Professional Documents

Culture Documents

Aramid Yt510

Aramid Yt510

Uploaded by

Srinath SelvakumaranCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aramid Yt510

Aramid Yt510

Uploaded by

Srinath SelvakumaranCopyright:

Available Formats

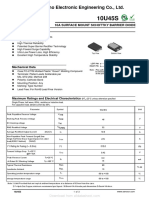

YT510 Technical Data Sheet

180

YT510, a calendered paper,

Percent of Room Temperature Value, %

160

offers excellent dielectric strength, mechanical Dielectrc Constant

140

properties, flexibility and resilience. There are 120

100 Dissipation Factor

9 thicknesses, from 2 mil to 30 mil (0.05mm to

80

0.76mm). YT510 is used in almost every 60 Dielectrc Strength

40

known electrical sheet insulation applications.

20

High temperature resistance YT510 can offer 0

0

RT 50 100 150 200 250 300

short-term overloading. Temperature,℃

Figure 1-a Effect of Temperature on

Electrical Properties Electric Properties of Metastar® 510 Paper

19

The typical electrical property values for Surface Resistivity,Volume Resistivity, ·m 10

18

10

YT510 paper are shown in Table1. 17

10

The AC Rapid Rise dielectric strength data of 10

16

Surface Resistivity

15

10

Table1, representing voltage stress levels, 14

10

withstood immediate at a frequency of 50Hz. 10

13

12

10 Volume Resistivity

11

10

Figure 1 shown temperature effect on 10

10

0

RT 50 100 150 200 250 300

dielectric capacity (0.08mm, 3mil). As shown Temperature,℃

in Figure 1, Temperature has a minor effect on Figure 1-b Effect of Temperature on

electric properties and resistivity versus. Resistivity Versus of Metastar® 510 Paper

Table 1 Typical Electrical Properties of YT510 Aramid Paper

mil 2 3 5 7 10 12 15 20 30

Nominal Thickness

mm 0.05 0.08 0.13 0.18 0.25 0.30 0.38 0.51 0.76

V/mil 330 355 450 500 550 575 500 450 475

Dielectric Strength 1)

kV/mm 13 14 18 20 22 23 20 18 19

Dielectric Constant 2) — 1.5 1.5 2.1 2.4 2.5 2.7 3.0 3.1 3.2

Dissipation Factor 2) ×10-3 4 5 6 7 8 8 8 8 8

1)Testing standard GB/T1408.1-2006,using Ф25 mm top electrode and Ф75 mmbottom electrode;

2)Testing standard GB/T1409-2006,usingФ50 mm electrode and 50Hz test frequency.

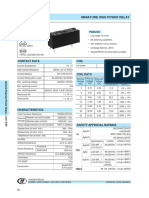

The effects of moisture (humidity) on the Mechanical Properties

electrical properties of YT510 are YT510 have compact structure,

shown in Table 2. It shows that it only have smooth surface, stable size and excellent

minor effect on electrical parameters. mechanical properties. Table 3 is the typical

mechanical properties of YT510.

Table 2 Effect of Humidity on

Resistivity Versus of Metastar® 510 Paper

Figure 2 and 3 reflects the temperature and

Relative Humidity % OD 50 95 moisture effect on mechanical properties of

Dielectric Strength kV/mm 16.4 16.2 15.6 YT510 paper. The influence of two

Dielectric Constant — 2.1 2.1 2.1 factors are similar, like elongation, tear strength

Dissipation Factor ×10-3 5.3 6.0 5.9 and toughness are improved, tensile strength are

Ω small decreased. We suggest that the paper should

Surface Resistivity 13 1600 160 0.0025

×10

be kept sealed in its protective polyethylene

Ω·m wrapper, to maintain uniform moisture content,

Volume Resistivity 13 11 36 0.0330

×10

until just before use.

Table 3 Typical Mechanical Properties of YT510 Aramid Paper

Nominal mil 2 3 5 7 10 12 15 20 30

Testing standard

Thickness mm 0.05 0.08 0.13 0.18 0.25 0.30 0.38 0.51 0.76

Typical

mm 0.055 0.078 0.13 0.18 0.245 0.29 0.365 0.515 0.755 GB/T451.3-2002

Thickness

Basis Weight g/m2 41 63 116 175 249 309 390 510 690 GB/T451.2-2002

Density g/cc 0.74 0.80 0.90 0.97 1.01 1.06 1.07 1.00 0.91

Tensile MD 39 66 140 220 255 320 380 500 650

Strength

N/cm CD 15 29 56 105 165 200 260 345 450

GB/T12914-2008

MD 7.0 8.5 10.0 11.0 13.5 16 13 13 13

Elongation%

CD 6.5 9.0 11.5 12.5 14.5 15.5 12 13 12

Tear MD 0.65 1.00 2.00 3.50 5.00 6.50 10.00 13 N/A

)

Strength3 GB/T455-2002

N CD 1.15 1.70 3.30 4.80 6.00 8.00 13.50 16 N/A

Shrinkage MD 3.5 3.5 3.0 3.0 3.0 3.0 3.0 3.0 3.0

at 300℃

CD 3.0 3.0 2.5 2.5 2.5 2.5 2.5 2.0 2.0 IEC60819-2:2002

%

3)Elmendorf tear strength, MD=Machine direction, CD=Cross direction.

160

120

Percent of Room Temperature Value

Elongation MD 140

Elongation MD

100

Percent of Bone-dry Value

120

80 100

Tensile Strength MD

80 Tensile Strength MD

60

60

40

40

20

20

0 0

0

RT 50 100 150 200 OD

0 20 40 60 80 100

Temperature,℃ Relative Humidity, %

Figure 2 Temperature Effect on Mechanical properties Figure 3 Humidity Effect on Mechanical properties

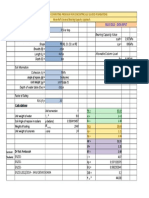

Terminal Property

when under 400, it could remain high

Terminal property is an important property

mechanical properties for 18.1hours.

of aramid paper. it represents the work ability

of long-time exposure of paper to high

Terminal conductivity, the thermophysical

temperature. paper is confirmed as

property of solid materials, represents the ability

220℃ insulation by UL, and also confirmed by

of conduct terminal about insulation materials.

many years’ application.

It determines radiating ability of massive

structure. The conductivity of paper

Figure 4 is the relationship between paper’s

is closed to fiber paper, and is positively

useful life and temperature. Through Arrhenius

correlated with density, as shown in Figure 5.

aging equation, the RTI of YT510’s is 215.4℃,

6 260

Aging time, Hr to 50% of Initial Strength in MD

10

240

220

Thermal Conductivity, mW/mK

5 200

10

180

160

5474.21

lg time 6.87 140

10

4 T 273

120

100

80

3

10 60

40

20

2

10 0

100 140 180 220 260 300 340 380 50 100 150 200 250 300

Temperature,℃ Temperature, ℃

Figure 4 Useful life Versus Temperature Figure 5 Thermal Conductivity Versus Temperature

of Metastar® 510-0.05mm (2mil) Paper for Metastar® 510-0.25mm (10mil) Paper

Chemical Stability

YT510 have excellent chemi The limiting Oxygen of YT

-cal stability. Owing to its stable molecular 510 is over 28%, it will not support combustion

structure and corrosion resistance, it has a or fusion in the ambient air., It forms thermal

slight softening and swelling effect on paper, insulation protection layer under high

like Figure 6. The compatibility of YT510 temperature in its surface, and own UL94

paper and its pressboard with virtually all VTM-0 and V-0 certification, Besides, it has

classes of electrical varnishes and adhesives, as nice outstanding resistance, that let YT510

well as transformer fluids and with lubricating could use in critical control equipment for

oils and refrigerants is absolutely good. high-radiation application.

Ethanol Acetone Toluene Xylene Silicone Oil Transformer Oil

Ethanol Acetone Toluene Xylene Silicone Oil Transformer Oil

100.4100.4 100.5

Percent of original dimension, %

130

Percent of original dimension, %

100.2

100.2100.0 100.0

125

99.8 99.5

100.0 99.0

120

97.8

99.8 97.6 98.5

110

97.4 98.0 105

97.8 97.2 97.5

97.0 100

0 10 20 30 40 50 60 70 0 10 20 30 40 50 60 70 0 10 20 30 40 50 60 70

97.6 时间/天

Time, D

Time, D

Time, 时间/天

Time, D

97.4

(a)MD size (b)CD size (c)Thickness size

97.2104 240

Percent of original property value,%

150

220

97.0 102

140 200

1000 10 20 30 40 50 60 70

130 180

98

120 Time, D 160

96

110

94

92 100 90

90 90

70

0 10 20 30 40 50 60 70 0 10 20 30 40 50 60 70 0 10 20 30 40 50 60 70

Time, D

Time, D

时间/天

Time, D 时间/天

Time, D

(d)Tensile strength ( MD ) (e)Elongation (MD ) (f)Dielectric strength

Figure 6 Chemical stability of Metastar® YT510-0.08mm Paper

Please note:

Yantai Metastar Special Paper Co.,Lod. The properties are average values and should not be used as

Tel:0086-535-69551622 specification limits. All properties were measured in air under

请注意

Fax:0086-535-6931150 23°C, 50%RH. Metastar® papers have machine direction(MD)

Add:No.1 Emeishan Rd., ETDZ, Yantai, China 264006 and cross direction(XD). Please orient the paper in the optimum

Http://www.metastar.cn direction to obtainits maximum potential performance.

You might also like

- Full Revised Specification For Well Head Control PanelDocument105 pagesFull Revised Specification For Well Head Control Panelamjath584100% (12)

- Service Training 3412-3625 - EngineDocument1,192 pagesService Training 3412-3625 - EngineTuan Pham100% (2)

- Abc of Capacitors: Basic PrinciplesFrom EverandAbc of Capacitors: Basic PrinciplesWürth ElektronikNo ratings yet

- S-0701-PE Chief Engineer's ReportDocument2 pagesS-0701-PE Chief Engineer's ReportThiet PhamNo ratings yet

- Manual GA 55 VSD Atlas CompresorDocument114 pagesManual GA 55 VSD Atlas Compresormondaxa_mme50% (4)

- IEEE AgingDocument4 pagesIEEE Agingdidit hadisantosoNo ratings yet

- Erc01 10Document2 pagesErc01 10WonshikNo ratings yet

- Nomex Tape410 TechnicaldatasheetDocument7 pagesNomex Tape410 TechnicaldatasheetAdrian LeeNo ratings yet

- Aluminum Electrolytic Capacitors: SpecificationsDocument2 pagesAluminum Electrolytic Capacitors: SpecificationsManikandan GurunathanNo ratings yet

- Solid Tantalum Capacitors Voltage DeratingDocument3 pagesSolid Tantalum Capacitors Voltage DeratingChen Chun-LiNo ratings yet

- M&I Unit 3Document6 pagesM&I Unit 3KeerthiSahaNo ratings yet

- D-HR Series 2016Document2 pagesD-HR Series 2016MohanNo ratings yet

- Lighning Prblms2003 1Document52 pagesLighning Prblms2003 1Sithumini SankalpanaNo ratings yet

- Features Description: Lt1004 Micropower Voltage ReferenceDocument12 pagesFeatures Description: Lt1004 Micropower Voltage ReferenceXan OVNo ratings yet

- Plug in Power Relay RS: Options and Ordering CodesDocument2 pagesPlug in Power Relay RS: Options and Ordering CodesMarian BaciuNo ratings yet

- DPT16 21668 Nomex 410 Tech Data Sheet Me03 REFERENCEDocument8 pagesDPT16 21668 Nomex 410 Tech Data Sheet Me03 REFERENCEtesting eiplNo ratings yet

- Phototriac Basics: Optocouplers, Solid-State RelaysDocument13 pagesPhototriac Basics: Optocouplers, Solid-State RelaysAntonio MarquezNo ratings yet

- Chapter 20 Electric Circuits Cutnell11eDocument64 pagesChapter 20 Electric Circuits Cutnell11ebob robNo ratings yet

- Galaxy Electrical: Plastic Silicon RectifierDocument2 pagesGalaxy Electrical: Plastic Silicon RectifierBatbaatar MongolNo ratings yet

- 1 s2.0 0026271467900078 MainDocument17 pages1 s2.0 0026271467900078 MainPramod YadavNo ratings yet

- 1n4140 Diode PDFDocument2 pages1n4140 Diode PDFCarlos BermudezNo ratings yet

- SK1045Document2 pagesSK1045Ed BlasNo ratings yet

- Alldatasheet: Z Ibo Seno Electronic Engineering Co., LTDDocument3 pagesAlldatasheet: Z Ibo Seno Electronic Engineering Co., LTDLiver Haro OrellanesNo ratings yet

- ABB POLIM I..N MV HV Surge Arrester Line Discharge Class 2 AC Systems 72kV Indoor OutdoorDocument5 pagesABB POLIM I..N MV HV Surge Arrester Line Discharge Class 2 AC Systems 72kV Indoor OutdoorAlberto JimenezNo ratings yet

- CuZn40 01 2019 PDFDocument7 pagesCuZn40 01 2019 PDFMisaelNo ratings yet

- Plastic Silicon Rectifiers: VOLTAGE RANGE: 50 - 1200 V Current: 3.0 ADocument2 pagesPlastic Silicon Rectifiers: VOLTAGE RANGE: 50 - 1200 V Current: 3.0 Asezar safokNo ratings yet

- AC1005 - 5 Amp Current Transformer: Low Cost 50/60Hz Current TransformersDocument1 pageAC1005 - 5 Amp Current Transformer: Low Cost 50/60Hz Current TransformersKarina SantillanNo ratings yet

- DC Components Co., LTD.: 10A05 Thru 10A10Document3 pagesDC Components Co., LTD.: 10A05 Thru 10A10Faulhaber AdrianNo ratings yet

- Trifazice TBR25 - SerDocument2 pagesTrifazice TBR25 - SerroscribNo ratings yet

- ABB OfferDocument32 pagesABB OfferAurobindo MandalNo ratings yet

- Technical Data Sheet Linen PhenolicDocument1 pageTechnical Data Sheet Linen PhenolicKissa DolautaNo ratings yet

- Data Sheet: PS200 PS2010Document3 pagesData Sheet: PS200 PS2010nvk nvvNo ratings yet

- Silicon Rectifier: Thru 1N4 1N4001Document9 pagesSilicon Rectifier: Thru 1N4 1N4001Jeffrey ValleNo ratings yet

- sk13 DiodeDocument3 pagessk13 DiodeДрагиша Небитни ТрифуновићNo ratings yet

- JTX EngDocument3 pagesJTX EngConrad ConradmannNo ratings yet

- Galaxy Electrical: Plastic Silicon RectifiersDocument2 pagesGalaxy Electrical: Plastic Silicon RectifiersSudheendra RaoNo ratings yet

- Schrack Power PCB Relay RTH 105°C 16ADocument2 pagesSchrack Power PCB Relay RTH 105°C 16AjpbarrioNo ratings yet

- Vishay ESTA: RippleDocument3 pagesVishay ESTA: RipplelakisNo ratings yet

- Features Description: Ltz1000/Ltz1000A Ultra Precision ReferenceDocument8 pagesFeatures Description: Ltz1000/Ltz1000A Ultra Precision Referenceعبد الكريم ملوحNo ratings yet

- SK 1045 yDocument2 pagesSK 1045 ysahabateman100% (1)

- 10A05 Thru 10A10: REVERSE VOLTAGE - 50 To 1000 Volts FORWARD CURRENT - 10.0 AmperesDocument2 pages10A05 Thru 10A10: REVERSE VOLTAGE - 50 To 1000 Volts FORWARD CURRENT - 10.0 AmperesEdwin Ferney RoaNo ratings yet

- Subminature High Power Relay 4P SLA Series: C US FeaturesDocument2 pagesSubminature High Power Relay 4P SLA Series: C US Featuresomar_cohen_1No ratings yet

- Micro Relay K (THT - THR) : Automotive Relays PCB Single RelaysDocument5 pagesMicro Relay K (THT - THR) : Automotive Relays PCB Single RelaysIsmael ZerpaNo ratings yet

- DatasheetDocument2 pagesDatasheetOlivares Vega Miguel AngelNo ratings yet

- 1N5391G THRU 1N5399G: Chenyi ElectronicsDocument3 pages1N5391G THRU 1N5399G: Chenyi ElectronicsJoel GOMES ALVESNo ratings yet

- Description Mechanical Dimensions: 3.0 Amp Miniature Plastic Silicon RectifiersDocument2 pagesDescription Mechanical Dimensions: 3.0 Amp Miniature Plastic Silicon RectifiersLaua G-m ANo ratings yet

- Rectron: SemiconductorDocument3 pagesRectron: SemiconductorAbdul HameedNo ratings yet

- JQX 68FDocument2 pagesJQX 68FCarlos AguiarNo ratings yet

- 20 Etf 12Document7 pages20 Etf 12y.kiktenkoNo ratings yet

- Some of The Considerations For Materials Operating Under High-Voltage Direct-Current StressesDocument9 pagesSome of The Considerations For Materials Operating Under High-Voltage Direct-Current StressesBraulio VillaNo ratings yet

- 1 4509Document2 pages1 4509Umesh KotadiaNo ratings yet

- Design of A High-Power Zener Diode and Its Energy Absorption CapabilityDocument4 pagesDesign of A High-Power Zener Diode and Its Energy Absorption CapabilitykrishNo ratings yet

- Puente de Diodos DatasheetDocument2 pagesPuente de Diodos DatasheetSaúl CastilloNo ratings yet

- Dongguan Sanyou Electrical Appliances Co LTD SFK 112dm - Ebc4cc638cDocument2 pagesDongguan Sanyou Electrical Appliances Co LTD SFK 112dm - Ebc4cc638cIlyaNo ratings yet

- Ravatherm Xps X 700 SL Tds Version 4 20231130Document1 pageRavatherm Xps X 700 SL Tds Version 4 20231130januszkunce57No ratings yet

- PBL401 - PBL407: Not Recommended For New Design USE GBU4005 - GBU410Document3 pagesPBL401 - PBL407: Not Recommended For New Design USE GBU4005 - GBU410alexnder gallegoNo ratings yet

- RL201G THRU RL207G: Chenyi ElectronicsDocument3 pagesRL201G THRU RL207G: Chenyi ElectronicslucasmosnaNo ratings yet

- Type 1 + 2 Surge Protector DS250E SeriesDocument2 pagesType 1 + 2 Surge Protector DS250E SeriesleonardomarinNo ratings yet

- Taitron TU1002 Rectifier BridgeDocument4 pagesTaitron TU1002 Rectifier BridgeRui MouraNo ratings yet

- MBRS140T3 Surface Mount Schottky Power RectifierDocument4 pagesMBRS140T3 Surface Mount Schottky Power RectifierfreddyNo ratings yet

- Wiw3362 W 503 PDFDocument1 pageWiw3362 W 503 PDFabathunNo ratings yet

- 5 - 477 AFL Dead-End & Joint High Temp Sustained LoadDocument5 pages5 - 477 AFL Dead-End & Joint High Temp Sustained LoadLuis MartinezNo ratings yet

- R404N02000 27 04 17a-2501314-DatasheetDocument3 pagesR404N02000 27 04 17a-2501314-DatasheetsanetNo ratings yet

- N BrochureDocument12 pagesN BrochureSrinath SelvakumaranNo ratings yet

- Service Advisor - The Key Point of Chery Core ProdurceDocument41 pagesService Advisor - The Key Point of Chery Core ProdurceSrinath SelvakumaranNo ratings yet

- Nigerbev ProposalDocument13 pagesNigerbev ProposalSrinath SelvakumaranNo ratings yet

- MistakesDocument78 pagesMistakesSrinath SelvakumaranNo ratings yet

- Aramid Paper YT510Document2 pagesAramid Paper YT510Srinath SelvakumaranNo ratings yet

- Control Panels IEC Norms EC Directives en-USDocument336 pagesControl Panels IEC Norms EC Directives en-USreeawsNo ratings yet

- Pitman BP40 Spec Sheet-R5Document5 pagesPitman BP40 Spec Sheet-R5helpdesk0No ratings yet

- Design & Analysis of Different Types of Sleepy Methods For Future TechnologiesDocument6 pagesDesign & Analysis of Different Types of Sleepy Methods For Future TechnologiesseventhsensegroupNo ratings yet

- PruebaDocument2 pagesPruebaGato LliviNo ratings yet

- Disassembly & ReassemblyDocument4 pagesDisassembly & ReassemblyvivijaNo ratings yet

- Lecture 6-7 Synthesis of Simple Planar MechanismsDocument12 pagesLecture 6-7 Synthesis of Simple Planar MechanismsmayankmaroliyaNo ratings yet

- Properties of Matter Unit Test 2018 - NaikuDocument8 pagesProperties of Matter Unit Test 2018 - NaikuBianca TejadaNo ratings yet

- Moisture ContentDocument8 pagesMoisture ContentHafrizDaniel0% (1)

- Ultimate Bearing Capacity Xls ProgramDocument1 pageUltimate Bearing Capacity Xls Programaggrey noah100% (1)

- Samggh Catlog .Document84 pagesSamggh Catlog .Man BurstNo ratings yet

- Oxygen Meter: Model: DO-5510Document2 pagesOxygen Meter: Model: DO-5510Nabiha JafnahNo ratings yet

- 2019 AdjustaStairs BrochureDocument12 pages2019 AdjustaStairs BrochureMauricio P. Romero ChacaltanaNo ratings yet

- IGCSE Physics NotesDocument7 pagesIGCSE Physics NotesRhea AgrawalNo ratings yet

- Haptics: VREG - S4A - 1P8 NFC - Simvcc1Document6 pagesHaptics: VREG - S4A - 1P8 NFC - Simvcc1AlineNo ratings yet

- Configuration - TrailersDocument2 pagesConfiguration - TrailersJohan ConradieNo ratings yet

- Monitor Tables NotesDocument66 pagesMonitor Tables NotesRaghavendra PrabhuNo ratings yet

- Material Optimisation of A Crane HookDocument6 pagesMaterial Optimisation of A Crane HookPARITOSHsmNo ratings yet

- GCS General Control BrochureDocument4 pagesGCS General Control BrochureGlobalContSolutionsNo ratings yet

- Instalar Piklab en Stretch o BusterDocument5 pagesInstalar Piklab en Stretch o BusterGustavo A. Sarache MillanNo ratings yet

- Expetiment 1 AIC (KTU)Document7 pagesExpetiment 1 AIC (KTU)Kirti ArunNo ratings yet

- Assembly/Dissassembly Instruction: Top & Bottom Disassembly ModelDocument9 pagesAssembly/Dissassembly Instruction: Top & Bottom Disassembly ModelRobson BarrosNo ratings yet

- Industrial Gas Turbines - Siemens PDFDocument8 pagesIndustrial Gas Turbines - Siemens PDFeankiboNo ratings yet

- Exploded Views and Parts ListDocument23 pagesExploded Views and Parts ListhughdempseyNo ratings yet

- MGL TROUBLESHOOTING GUIDE Rev 4Document11 pagesMGL TROUBLESHOOTING GUIDE Rev 4Recep TorunNo ratings yet

- Dynapac CA302 - 68411316Document3 pagesDynapac CA302 - 68411316Meleștean MihaiNo ratings yet

- Static Pressure and Pressure Head in FluidsDocument8 pagesStatic Pressure and Pressure Head in Fluidsyarzar17No ratings yet