Professional Documents

Culture Documents

Foundations On Sandstone and Shale in The Sydney Region

Foundations On Sandstone and Shale in The Sydney Region

Uploaded by

Shahin FalahatiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Foundations On Sandstone and Shale in The Sydney Region

Foundations On Sandstone and Shale in The Sydney Region

Uploaded by

Shahin FalahatiCopyright:

Available Formats

G. MOSTYN and B.F.

WALKER

1

In 1978 a sub-committee of the Australian Geomechanics Society a paper titled "Design for

Foundations on Shale and Sandstone in the Sydney Region" et 1978). The paper included a classification

system for the Sydney shales and sandstones and recommended design parameters for and socketed pile

foundations. The classification system and given in the paper were based on data from field tests

and on the experience of the five authors. They have been adopted by the design and construction fraternities on a

very wide basis over the past 20 years. have also been found useful outside of the geographic area for which

were intended.

However, the 1978 paper was written before a substantial burst in research to foundations on rock

which occurred from the late 1970's to the 1980's. The information from this research work, with

experience with the 1978 system and developments in limit state warrant some revisions to the

muvrn"'°" and This paper summarises relevant research over the two decades, provides

modifications to the classification system to remove and gives revised for

in limit state design.

2

It appears to have been in and n<>r..-·n 1'~ of the USA, in the late 1960's and 1970's that serious research

started in relation to foundations on rock which interest in Australia, South other parts of the USA and

some parts of the UK. of rock was done by and Roy (1972) and Bishnoi

(1968), while Gm (1970) of the load distribution in a rock socketed linear

and non-linear finite element analyses.

and Sydney up the baton in the

late 1970's and undertook substantial field and and theoretical studies (Rowe and Pells, 1980; Pens

et al, 1980; Williams, 1980; Williams et 1980; Williams and 1981). In Canada, Horvath (1982) undertook

similar field and testing. Interaction continued with north American workers (eg 1988 and

Rowe, 1984) and culminated in three key publications,

Structural Foundation on Rock Conference held in Sydney in 1980).

The Design of Piles Socketed into Weak Rock (National Research Council, Ottawa, 1984).

Analysis and Design of Drilled Shaft Foundations Socketed into Rock 1987).

Since the period of the 1980's research and field testing work has continued at Monash

(Seidel and 1995 and 1999) where a commercial program, ROCKET, has been'"''""'""'"~'"

provides a design tool based on analyses a detailed understanding of the role of sidewall

the of socketed

_______ ,,_ the contained in the above research have served to ~r'""'"'°

pressures up to which load-deflection behaviour is and the very

bearing pressures which may be deemed to be ultimate capacities. Once these pressures are design is trivial.

in regard to socketed a considerable effort has been extended to

sidewall shear stress versus '""'IY'"''"-"'""'" behaviour, and the applied mechanics of interaction between sidewall and

end

Australian Geomechanics - Dec 1998 17

It is considered that the three information for proper of foundations

on and in rock. contain several different design methods which include rock mass and

the mechanics of foundation interaction.

3

There are three key facets which process. These are:

1. Construction ~·~,~-,~v•v"'

2. Knowledge of the rock mass "'"''""''"'""<•~

3. mechanics of socket behaviour.

3.1 CONSTRUCTION METHODOLOGY AND CONTROL

The ""''T-lr1"11TIO .....~<>t 11 nn is whether the foundation is to be designed for load between side and base or

or base only design. This decision depends on geometry and the construction method.

in rock over minimum is

If the base may not be clean or the concrete be of doubtful then the should be u"'o''"''"'"

shear only. This has in regard to the design safety factor because without the --1x1tCK-·UD' of end

bearing total reliance rests on the side shear

For deep > 1) the second construction issue relates to sidewall cleanliness and

parameters and methods discussed here presume that the socket sidewalls will be free of crushed and smeared rock.

also presume a of the sidewall roughness. Ensuring clean sidewalls of is not a

trivial construction with sandstones and shales, and with the sedimentary foundation

rocks of Brisbane's Gateway Bridge, suggests that the easiest way to ensure dean sidewalls is for the socket to be

drilled under water. the socket hole can be filled with water after and then stirred using the

bucket or auger. Another alternative is to use a tool fitted with sidewall teeth which is

up and down the socket a few times after of This latter has to be used in rocks which

soften or slake when exposed to free water.

Walker and Pells (1998) give guidelines for "'IY"'"'"''""'"v'"' for socketed

inspection and That paper is based on experience in the Sydney area and alternative '""'"""'"r1'""

may be in other geological environments.

It is noted that a great number of socketed are installed auger and under

conditions where there is insufficient attention given to base or sidewall cleanliness. For such foundations

the modern design parameters and methods are that those for such

work very conservative allowable loads.

3.2 KNOWLEDGE OF ROCK MASS PARAMETERS

In essence all the modern methods good of:

1. The moduli of the rock.

2. The average unconfined compressive of the rock.

3. The average roughness of the sidewalls for a

Assessment of Items 1 and 2 are a basic of rock mechanics and there are good in many texts for

and assessing these The (1984) is an excellent source of information.

There is no universal classification of A classification in Walker and Pens

(1998). It has been found that sockets in sandstone need to be R2, or brittle failure of the

18 Australian Geomechanics - Dec 1998

interface. Sockets of R4 side shear stresses than those of R2 or

R3.

Substantial work on the fundamental influence of roughness on side shear behaviour has been v~... .,.,v.~,~

in the decade. Seidel and Haberfield (1995 and 1999) have a

mean asperity angle and the scale at which the mean angle is measured. Their research has shown

at a given the shear resistance is controlled the of asperities with chord of twice

..,v,,...,u .... the shear resistance at a of lOmm the

with a chord of about 20mm.

3.3 APPLIED MECHANICS OF SIDE SHEAR BEHAVIOUR

There are three very matters of which engineers need to be aware when on side shear.

The first is that load will be shared between the sidewall and base according to the relative stiffnesses of '""'"'"'"''

sidewall rock and toe rock. It is not tenable to ascribe certain of load to

the sidewalls and the base in accordance with notional allowable values. In other words allowable side shear and

allowable end stresses are not additative. For example in a Sm 0.6m diameter socket in good

sandstone it is probable that> 95% of the load will be taken by side shear.

The second is that sidewall roughness is R2 or better (see Walker & Pens, 1998) the sidewall stress-

01sprn,ce1ne1n behaviour will be non-brittle. Peak shear will be mobilised at a small and will

behaviour).

The third is that side-shear resistance is end

pressures.

These three points mean that in order to mobilise base resistance it is necessary to invoke sidewall In

other words one has to mobilise full sidewall resistance if one is to make use of the substantial capacity which may be

available in end In turn this means that all the safety will be in end

as to the ultimate capacity in end bearing then mobilization of full side

In regard to sidewall it should be noted that the progression from first slip, at the location of shear stress,

to slip, takes over a small interval of (Ku.lhawy and Carter, 1988; Rowe and

1984). Therefore for most purposes it is the small of load

behaviour representing progressive and to assume the to be bilinear (see

4

A review of design parameters for rock socketed on rock is given in a review paper in

the 8th Australia New Zealand Geomechanics Conference The present paper restricts consideration to

the Triassic sandstones and shales of the region. However, before design side shear and end

bearing it is necessary to revisit the 1978 classification system for the shales and sandstones.

4.1 CLASSIFICATION SYSTEM

The of the two decades indicates that the 1978 classification system warrants no ,,.~uu1u:i.u revision.

A minor change is that clays are treated to other seams. The matter clarification is the

definition of defect spacing. The revised classification is given in Table 1.

The classification system is based on rock defect spacing and allowable seams as set out below. An three

factors must be satisfied.

Australian Geomechanics - Dec 1998 19

FULL SUP

"O

0

0

...J PROGRESSIVE SLIP

Displacement

Class hie seams

I >600mm <l.5%

II >12 >600mm <3%

III >7 >200mm <5%

IV >2 >60mm <10%

v >1 N.A. N.A

Table la Classification for sandstone

Class Defect Allowable seams

I >600mm <2%

II >7 >200mm <4%

m >2 >60mm <8%

IV >1 >20mm <25%

v >l N.A. N.A.

Table lb Classification for shale

4.1.1 DEFECT SPACING

Pens et al (1978) ~~''"'''" a scale for "degree of in McMahon et al (1975). This scale was

neither exhaustive nor auc.-u<~U.J exclusive and, it was difficult to In fact many

organisations it when Pelis et al (1978). It is considered that some scale degree of

20 Australian Geomechanics - Dec 1998

fracturing is The Austral.ian Standard for Geotechnical. Site (AS1726-1993) does not

include such a scale but the draft International. Standard for Identification and Descriptions of Rock (ISO/DIS 14689)

and ISRM suggested methods have the scale given in Table 2 to the of natural. fractures in N or H

sized core. The boundaries in this scal.e have been in the revised scheme.

4.1.2 ALLOWABLE SEAMS

Seams include fragmented, weathered or similar zones, to the loaded surface. The

limits suggested in the table relate to a defined zone of influence. For footings, the zone of influence is defined as

1.5 times the least dimension. For socketed footings, the zone includes the of the socket a further

to the width of the For tunnel or excavation assessment purposes the defects are assessed over a

Terms used to describe defect sp~lci1rai:,(

>2000 spaced

600-200 spaced

200-600 spaced

60-200 Closely spaced

20-60 Very closely spaced

<20 Extre:mel dosel s aced

1

After ISO 14689 and ISRM

Table 2 Defect

4.2 SIDEWALL SHEAR RESISTANCE

Two have been taken in to the of sidewal.l shear

By far the :most used <>nr,.-o,>rh between sidewall shear

and the rock substance unconfined compressive

('tavepeak) see Williams & Pens (1981), Horvath

(1982) and Rowe & Armitage (1984). The is

Figure 2 gives the results of field and laboratory tests on mudstones and sandstones as evaluated by Williams & Pens

(1981).

1·0

0·9

o Mudstone

0·8 0

x Shale

0·7 @ Sandstone

~

... 0·6

0

Line of Best Fit

00 0·5 0

u.

c 0·4

0

+:

0

::l

"O

0·3

<I)

Cl: 0·2

0·1

0

10 100

Unconfined Compressive Strength MPa

2 Side Shear Reduction Factor

Australian Geomechanics - Dec 1998 21

Williams & Pens rock mass affects the side shear resistance and

'tave peak= (2)

where

modulus reduction factor which can be estimated from

Figure4.

It should be noted that the above equations do not represent lower bounds to an data but are close to the best fit

v"'~"••v•··~ and correlation coefficients of than 80%.

One of the problems with test data from all over the world in one basket is that there i§ a scatter;

geological differences and differences in construction methodology are lost. For example 3 shows the

"'"''uuu'"'"V between 'tave peak and qu for sockets in Hawkesbury Sandstone. It can be seen that for sockets of

a:?:: 0.2. This is substantially than would be obtained from the line of best fit from Figure 2.

0.2

0.1

x-Cast undqr OOntonitcz

3 4 5 6 7 8 910 15 20 30 40 50 60

Unconfin<?d Compr'1ssiv'1 Str<1ngth (MPo)

3 Side Shear Reduction Factor for Sandstone

0-2

o,.!.-~~.,.-~~-,---~~.-~~,.--~--;

0 02 0-4 0·6 0·8 l·O

Emass/ Eintact

4 Reduction Factor for Rock Mass Stiffness

22 Australian Geomechanics - Dec 1998

The data given i.n 2 and 3 have been used as the basis for recommendations

given in the 1978 paper. At the same time the new !',U<'-''-''·'"~''" in Table 5, are ultimate values so as to

fit wi.th limit state design ... ~·~n,~v•v,.,

Sockets in or anchors may be for the ultimate side shear values in Table 5 but a

<l>s value of 0.5 (see Section 5). This presumes sidewalls free of smeared material and crushed rock and a

roughness at least to R2 or better. In small diameter anchor holes it is not feasible to assess the

roughness. It may be assumed that if the holes are drilled percussive the

sidewall roughness will be This is not true for holes drilled diamond

generalised design parameters cannot be given for this case. Sockets in and anchors where ""'"""'''""''""

be checked for liftout of a mass of rock around the socket/anchor. The authors recognise that the shape of the liftout

mass would be very In Classes I to III shale and sandstone the mass is to slab-like shapes

whereas in Classes IV and V it is :more likely to the cone used for soil anchors. Based on

limited laboratory and field and precedent in soil it is suggested that the design check be made on the

basis:

Assume a cone with an included angle of 90° measured from the distal end of the socket or anchor.

a mobilised shear on the side of the cone ('tc) of 10% of the ultimate values in Table 5 for Classes

I, II and III and 5% for Classes IV and V.

Calculate the of the cone, unit (w).

Calculate the vertical components of resistance generated shear on the side of the cone.

Perform an ultimate limit state design check as per 7 and 8 in Section 6.

4.3 END BEARING

Detailed discussions of the capacity of rock are given in Bishnoi (1968), Carter and n.u•ua.vv (1987),

and Roy (1972), Pens and Turner (1980) and It has been shown that

1. For intact rock the ultimate is many times greater than the unconfined compressive

(ju of the rock (see Tables 3 and 4 for Pv.,.,.,.,..,,,of theoretical calculations and field

Method

Classical lasticit

Material Test Substance as

unconfined of

q .. q ..

MPa

Sandstone 20-33 11 (average)

Sandstone (2) 103 > 10

Limestone 75 7 to 11

Class 2 Field 14 5.5

Class 4 Field 6 2 to 2.5

Melbourne Mudstone Field 3 6

(Surface)

Melbourne Mudstone Field 2 >12.5

>3) harden in

Table 4. Measured capacities - Model and field tests

Australian Geomechanics - Dec 1998 23

2. The behaviour for a massive rock is linear up to pressures of

between 2 and 4 times Qu·

3. The ultimate capacity of a rock mass beneath the toe of a socketed pile can be

by Ladanyi's

4. Ultimate bearing capacities for intact and rock are attained at large > 5% of

the minimum dimension.

5. The load-deflection behaviour of a rock mass is linear up to pressures at which significant

propagates Based on the work of Bishnoi (1968) such cracking may be

expected at between about 75% and 125% Qu·

The above mean that for design in many rock masses the base behaviour can be modelled as

elastic up to Serviceability Limits.

Based on the research findings summarised above, values of end pressure on the Sydney shales and sandstones

to cause settlements of < 1% of a diameter mm1murn uu."'"'''""J"J are given in Table 5. Load-

'""l-""'-"'°'u'°'" behaviour would be linear up to those values. Also in Table 5 are ultimate end bearing values

which may be used for strength limit states.

v~••v .... ,..,~ is the design of footings to boundaries. In the (eg

was to reduce pressures by some nominal value. This is as it may not be

safe if there is an au11au;:;uL excavation and associated in the rock which would allow kinematic failure of

the mass beneath the ""'m" 0 ~" footing. the reduction may be unnecessary given that end pressures

are controlled allowable settlements.

It is suggested that if it is that all settle about the same amount then boundary pressures

should be about 60% of the pressure on footings remote from the vvcm~~ is in this regard

defined as one where the distance from the centre of the to the width normal

to the Where there are existing excavations below level a careful check must be made for

kinematic failure of a bounded block. In the Sydney CBD area such orc>ble:ms are adjacent

to N-S oriented faces. This is because the dominant set strikes NNE with of 65° to 90° either west or east.

Class Ultimate end Ultimate shaft

MPa MPa kPa MPa

I >120 12 3000 >2000

II 60 to 120 0.5 1500 900

Max. 12 to to

3000 2000

m 20 to 40 0.5 qu 800 350

Max. 6 to to

1500 1200

IV 4 to 15 0.5 qu 250 100

Max. 3.5 to to

800 700

>3 1.0 150 50 to 100

vH.HH«•'-' values occur at large settlements(> 5% of minimum footing ~.,,.. ~••0""'

pressure to cause settlement of <l % of minimum dimension.

3

Clean socket of category R2 or better.

Table Sa values for vertical on sandstone

24 Australian Geomechanics - Dec 1998

Class Ultimate end Ultimate shaft

MPa MPa kPa MPa

I >120 Max. 8 1000 >2000

II 30 to 120 0.5 qu 600 700

Max. 6 to to

1000 2000

III 6 to 30 0.5 350 200

Max. 3.5 to to

600 1200

IV >3 1.0 150 100 to 500

v >3 0.7 50 to 100 50 to 300

values occur at large settlements(> 5% of minimum footing dimensions).

bearing pressure to cause settlement of <1 % of minimum footing dimension.

3

Clean socket of roughness category R2 or better. Values may have to be reduced because of smear.

Table Sb Design values for vertical loading on shale

5 SAFETY

To date most design methods for footings on rock have been based on working loads with conventional

geotechnical engineering safety factors. Thus, for example, Williams & Pens (1981) propose a working load Safety

Factor of 2.5 for side shear only sockets.

·~··~·~·J geotechnical engineers are being dragged, and into the structural engineer's world

of Limit State Design. The current Australian Code (AS2159-1995) is a Limit State document and therefore,

reluctantly, the writers accept that design of footings on rock must follow the same An of what

this means is as follows.

5.1 LOADS AND LOAD COMB INA TIO NS

to AS1170.1-1989 Code) there are 6 basic combinations 3 vv<-•vrncu

dead load, live wind load and earthquake load which have to be considered for assessment of the limit

state. There are a further 5 different combinations for assuming short term serviceability limit states and a further 3

for long term serviceability limit states.

These combinations of load can make the design process tedious. in many cases in the

Sydney area the following combinations of load govern design of footings and rock socketed piles:

Load (S*) = 1.25G + 1.SQ (3)

Load (S*) = 1.25G + + \jfeQ

Long Term Serviceability

Load =G + \Jf1Q (5)

where

G = dead load

Q = live load

Wu = wind load

'Ve = 0.4 (except for storage facilities where 'Ve= 0.6)

\jf 1 = 'Ve

Australian Geomechanios - Dec 1998 25

Earth pressure and loads are considered as dead loads of G) for long term serviceability. For strength Hmit

state, earth pressures are to live loads and loads are equivalent to dead loads. Note that in the

of Limit State design, the term Action Effect' rather than 'Load' should have been used in 3 to 5.

5.2 STRENGTH AND SERVICEABILITY

According to AS2159-1995 (Piling Code) the key definitions are:

The limit state at which static equilibrium is lost or at which there is failure of the supporting or

structural elements.

This covers four calculated values,

Rg* = Design geotechnical strength of

R,,g = Ultimate geotechnical of

R.. = Design structural strength of

= Ultimate structural of

The limit state at which deformation of the piles will cause loss of serviceability of the structure.

In English this means the which is constrained by allowable settlements, or lateral movements.

For some unknown reason this ·~~~..,,,., is not given a sub and symbol.

5.2.1 STRENGTH

The design ge<)te<;hn R*g is a factored down version of the calculated ultimate geotechnical

strength, ie:

Rg =<JlgRug

The design is Rg > S*.

Various values of <Ps are given in Table 4.1 of AS2159 but none cover the methods used for ultimate

capacity of rock sockets. In the writer's the values are for calculations of "" 7

""''"""'

sockets (side shear and end bearing) using any of the methods given in Section 6 of this Paper.

Geological environments where there are substantial field testing data

(in Australia this would at least include Melbourne mudstone and

Hawkesbury sandstone)

(ii) Geological environments similar to but where no spe:citic field

testing data are available <!Jg= 0.65

Geological environments not covered by the world wide data base

on side shear and end <j}g = 0.5

For side shear sockets the recommended values for the categories listed above are:

(i) <jlg = 0.6

cpg = 0.5

(iii) <Ps = 0.35

26 Australian Geomechanics - Dec 1998

The above recommendations presume that construction control of sidewall and base cleanliness is

assured. If this is not the case then the Designer should be very conservative and it is not to

nrP•~"'·intim> design criteria.

Calculation of Rus is discussed in Section 6.

5.2.2 SERVICEABILITY

Deflection limits (settlements and lateral are constraints lllltJOSc~a by the structure and are

provided by the Structural In the absence of it is reasonable to design for

settlements of between 5mm and 15mm.

AS2159 provides for no "safety factor" in for serviceability. In fact Clause 4.4.4 states

"calculations of settlement, settlement .... shall be carried out geotechnical

appropriately selected and to which no reduction factor is applied". from this clause being ~~w··vr-,·~~

writers consider that it is wrong. This is because, as is discussed in Section 6, design of footings on or in rock are

often governed by serviceability. Yet no allowance is made for the substantial in assessing

deformation parameters.

It is recommended that modulus reduction factor should be for calculations to term

Suggested values are:

(a) in situ deformation assessed from pressuremeter

testing or other large scale in situ measurements <Pm= 0.75

(b) in situ deformation properties assessed by correlation with rock

mechanics indices such as or RMR = 0.5

Table 5 gives in situ modulus values for the different classes of shale and sandstone. These values are

essentially the same as given in the 1978 paper. have been checked against a number of field records over the

two decades. Choice of the value from the ranges given in the table must be made on the basis of

whether the rock is at the upper level or lower level of the class. On the that this choice is made

the authors consider that a value of 0.75 may be adopted for serviceability state calculations.

6J FOUNDATIO NS IN COMPRESSION

Given the design "'""""""'""""C in Table 5 it is a trivial mater to ,..,,,.+;-,,..,,.,.. the gec,tecbni1caJ. design for or

footings.

For socketed piles the writers considered that there are three methods which may be used with confidence.

These are:

Elastic design (Rowe & 1980; Pens et al, 1978)

Side slip design (Rowe & Armitage, 1984; Carter and

Non-linear design 1980; Seidel &

The use of these methods in with limit state design procedures is in detail in a review paper at

the 8th ANZ Conference (Pells, and there is no need to repeat the information here.

The writers strongly the use of the method of Rowe and (1984).

given in Table 5, and the procedures allow a to

influence of and geotechnical on the

Australian Geomechanics Dec 1998 27

ue11e1«Jut:u by Williams et al (1980) allows for non-linear behaviour of a rock socket. The

be used for any geological environment but requires good field test data to provide the

The data given in Table 5 are not suited to this method. The Williams method is a little

laborious and it is understood personal communications) that the advent of the program ROCKET

has largely lead its demise.

As set out in Seidel & Haberfield (1999, ROCKET essentially addresses vertical

concrete shaft and rock. The side shear resistance is coupled with an

displacement behaviour of the base in order to load behaviour of a ...,v.... ., • ...,,..,

total displacements of a socket additional calculations are made of:

• vertical elastic deformation of the rock mass, and

e elastic shortening of the shaft.

as with all other users, have no knowledge of the inner workings of ROCKET. It is a user-

program which dearly, in allows a designer to explore the sensitivity of a design to the 8

..,.., •..,"''"'t"r" which affect sidewall behaviour. The program is not suited to be used with the parameters given in Table

5.

6.2 FOUNDATIONS IN UPLIFT

As discussed in Section 4.2 it is recommended that designs be checked for

rock. Both are ultimate limit state calculations and the following equations are ""'"''"""''"'

(6)

where

d = shaft diameter

L =shaft

'tave peak = ultimate side shear value from Table 5

<l>g= 0.5

Cone-Hftout

(7)

where

'tc =mobilised side shear on 90° cone (see Section 4.2)

<l>s = 0.75

S::U ct

0 =S*-w

w = effective weight of cone

1. The classification system for shales and sandstones in the Sydney given in 1978 has stood the test of

time and warrants no revision. The changes proposed in this paper remove some

in relation to the definitions of defect spacings.

2. The parameters for side shear and end bearing given in the 1978 paper warrant modifications in

of the substantial research work completed in the two decades and in accordance with current

for limit state design. New recommendations are given for these design parameters.

3. for side shear and end bearing must be used in with design methods

model the interaction between side shear and bearing characteristics.

The paper summarises alternative methods which may be used with confidence.

4. Designs of surface footings and socketed should be done in accordance with limit state

The Australian Code does not cover rock sockets and therefore this paper makes

recommendations to fill gaps in the Code.

28 Australian Geomechanics - Dec 1998

American Society of Civil Rock Foundations. Technical and Guides As

ri.u.11.1""' from US. No ASCE New York.

Jointed Rock. PhD Thesis ~~·J·,..,··~ Institute of

F.H. (1987). of Drilled Shaft Foundations Socketed into Rock.

1493-4 for Electric Power Research California.

S.A. Load Transfer Mechanism for Caissons Socketed into Rock. PhD

iiv'""'·'" J.C. Construction of Bored Piles in Weathered Rocks. Road Construction

No69.

Behaviour of Rock-Socketed Drilled Pier Foundations. PhD

J.P. (1988). of Drilled Shaft Foundations. Univ.

of Rock Masses. Proc. 7th Canadian

on Rock Me:cmm

.. ..._ ..,..,u,.... v ... B.K., Rocks in the

Sydney Area. Australian Geomechanics Journal Vol

Rowe, R.K. and An into Side Shear for Socketed

in Sandstone. Int Conf. Structural Foundations on

P.J.N. and R.M. (1980) End on Rock with Particular Reference to Sandstone. Int Conf.

Structural Foundations on

Pells, P.J.N., Rodway, for Shales and

Sandstones in the Australian Geomechanics

P.J.N. (1999). State of Practice for the of Socketed Piles in Rock. 8th ANZ Geomechanics

Hobart.

of Piles Socketed Into Weak Geotechnical Research

of Western Ontario.

Rowe, R.K. and P.J.N. (1980). A theoretical of socket behaviour. Int. Conf. Structural

Foundations on Rock, Balkema.

Seidel, J.P. and C.M. (1995). The Axial Capacity of Pile Sockets in Rocks and Hard Soils. Ground

March 1995.

C.M. (1999). The Shear Behaviour of Concrete - Soft Rock Joints. Part 1: 1·'"'""''"im.~n•nl

Part 2: Theoretical Part 3: Performance of Drilled Shafts. ASCE Journal of

socketed into sandstone and shale. Australian

D.L. and Davies, P. Ultimate Tensile Loads of Bored Piles Socketed into Sandstone Rock. Inst. Conf

of Structural Foundations on rock, Balkema,

.... ~.. ~. A.F. (1980). The and Performance of Piles Socketed into Weak Rock. PhD Monash

The of Socketed Piles in Weak Rock. Int. Conf.

Side Resistance Rock Sockets in "'a'''"''v""'• Mudstone and Shale. Canadian

p 502-513.

Foundations on Rock.

Australian Goomechanics - Dec 1998 29

You might also like

- Precast Stairs AucklandDocument43 pagesPrecast Stairs AucklandDave Robert HasibuanNo ratings yet

- SpeediBolt Range DCP SPB 001Document24 pagesSpeediBolt Range DCP SPB 001eusufiqbalNo ratings yet

- A2 PDFDocument16 pagesA2 PDFMirza SakibNo ratings yet

- Priestley 1997Document37 pagesPriestley 1997Randolph BorgNo ratings yet

- TDS Ucarsol AP 814Document8 pagesTDS Ucarsol AP 814Elton SitumeangNo ratings yet

- 54 2 PellsDocument27 pages54 2 PellsAaron HongNo ratings yet

- Shallow Foundations: Discussions and Problem SolvingFrom EverandShallow Foundations: Discussions and Problem SolvingRating: 5 out of 5 stars5/5 (1)

- VG0-Pap - (ASCE) - Shear Behaviour of Joints in Segmental BridgesDocument22 pagesVG0-Pap - (ASCE) - Shear Behaviour of Joints in Segmental BridgesPATHA ADITHSAINo ratings yet

- V4i5 Ijertv4is051043Document9 pagesV4i5 Ijertv4is051043Joaquim Minusse TchamoNo ratings yet

- (2020) Experimental Testing of Innovative Panel-To-Panel Connections For PrecastDocument15 pages(2020) Experimental Testing of Innovative Panel-To-Panel Connections For PrecastSofía Córdoba SáenzNo ratings yet

- Adapt Pt7 Manual Vol IDocument273 pagesAdapt Pt7 Manual Vol INetzoo FlixNo ratings yet

- Behavior of Braced FramesDocument12 pagesBehavior of Braced FramesJaime MercadoNo ratings yet

- Randolph 1981Document13 pagesRandolph 1981SaeedNo ratings yet

- Diaphragm WallDocument4 pagesDiaphragm Wallリムスィギャン瑞娴No ratings yet

- Modelling High Rise Structures Using MicrostranDocument10 pagesModelling High Rise Structures Using Microstranlerouge09No ratings yet

- Filippo Brunelleschi Vs Jean NouvelDocument11 pagesFilippo Brunelleschi Vs Jean Nouvelapi-249720631No ratings yet

- Concrete Construction Article PDF - Sydney Opera HouseDocument2 pagesConcrete Construction Article PDF - Sydney Opera HouseDaffa ScuderiaNo ratings yet

- A New Method of Quality Control For Construction Joints in Diaphragm WallsDocument11 pagesA New Method of Quality Control For Construction Joints in Diaphragm WallsfreezefreezeNo ratings yet

- Chowdhury266241 Published PDFDocument16 pagesChowdhury266241 Published PDFJohnNo ratings yet

- Timber DecayDocument5 pagesTimber Decaynajmie99No ratings yet

- As 3600-2001 Amdt 1-2002 Concrete StructuresDocument5 pagesAs 3600-2001 Amdt 1-2002 Concrete StructuresmmNo ratings yet

- Timber Engineering Notebook Series: No. 1: Timber As A Structural Material - An IntroductionDocument6 pagesTimber Engineering Notebook Series: No. 1: Timber As A Structural Material - An IntroductionJianhua WuNo ratings yet

- A Five Story Precast Concrete Test Building For Seismic Conditions - Design DetailsDocument8 pagesA Five Story Precast Concrete Test Building For Seismic Conditions - Design Detailswrite2eddyNo ratings yet

- GEO MayJun2015 - Low ResDocument77 pagesGEO MayJun2015 - Low ResLe Nguyen VuNo ratings yet

- IS 2911-2 (1980) - Code of Practice For Design of Timber Piles PDFDocument21 pagesIS 2911-2 (1980) - Code of Practice For Design of Timber Piles PDFFOUGE ADMINNo ratings yet

- Qk1v7mgk Seismic Design and Retrofit of Bridges PriestlyDocument6 pagesQk1v7mgk Seismic Design and Retrofit of Bridges PriestlyMMaulanaNo ratings yet

- Miranda Paper 1999Document9 pagesMiranda Paper 1999Jesus RodríguezNo ratings yet

- SP33Document151 pagesSP33sooricivil100% (1)

- The Arup Journal Issue 1 1985Document48 pagesThe Arup Journal Issue 1 1985Arthur RebouçasNo ratings yet

- Everdure Waterstop - Page1Document1 pageEverdure Waterstop - Page1Jefferd AlicanNo ratings yet

- Analyzing The Seismic Behavior of Set Back Buildings by Using E-TABSDocument9 pagesAnalyzing The Seismic Behavior of Set Back Buildings by Using E-TABSrock_musicNo ratings yet

- Journal of Structural Engineering Volume 110 Issue 7 1984 (Doi 10.1061 - (ASCE) 0733-9445 (1984) 110 - 7 (1513) ) Mitchell, Denis Cook, William D. - Preventing Progressive Collapse of Slab STDocument20 pagesJournal of Structural Engineering Volume 110 Issue 7 1984 (Doi 10.1061 - (ASCE) 0733-9445 (1984) 110 - 7 (1513) ) Mitchell, Denis Cook, William D. - Preventing Progressive Collapse of Slab STsteveh2401No ratings yet

- Randolph1981 PDFDocument13 pagesRandolph1981 PDFSaeedNo ratings yet

- ICE Paper - Nonlinear Finite Element Analysis of ConcreteDocument11 pagesICE Paper - Nonlinear Finite Element Analysis of ConcreteASHOK SINHA KARANAMNo ratings yet

- Burland Et Al (1978) - Behaviour of Gravity Foundation Under Working and PDFDocument10 pagesBurland Et Al (1978) - Behaviour of Gravity Foundation Under Working and PDFdogen1980No ratings yet

- Eb 6Document7 pagesEb 6AndyPalmerNo ratings yet

- Shear Transfer in Concrete Having Reinforcement at An Angle To Shear PlaneDocument26 pagesShear Transfer in Concrete Having Reinforcement at An Angle To Shear PlanePremasiri Karunarathna100% (1)

- Behavior and Design of Single Plate Shear ConnectionsDocument21 pagesBehavior and Design of Single Plate Shear ConnectionsMilmxmenNo ratings yet

- ConcreteDurability PDFDocument101 pagesConcreteDurability PDFSuyenthan SathishNo ratings yet

- Adapt PT SuppDocument208 pagesAdapt PT SuppLau Kim HwaNo ratings yet

- Actions On StructuresDocument5 pagesActions On Structuresabdul kareeNo ratings yet

- SS EN 1992-2 - 2012 - PreviewDocument12 pagesSS EN 1992-2 - 2012 - PreviewHS EngineeringNo ratings yet

- Soil - Structure Interaction - General ReportDocument28 pagesSoil - Structure Interaction - General ReportCeline DenalyNo ratings yet

- Peck1993 - Discussion of "Estimation Earth Pressures Due To CompactionDocument2 pagesPeck1993 - Discussion of "Estimation Earth Pressures Due To CompactionSantiago OsorioNo ratings yet

- Horizontally Connected High-Rise Buildings Under Earthquake LoadingsDocument15 pagesHorizontally Connected High-Rise Buildings Under Earthquake LoadingsMaulana Nur IkhsanNo ratings yet

- Earthquake Engineering in Australia, Canberra 24-26 November 2006Document304 pagesEarthquake Engineering in Australia, Canberra 24-26 November 2006Drift0242No ratings yet

- Perstressed Flat Slab MARTIDocument19 pagesPerstressed Flat Slab MARTItotololomomoNo ratings yet

- Prediciting Axial Capacity of Screw PilesDocument8 pagesPrediciting Axial Capacity of Screw PilesmagnusmasonNo ratings yet

- The Analysis and Design of and The Evaluation of Design Actions For Reinforced Concrete Ductile Shear Wall StructuresDocument36 pagesThe Analysis and Design of and The Evaluation of Design Actions For Reinforced Concrete Ductile Shear Wall StructuresmamandaweNo ratings yet

- Anchorage of Reinforcing BarsDocument148 pagesAnchorage of Reinforcing BarsAntonette Marie ElgarioNo ratings yet

- Tension Flange Effective Width in Reinforced Concrete Shear Walls PDFDocument8 pagesTension Flange Effective Width in Reinforced Concrete Shear Walls PDFgrahambrasicNo ratings yet

- Preservative Treatment For Timber A Guide To Specification PDFDocument5 pagesPreservative Treatment For Timber A Guide To Specification PDFArtemia Loayza ArguellesNo ratings yet

- Floor Levelness in Building ConstructionDocument4 pagesFloor Levelness in Building ConstructioncaioNo ratings yet

- Baker 1949Document10 pagesBaker 1949Jakob FiskerNo ratings yet

- Asce 7-22 CH 14com - For PCDocument17 pagesAsce 7-22 CH 14com - For PCsharethefilesNo ratings yet

- PHD Thesis BentzDocument320 pagesPHD Thesis Bentzcrusanu50% (2)

- Construction On Soft Soil1Document80 pagesConstruction On Soft Soil1BluebelgianNo ratings yet

- Eb 8Document7 pagesEb 8SyedjamelNo ratings yet

- Slimdek Pattern BookDocument40 pagesSlimdek Pattern BookBabak WSP GroupNo ratings yet

- History of Shear Design PresentationDocument42 pagesHistory of Shear Design PresentationMuhammad AbdullahNo ratings yet

- 3 Thick CylindersDocument21 pages3 Thick CylindersMalay ShahNo ratings yet

- Construction Materials and Testing ModuleDocument66 pagesConstruction Materials and Testing Moduleacurvz2005No ratings yet

- Exercises Organic Redox Plus SolutionDocument6 pagesExercises Organic Redox Plus SolutionandreeatalosNo ratings yet

- RNA Isolation ProtocolDocument4 pagesRNA Isolation ProtocolSannan TareenNo ratings yet

- Cheta 9Document91 pagesCheta 9Camilo VaquenNo ratings yet

- Acs Local Exam 1990Document10 pagesAcs Local Exam 1990kateexdNo ratings yet

- Magnetic Aqueous StudyDocument4 pagesMagnetic Aqueous StudyMarvin GagarinNo ratings yet

- Dielectric Studies of Multiferroic Compounds Ho0.9RE0.1CrO3-CIDocument5 pagesDielectric Studies of Multiferroic Compounds Ho0.9RE0.1CrO3-CINeeraj PanwarNo ratings yet

- MSM Module 1Document59 pagesMSM Module 1Nk KumarNo ratings yet

- Chemistry - Extra Edge Topics For NEET 2020 PDFDocument4 pagesChemistry - Extra Edge Topics For NEET 2020 PDFalishNo ratings yet

- STS Lesson 11 (Almerol) PDFDocument3 pagesSTS Lesson 11 (Almerol) PDFBrent AlmerolNo ratings yet

- Water Properties Lab ReportDocument2 pagesWater Properties Lab Reportapi-454228134100% (2)

- Force and Pressure Class 8 Notes - Chapter 11Document9 pagesForce and Pressure Class 8 Notes - Chapter 11anushree ranadeNo ratings yet

- God Particle 2012Document3 pagesGod Particle 2012DanielleNo ratings yet

- Electrochemical Investigations On Advanced Lithium-Ion Batteries by Three-Electrode MeasurementsDocument6 pagesElectrochemical Investigations On Advanced Lithium-Ion Batteries by Three-Electrode MeasurementswondNo ratings yet

- Thyristor Ss 630 Arc Welding MachineDocument2 pagesThyristor Ss 630 Arc Welding MachineAlfredo GutierrezNo ratings yet

- SH BusbarsDocument28 pagesSH BusbarsSanjeewa Hemaratne100% (2)

- Gloves - Plutonium Facility - Los AlamosDocument20 pagesGloves - Plutonium Facility - Los AlamosAnna OlszewskaNo ratings yet

- Lab Report 7 Borda PendulumDocument7 pagesLab Report 7 Borda PendulumazarmechNo ratings yet

- Spacecool Inc. - PamphletDocument13 pagesSpacecool Inc. - PamphletAndi Ainul RimbawanNo ratings yet

- E 4575 Dry Ice Solid Carbon Dioxide Safety Data Sheet SdsDocument9 pagesE 4575 Dry Ice Solid Carbon Dioxide Safety Data Sheet Sdsjohnpatt888No ratings yet

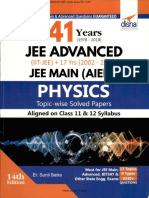

- Past 41 Years IIT Chapterwise - Puucho PDFDocument548 pagesPast 41 Years IIT Chapterwise - Puucho PDFPurvi Binani100% (3)

- Dhruv Tuition Classes Class-X Science Term-1 Sample Paper 2Document13 pagesDhruv Tuition Classes Class-X Science Term-1 Sample Paper 2Nisha SinghNo ratings yet

- EP1651126B1Document22 pagesEP1651126B1BhargavNo ratings yet

- General Organic ChemistryDocument115 pagesGeneral Organic ChemistryVINOD KUMAR MEENA PGT CHEMISTRY, KVS100% (3)

- GATE PSU Study Material Process Calculations PDFDocument7 pagesGATE PSU Study Material Process Calculations PDFDEEPMALA KUMARINo ratings yet

- Modelling of Graphene Nano-Ribbon Transistors (Gnr-Fets) With Enhanced Drive CurrentsDocument9 pagesModelling of Graphene Nano-Ribbon Transistors (Gnr-Fets) With Enhanced Drive CurrentsShailendra YadavNo ratings yet

- Journal of Pharmacovigilance: Spray-Drying: An Emerging Technique For Pharmaceutical Product DevelopmentDocument2 pagesJournal of Pharmacovigilance: Spray-Drying: An Emerging Technique For Pharmaceutical Product DevelopmentCarolina FloresNo ratings yet

- Chapter 1 - Introduction To Analytical ChemistryDocument9 pagesChapter 1 - Introduction To Analytical ChemistryDoom RefugeNo ratings yet