Professional Documents

Culture Documents

DB203 Basic Comp-Limiter Design THAT4305

DB203 Basic Comp-Limiter Design THAT4305

Uploaded by

bruno magalhãesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DB203 Basic Comp-Limiter Design THAT4305

DB203 Basic Comp-Limiter Design THAT4305

Uploaded by

bruno magalhãesCopyright:

Available Formats

THAT Corporation Design Brief 203

Basic Compressor/Limiter Design

with the THAT4305

Abstract

THAT Corporation’s Analog Engines are ideal basic building blocks for compressor/limiter designs. This design

brief describes in detail the circuitry for two basic compressor/limiter designs using the THAT4305 Analog Engine.

The first design is an above-threshold, hard-knee compressor with variable ratio, threshold and gain controls. The

second design adds a soft-knee threshold. Suggestions for alignment are presented, as are ideas for modifying the

basic circuits to allow common variations.

Basic Compressor/Limiter Design

This design brief describes how to use THAT Corporation’s 4305 Analog Engine to make basic above-threshold

compressor/limiters. Throughout the text, it is assumed that the reader has become familiar with the basic

application of these devices. For additional information on the operation of the devices themselves, please refer

to the 4305 data sheet. A THAT 4305 makes an ideal RMS detector and VCA controller pair for audio compressor

and limiter designs. The RMS detector provides a dc output in logarithmic (decibel-scaled) format, while a VCA

accepts gain control commands in exponential format (also decibel-scaled). The combination of a RMS detector

and a VCA makes it possible to construct a variety of compressors and/or limiters with unprecedented ease, freeing

the design engineer to concentrate on the functional requirements of a design, rather than on the methods to

achieve this functionality.

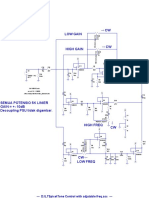

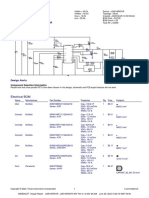

Above-Threshold Compressor

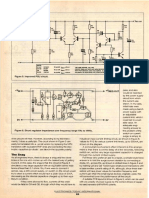

Figure 1 shows a basic above-threshold compressor utilizing a 4305 Analog Engine. This design offers

independent control over threshold, compression ratio, and after compression gain. Time constants are handled

“automatically” by the RMS detector. The design exploits the highly predictable behavior of the 4305 to make

possible a simple, effective and versatile feedforward approach to gain control. (For a mathematical analysis of

this class of circuit, see DN-01A, The Mathematics of Log-Based Dynamic Processors, also available from THAT

Corporation.)

C2 22p NPO

V+

SIGNAL PATH

R6 20k

9

4305 VCA

12

C1 V+

R1 15 Ec- OUT

IN -IN -

Ec+ 13

GND

20k V- OA1 OUT

10u 11

R2 6 +

8 NE5534,

V IN 6k2

LF351, etc. V OUT

C6 V- V+

100p

V+

-40 THRESHOLD GAIN +20

R17 R21

C3 50k 50k

10u +20 lin lin R22

RMS DETECTOR -20

R16 243k

162k V- 1%

V TH V- R23

1%

4305 RMS

R7 R18 COMPRESSION

2 2k0 1%

IN OUT

CT 5

32k4 C5 2k0 1% R20

1% 4 R19 -

1k 2k0 1% OA3

D1 22p lin +

V+

R14

VG

- D2

C4 CT

2k0 1% OA2 RATIO CONTROL

22u 10u

+

V RM S

Un le ss o th erwi se n oted: 1. Al l di od es 1 N414 8

2. Al l Cap acitors 1 0% 3. Al l resi sto rs 5%

THRESHOLD DETECTOR 4. V+ = +1 5V, V- = -15V 5. Al l op am ps 553 2

Figure 1. Basic Above-Threshold Compressor/Limiter.

THAT Corporation; 45 Sumner Street; Milford, MA 01757-1656; USA

Tel: +1 508 478 9200; Email: sales@thatcorp.com; Web: www.thatcorp.com

Copyright © 2019, THAT Corporation; All rights reserved; Document 600xxx Rev G-NOT-RELEASED

THAT Corporation Design Brief 203 Page 2 of 6 Basic Compressor / Limiter Design

with the THAT4305

Signal Path

The audio signal flows only through the 4305 VCA and OA1, making the signal path short enough to locate it

entirely around the input and output jacks on the PC board. Input signals are coupled to the VCA through C1 and

R1. Since the input of the VCA is a virtual ground, R1 determines the strength of the input (current) to the VCA.

The 20 kΩ resistor shown is optimum for input voltages of up to about 10 VRMS, or +22.22 dBu; C1 (along with R1)

sets the low-frequency limit in the signal path (𝑓𝑐 = 1⁄(2𝜋 ∙ 𝑅1 ∙ 𝐶1)). As shown, the -3 dB corner is at about

0.8 Hz. The VCA produces an output current signal in pin 13 which is a replica of the input signal, scaled (in decibels)

by the voltage at pin 12. OA1 converts this current back to a voltage based on its feedback resistor, R6. For R1 = R6,

as shown, VIN = VOUT whenever pin 12 (the control port) is at 0 V (this is unity, or 0 dB gain). For every 6.2 mV

increase in the voltage at pin 12, the gain decreases by 1 dB. For every 6.2 mV decrease in voltage, the gain

increases by 1 dB. Therefore, the output signal level depends only on the input signal and the control voltage

applied to pin 12.

RMS-Level Detector

The input signal is also applied to the 4305 RMS detector through C3 and R7 (like the VCA, the RMS’s input is

a virtual ground). In this circuit, the RMS detector is configured to provide 0 V at its output (pin 5) when

approximately 243 mV rms (-10 dBu) is present at the circuit input. As the input signal varies, the RMS detector’s

output voltage will vary. For each 1 dB of increase in input level, its output increases by 6.2 mV. Every 1 dB

decrease in input level causes a 6.2 mV decrease in dc output.

Adjusting the Threshold

The output of the RMS detector is connected to

OA2, which is configured as an inverting, half-wave

operational rectifier. Neglecting the effect of R16 and

R17, when VRMS is negative, the output of OA2 will be

positive, and D2 blocks this voltage from reaching VTH.

Therefore, VTH = 0 for VRMS < 0. However, when VRMS

is positive, the output of OA2 goes negative, and V TH

follows VRMS with a gain of –1. Therefore, VTH = –VRMS

for VRMS > 0 V.

Neglecting the effects of R16 and R17, OA2 and

its associated circuitry only passes information when

the input signal is above the input level which causes Figure 2. VTH vs. VIN for various THRESHOLD settings.

VRMS = 0 V (the threshold). No information passes for

signals below this threshold. The transition from below to above threshold is sharp, because the operational

rectifier used as the threshold detector linearizes the diode’s exponential V-I characteristic.

R17 and R16 provide a means of adjusting the threshold. For supply rails of ±15 V, R17 adjusts the threshold

over ±186 mV (from (V+)*R18/R16 to (V-)*R18/R16) equivalent to ±30 dB at 6.2 mV/dB. With the wiper of R17

towards V+, VTH will respond for any VRMS > -186 mV, or VIN > -40 dBu. With the wiper of R16 towards V-, VTH will

respond for VRMS > +186 mV, or VIN > 20 dBu. This adjusts the threshold over the range +20 dBu to -40 dBu.

Note that a linear-taper potentiometer should be used for R17, the THRESHOLD control. This is because the

signal at the RMS detector output represents the log of the input signal level (it has already been converted to

decibels.) A linear change in threshold voltage corresponds to a linear change in decibel threshold.

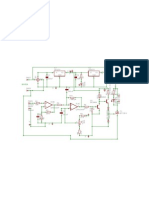

VTH therefore represents the decibel level of the input signal above THRESHOLD. See Figure 2 for a plot of

VTH versus VIN, with various settings of the THRESHOLD control.

Adjusting Compression

R19, the COMPRESSION control, allows the user to scale VTH before it is passed on to the rest of the circuitry.

Neglecting the action of R21 and R22, when the wiper of R19 is at its ground end, no signal is passed on to OA3.

When the wiper is at the opposite end (the maximum), the output of OA3 (V G) exactly mirrors VTH. For settings in

between, VG will be a mirror image of some fraction of VTH, with the fraction determined by the setting of the

COMPRESSION control.

THAT Corporation; 45 Sumner Street; Milford, MA 01757-1656; USA

Tel: +1 508 478 9200; Email: sales@thatcorp.com; Web: www.thatcorp.com

Copyright © 2019, THAT Corporation; All rights reserved; Document 600xxx Rev G-NOT-RELEASED

THAT Corporation Design Brief 203 Page 3 of 6 Basic Compressor / Limiter Design

with the THAT4305

When COMPRESSION is at maximum, VG = VTH, so

VG in turn represents VIN above threshold at

6.2 mV/dB. But, VG is applied to pin 12 of the 4305

VCA, which controls gain at the rate of -6.2 mV/dB. For

every 1 dB increase in VIN (above threshold) VG

increases by 6.2 mV, and the gain of the VCA decreases

by 1 dB. Therefore, at maximum COMPRESSION, the

signal gain decreases in exact proportion to signal level

increases above threshold, preventing any increase in

output level above the threshold.

For intermediate settings of the COMPRESSION

control, the decrease in signal gain is proportional to,

but less than, the increase in signal level above Figure 3. VG vs. VIN for various COMPRESSION settings.

threshold. For example, at the electronic halfway point

for R19, signal gain will decrease by 0.5 dB for each

1 dB increase in input signal above threshold. This will

result in an increase in output signal of 0.5 dB for each

1 dB increase in input signal.

The Compression Ratio is a measure of the

increase in output signal for increases in input signal

above threshold. It is defined as

𝛥𝑉𝐼𝑁

𝑅𝐴𝑇𝐼𝑂 = ,

∆𝑉𝑂𝑈𝑇

where ΔVIN is the decibel change in input signal and

ΔVOUT is the decibel change in output signal. The

compression ratio is ∞:1 when the COMPRESSION Figure. 4. VG vs. VIN for various GAIN settings.

control is at its maximum, and 1:1 at its minimum. For

settings in between, the ratio is determined by the

setting of R19, taking into account the loading effect

of R20. If the electrical setting of the COMPRESSION

control is expressed as a ratio R relative to full scale

(i.e., maximum is 1.0, 50% of full scale is 0.5, etc.), then

the compression ratio is determined by the setting of

the COMPRESSION control as follows: RATIO = 1/(1-R).

In the circuit shown, 2:1 compression will occur at

slightly more than the halfway point in the pot’s

rotation, due to the loading of R20. It is not

uncommon in this sort of design to add a resistor

between the top of R19 and its wiper, in order to set

4:1 compression at the 50% rotation point.

(Approximately 180 Ω would be right.)

Figure. 5. VIN vs. VOUT for various Control Settings.

Figure 3 plots VG versus VIN, for several settings

of the COMPRESSION control, at a fixed THRESHOLD setting.

Adjusting Gain

The action of R21 and R22, neglected in the foregoing analysis, is to add a dc offset to the gain control voltage,

VG. This causes a static gain or loss in the signal path, at the familiar constant of 6.2 mV/dB. As shown, with ±15 V

supply rails, varying R21 (the GAIN control) will cause VG to vary over ±124 mV. This corresponds to approximately

±20 dB of gain change. This variation is useful in making up for level lost during compression. Figure 4 plots VG vs.

VIN for various settings of the GAIN control, at constant COMPRESSION and THRESHOLD settings.

Resulting Compression Characteristic

The circuit of Figure 1 produces a family of input vs. output characteristic curves as shown in Figure 5. Note

that the onset of compression (the bend in the curves) is sharp, deriving from the sharp rectification characteristic

of the operational rectifier used in the threshold detector. Also note the similarity of the previous curves showing

control voltages versus VIN to the plots of VOUT vs. VIN. This follows from the fact that the RMS detector produces

a decibel representation of the input signal, and that the VCA responds directly to decibel gain commands.

THAT Corporation; 45 Sumner Street; Milford, MA 01757-1656; USA

Tel: +1 508 478 9200; Email: sales@thatcorp.com; Web: www.thatcorp.com

Copyright © 2019, THAT Corporation; All rights reserved; Document 600xxx Rev G-NOT-RELEASED

THAT Corporation Design Brief 203 Page 4 of 6 Basic Compressor / Limiter Design

with the THAT4305

Trim Adjustments

The THAT4305 does not require any trim adjustments.

Time Constants

The time constants of the compressor shown in Figure 1 are entirely determined by the RMS detector and

choice of its timing component, CT. As shown, the integration time of the RMS detector is set to approximately

32 ms, appropriate for most audio applications. For certain applications, however, it may be desirable to vary this.

Simply changing the value of CT will scale the integration time proportionately, and is conceptually the easiest way

to alter timing (see the 4305 data sheet for details).

More elaborate variations in time constants are also possible. For more detail about the time constants in

RMS-based compressor limiters, see Audio Engineering Society Preprint number 4054, Attack and Release Time

Constants in RMS-Based Compressors and Limiters, by Fred Floru.

Higher (or Lower) Input Levels

1.8 mA is the maximum recommended signal current (IIN + IOUT) for the 4305 VCA when it is operated from

+/-15V power supplies. (IIN is the input signal current, IOUT is the output signal current.) The IOUT which corresponds

to a given IIN will be determined by the control settings, but the maximum IOUT is likely to be several dB lower than

the peak IIN due to the compressor action. A reasonable assumption is that the peak IOUT is 6 dB less than the peak

IIN. In that event, for IIN + IOUT = 1.8 mA, IIN = 1.2 mA and IOUT = 600 µA.

With the values shown for R1 and R6, 1.2 mA (peak) of input current will flow when the input signal reaches

17 VRMS (+26.83 dBu). To accommodate higher input voltages, R1 should be scaled larger. Where the maximum

input signal will never approach +26.83dBu, R1 (and R6) may be reduced proportionately, obtaining a

commensurate improvement in signal-to-noise ratio.

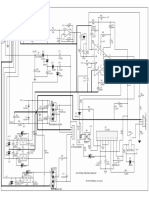

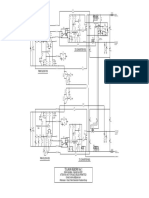

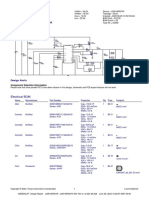

Soft-Threshold Compressor

The preceding basic above-threshold compressor design may be easily altered to suit different applications.

One common variation is to provide a "soft knee" in the compression characteristic (see Figure 9) for a look at this

characteristic. The circuit of Figure 6 will accomplish this.

C2 22p NPO

V+

SIGNAL PATH

R6 20k

9 4305 VCA

12

C1 V+

R1

15 Ec- OUT

IN -IN -

Ec+ 13

GND OA1 OUT

20k V-

10u 11

R2 6 +

8 NE5534,

V IN 6k2

LF351, etc. V OUT

C6 V-

100p V+

C3

10u THRESHOLD V+

-40

R17 GAIN +20

RMS DETECTOR

50k V+

lin R21

+20 50k

lin R22

R24 -20

4305 RMS 634k

R7 V- 75k

2

IN OUT R16 1%

R25 D1 V-

CT 5 412k

32k4 R23

1% 4 1%

10k0 1%

V+ 4k99 1%

R18 D2 COMPRESSION

C4 CT R20

10k0 1%

22u 10u R14 -

R19

- 9k09 1% OA3

V TH 1k

4k99 1% OA2 +

+ lin

V RM S

VG

Un le ss o th erwi se n oted: 1. Al l op am ps 553 2

2. Al l di od es 1 N414 8 3. Al l resi sto rs 5%

4. Al l ca paci to rs 1 0% 5. V+ = +1 5V, V- = -15V SOFT THRESHOLD DETECTOR RATIO CONTROL

Figure. 6. Basic Soft-Threshold Compressor/Limiter

In Figure 6, the operational rectifier used as the threshold detector in Figure 1 has been replaced with an

open-loop diode (D2). A silicon diode such as the 1N4148 used in Figure 6 has an exponential V-I characteristic,

requiring several tenths of a volt to switch from non-conducting to conducting. In the circuit shown, the effective

THAT Corporation; 45 Sumner Street; Milford, MA 01757-1656; USA

Tel: +1 508 478 9200; Email: sales@thatcorp.com; Web: www.thatcorp.com

Copyright © 2019, THAT Corporation; All rights reserved; Document 600xxx Rev G-NOT-RELEASED

THAT Corporation Design Brief 203 Page 5 of 6 Basic Compressor / Limiter Design

with the THAT4305

resistance of D2 will vary with the voltage at the output of OA2, from virtually infinite for negative voltages to tens

of ohms at voltages approaching 700 mV. The variation produces a "sloppy" half-wave rectification of the RMS

detector’s output signal.

The range of voltages over which the D2 provides useful variation in impedance is from about 300 mV to

600 mV, or about 300 mV in total. A 300 mV variation at the RMS detector’s output represents approximately

50 dB variation in signal level — too much to be directly useful for the threshold region. Therefore, additional gain

(OA2, R14, R18, etc.) has been provided to present D2 with a larger voltage range, thereby sharpening the resulting

threshold characteristic. The gain from VRMS to VTH reaches a maximum of approximately 1.8. (At 20 dB

compression, D2 has an impedance of 100 Ω.) R16 has been changed to produce the same threshold range as in

the original circuit.

Figure 7 plots VTH vs. VIN for the circuit of Figure 6 (with variations in THRESHOLD setting). Notice the gradual

transition from 0 V output (no signal passing through) to positive signal output (passing V RMS onwards). A sharper

transition may be achieved by increasing the closed loop gain of OA2 while simultaneously reducing the closed-

loop gain of OA3 by the same ratio.

R24, D1 and R25 are included to provide

temperature compensation for the forward voltage

drop of D2. Assuming +/-15V power supply rails, R24

sets up a current of approximately 130 µA through

D1, giving D1 an impedance of approximately 200 Ω.

R25 adds D1’s forward drop through the summing

junction of OA2 such that it appears in the output of

OA2 at a gain of -1. The forward voltage drop of D1

varies with temperature at approximately 2 mV/°C.

The forward voltage drop of D2 will vary at the same

Figure. 7. VTH vs. VIN for the Soft-Knee Circuit.

rate. The compensation thus adds enough drift to

OA2’s output voltage to compensate for the drift of

D2.

For optimum compensation, D1 and D2 should be matched and co-located so they will track in temperature.

Note that this scheme will not compensate for all the drift of the circuit. The shape of the "knee" drifts slightly

because a diode depends on absolute temperature for its transimpedance. The circuit shown minimizes this effect

by matching the currents through D1 and D2 at the point of 10 dB compression (for R19 at its maximum setting).

The final difference between the circuits of Figure 1 and Figure 6 is in the resistor values around OA3. R20

was scaled upwards to reduce loading on R19, R23 was changed to produce a gain of 0.55 (approximately 1/1.8).

This compensates for the control path gain introduced by OA2 and its associated components, and for the loss

caused by D2. (The compensation for D2 is approximate, since the diode’s impedance varies with current.) And,

R22 was scaled to produce a ±20 dB gain command at VG. The gain from VRMS to VG is approximately 1.0 for signals

far above threshold (those which turn on D2), with R19 at its maximum rotation.

The THRESHOLD, COMPRESSION, and GAIN controls operate just as they did in Figure 1. THRESHOLD adds in

a varying offset to raise or lower the apparent input signal level (from the point of view of the threshold detector);

COMPRESSION allows attenuation of the signal above threshold voltage, and GAIN allows addition of a varying

offset to the static gain of the 4305 VCA.

THAT Corporation; 45 Sumner Street; Milford, MA 01757-1656; USA

Tel: +1 508 478 9200; Email: sales@thatcorp.com; Web: www.thatcorp.com

Copyright © 2019, THAT Corporation; All rights reserved; Document 600xxx Rev G-NOT-RELEASED

THAT Corporation Design Brief 203 Page 6 of 6 Basic Compressor / Limiter Design

with the THAT4305

The result of these changes is to produce a family of "soft-knee" characteristic curves, as shown in Figure 8

and Figure 9. Note the similarity in shape between the plots of control voltage versus input voltage and the plot

of output voltage versus input voltage. The THAT4305 Analog Engine allows the designer to execute a desired

compression characteristic by designing a dc-processing circuit which has that transfer characteristic. This makes

achieving unusual characteristics particularly easy with these parts.

Figure. 8. VG vs. VIN for the Soft-Knee Circuit. Figure. 9. VOUT vs. VIN for the Soft-Knee Circuit.

Closing Thoughts

THAT Corporation welcomes comments, questions and suggestions regarding this application note and its

subject matter. Our engineering staff has extensive experience in designing commercial compressor/limiters based

on the VCAs and RMS-level detectors. We are pleased to offer assistance in optimizing circuitry for your application.

Please feel free to contact us with your thoughts and questions.

THAT Corporation; 45 Sumner Street; Milford, MA 01757-1656; USA

Tel: +1 508 478 9200; Email: sales@thatcorp.com; Web: www.thatcorp.com

Copyright © 2019, THAT Corporation; All rights reserved; Document 600xxx Rev G-NOT-RELEASED

You might also like

- Schematic - YAXUN 881D+ - 2022-01-01Document1 pageSchematic - YAXUN 881D+ - 2022-01-01Murilo de Andrade Melo89% (9)

- SKP MAX-310X-410X-710X-DiagramaDocument1 pageSKP MAX-310X-410X-710X-Diagramaoscar40% (5)

- 5008S Fresenuis Service ManualDocument318 pages5008S Fresenuis Service ManualEslam Karam100% (10)

- Bugera V55-Schematic PDFDocument1 pageBugera V55-Schematic PDFzogivaNo ratings yet

- DientuungdungDocument1 pageDientuungdungakira2020No ratings yet

- SSM 2120 Nivel Detector dn126Document8 pagesSSM 2120 Nivel Detector dn126Edson Francisco SilvaNo ratings yet

- LA500 Schematic 120304Document1 pageLA500 Schematic 120304samoNo ratings yet

- ECHOFEX SchematicDocument1 pageECHOFEX SchematicHristoIlievNo ratings yet

- GAIN +-6 DB Potensio Linier.: Decoupling Capacitor Untuk Op-Amp Tidak DigambarDocument1 pageGAIN +-6 DB Potensio Linier.: Decoupling Capacitor Untuk Op-Amp Tidak Digambar90d0n9 J4m8uNo ratings yet

- Tone Control With Adjutable Freq Ver 1Document1 pageTone Control With Adjutable Freq Ver 1Supratman Dtt WtdaNo ratings yet

- Schematic - TOTEMPOLE BALAP - Sheet - 1 - 20190930201614Document1 pageSchematic - TOTEMPOLE BALAP - Sheet - 1 - 20190930201614jean grangeonNo ratings yet

- +vs - VS: TDA7294V U1Document1 page+vs - VS: TDA7294V U1asep ridwanNo ratings yet

- Filtro Ideal - CircuitoDocument1 pageFiltro Ideal - CircuitoLuiz Alberto SilvaNo ratings yet

- Bal869anced 976y o I68ponput v.1bDocument1 pageBal869anced 976y o I68ponput v.1bmdeky20No ratings yet

- Pasabanda ADA4096 Clase 21 May 2021Document2 pagesPasabanda ADA4096 Clase 21 May 2021Patricio Palenque ReyesNo ratings yet

- HV100 PwrAmp-Sche - RevBDocument1 pageHV100 PwrAmp-Sche - RevBSzabo Mihai-PaulNo ratings yet

- Max310x 410X 710XDocument3 pagesMax310x 410X 710Xroberto-741945No ratings yet

- MAX310X_410X_710XDocument3 pagesMAX310X_410X_710Xroberto-741945No ratings yet

- A Low-Cost VCA Limiter: THAT Corporation Design Note 129Document5 pagesA Low-Cost VCA Limiter: THAT Corporation Design Note 129Edson Francisco SilvaNo ratings yet

- JLM DINgO Complete SchematicDocument1 pageJLM DINgO Complete SchematicsamoNo ratings yet

- SUB-Class IGBT Ver. b2Document4 pagesSUB-Class IGBT Ver. b2Kichiro CarvajalNo ratings yet

- CDV700Pro Construction Tutorial PDFDocument33 pagesCDV700Pro Construction Tutorial PDFjuan9gonzalez_9No ratings yet

- Convertidor AC ImplementadoDocument3 pagesConvertidor AC ImplementadoCarlos VillamarNo ratings yet

- VOX AC15C1 Service ManualDocument22 pagesVOX AC15C1 Service Manualblondeb3No ratings yet

- 68W High Performance Stereo Audio Amplifier Using LM3886 3Document1 page68W High Performance Stereo Audio Amplifier Using LM3886 3HristoIlievNo ratings yet

- Fixed Point FFT Circuit and LayoutDocument1 pageFixed Point FFT Circuit and LayoutAlexe VictorNo ratings yet

- Roland Funny Cat SchematicDocument4 pagesRoland Funny Cat SchematicGustavoTfLa100% (1)

- Service Information Service Information: WWW - Laney.co - UkDocument3 pagesService Information Service Information: WWW - Laney.co - UkCarlos Cárdenas BarbaNo ratings yet

- CP10 CHDocument2 pagesCP10 CHGladson GoesNo ratings yet

- DIY Naim MC To MM Mod Sch2Document1 pageDIY Naim MC To MM Mod Sch2tubetymeNo ratings yet

- TDA7294 400W Dual Bridge Stereo Amplifier Technical MrigankaDocument2 pagesTDA7294 400W Dual Bridge Stereo Amplifier Technical MrigankaNelsonNo ratings yet

- D1KPro Schematic Ver.4aDocument2 pagesD1KPro Schematic Ver.4aWahyudi100% (2)

- Mach InveterDocument1 pageMach InvetervutruongspdtNo ratings yet

- Diagrama Esquemá: Av-InDocument6 pagesDiagrama Esquemá: Av-InFrancisco Carlos SilvaNo ratings yet

- Laney Lg12 SMDocument3 pagesLaney Lg12 SMJavier RojasNo ratings yet

- TD-Java Reborn Ver.1aDocument4 pagesTD-Java Reborn Ver.1aHarlan 123No ratings yet

- Tone Control 3pot PDFDocument1 pageTone Control 3pot PDFDanang PrasetiyoNo ratings yet

- Sginverter 230515Document1 pageSginverter 230515Ibrahim Dalafika AbdullahiNo ratings yet

- Sboa 212 ADocument5 pagesSboa 212 AGathy Brayoh100% (1)

- Daylight BlockingDocument1 pageDaylight BlockingAMANNo ratings yet

- Commax DPV 4HPDocument1 pageCommax DPV 4HPbolek.sNo ratings yet

- Carvin Schematic - DCM2000 REV. HDocument2 pagesCarvin Schematic - DCM2000 REV. Hdod100% (2)

- ECP 2 ReportDocument2 pagesECP 2 ReportDejvis dishiNo ratings yet

- SHC Uart Sac24100Document2 pagesSHC Uart Sac24100bui thuy100% (1)

- Compli CFA TEF Mode Ampli - BindDocument8 pagesCompli CFA TEF Mode Ampli - Bindbahattin147No ratings yet

- Vco Asm1 CCTDocument1 pageVco Asm1 CCTmittyNo ratings yet

- Vco Asm1 CCT PDFDocument1 pageVco Asm1 CCT PDFmittyNo ratings yet

- ETI 1994 04 OCR Page 0024Document1 pageETI 1994 04 OCR Page 0024Jianghong ShenNo ratings yet

- Biema q400 SCHDocument11 pagesBiema q400 SCHEmz TaperlaNo ratings yet

- TD-Java Reborn Ver.1Document5 pagesTD-Java Reborn Ver.1Nguyễn Huy ChungNo ratings yet

- STATIEDocument1 pageSTATIEMeleaca GeorgianNo ratings yet

- Pimeta V1Document2 pagesPimeta V1Donny Adi Hertanto MbtNo ratings yet

- Laney rb1 SCH PDFDocument3 pagesLaney rb1 SCH PDFDiego LimaNo ratings yet

- D1KPro Schematic Ver.1Document3 pagesD1KPro Schematic Ver.1Danang Prasetiyo100% (1)

- MK5PFC-II Schematic Main - D: Filter BoardDocument1 pageMK5PFC-II Schematic Main - D: Filter BoardJdedios66No ratings yet

- IN OUT: For 12 VDC Supply Input & Load: Omit U2 IC and Use Jumper As Shown BelowDocument1 pageIN OUT: For 12 VDC Supply Input & Load: Omit U2 IC and Use Jumper As Shown BelowJuan TiradoNo ratings yet

- Ciclotron Ambw EsdDocument11 pagesCiclotron Ambw EsdTiago DiasNo ratings yet

- Opamp TIDocument5 pagesOpamp TIAmogh Gajaré100% (1)

- HC2 DIY Handclap Schematics 1 0 SyntherjackDocument1 pageHC2 DIY Handclap Schematics 1 0 SyntherjackJoao Vitor Nava StorckNo ratings yet

- Rane vp12Document7 pagesRane vp12bruno magalhãesNo ratings yet

- WBDesign138 Startup-2Document10 pagesWBDesign138 Startup-2bruno magalhãesNo ratings yet

- High Frequency Wire Wound TransformersDocument6 pagesHigh Frequency Wire Wound Transformersbruno magalhãesNo ratings yet

- WBDesign138 - Load Transient-3Document11 pagesWBDesign138 - Load Transient-3bruno magalhãesNo ratings yet

- 8610 AxfDocument6 pages8610 Axfbruno magalhãesNo ratings yet

- LF18G401 Spec SheetDocument2 pagesLF18G401 Spec Sheetbruno magalhãesNo ratings yet

- SN 18elfDocument1 pageSN 18elfbruno magalhãesNo ratings yet

- Ciclotron TIP3000 2AB IIDocument2 pagesCiclotron TIP3000 2AB IIbruno magalhãesNo ratings yet

- Sysiot SR Ru123g05bDocument3 pagesSysiot SR Ru123g05bbruno magalhãesNo ratings yet

- Isobus Implement Connector: Amphenol's IBICDocument4 pagesIsobus Implement Connector: Amphenol's IBICbruno magalhãesNo ratings yet

- ALi+M3602+DVB-S+HD+Ver +1 0Document14 pagesALi+M3602+DVB-S+HD+Ver +1 0bruno magalhãesNo ratings yet

- Plastic and Paper PDFDocument12 pagesPlastic and Paper PDFBhanu Pratap SolankiNo ratings yet

- Unhappy Meals - Michael Pollan - The New York TimesDocument25 pagesUnhappy Meals - Michael Pollan - The New York TimesBob0% (1)

- English Upsr: English Paper 2 - Section B 2 (B) - How To Write Your Reasons - SamplesDocument6 pagesEnglish Upsr: English Paper 2 - Section B 2 (B) - How To Write Your Reasons - SamplesAhmad Firdaus IdrisNo ratings yet

- Binary Vapor Liquid Equilibrium (Vle) Calculator PDFDocument11 pagesBinary Vapor Liquid Equilibrium (Vle) Calculator PDFSalman ZafarNo ratings yet

- Health The Basics 11th Edition Donatelle Test BankDocument19 pagesHealth The Basics 11th Edition Donatelle Test BankJosephWilliamsinaom100% (6)

- Opening Your Own Bank Drops: Edited EditionDocument4 pagesOpening Your Own Bank Drops: Edited EditionGlenda83% (6)

- Cost FM Sample PaperDocument6 pagesCost FM Sample PapercacmacsNo ratings yet

- Kingsmill Materia MedicaDocument32 pagesKingsmill Materia Medicamax quayleNo ratings yet

- Create Database Taller-AdalbertoDocument2 pagesCreate Database Taller-AdalbertoAdalberto GonzalezNo ratings yet

- Christmas Vigil MassDocument106 pagesChristmas Vigil MassMary JosephNo ratings yet

- JF 2 14 PDFDocument32 pagesJF 2 14 PDFIoannis GaridasNo ratings yet

- Consumer Behavior, Market Research, and AdvertisementDocument37 pagesConsumer Behavior, Market Research, and AdvertisementMohamed AbdelazizNo ratings yet

- SPECALOG Hitachi Ex2600-6Document7 pagesSPECALOG Hitachi Ex2600-6andrefilthNo ratings yet

- Stream User-ManualDocument36 pagesStream User-ManualSreekanth NakkaNo ratings yet

- Money Exchange: Materials/Equipment You Would NeedDocument7 pagesMoney Exchange: Materials/Equipment You Would NeedEsther Joy PerezNo ratings yet

- Understanding Nuances and Commonalities of Job DesDocument10 pagesUnderstanding Nuances and Commonalities of Job DesAmrezaa IskandarNo ratings yet

- Philippine Statistics Authority: Date (2021)Document9 pagesPhilippine Statistics Authority: Date (2021)Nah ReeNo ratings yet

- Astm A 1011 2005Document8 pagesAstm A 1011 2005gao yanminNo ratings yet

- ScheduleDocument2 pagesScheduleJen NevalgaNo ratings yet

- 9de13c0f0c009828f703d0103efa820b.xlsDocument70 pages9de13c0f0c009828f703d0103efa820b.xlsPreeti JaiswalNo ratings yet

- Comparative Investment ReportDocument8 pagesComparative Investment ReportNelby Actub MacalaguingNo ratings yet

- Chapter 1.2 Types of Organisation (Notes)Document5 pagesChapter 1.2 Types of Organisation (Notes)S RameshNo ratings yet

- List of TradeMark Forms & Therein PDFDocument17 pagesList of TradeMark Forms & Therein PDFShreeneetRathiNo ratings yet

- 2011 C1 CoMe ORGMIDocument8 pages2011 C1 CoMe ORGMIADJ ADJNo ratings yet

- 6068TF250 Engine Performance CurveDocument2 pages6068TF250 Engine Performance CurveJulioNo ratings yet

- OpenFOAM编程指南Document100 pagesOpenFOAM编程指南Feishi XuNo ratings yet

- Latest Volleyball News From The NCAA and NAIADocument3 pagesLatest Volleyball News From The NCAA and NAIAFernan RomeroNo ratings yet

- Sandy Point Brochure 2016Document7 pagesSandy Point Brochure 2016miller999No ratings yet

- B94-6 R1995 E1984Document21 pagesB94-6 R1995 E1984zojoNo ratings yet