board Feb 2023 - 2024cuddalorespeakeasyNo ratings yet

- Highway Engineering Lab ManualDocument68 pagesHighway Engineering Lab ManualRamBhuvan SonkarNo ratings yet

- Certificado Del Estandar de Referencia para IrDocument7 pagesCertificado Del Estandar de Referencia para IrVERONICANo ratings yet

- MSD BhattaDocument180 pagesMSD Bhattarakesh hyalijNo ratings yet

- Sikafloor 225N: UV Resistant Epoxy SystemDocument4 pagesSikafloor 225N: UV Resistant Epoxy SystemBudhi KurniawanNo ratings yet

- Optimal Particle Size Distribution of White Sugar: Optimálizácia Rozdelenia Častíc Bieleho CukruDocument7 pagesOptimal Particle Size Distribution of White Sugar: Optimálizácia Rozdelenia Častíc Bieleho CukruClifford Dwight RicanorNo ratings yet

- Product Certificate Welding Wire-ModelDocument1 pageProduct Certificate Welding Wire-ModelRamona CrangasNo ratings yet

- Manufacturing of Solid Dosage FormsDocument73 pagesManufacturing of Solid Dosage FormsNitin SheokandNo ratings yet

- Enhanced In-Situ Testing 2000Document24 pagesEnhanced In-Situ Testing 2000Sorabh GuptaNo ratings yet

- Multi-Level Single-Channel Speech Enhancement Using A Unified Framework For Estimating Magnitude and Phase SpectraDocument13 pagesMulti-Level Single-Channel Speech Enhancement Using A Unified Framework For Estimating Magnitude and Phase Spectrapravin2275767No ratings yet

- SM 04 Mechanical Analysis of SoilDocument31 pagesSM 04 Mechanical Analysis of SoilKamran KhanNo ratings yet

- Week 5 7.9 Identify Equivalent ExpressionsDocument3 pagesWeek 5 7.9 Identify Equivalent Expressionsmatthew ChapmanNo ratings yet

- 03 Uppercat Free Upcat KeyDocument40 pages03 Uppercat Free Upcat Keyadrian suppNo ratings yet

- MDB Part 1Document22 pagesMDB Part 1Michelle Angela Cabrera GabisNo ratings yet

Opticline CS Technical Data 2019 04 en

Opticline CS Technical Data 2019 04 en

Uploaded by

Doanh NguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Opticline CS Technical Data 2019 04 en

Opticline CS Technical Data 2019 04 en

Uploaded by

Doanh NguyenCopyright:

Available Formats

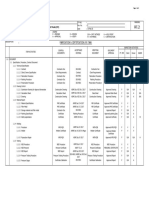

Technical data Opticline CS

Model1) CS155 CS305 CS308 CS314 CS608 CS614

Measuring capacity [mm]

Max. diameter 50 50 80 140 80 140

Length 150 300 300 300 600 600

Workpiece capacity

Diameter [mm] 90 90 90 150 90 150

Length [mm] 150 300 300 300 600 600

Workpiece weight2) [N] 100 150 150 200 200 200

Resolution

Diameter, length ≤0.2 μm

Rotation 0.0018°

Accuracy / MPE3)

Diameter (2.0+D[mm]/100) μm

Length (5.0+L[mm]/100) μm

Copyright © JENOPTIK Industrial Metrology Germany GmbH. All rights reserved. Pictures may show options and are not legally binding. Subject to change without notice.

Repeatability (4s)4)

Diameter 0.5 μm

Length 3.0 μm

Speed

Measuring automatically optimized: 10 – 80 mm/s

Measuring rotation 1 rps

Positioning 200 mm/s

Positioning rotation 1 rps

Measuring cycle dependent on type and number of test characteristics – typically 3 ... 30 s

Dimensions [mm]

Measuring system [BxTxH] 690 x 570 x 920 690 x 570 x 1070 690 x 570 x1070 700 x 750 x 1190 700 x 750 x1490 700 x 750 x 1490

Weight [kg]

Measuring system5) 110 160 165 230 250 265

Clamping tool interfaces

Morse taper headstock MT2

Morse taper tailstock MT2

Clamping stroke tailstock manual, 20 mm

Power supply

Connection AC-PH, N, PE

Voltage 200 – 240/100 – 120 V (127 V on demand)

Power frequency 50/60 Hz

Max. consumption 1.5 kVA

Fuse 16 A

Option tactile probing system

TSP -

BTS -

T3D -

1)

Environmental conditions: not chemically aggressive, not explosive, not radioactive. Temperature range from +10° C to +40° C, max. relative humidity 85 % without condensation.

Dust aerosol values: according to TRGS 900 (Industrial safety regulations and technical rules for workplace environment and hazardous substances).

2)

Workpiece positioning without knocks or strong lateral forces. Max. mass moment of inertia: 0.04 kg/m². Improper workpiece positioning may damage the headstock or bearings.

3)

Maximum permissible error according to EN ISO 10360 / VDI/VDE 2617, relating to DAkkS reference standard (uncertainty D: 0.3 μm and L: 0.4 μm). Environmental conditions

in accordance with VDI/VDE 2617, 18 – 22° C, class 3 (gradient 1 K/h, 2 K/24h, 0.5 k/m). Mechanical ambient conditions in accordance with EN 60721-3-3 class 3M1.

4)

Typical range over 25 repeat measurements on ground part surfaces. In accordance with VIM, International Dictionary of Metrology.

5)

Weight depends on configuration in terms of variants and options.

2019-04

Opticline CS technical data en

JENOPTIK Industrial Metrology Germany GmbH | Alte Tuttlinger Strasse 20 | 78056 Villingen-Schwenningen | Germany

P +49 7720 602-0 | F +49 7720 602-444 | metrology@jenoptik.com | www.jenoptik.com/metrology

You might also like

- Opticline C Technical Data 2019 04 enDocument1 pageOpticline C Technical Data 2019 04 enDoanh NguyenNo ratings yet

- 180307-Prodcut Leafelt For NMD500 Series Metal Detector (Fat Man)Document2 pages180307-Prodcut Leafelt For NMD500 Series Metal Detector (Fat Man)Prima AdyNo ratings yet

- Strenx Tube 700QLH: General Product DescriptionDocument2 pagesStrenx Tube 700QLH: General Product Descriptionflastrico832No ratings yet

- Stainless Steel 1.4401 316Document3 pagesStainless Steel 1.4401 316Luis LoayzaNo ratings yet

- Data Sheet Raex 450Document3 pagesData Sheet Raex 450Amit GauravNo ratings yet

- Datasheet TBUT000400 enDocument2 pagesDatasheet TBUT000400 enpetkoNo ratings yet

- TDB-E-CM 725-Technisches DatenblattDocument2 pagesTDB-E-CM 725-Technisches DatenblattNarimane Benty100% (1)

- Large Exhaust FanDocument12 pagesLarge Exhaust Fanskarun500No ratings yet

- Waw 1000e 111Document18 pagesWaw 1000e 111ShemelsNo ratings yet

- Datasheet Robocut A C400ic ENDocument2 pagesDatasheet Robocut A C400ic ENbureau d'études techniques et méthodesNo ratings yet

- CHM 300 DTDocument2 pagesCHM 300 DTDaniel AceitunoNo ratings yet

- ROP-N3-C-065-W-G-L-B-B-B-NA: Product FeaturesDocument2 pagesROP-N3-C-065-W-G-L-B-B-B-NA: Product FeaturesChín Hồng NguyễnNo ratings yet

- Factors That Influence - PDF - XX PDFDocument43 pagesFactors That Influence - PDF - XX PDFharmlesdragonNo ratings yet

- RTL Series Linear Motion PotentiometerDocument2 pagesRTL Series Linear Motion Potentiometeralireza.str1995No ratings yet

- Fisa Tehnica Pentur Cablu Anti Incendiu JHSTH-2x2x0.8x500MDocument2 pagesFisa Tehnica Pentur Cablu Anti Incendiu JHSTH-2x2x0.8x500MSava SergiuNo ratings yet

- Torsion Testing MachineDocument5 pagesTorsion Testing Machinegosaye desalegnNo ratings yet

- Triple RRU SupportDocument2 pagesTriple RRU SupportVitalii LukianchikovNo ratings yet

- WP Dynamic Data-Sheet200925Document4 pagesWP Dynamic Data-Sheet200925Tan VuNo ratings yet

- HTM SeriesDocument6 pagesHTM Seriesys710924No ratings yet

- DA-acr-15D Directriz para El Muestreo de ProductosDocument1 pageDA-acr-15D Directriz para El Muestreo de Productossadit mayorcaNo ratings yet

- Product Specifications: CNT-300-300MDocument3 pagesProduct Specifications: CNT-300-300MsysloNo ratings yet

- CTS 30Document1 pageCTS 30Maria T YateNo ratings yet

- DS MMS33 enDocument5 pagesDS MMS33 engezhoubapichanakiNo ratings yet

- Arad Multi Jet Water MeterDocument2 pagesArad Multi Jet Water MeterJullian Gomez GregorioNo ratings yet

- Datasheet TBPU000083 enDocument2 pagesDatasheet TBPU000083 enzuda.ahamdNo ratings yet

- Technical Data S3Document2 pagesTechnical Data S3Mario AlejandroNo ratings yet

- Ds Lc15dx enDocument3 pagesDs Lc15dx enradule021No ratings yet

- Accutom10 100 Tech EnglishDocument2 pagesAccutom10 100 Tech EnglishDaniel CNo ratings yet

- TEST-E Series Computer Controlled Electro-Hydraulic Servo Universal Testing MachineDocument3 pagesTEST-E Series Computer Controlled Electro-Hydraulic Servo Universal Testing MachineCirclesOnSandNo ratings yet

- Model: TTE: Electronic Control Panel (Series: 9901)Document2 pagesModel: TTE: Electronic Control Panel (Series: 9901)poongodiskNo ratings yet

- Ultrasonic Thickness GaugeDocument5 pagesUltrasonic Thickness GaugecarlosNo ratings yet

- Ti64 PDFDocument5 pagesTi64 PDFqualityfreekNo ratings yet

- VM-3B ManualDocument2 pagesVM-3B ManualBHAART PANCHALNo ratings yet

- PALM Flat Scanner: For General Weld InspectionDocument4 pagesPALM Flat Scanner: For General Weld InspectionYoucef ChorfaNo ratings yet

- H 1000 2124 01 B - SP80 - DatasheetDocument4 pagesH 1000 2124 01 B - SP80 - DatasheetDarko MemarovicNo ratings yet

- Specialty Turbine Flowmeters: NufloDocument2 pagesSpecialty Turbine Flowmeters: NufloJose CameloNo ratings yet

- Strenx 700MC Plus: General Product DescriptionDocument1 pageStrenx 700MC Plus: General Product DescriptionMircea FloreaNo ratings yet

- BTU - LandisGyr-Ultraheat-Ultracold-T550-UH50Document6 pagesBTU - LandisGyr-Ultraheat-Ultracold-T550-UH50ahmed abdellahNo ratings yet

- Trigear Brochure - 2121 PDFDocument5 pagesTrigear Brochure - 2121 PDFDeep PatelNo ratings yet

- ROE-05-C-100-W-G-R-B-R-B-B-NA: Product FeaturesDocument2 pagesROE-05-C-100-W-G-R-B-R-B-B-NA: Product FeaturesChín Hồng NguyễnNo ratings yet

- Sefar Spécification: SEFAR TETEX MONO 03-1010-K 056 140 CM Numéro D' Article: 3B03-1000-140-00Document1 pageSefar Spécification: SEFAR TETEX MONO 03-1010-K 056 140 CM Numéro D' Article: 3B03-1000-140-00Bkiri AbderrahimNo ratings yet

- Drilling Machine TR40Document1 pageDrilling Machine TR40عمر عمرNo ratings yet

- MAG-DS-00508-EN ModMAG M7600 Electromagnetic Flow Meters Product Data SheetDocument4 pagesMAG-DS-00508-EN ModMAG M7600 Electromagnetic Flow Meters Product Data SheetPhilippe jean-louisNo ratings yet

- CMM Coordinate Measuring MachinesDocument16 pagesCMM Coordinate Measuring MachinesDoanh NguyenNo ratings yet

- WMTCNC CNC Lathe Machines (Slant Bed & Flat Bed Lathe)Document118 pagesWMTCNC CNC Lathe Machines (Slant Bed & Flat Bed Lathe)walid ben khedherNo ratings yet

- Liebherr Measuring Instruments WGT 280 1200Document8 pagesLiebherr Measuring Instruments WGT 280 1200CAT MINING SHOVELNo ratings yet

- 1.4401 EnglDocument4 pages1.4401 EnglpdmsNo ratings yet

- Detection Distance of 100 MM For Both Ferrous and Non-Ferrous SubstancesDocument6 pagesDetection Distance of 100 MM For Both Ferrous and Non-Ferrous SubstancesSebastian-Ionut ValacheNo ratings yet

- MP 35Document9 pagesMP 35jailsonNo ratings yet

- Suzhou Hanxin Machinery CatalogueDocument19 pagesSuzhou Hanxin Machinery CatalogueKhaled BOUALINo ratings yet

- Features: Advantages:: Semi-Automatic Balancing MachineDocument2 pagesFeatures: Advantages:: Semi-Automatic Balancing Machinelipeng828No ratings yet

- CMC mvm001 Vibration Sensor Ds Rev A00Document2 pagesCMC mvm001 Vibration Sensor Ds Rev A00bianhuiNo ratings yet

- TDC 09 - R1 - S690 QL & Weldox 700Document2 pagesTDC 09 - R1 - S690 QL & Weldox 700Thennarasu VelloreNo ratings yet

- Automatic Compression Testers For Cylinders: SeriesDocument4 pagesAutomatic Compression Testers For Cylinders: SeriesJosé Fco. Cerda M.No ratings yet

- Stainless Steel 1.4404 316lDocument3 pagesStainless Steel 1.4404 316lDilipSinghNo ratings yet

- Stainless Steel 1.4404 316lDocument3 pagesStainless Steel 1.4404 316lDilipSinghNo ratings yet

- Now IP 66: Krautkramer USM 32XDocument2 pagesNow IP 66: Krautkramer USM 32XZouhair BenmabroukNo ratings yet

- Datasheet Strenx 700E - en - 2016Document3 pagesDatasheet Strenx 700E - en - 2016peterNo ratings yet

- Brochuresmx 1000 SMX 1000 LC 251 e 023 ADocument18 pagesBrochuresmx 1000 SMX 1000 LC 251 e 023 ADoanh NguyenNo ratings yet

- Xslicer-SMX 160 KVDocument16 pagesXslicer-SMX 160 KVDoanh NguyenNo ratings yet

- TA7000series ProductGuide Eng Mar2016 SDocument44 pagesTA7000series ProductGuide Eng Mar2016 SDoanh NguyenNo ratings yet

- Powertrain REVO RetrofitDocument4 pagesPowertrain REVO RetrofitDoanh NguyenNo ratings yet

- CMM Coordinate Measuring MachinesDocument16 pagesCMM Coordinate Measuring MachinesDoanh NguyenNo ratings yet

- PSS-40 Solution Rev 2Document20 pagesPSS-40 Solution Rev 2Doanh NguyenNo ratings yet

- Industrial X-Ray and CTDocument7 pagesIndustrial X-Ray and CTDoanh NguyenNo ratings yet

- Altera - ENDocument8 pagesAltera - ENDoanh NguyenNo ratings yet

- Nikon Solutions enDocument21 pagesNikon Solutions enDoanh NguyenNo ratings yet

- 2ce Iwhh 10Document7 pages2ce Iwhh 10Doanh NguyenNo ratings yet

- L300L200 FinalDocument5 pagesL300L200 FinalDoanh NguyenNo ratings yet

- Nexiv VMZ H en - NewDocument3 pagesNexiv VMZ H en - NewDoanh NguyenNo ratings yet

- ByprovinceDocument128 pagesByprovinceLun Do100% (1)

- Design and Develoment of Vertical Lifting Bridge Ijariie14643Document8 pagesDesign and Develoment of Vertical Lifting Bridge Ijariie14643Anshika MendheNo ratings yet

- Fabrication & Certification LPG Tank:: 0: 10-Feb-20:::: Field Inspection & Test Plan (Itp)Document3 pagesFabrication & Certification LPG Tank:: 0: 10-Feb-20:::: Field Inspection & Test Plan (Itp)Rifki HasyaNo ratings yet

- Effect of Resonance Frequency, Power Input, and Saturation Gas Type On The Oxidation Efficiency of An Ultrasound HornDocument7 pagesEffect of Resonance Frequency, Power Input, and Saturation Gas Type On The Oxidation Efficiency of An Ultrasound HornHamza FerkousNo ratings yet

- Fot Sing 2005Document4 pagesFot Sing 2005DieseNo ratings yet

- Universal Manuscript Template For Optica Publishing Group JournalsDocument6 pagesUniversal Manuscript Template For Optica Publishing Group JournalsFresh Prince Of NigeriaNo ratings yet

- CE70-Structural Theory: Analysis of Statically Determinate StructuresDocument12 pagesCE70-Structural Theory: Analysis of Statically Determinate StructuresJaymark S. GicaleNo ratings yet

- Beta Monic Ai-MonicaiDocument2 pagesBeta Monic Ai-MonicaiJAYAKUMARNo ratings yet

- (Asce) 1090-0241 (2006) 132 6Document10 pages(Asce) 1090-0241 (2006) 132 6Tarek KhallafNo ratings yet

- Assess Your Understanding: Are You Prepared?Document5 pagesAssess Your Understanding: Are You Prepared?GoldNo ratings yet

- Stergianos Calibration 2022Document292 pagesStergianos Calibration 2022laronasaboneNo ratings yet

- BS 8110-2 Structural Use Of...Document93 pagesBS 8110-2 Structural Use Of...ndesigngmail50% (2)

- Nonlinear Static Seismic Performance Assessment of Plan-Irregular Steel StructuresDocument29 pagesNonlinear Static Seismic Performance Assessment of Plan-Irregular Steel Structuresrithy khouyNo ratings yet

- Soil Comp Action Test Report by Yasas89Document6 pagesSoil Comp Action Test Report by Yasas89yasas8991% (11)

- Force and Laws of Motion Chapter 2 Notes Part2Document4 pagesForce and Laws of Motion Chapter 2 Notes Part2A48 SHAIKH WAJIDNo ratings yet

- Emd Part1Document414 pagesEmd Part1kgrhoads100% (3)

- Penentuan Uji Kelarutan KTI ParacetamolDocument6 pagesPenentuan Uji Kelarutan KTI ParacetamolMinul1412No ratings yet

- Sample QP 1 - 12th Maths - Pre Board Feb 2023 - 2024Document6 pagesSample QP 1 - 12th Maths - Pre Board Feb 2023 - 2024cuddalorespeakeasyNo ratings yet

- Highway Engineering Lab ManualDocument68 pagesHighway Engineering Lab ManualRamBhuvan SonkarNo ratings yet

- Certificado Del Estandar de Referencia para IrDocument7 pagesCertificado Del Estandar de Referencia para IrVERONICANo ratings yet

- MSD BhattaDocument180 pagesMSD Bhattarakesh hyalijNo ratings yet

- Sikafloor 225N: UV Resistant Epoxy SystemDocument4 pagesSikafloor 225N: UV Resistant Epoxy SystemBudhi KurniawanNo ratings yet

- Optimal Particle Size Distribution of White Sugar: Optimálizácia Rozdelenia Častíc Bieleho CukruDocument7 pagesOptimal Particle Size Distribution of White Sugar: Optimálizácia Rozdelenia Častíc Bieleho CukruClifford Dwight RicanorNo ratings yet

- Product Certificate Welding Wire-ModelDocument1 pageProduct Certificate Welding Wire-ModelRamona CrangasNo ratings yet

- Manufacturing of Solid Dosage FormsDocument73 pagesManufacturing of Solid Dosage FormsNitin SheokandNo ratings yet

- Enhanced In-Situ Testing 2000Document24 pagesEnhanced In-Situ Testing 2000Sorabh GuptaNo ratings yet

- Multi-Level Single-Channel Speech Enhancement Using A Unified Framework For Estimating Magnitude and Phase SpectraDocument13 pagesMulti-Level Single-Channel Speech Enhancement Using A Unified Framework For Estimating Magnitude and Phase Spectrapravin2275767No ratings yet

- SM 04 Mechanical Analysis of SoilDocument31 pagesSM 04 Mechanical Analysis of SoilKamran KhanNo ratings yet

- Week 5 7.9 Identify Equivalent ExpressionsDocument3 pagesWeek 5 7.9 Identify Equivalent Expressionsmatthew ChapmanNo ratings yet

- 03 Uppercat Free Upcat KeyDocument40 pages03 Uppercat Free Upcat Keyadrian suppNo ratings yet

- MDB Part 1Document22 pagesMDB Part 1Michelle Angela Cabrera GabisNo ratings yet