Professional Documents

Culture Documents

SGM6014 SGMicro

SGM6014 SGMicro

Uploaded by

wang seikeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SGM6014 SGMicro

SGM6014 SGMicro

Uploaded by

wang seikeCopyright:

Available Formats

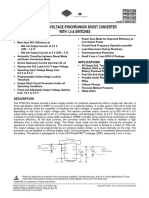

SGM6014

1.4MHz, 2A Synchronous

Step-Down Converter

GENERAL DESCRIPTION FEATURES

The SGM6014 is a high efficiency monolithic ● High Efficiency: Up to 95%

synchronous step-down regulator using 1.4MHz ● 2.5V to 5.5V Input Voltage Range

constant frequency, current mode architecture. The ● 1.4MHz Constant Frequency Operation

device is available in an adjustable version. It is ideal ● 2A Output Current

for portable equipment requiring very high current up to ● 3.3V Fixed and Adjustable Output Voltages

2A from single-cell Li-Ion batteries while still achieving ● 100% Duty Cycle for Lowest Dropout

over 95% efficiency during peak load conditions. The ● Less than 2µA Shutdown Current

SGM6014 can enter pulse frequency modulation (PFM) ● Low Quiescent Current: 55μA in PFM Mode

(low IQ) mode with typically 55μA quiescent current for ● Low RDS(ON) Internal Switches: 0.135Ω

highest light load efficiency to maximize battery life. ● Allows Use of Ceramic Capacitors

● Current Mode Control for Excellent Line and

The SGM6014 also can run at 100% duty cycle for low

Load Transient Response

dropout operation, extending battery life in portable

● Internal Soft-Start Protection

systems while light load operation provides very low

● Short Circuit and Thermal Protection

output ripple for noise sensitive applications. It can

● -40℃ to +85℃ Operating Temperature Range

supply up to 2A output load current from a 2.5V to 5.5V

● Available in Green TDFN-3×3-10L Package

input voltage and the output voltage can be regulated

as low as 1.2V. The high switching frequency (1.4MHz)

minimizes the size of external components while

APPLICATIONS

keeping switching losses low. The internal slope PDA, Pocket PC and Smart Phones

compensation setting allows the device to operate with USB Powered Modems

smaller inductor values to optimize size and provide CPUs and DSPs

efficient operation. PC Cards and Notebooks

SGM6014 is available in both adjustable and 3.3V fixed Cellular Phones

output voltage versions; in the Green TDFN-3×3-10L Digital Cameras

package. It is rated over the -40℃ to +85℃ DSP Core Supplies

temperature range. Portable Instruments

TYPICAL APPLICATION

L

2.2μH

VIN 1 8

EN SW VOUT

2.5V ~ 5.5V

1.8V/2A

2 SW 7 R1

IN

C1 300kΩ

3 SGM6014-ADJ 5

22μF AIN FB C2

22μF

6 10 R2

GND PGND

150kΩ

4 9

GND PGND

Figure 1. Basic Application Circuit for the Adjustable Output Version

SG Micro Corp SEPTEMBER 2017 – REV. A. 3

www.sg-micro.com

1.4MHz, 2A Synchronous

SGM6014 Step-Down Converter

PACKAGE/ORDERING INFORMATION

SPECIFIED

PACKAGE ORDERING PACKAGE PACKING

MODEL VOUT (V) TEMPERATURE

DESCRIPTION NUMBER MARKING OPTION

RANGE

SGM

Adjustable TDFN-3×3-10L -40℃ to +85℃ SGM6014-ADJYTD10G/TR SHDD Tape and Reel, 3000

XXXXX

SGM6014

SGM

3.3 TDFN-3×3-10L -40℃ to +85℃ SGM6014-3.3YTD10G/TR SIBD Tape and Reel, 3000

XXXXX

NOTE: XXXXX = Date Code and Vendor Code.

Green (RoHS & HSF): SG Micro Corp defines "Green" to mean Pb-Free (RoHS compatible) and free of halogen substances. If

you have additional comments or questions, please contact your SGMICRO representative directly.

ABSOLUTE MAXIMUM RATINGS OVERSTRESS CAUTION

Input Supply Voltage ............................................ -0.3V to 6V Stresses beyond those listed may cause permanent damage

EN Voltage................................................-0.3V to VIN + 0.3V to the device. Functional operation of the device at these or

FB/OUT, SW Voltages ..............................-0.3V to VIN + 0.3V any other conditions beyond those indicated in the operational

Power Dissipation, PD @ TA = +25℃ section of the specification is not implied. Exposure to absolute

TDFN-3×3-10L ............................................................... 2.2W maximum rating conditions for extended periods may affect

Package Thermal Resistance reliability.

TDFN-3×3-10L, θJA .................................................... 45℃/W

Junction Temperature .................................................+150℃ ESD SENSITIVITY CAUTION

Storage Temperature Range ........................ -65℃ to +150℃ This integrated circuit can be damaged by ESD if you don’t

Lead Temperature (Soldering, 10s) ............................+260℃ pay attention to ESD protection. SGMICRO recommends that

ESD Susceptibility all integrated circuits be handled with appropriate precautions.

HBM ............................................................................. 3000V Failure to observe proper handling and installation procedures

MM ................................................................................. 200V can cause damage. ESD damage can range from subtle

performance degradation to complete device failure. Precision

RECOMMENDED OPERATING CONDITIONS integrated circuits may be more susceptible to damage

Input Voltage Range ...........................................2.5V to 5.5V because very small parametric changes could cause the

Operating Temperature Range ....................... -40℃ to +85℃ device not to meet its published specifications.

DISCLAIMER

SG Micro Corp reserves the right to make any change in

circuit design, specification or other related things if necessary

without notice at any time.

SG Micro Corp SEPTEMBER 2017

www.sg-micro.com

2

1.4MHz, 2A Synchronous

SGM6014 Step-Down Converter

PIN CONFIGURATION

(TOP VIEW)

EN 1 10 PGND

IN 2 9 PGND

GND

AIN 3 8 SW

GND 4 7 SW

FB/OUT 5 6 GND

TDFN-3×3-10L

PIN DESCRIPTION

PIN NAME FUNCTION

Enable Pin. Pulling EN to ground forces the device into shutdown mode. Pulling EN to IN enables

1 EN

the device. EN should not be left floating and must be terminated.

Supply Voltage Input. Must be closely decoupled to GND, with a 22µF or greater ceramic

2 IN

capacitor.

3 AIN Analog Supply Input. Provides bias for internal circuitry.

4, 6 GND Analog Ground.

Feedback Pin. Receives the feedback voltage from an external resistive divider across the

FB

output. The internal voltage divider is disabled for adjustable version. (SGM6014-ADJ)

5

Output Voltage Pin. An internal resistive divider divides the output voltage down for comparison

OUT

to the internal reference voltage. (SGM6014-3.3)

7, 8 SW Switching Node Pin. Connect the output inductor to this pin.

9, 10 PGND Power Ground.

Exposed

GND Analog Ground Exposed Pad. Must be connected to GND plane.

Pad

SG Micro Corp SEPTEMBER 2017

www.sg-micro.com

3

1.4MHz, 2A Synchronous

SGM6014 Step-Down Converter

ELECTRICAL CHARACTERISTICS

(VIN = 3.6V, TA = -40℃ to +85℃, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Input Voltage Range VIN 2.5 5.5 V

Regulated Output Voltage VOUT 1.2 VIN (1) V

PWM Mode VFB = 0.58V 300 420

Adjustable

Input DC PFM VFB = 0.62V 55 95

Version IQ μA

Bias Current Mode

Fixed Version VFB = 0.62V 55 110

Shutdown VIN = 5.5V, VEN = 0V 0.01 2

Feedback Input Bias Current IFB VFB = 0.65V 0.001 1 μA

VIN = 2.5V to 5.5V, TA = +25℃ 0.587 0.6 0.616

Regulated Feedback Voltage VFB V

VIN = 2.5V to 5.5V, TA = -40℃ to +85℃ 0.583 0.6 0.619

Line Regulation VIN = 2.5V to 5.5V, ILOAD = 350mA 0.1 0.6 %/V

Load Regulation ILOAD = 200mA to 2000mA 0.07 %/A

Output Voltage Adjustable Version VIN = 2.5V to 5.5V, ILOAD = 350mA -3.5 +3.5

%

Accuracy Fixed Version VIN = 2.5V to 5.5V, ILOAD = 350mA -3.5 +5

Oscillator Frequency fOSC 1.4 MHz

Startup Time tS From Enable to Output Regulation 500 μs

Over-Temperature Shutdown Threshold tSD 150 ℃

Over-Temperature Shutdown Hysteresis tHYS 15 ℃

Peak Switch Current IPK 2.7 A

RDS(ON) of P-Channel FET VIN = 3.6V 135

RDS(ON) mΩ

RDS(ON) of N-Channel FET VIN = 3.6V 115

Logic-High Voltage VEN_H VEN Rising 1.5

EN Threshold V

Logic-Low Voltage VEN_L VEN Falling 0.4

Enable Leakage Current IEN VEN = 0V or VIN 0.01 1 μA

NOTE:

1. The maximum output voltage is 4.4V.

SG Micro Corp SEPTEMBER 2017

www.sg-micro.com

4

1.4MHz, 2A Synchronous

SGM6014 Step-Down Converter

TYPICAL PERFORMANCE CHARACTERISTICS

TA = +25℃, L = 2.2μH, CIN = COUT = 22μF, unless otherwise noted.

Efficiency vs. Load Current Output Voltage vs. Load Current

100 1.236

VIN = 2.5V 1.224

VIN = 3.6V

80

Output Voltage (V)

1.212

Efficiency (%)

VIN = 5.0V V = 4.2V

IN VIN = 5.5V

60 VIN = 4.2V 1.200

VIN = 5.0V 1.188 VIN = 2.5V VIN = 3.6V

40

VIN = 5.5V 1.176

VOUT = 1.2V VOUT = 1.2V

20 1.164

0.1 1 10 100 1000 10000 0 400 800 1200 1600 2000

Load Current (mA) Load Current (mA)

Efficiency vs. Load Current Output Voltage vs. Load Current

100 1.545

VIN = 2.5V

VIN = 3.6V 1.530

80

Output Voltage (V)

1.515 VIN = 5.0V VIN = 5.5V

Efficiency (%)

VIN = 4.2V

VIN = 5.0V

60 1.500

VIN = 4.2V

1.485 VIN = 3.6V VIN = 2.5V

40

VIN = 5.5V 1.470

VOUT = 1.5V

20 VOUT = 1.5V

1.455

0.1 1 10 100 1000 10000

0 400 800 1200 1600 2000

Load Current (mA)

Load Current (mA)

Efficiency vs. Load Current Output Voltage vs. Load Current

100 1.854

VIN = 2.5V

1.836

80

Output Voltage (V)

1.818 VIN = 5.0V

VIN = 3.6V VIN = 4.2V VIN = 5.5V

Efficiency (%)

60 VIN = 4.2V 1.800

VIN = 5.5V 1.782 VIN = 3.6V

VIN = 2.5V

40

VIN = 5.0V 1.764

VOUT = 1.8V VOUT = 1.8V

20 1.746

0.1 1 10 100 1000 10000 0 400 800 1200 1600 2000

Load Current (mA) Load Current (mA)

SG Micro Corp SEPTEMBER 2017

www.sg-micro.com

5

1.4MHz, 2A Synchronous

SGM6014 Step-Down Converter

TYPICAL PERFORMANCE CHARACTERISTICS (continued)

TA = +25℃, L = 2.2μH, CIN = COUT = 22μF, unless otherwise noted.

Efficiency vs. Load Current Output Voltage vs. Load Current

100 3.399

3.366

VIN = 3.7V VIN = 4.2V

80

Output Voltage (V)

3.333

Efficiency (%)

VIN = 5.0V VIN = 5.0V VIN = 5.5V

60 3.300

VIN = 5.5V

3.267

40 VIN = 4.2V VIN = 3.7V

3.234

VOUT = 3.3V VOUT = 3.3V

20 3.201

0.1 1 10 100 1000 10000 0 400 800 1200 1600 2000

Load Current (mA) Load Current (mA)

Quiescent Current vs. Temperature

Quiescent Current vs. Input Voltage

500

500

VOUT = 1.8V VIN = 3.6V

450 450 VOUT = 1.8V

VFB = 0.58V

Quiescent Current (μA)

VFB = 0.58V

Quiescent Current (μA)

400 400

350 350

300 300

250 250

200 200

2.5 3 3.5 4 4.5 5 5.5 -50 -25 0 25 50 75 100

Input Voltage (V) Temperature (℃)

N-Channel RDS(ON) vs. Input Voltage P-Channel RDS(ON) vs. Input Voltage

180 200

160 180

140

160

RDS(ON)_N (mΩ)

RDS(ON)_P (mΩ)

+85℃

120 +85℃

140

100 +25℃ 120

+25℃

80

-40℃ 100

-40℃

60

80

2.5 3 3.5 4 4.5 5 5.5

2.5 3 3.5 4 4.5 5 5.5

Input Voltage (V)

Input Voltage (V)

SG Micro Corp SEPTEMBER 2017

www.sg-micro.com

6

1.4MHz, 2A Synchronous

SGM6014 Step-Down Converter

TYPICAL PERFORMANCE CHARACTERISTICS (continued)

TA = +25℃, L = 2.2μH, CIN = COUT = 22μF, unless otherwise noted.

Reference Voltage vs. Temperature Switching Frequency vs. Temperature

0.62 1.50

VIN = 3.6V VIN = 3.6V

Switching Frequency (MHz)

VOUT = 1.8V

Reference Voltage (V)

0.61 1.45

0.60 1.40

0.59 1.35

0.58 1.30

-50 -25 0 25 50 75 100 -50 -25 0 25 50 75 100

Temperature (℃) Temperature (℃)

Output Ripple Output Ripple

VOUT = 1.8V, VIN = 3.6V, ILOAD = 2A VOUT = 1.8V, VIN = 3.6V, ILOAD = 0A

10mV/div

50mV/div

VOUT VOUT

100mA/div

200mA/div

ISW ISW

Time (400ns/div) Time (20ms/div)

Load-Transient Response Load-Transient Response

VIN = 3.6V, VOUT = 1.8V VIN = 3.6V, VOUT = 1.8V

200mV/div

200mV/div

VOUT VOUT

0A to 2A Step 200mA to 2A Step

1A/div

1A/div

ISW

ISW

Time (400μs/div) Time (400μs/div)

SG Micro Corp SEPTEMBER 2017

www.sg-micro.com

7

1.4MHz, 2A Synchronous

SGM6014 Step-Down Converter

TYPICAL PERFORMANCE CHARACTERISTICS (continued)

TA = +25℃, L = 2.2μH, CIN = COUT = 22μF, unless otherwise noted.

Soft Start Soft Start

VOUT = 1.8V, VIN = 3.6V, ILOAD = 0A VOUT = 1.8V, VIN = 3.6V, ILOAD = 2A

2V/div

2V/div

1V/div

1V/div

EN EN

500mA/div

VOUT VOUT

100mA/div

IIN IIN

Time (400μs/div) Time (400μs/div)

Line Regulation

0.4

0.3

0.2 ILOAD = 1mA

ILOAD = 600mA

Accuracy (%)

0.1 ILOAD = 10mA

0

-0.1

ILOAD = 1A

ILOAD = 1.5A

-0.2 ILOAD = 2A

-0.3

VOUT = 1.8V

-0.4

2.5 3 3.5 4 4.5 5 5.5

Input Voltage (V)

SG Micro Corp SEPTEMBER 2017

www.sg-micro.com

8

1.4MHz, 2A Synchronous

SGM6014 Step-Down Converter

DETAILED DESCRIPTION

The SGM6014 is a step-down switching regulator beginning of a PWM cycle and the current in the

optimized for battery-powered handheld applications. P-Channel MOSFET starts ramping up. When the sum

The regulator operates at typically 1.4MHz fixed of the CSA output and the compensation slope reaches

switching frequency under heavy load condition to the control reference of the current loop, the PWM

allow small external inductor and capacitors to be used comparator COMP sends a signal to the PWM logic to

for minimal printed-circuit board (PCB) area. At light turn off the P-Channel MOSFET and to turn on the

load, the regulator can enter PFM mode to reduce the N-Channel MOSFET. The N-MOSFET remains on till

switching frequency, to minimize the switching loss and the end of the PWM cycle.

to maximize the battery life. The quiescent current

The output voltage is regulated by controlling the

under PFM mode with no loading is typically only 55μA.

reference voltage to the current loop. The bandgap

The supply current is typically only 0.01μA when the

circuit outputs a 0.6V reference voltage to the voltage

regulator is disabled.

control loop. The feedback signal comes from the FB

pin. The soft-start block only affects the operation

PWM Control Scheme during the start-up. The EAMP is a transconductance

The SGM6014 uses the peak-current-mode

amplifier, which converts the voltage error signal to a

pulse-width modulation (PWM) control scheme for fast

current output. The voltage loop is internally

transient response and pulse-by-pulse current limiting.

compensated by an RC network.

The current loop consists of the oscillator, the PWM

comparator (COMP), current sensing circuit, and the

PFM Mode

slope compensation for the current loop stability. The

At light load the SGM6014 enters pulse frequency

current sensing circuit consists of the resistance of the

modulation (PFM) mode to minimize the switching loss

P-Channel MOSFET when it is turned on and the

by reducing the switching frequency.

current sense amplifier (CSA). The control reference for

the current loops comes from the error amplifier (EAMP) The output voltage reduces gradually due to the load

of the voltage loop. current discharging the output capacitor. When the

output voltage drops to the nominal voltage, the

The PWM operation is initialized by the clock from the

regulator resumes normal PWM mode operation.

oscillator. The P-Channel MOSFET is turned on at the

SG Micro Corp SEPTEMBER 2017

www.sg-micro.com

9

1.4MHz, 2A Synchronous

SGM6014 Step-Down Converter

APPLICATION INFORMATION

Setting the Output Voltage Inductor Selection

Figure 1 shows the basic application circuit with the For most designs, the SGM6014 operates with inductor

SGM6014 adjustable output version. For applications values of 1μH to 4.7μH. Small value inductors are

requiring an adjustable output voltage, the SGM6014 physically smaller but require faster switching, which

adjustable version can be externally programmed. results in some efficiency loss. The inductor value can

Resistors R1 and R2 in Figure 1 program the output be derived from the following equation:

voltage to be equal to or higher than 1.2V. To limit the

VOUT ⋅ ( VIN − VOUT )

bias current required for the external feedback resistor L=

VIN ⋅ ΔIL ⋅ fOSC

string while maintaining good noise immunity, the

minimum suggested value for R2 is 41kΩ. Although a where ΔIL is inductor ripple current. Large value

larger value will further reduce quiescent current, it will inductors lower ripple current and small value inductors

also increase the impedance of the feedback node, result in high ripple current. Choose inductor ripple

making it more sensitive to external noise and current approximately 30% of the maximum load

interference. Table 1 summarizes the resistor values current 2A, or ∆IL = 600mA. For output voltages above

for typical output voltages. 2.0V, when light-load efficiency is important, the

The external resistors set the output voltage according minimum recommended inductor is 2.2μH.

to the following equation: Manufacturer’s specifications list both the inductor DC

R1 V current rating, which is a thermal limitation, and the

VOUT = 0.6 V × 1 + R1 = OUT − 1 × R2 peak current rating, which is determined by the

R2 0 .6 V

saturation characteristics. The inductor should not

Table 1. Standard 1% Resistors Substituted for show any appreciable saturation under normal load

Calculated Values conditions. Some inductors may meet the peak and

VOUT (V) R1 (kΩ) R2 (kΩ) average current ratings yet result in excessive losses

1.2 150 150 due to a high DCR.

1.8 300 150 Always consider the losses associated with the DCR

3.3 450 100 and its effect on the total converter efficiency when

selecting an inductor. For optimum voltage-positioning

When the battery input voltage decreases near the load transients, choose an inductor with DC series

value of the output voltage, the SGM6014 allows the resistance in the 20mΩ to 100mΩ range. For higher

main switch to remain on for more than one switching efficiency at heavy loads (above 200mA), or best load

cycle and increases the duty cycle until it reaches regulation (but some transient overshoot), the

100%. The duty cycle D of a step-down converter is resistance should be kept below 100mΩ. The DC

defined as: current rating of the inductor should be at least equal to

the maximum load current plus half the ripple current to

VOUT prevent core saturation (2A + 600mA).

D = t ON ⋅ fOSC ⋅ 100% ≈ ⋅ 100%

VIN

where tON is the main switch on-time and fOSC is the Slope Compensation

oscillator frequency. The minimum on-time is typically The SGM6014 step-down converter uses peak current

100ns; therefore, the minimum duty cycle is equal to mode control with slope compensation for stability

100 × 100ns × fOSC (Hz). when duty cycles are greater than 50%. The slope

compensation is set to maintain stability with lower

value inductors which provide better overall efficiency.

The output inductor value must be selected so the

inductor current down slope meets the internal slope

compensation requirements.

SG Micro Corp SEPTEMBER 2017

www.sg-micro.com

10

1.4MHz, 2A Synchronous

SGM6014 Step-Down Converter

APPLICATION INFORMATION (continued)

As an example, the value of the slope compensation is least a 2.2μF input capacitor is recommended. A 22μF

set to 1.5A/μs which is large enough to guarantee ceramic capacitor for most applications is sufficient. A

stability when using a 2.2μH inductor for all output large value may be used for improved input voltage

voltage levels from 1.2V to 4.4V. filtering. The maximum input capacitor RMS current is:

The worst case external current slope (m) using the VOUT V

2.2μH inductor is when VOUT = 4.4V. To keep the output IRMS = ILOAD ⋅ ⋅ 1 − OUT

VIN VIN

voltage stable when the duty cycle is above 50%, the

internal slope compensation (ma) should be: The input capacitor RMS ripple current varies with the

1 1 V input and output voltage and will always be less than or

ma ≥ m =× OUT =

1A/μs equal to half of the total DC load current:

2 2 L

Therefore, to guarantee current loop stability, the slope 1

IRMS(MAX ) = ⋅ ILOAD

of the compensation ramp must be greater than 2

one-half of the down slope of the current waveform. So A laboratory test set-up typically consists of two long

the internal slope compensated value of 1.5A/μs will wires running from the bench power supply to the

guarantee stability using a 2.2μH inductor value for all evaluation board input voltage pins. The inductance of

output voltages from 1.2V to 4.4V. these wires, along with the low-ESR ceramic input

capacitor, can create a high Q network that may affect

Input Capacitor Selection converter performance. This problem often becomes

The input capacitor reduces the surge current drawn apparent in the form of excessive ringing in the output

from the input and switching noise from the device. The voltage during load transients. Errors in the loop phase

input capacitor impedance at the switching frequency and gain measurements can also result.

should be less than the input source impedance to

Since the inductance of a short PCB trace feeding the

prevent high frequency switching current passing to the

input voltage is significantly lower than the power leads

input. The calculated value varies with input voltage

from the bench power supply, most applications do not

and is a maximum when VIN is double the output

exhibit this problem.

voltage.

In applications where the input power source lead

VOUT V

⋅ 1 − OUT inductance cannot be reduced to a level that does not

VIN VIN

CIN = affect the converter performance, a high ESR tantalum

VPP or aluminum electrolytic capacitor should be placed in

− ESR ⋅ fOSC

ILOAD parallel with the low ESR, ESL bypass ceramic

1 capacitor. This dampens the high Q network and

CIN(MIN) = stabilizes the system.

VPP

− ESR ⋅ 4 ⋅ fOSC

I

LOAD Output Capacitor Selection

A low ESR input capacitor sized for maximum RMS The function of output capacitance is to store energy to

current must be used. Ceramic capacitors with X5R or attempt to maintain a constant voltage. The energy is

X7R dielectrics are highly recommended because of stored in the capacitor’s electric field due to the voltage

their low ESR and small temperature coefficients. At applied.

SG Micro Corp SEPTEMBER 2017

www.sg-micro.com

11

1.4MHz, 2A Synchronous

SGM6014 Step-Down Converter

APPLICATION INFORMATION (continued)

The value of output capacitance is generally selected to ESL can be a problem by causing ringing in the low

limit output voltage ripple to the level required by the megahertz region but can be controlled by choosing

specification. Since the ripple current in the output low ESL capacitors, limiting lead length (PCB and

inductor is usually determined by L, VOUT and VIN, the capacitor), and replacing one large device with several

series impedance of the capacitor primarily determines smaller ones connected in parallel.

the output voltage ripple. The three elements of the

In conclusion, in order to meet the requirement of small

capacitor that contribute to its impedance (and output

output voltage ripple and regulation loop stability,

voltage ripple) are equivalent series resistance (ESR),

ceramic capacitors with X5R or X7R dielectrics are

equivalent series inductance (ESL), and capacitance

recommended due to their low ESR and high ripple

(C).

current ratings. The output ripple VOUT is determined by:

The output voltage droop due to a load transient is

VOUT ⋅ ( VIN − VOUT ) 1

dominated by the capacitance of the ceramic output ΔVOUT ≤ ⋅ ESR +

capacitor. During a step increase in load current, the VIN ⋅ L ⋅ fOSC 8 ⋅ f OSC ⋅ C OUT

ceramic output capacitor alone supplies the load

A 22μF ceramic capacitor can satisfy most applications.

current until the loop responds. Within three switching

cycles, the loop responds and the inductor current

Thermal Calculations

increases to match the load current demand. The

There are three types of losses associated with the

relationship of the output voltage droop during the three

SGM6014 step-down converter: switching losses,

switching cycles to the output capacitance can be

conduction losses, and quiescent current losses.

estimated by:

Conduction losses are associated with the RDS(ON)

3 ⋅ ∆ILOAD characteristics of the power output switching devices.

COUT =

VDROP ⋅ fOSC Switching losses are dominated by the gate charge of

the power output switching devices. At full load,

In many practical designs, to get the required ESR, a assuming continuous conduction mode (CCM), a

capacitor with much more capacitance than is needed simplified form of the losses is given by:

must be selected. For both continuous and

ILOAD ⋅ [RDSON(HS) ⋅ VOUT + RDSON(LS) ⋅ (VIN - VOUT )]

2

discontinuous inductor current mode operation, the PTOTAL = + (t SW ⋅ F ⋅ ILOAD + IQ ) ⋅ VIN

VIN

ESR of the COUT needed to limit the ripple to ∆VOUT, V

peak-to-peak is: IQ is the step-down converter quiescent current. The tSW

is used to estimate the full load step-down converter

ΔVOUT switching losses.

ESR ≤

ΔIL

For the condition where the step-down converter is in

Ripple current flowing through a capacitor’s ESR dropout at 100% duty cycle, the total device dissipation

causes power dissipation in the capacitor. This power reduces to:

dissipation causes a temperature increase internal to 2

PTOTAL = ILOAD ⋅ R DSON(HS) + IQ ⋅ VIN

the capacitor. Excessive temperature can seriously

shorten the expected life of a capacitor. Capacitors Since RDS(ON), quiescent current, and switching losses

have ripple current ratings that are dependent on all vary with input voltage, the total losses should be

ambient temperature and should not be exceeded. The investigated over the complete input voltage range.

output capacitor ripple current is the inductor current, IL, Given the total losses, the maximum junction

minus the output current. The RMS value of the ripple temperature can be derived from the θJA for the

current flowing in the output capacitance (continuous

TDFN-3×3-10L package which is 45℃/W

inductor current mode operation) is given by:

TJ(MAX ) = PTOTAL ⋅ θ JA + TAMB

3

IRMS = ΔIL ⋅ = ΔIL ⋅ 0.289

6

SG Micro Corp SEPTEMBER 2017

www.sg-micro.com

12

1.4MHz, 2A Synchronous

SGM6014 Step-Down Converter

REVISION HISTORY

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

SEPTEMBER 2017 ‒ REV.A.2 to REV.A.3

Deleted SGM6014-1.2YTD10G and SGM6014-1.8YTD10G .............................................................................................................................. All

AUGUST 2015 ‒ REV.A.1 to REV.A.2

Update exposed pad function .............................................................................................................................................................................. 3

NOVEMBER 2013 ‒ REV.A to REV.A.1

Add fixed output voltage versions ...................................................................................................................................................................... All

Change ESD susceptibility .................................................................................................................................................................................. 2

Change electrical characteristics ......................................................................................................................................................................... 4

Changes from Original (JULY 2013) to REV.A

Changed from product preview to production data ............................................................................................................................................. All

SG Micro Corp SEPTEMBER 2017

www.sg-micro.com

13

PACKAGE INFORMATION

PACKAGE OUTLINE DIMENSIONS

TDFN-3×3-10L

D e

N10

k D1

E E1

N5 N1

L b

TOP VIEW BOTTOM VIEW

2.4

1.7 2.8

A A1

A2

SIDE VIEW 0.6

0.24 0.5

RECOMMENDED LAND PATTERN (Unit: mm)

Dimensions Dimensions

Symbol In Millimeters In Inches

MIN MAX MIN MAX

A 0.700 0.800 0.028 0.031

A1 0.000 0.050 0.000 0.002

A2 0.203 REF 0.008 REF

D 2.900 3.100 0.114 0.122

D1 2.300 2.600 0.091 0.103

E 2.900 3.100 0.114 0.122

E1 1.500 1.800 0.059 0.071

k 0.200 MIN 0.008 MIN

b 0.180 0.300 0.007 0.012

e 0.500 TYP 0.020 TYP

L 0.300 0.500 0.012 0.020

SG Micro Corp TX00060.000

www.sg-micro.com

PACKAGE INFORMATION

TAPE AND REEL INFORMATION

REEL DIMENSIONS

TAPE DIMENSIONS

P2 P0

W

Q1 Q2 Q1 Q2 Q1 Q2

B0

Q3 Q4 Q3 Q4 Q3 Q4

Reel Diameter

P1 A0 K0

Reel Width (W1)

DIRECTION OF FEED

NOTE: The picture is only for reference. Please make the object as the standard.

KEY PARAMETER LIST OF TAPE AND REEL

Reel Width

Reel A0 B0 K0 P0 P1 P2 W Pin1

Package Type W1

Diameter (mm) (mm) (mm) (mm) (mm) (mm) (mm) Quadrant

(mm)

DD0001

TDFN-3×3-10L 13″ 12.4 3.35 3.35 1.13 4.0 8.0 2.0 12.0 Q1

SG Micro Corp TX10000.000

www.sg-micro.com

PACKAGE INFORMATION

CARTON BOX DIMENSIONS

NOTE: The picture is only for reference. Please make the object as the standard.

KEY PARAMETER LIST OF CARTON BOX

Length Width Height

Reel Type Pizza/Carton

(mm) (mm) (mm) DD0002

13″ 386 280 370 5

SG Micro Corp TX20000.000

www.sg-micro.com

You might also like

- G500HTXi Installation ManualDocument211 pagesG500HTXi Installation ManualVitor BertinNo ratings yet

- Main Ten ComDocument83 pagesMain Ten Comsuk201080% (10)

- PMM VFD Manual d11 03 010410Document100 pagesPMM VFD Manual d11 03 010410molanoavilaNo ratings yet

- Green Solution TechnologyDocument18 pagesGreen Solution TechnologysergioNo ratings yet

- Features Description: Low Cost Green-Mode PWM Controller For Flyback ConvertersDocument13 pagesFeatures Description: Low Cost Green-Mode PWM Controller For Flyback ConvertersfjfjgkNo ratings yet

- A05c 0S 000060 - Aoz2261nqi 11Document18 pagesA05c 0S 000060 - Aoz2261nqi 11Chiapin LeeNo ratings yet

- RT9080N Datasheet ModDocument14 pagesRT9080N Datasheet ModDavid MAILLOTNo ratings yet

- Recommended FOR NEW Design: Dual Synchronous Buck Pseudo Fixed Frequency DDR Power Supply ControllerDocument17 pagesRecommended FOR NEW Design: Dual Synchronous Buck Pseudo Fixed Frequency DDR Power Supply ControllerCarlos AntonioNo ratings yet

- Datasheet PDFDocument16 pagesDatasheet PDFRaul LeonNo ratings yet

- High Input Voltage Buck-Boost Converter With 2A Switch CurrentDocument31 pagesHigh Input Voltage Buck-Boost Converter With 2A Switch Currentbarmircea10No ratings yet

- General Description Features: 28V/6A Synchronous Ezbuck RegulatorDocument15 pagesGeneral Description Features: 28V/6A Synchronous Ezbuck RegulatorholinsunNo ratings yet

- SG6842 SystemGeneralDocument15 pagesSG6842 SystemGeneralHarri RahadianNo ratings yet

- Nb679a MpsDocument19 pagesNb679a MpswarkeravipNo ratings yet

- Datasheet LTC3728L & LTC3728LX PDFDocument32 pagesDatasheet LTC3728L & LTC3728LX PDFSelmar CavalcantiNo ratings yet

- Max15058 PDFDocument22 pagesMax15058 PDFjhnkerenNo ratings yet

- Application Note: SY8286A: General Description FeaturesDocument16 pagesApplication Note: SY8286A: General Description FeaturesRodney RibeiroNo ratings yet

- 28V, 6.5A, Low Iq, Synchronous Buck Converter With 2-Bit VIDDocument24 pages28V, 6.5A, Low Iq, Synchronous Buck Converter With 2-Bit VIDElla Wijaya ChandraNo ratings yet

- Dual, Interleaved, Step-Down DC-to-DC Controller With TrackingDocument32 pagesDual, Interleaved, Step-Down DC-to-DC Controller With Trackingkakashi benaoudaNo ratings yet

- Silergy-Corp-SY8286ARAC C178251Document16 pagesSilergy-Corp-SY8286ARAC C178251ziya tutuNo ratings yet

- 2.5A, 18V, 500Khz Acot Synchronous Step-Down Converter: General Description FeaturesDocument14 pages2.5A, 18V, 500Khz Acot Synchronous Step-Down Converter: General Description FeaturesMaxNo ratings yet

- Lmg1210 200-V, 1.5-A, 3-A Half-Bridge Mosfet and Gan Fet Driver With Adjustable Dead Time For Applications Up To 50 MHZDocument30 pagesLmg1210 200-V, 1.5-A, 3-A Half-Bridge Mosfet and Gan Fet Driver With Adjustable Dead Time For Applications Up To 50 MHZharshalvikasNo ratings yet

- Ice 2 As 01Document24 pagesIce 2 As 01teleserviceNo ratings yet

- REN Isl6269a DST 20040119Document15 pagesREN Isl6269a DST 20040119Martin WhybrowNo ratings yet

- Datasheet AP72200Document30 pagesDatasheet AP72200ecoplazabrNo ratings yet

- Sgmicro-Sgm6132yps8g-Tr C87095Document14 pagesSgmicro-Sgm6132yps8g-Tr C87095ghozi mtNo ratings yet

- Soft Starter PDFDocument6 pagesSoft Starter PDFPaun AlNo ratings yet

- AOZ2260QI-18 - 2 Up9011q Atau 5388 Di HP AmdDocument15 pagesAOZ2260QI-18 - 2 Up9011q Atau 5388 Di HP AmdNgipik Komp PatiNo ratings yet

- 1Mhz, All-Ceramic, 3A PWM Buck DC/DC Converter: Global Mixed-Mode Technology IncDocument1 page1Mhz, All-Ceramic, 3A PWM Buck DC/DC Converter: Global Mixed-Mode Technology IncLeonardo FusserNo ratings yet

- Low Input Voltage Synchronous Boost Converter With 1.3-A SwitchesDocument28 pagesLow Input Voltage Synchronous Boost Converter With 1.3-A SwitchesbecemNo ratings yet

- Tps 63010Document27 pagesTps 63010Farouk AnçaNo ratings yet

- Si-8001ffe Ds enDocument9 pagesSi-8001ffe Ds enalexNo ratings yet

- A4931 DatasheetDocument12 pagesA4931 DatasheetDiego HernandezNo ratings yet

- AT1526 GlobalMixed ModetechnologyDocument2 pagesAT1526 GlobalMixed ModetechnologyFafa MangstabNo ratings yet

- AOZ123 DatasheetDocument18 pagesAOZ123 Datasheetmartin sembinelliNo ratings yet

- AP63200/AP63201/AP63203/AP63205: 3.8V To 32V Input, 2A Low Iq Synchronous Buck With Enhanced Emi ReductionDocument19 pagesAP63200/AP63201/AP63203/AP63205: 3.8V To 32V Input, 2A Low Iq Synchronous Buck With Enhanced Emi ReductionJonathan Da SilvaNo ratings yet

- AOZ6623DI Regulador de VoltajeDocument15 pagesAOZ6623DI Regulador de VoltajeDaiverJuarezNo ratings yet

- Ltc3314a 3125071Document27 pagesLtc3314a 3125071marcelituz2024No ratings yet

- 3A DDR Bus Termination Regulator: Features General DescriptionDocument1 page3A DDR Bus Termination Regulator: Features General Descriptionale barrazaNo ratings yet

- A5984 DatasheetDocument28 pagesA5984 DatasheetIndraz NilNo ratings yet

- 2N3958 DatasheetDocument5 pages2N3958 Datasheetjose santosNo ratings yet

- Fairchild - Semiconductor FAN73611MX DatasheetDocument14 pagesFairchild - Semiconductor FAN73611MX DatasheetDeddy WilopoNo ratings yet

- LM 3370Document33 pagesLM 3370in geniusNo ratings yet

- 1Mhz 1A Synchronous Step-Down Regulator: Features General DescriptionDocument2 pages1Mhz 1A Synchronous Step-Down Regulator: Features General DescriptionM. M.No ratings yet

- LM273yh3 DatasheetDocument22 pagesLM273yh3 DatasheetsongdashengNo ratings yet

- Features General Description: High Performance Single Synchronous Buck ConverterDocument22 pagesFeatures General Description: High Performance Single Synchronous Buck ConverterChiapin LeeNo ratings yet

- Power Module: Magi CDocument56 pagesPower Module: Magi CGiderosNo ratings yet

- 2.5A Switch Step Down Switching Regulator: DescriptionDocument10 pages2.5A Switch Step Down Switching Regulator: DescriptionVictor CuaicalNo ratings yet

- AOZ2023PIDocument11 pagesAOZ2023PIjuliocunachiNo ratings yet

- TPS61200Document29 pagesTPS61200BaCresNo ratings yet

- Features Descriptio: LTC1435 High Efficiency Low Noise Synchronous Step-Down Switching RegulatorDocument20 pagesFeatures Descriptio: LTC1435 High Efficiency Low Noise Synchronous Step-Down Switching RegulatorCarlos Henrique RibasNo ratings yet

- SP6213/SP6214: Micropower, SC-70, 100ma CMOS LDO RegulatorDocument10 pagesSP6213/SP6214: Micropower, SC-70, 100ma CMOS LDO RegulatorSlamet GojazzNo ratings yet

- AOZ3015AIDocument14 pagesAOZ3015AIIcomNo ratings yet

- 3 A, 2 MHZ Buck-Regulating Led Driver: Description Features and BenefitsDocument12 pages3 A, 2 MHZ Buck-Regulating Led Driver: Description Features and BenefitsElizabet VallejoNo ratings yet

- General Description Features: 28V/10A Synchronous Ezbuck RegulatorDocument15 pagesGeneral Description Features: 28V/10A Synchronous Ezbuck RegulatorРоман ІкалюкNo ratings yet

- Off-Line Quasi-Resonant Switching Regulators: STR-Y6763, STR-Y6765, and STR-Y6766Document13 pagesOff-Line Quasi-Resonant Switching Regulators: STR-Y6763, STR-Y6765, and STR-Y6766Renato Luther escalanteNo ratings yet

- DS9186B 00Document8 pagesDS9186B 00prexo zoneNo ratings yet

- SC900Document23 pagesSC900Robert PNo ratings yet

- Datasheet 2Document24 pagesDatasheet 2MIRJAKHON MNo ratings yet

- SGM8904 SGMicroDocument9 pagesSGM8904 SGMicroinfosolutionNo ratings yet

- AN30888A High Brightness LED Driver IC: Features DescriptionDocument22 pagesAN30888A High Brightness LED Driver IC: Features Description94430s19684No ratings yet

- SD6832 SLDocument10 pagesSD6832 SLMuhammad IchsanNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Samsung DVD p355bDocument141 pagesSamsung DVD p355bСергей ПлотниковNo ratings yet

- 1336f tg001 - en PDocument39 pages1336f tg001 - en PCaelumBlimpNo ratings yet

- SMP125HDT2 Service ManualDocument26 pagesSMP125HDT2 Service ManualdanielNo ratings yet

- BTS3900 GSM Commissioning Guide V300R008 03Document97 pagesBTS3900 GSM Commissioning Guide V300R008 03Iftikhar Lodhi100% (1)

- Semikron Datasheet Skiip 39anb16v1 25230180Document4 pagesSemikron Datasheet Skiip 39anb16v1 25230180trung Phạm thànhNo ratings yet

- Miller Big Blue 402d, 502d, 602dDocument116 pagesMiller Big Blue 402d, 502d, 602dLUIS ALFREDO SIERRA JUAREZNo ratings yet

- Easygen-2000 Series Genset Control: InstallationDocument72 pagesEasygen-2000 Series Genset Control: InstallationMustafa A.WNo ratings yet

- Opa 602Document15 pagesOpa 602cristinacintiaNo ratings yet

- Panasonic Tc-L37e5 CH La35Document69 pagesPanasonic Tc-L37e5 CH La35Liviu LiviuNo ratings yet

- AEC-6910 En-50155 Test ReportDocument29 pagesAEC-6910 En-50155 Test Reportd157952No ratings yet

- Lenovo Flex 2 Pro 15 Edge 15 Repair GuideDocument81 pagesLenovo Flex 2 Pro 15 Edge 15 Repair GuideRick SlickNo ratings yet

- Cencon InstalaciónDocument24 pagesCencon InstalaciónEmerson GutiérrezNo ratings yet

- Philips Az1004 01Document23 pagesPhilips Az1004 01Alejandro Méndez MasdeuNo ratings yet

- Accuvix A30Document318 pagesAccuvix A30Jose LagosNo ratings yet

- Panasonic Sa-Akx77lm-K SMDocument104 pagesPanasonic Sa-Akx77lm-K SMLesther GonzálezNo ratings yet

- BMS-0000005 Rev 6 Packaging RequirementDocument15 pagesBMS-0000005 Rev 6 Packaging RequirementLaszlo EdesNo ratings yet

- MA5800C SubracksDocument28 pagesMA5800C SubracksAlexander PischulinNo ratings yet

- Manual Capnografo npb-75mDocument65 pagesManual Capnografo npb-75mLuis Mendoza100% (2)

- Microprocessor Supervisory Circuits ADM690-ADM695: V Normal, V in BackupDocument16 pagesMicroprocessor Supervisory Circuits ADM690-ADM695: V Normal, V in BackupxX Crystal XxNo ratings yet

- Integrado POFF - AD7858AN DatasheetDocument32 pagesIntegrado POFF - AD7858AN DatasheetKratos EspejoNo ratings yet

- Training LCD LG 32LH30Document80 pagesTraining LCD LG 32LH30Gilmar FerreiraNo ratings yet

- 571118a 0001CDocument244 pages571118a 0001Cmuhammad arif sulaimanNo ratings yet

- PLC Phoenix PDFDocument116 pagesPLC Phoenix PDFeliasryanNo ratings yet

- Dacor Wall OvenDocument77 pagesDacor Wall OvenJim Harmke100% (2)

- Multiformat SDTV Video Decoder ADV7183B: FeaturesDocument100 pagesMultiformat SDTV Video Decoder ADV7183B: FeaturesFernando PiedadeNo ratings yet

- LG An110b-Jd An110w-Jd Chassis Re058aDocument33 pagesLG An110b-Jd An110w-Jd Chassis Re058aWayne WondNo ratings yet