Professional Documents

Culture Documents

Analysis

Analysis

Uploaded by

PSGOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis

Analysis

Uploaded by

PSGCopyright:

Available Formats

International Journal of Research p-I SSN: 2 3 4 8 -6 8 4 8

e-I SSN: 2 3 4 8 -7 9 5 X

Available at https://edupediapublications.org/journals

Vol ume 0 3 I s s ue 1 4

O c tober 2 0 1 6

Design and Analysis of Multi-Plate Clutch Unit

1 V. Madhu Kumar, 2 Ms. K. Lohith Jwalanthi

1 Pg Scholar, Department of Mechanical Engineering, Brilliant Grammer School Educational Society's

Group Of Institutions, Rangareddy(D) Telangana.

2 Associate Professor, Department of Mechanical Engineering, Brilliant Grammer School Educational

Society's Group Of Institutions , Rangareddy(D) Telangana.

ABSTRACT: software Pro / Engineer. We are carrying out

The clutch is a mechanical device that provides structural design analysis of the above to

for the transfer of energy (and therefore usually validate the design. We are in the analysis by

movement) of a component (a member of the changing the surfaces of friction materials.

address) to another (driven). The other When removing the result we will see which is

component of brake clutch. Multiple disc the best material for covering the roofs of

clutch can be used when a large torque is friction. And structural analysis plate multi-use

moving. It is installed inside the unit to the properties of the two materials clutch. The

driven shaft to permit axial movement. And the materials used for the coating is Cork, powder

complexity of the disks and external screws are metallurgy. And compared to the over all

attached to the housing, which is linked to the materials check out the best materials for the

drive shaft. Using multiple disc clutches health of the lining of the multi-plate clutch

widely in cars cars, motorcycles, machine plate in different circumstances coefficient of

tools, etc., have not usually from the inside friction.

they are usually made of stainless steel and INTRODUCTION:

bronze external hard drives. The materials used

Clutch is a mechanism for transmitting

for coating the friction surfaces are made of

cork, rubber, cast iron and metal powder. The rotation, which can be engaged and

project objective is to design a multi-plate

disengaged. Clutches are useful in devices that

clutch using empirical formulas. And drafting

have two rotating shafts. In these devices, one

and 2D drawing plate clutch multiple accounts

and a 3D model is created in 3D modeling shaft is typically driven by a motor or pulley,

Available online: https://edupediapublications.org/journals/index.php/IJR P a g e | 5 3 65

International Journal of Research p-I SSN: 2 3 4 8 -6 8 4 8

e-I SSN: 2 3 4 8 -7 9 5 X

Available at https://edupediapublications.org/journals

Vol ume 0 3 I s s ue 1 4

O c tober 2 0 1 6

and the other shaft drives another device. Let torque by using the surface friction between two

us take an instance where one shaft is driven faces of the clutch.

by a motor and the other drives a drill chuck.

Dog Clutch

The clutch connects the two shafts so that they

A dog clutch couples two rotating shafts or other

can either be locked together and spin at the

rotating components not by friction, but by

same speed (engaged), or be decoupled and

interference. Both the parts of the clutch are

spin at different speeds (disengaged).

designed so that one pushes into the other,

Depending on the orientation, speeds, material,

causing both to rotate at the same speed, so that

torque produced and finally the use of the

they never slip.

whole device, different kinds of clutches are

used. The clutch in itself is a mechanism, Cone Cutch

which employs different configurations and

Cone clutches are nothing, but frictional clutches

different principles in various models

with conical surfaces. The area of contact differs

available. In the following lines, we have

from normal frictional surfaces. The conical

provided the different kinds of clutches that are

surface provides a taper, which means that while a

available.

given amount of actuating force brings the

Different Kinds Of Clutch surfaces of the clutch into contact really slowly,

the pressure on the mating surfaces increases

Friction Clutch

rapidly.

Friction clutches are the most commonly used

Overrunning Clutch:Also known as the freewheel

clutch mechanisms. They are used to transmit

mechanisms, this type of clutch disengage the

driveshaft from the driven shaft, when the driven

Available online: https://edupediapublications.org/journals/index.php/IJR P a g e | 5 3 66

International Journal of Research p-I SSN: 2 3 4 8 -6 8 4 8

e-I SSN: 2 3 4 8 -7 9 5 X

Available at https://edupediapublications.org/journals

Vol ume 0 3 I s s ue 1 4

O c tober 2 0 1 6

shaft rotates faster than the driveshaft. An and engages the clutch, which then drives the

example of such a situation can be when a cyclist driven shaft.

stops peddling and cruises. However, in case of

Hydraulic Clutch

automobiles going down the hill, you cannot take

In a hydraulic clutch system, the coupling is

your feet off the gas pedal, as there is no free

hydrodynamic and the shafts are not actually in

wheel system. If you do so, the whole engine

contact. They work as an alternative to

system can be damaged.

mechanical clutches. They are known to have

Safety Clutch:Also known as the torque limiter,

common problems associated with hydraulic

this device allows a rotating shaft to "slip" or

couplings, and are a bit unsteady in transmitting

disengage when higher than normal resistance is

torque.

encountered on a machine. An example of a

Electromagnetic Clutch

safety clutch is the one mounted on the driving

shaft of a large grass mower. If a stone or These clutches engage the theory of magnetism

something else is encountered by the grass on to the clutch mechanisms. The ends of the

mower, it stops immediately and does not hamper driven and driving pieces are kept separate and

the blades. they act as the pole pieces of a magnet. When a

DC current is passed through the clutch system,

Centrifugal clutchCentrifugal and semi-

the electromagnet activates and the clutch is

centrifugal clutches are employed where they

engaged.

need to engage only at some specific speeds.

There is a rotating member on the driving shaft, 2. Plate friction material

which rises up as the speed of the shaft increases Different special friction materials are

availablefor wet and dry running clutches and

Available online: https://edupediapublications.org/journals/index.php/IJR P a g e | 5 3 67

International Journal of Research p-I SSN: 2 3 4 8 -6 8 4 8

e-I SSN: 2 3 4 8 -7 9 5 X

Available at https://edupediapublications.org/journals

Vol ume 0 3 I s s ue 1 4

O c tober 2 0 1 6

brakes. Thefriction material used represents the disengagement)process together with the static

mostimportant part of each friction

coefficient offriction μ0, when torque is being

combination,which effectively consist of, in

transmitted,depend on a number of factors: .

addition, thecounter frictional surface and, in the

case ofwet-running, the oil. The friction Combination of materials at the friction surfaces

combinationinfluences the behavior of the clutch

.Design of friction surfaces, e.g. with grooves

or brakewhen being engaged and disengaged,

orchannels .Surface structure, e.g. sliding finish

thepermissible thermal loading, the behavior

interms of wear and thereby the required size of .Friction surface pressure .Sliding speed

theclutch or brake. Only when these

.Temperature level and maximum temperature

importantproperties are known can the optimum

atfriction surface .Dry- or wet-running, e.g.

frictioncombination for a given application be

selectedin order to give the desired behavior and lubrication behavior,direction of cooling oil.

service life. In order to provide understanding of

theapplication selection of friction 3. LITERATURE REVIEW:

combinations,the following sections will describe

The Friction plate used in this Project is part of a

thecharacteristic properties and main areas of use

ofour different standard friction Wet Multi-Plate clutch System which is normally

combinations,namely steel/steel, steel/sintered used in commercial Motor vehicles. The clutch

lining and steelor cast iron/organic friction lining,

Friction plate is located between the Clutch

all of which have proved themselves in use over

manyyears.Should you have special requirements Center and the Pressure plate. The clutch

withregard to the dynamic torque, the static torque cushioning spring is a plate where is acts to

orthe lubricant to be used, please contact us.

absorb the vibration effect during clutch

Forsuch cases, special friction materials such as

platescoated with molybdenum are available. engagement as well as linking the clutch counter

Frictional behavior mate disc and the clutch disc base together.

The changes in the coefficient of friction Gorin and Shilyaev (1976)[1] studied

duringthe course of an engagement (or the analytical solutions between two rotating

Available online: https://edupediapublications.org/journals/index.php/IJR P a g e | 5 3 68

International Journal of Research p-I SSN: 2 3 4 8 -6 8 4 8

e-I SSN: 2 3 4 8 -7 9 5 X

Available at https://edupediapublications.org/journals

Vol ume 0 3 I s s ue 1 4

O c tober 2 0 1 6

annular disks having small gaps. Since the equations of heat conduction to model the heat

analytical solutions were derived from the Navier- generated by the asperity contact. Furthermore,

Stokes equations using an integral approach, i.e. the conducted experiments with multi- friction

the Slezkin- Targ method, the inertial terms were plates to measure the torque and temperature

not considered. The study was limited to laminar variation in the system. They found that during

flow between a rotating and a stationary disk, and engagement the temperature at the centerline of

computed exactly the radial, axial and tangential the separator plates begins to rise from its initial

velocity components. state. Also, it was observed that during the

engagement process the temperature at the end of

Li and Tao[2] (1994) compared three

clutch pack was much lower than that between the

types of outflow boundary conditions for

friction plates although the temperature at the

recirculating flows with experiment data for

both locations was almost identical prior to

convective heat transfer of a two-dimensional jet

engagement. Since the friction material insulates

impinging on a rectangular cavity. They tried a

the separator area surrounded by the friction

local mass conservation method, a local one-way

plates, it achieves a higher temperature than that

method and a fully-developed flow assumption.

of the separator area, whose one side is in contact

They concluded that, if possible, the area of the

with the piston Berger et al.[4] (1996) developed

outflow boundary should be located far enough

a Finite- Element Model (FEM) model to simultate

from the re circulating area in order to obtain a

the engagement of rough, grooved, paper-based

realistic numerical solution and avoid significant

permeable wet clutches. A modified 16 Reynolds

errors. Of the three methods that Li and Tao

equation was adopted from the Patir and Cheng

studied, the mass conservation method for the

flow model using average flow factors to include

outflow boundary model having are circulating

surface roughness effects. The Reynolds equation

flow at the boundaries had the best agreement

and force balance equations were discretized

with the experimental data. Natsumeda and

using the Galerkin approach. The simulation

Miyoshi[3] (1994) developed a numerical solution

results indicate that increasing the applied force

for the clutch 15 engagement process including

increases the torque peak and decreases the

the permeability of the friction plate, the

engagement time. Furthermore, the permeability

compressive strain and the asperity contact of the

of the friction material affects the magnitude of

friction material. In addition, they solved the

the increase in torque peak and the corresponding

Available online: https://edupediapublications.org/journals/index.php/IJR P a g e | 5 3 69

International Journal of Research p-I SSN: 2 3 4 8 -6 8 4 8

e-I SSN: 2 3 4 8 -7 9 5 X

Available at https://edupediapublications.org/journals

Vol ume 0 3 I s s ue 1 4

O c tober 2 0 1 6

decrease in engagement time. The FEM model at high rpm. The analytical solution of Yan et al.

radial grooves on the friction material and the agreed well with the experimental results,

computational results showed that an increase in however the need for adjustment of the oil

groove width results in a decrease of the torque viscosity was rather problematic. Also, since the

peak while groove depth only slightly affects the model corresponded to a non-grooved open wet

torque. Furthermore, the film thickness decay was clutch, there were limitations to any potential

shown to be related to increasing the torque peak. applications to a realistic wet clutch having a

However, no comparison between the simulation grooved friction plate and undergoing dynamic

and available experimental measurements were engagement.

made. In 1997, to obtain a more efficient

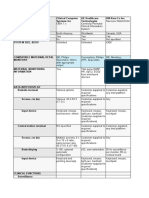

CONCLUSION

solution to the problem, the modified Reynolds

equation of Berger et al.[5] (1997) was simplified In this project the clutch plate has been

assuming axisymmetric flow, and neglecting the designed by using cad tool creo-2 and then

importing into cae tool (Ansys Work

compressive strain of the friction material. The

system of Reynolds and force balance equations Bench) and the clutch plate made up of

steel and bronze materials and cork as a

was reduced to a single, first-order differential

equation that resulted in a fast executing model. friction material in between For cork

Yuan et al. [6](2007) proposed an improved material we applied 0.25Mpa pressure on

that and calculated results like

hydrodynamic model for open, wet-clutch

behavior. This theoretical model includes not only deformation, stress and safety factor From

the above results we identified one

the effects of trapped air bubbles, but also surface

tension and wall adhesion. The surface tension problem with existing material while

between fluid and air at outer interface is assumed increasing coefficient of friction the stress

value also increased and to avoid this and

and the relation between the surface tension and

the pressure jump is formulated. With the we chosen copper powder metal and

analyzed with same boundary conditions.

formulation, an equivalent radius assumption was

made. The drag torque for the equivalent radius The changing materials having less stress

was validated with experiment results and the values compare to existing material and

have good safety factor values. Finally the

computed drag torque from this model was

proven to be more accurate than previous models cu powder metal have less deformation

Available online: https://edupediapublications.org/journals/index.php/IJR P a g e | 5 3 70

International Journal of Research p-I SSN: 2 3 4 8 -6 8 4 8

e-I SSN: 2 3 4 8 -7 9 5 X

Available at https://edupediapublications.org/journals

Vol ume 0 3 I s s ue 1 4

O c tober 2 0 1 6

and stress values and high safety factor cutch facing [J]. Journal of

and stiffness compare to cork results. Tribology, 1994, vol.2,pp.232-

237.

References

10. E J Berger, F Sadeghi, C M

1. "From the Hele-Shaw Experiment Krousgrill. Analytical and

to IntegrableSystems: A Historical numerical modeling of

Overview" (PDF). University of engagement of rough, permeable,

Bergen. Retrieved August 9, 2012. grooved wet clutches [J].Journal

2. JAnaldo M. English, Friction- of Tribology,1997,vol.

Clutch, US 255957, granted Apr. 4 119,pp.143- 148

1882. 11. Finite Element Modeling of

3. Charles C. Tillotson, Power- Engagement of Rough and

Transmission Clutch, US 850981, Grooved Wet Clutches E. J.

granted Apr. 23, 1907. Berger, F. Sadeghi and C. M.

4. Frank Wheeler, Clutch and stop Krousgrill

mechanism for presses, US 12. Y. Yuan, E. A. Liu, J. Hill, and Q.

470797, granted Dec. 14, 1891. Zou, “An improved hydrodynamic

5. Samuel Trethewey, Clutch, US model for open wet transmission

495686, granted Apr. 18, 1893. clutches,” Journal of Fluids

Engineering, Transactions of the

6. Fred. R. Allen, Clutch, US

1025043, granted Apr. 30, 1912. ASME, vol. 129, no. 3, pp. 333–

337, 2007.

7. John J. Zeitz, Friction-clutch, US

13. S.Jaya Kishore, M.Lavakumar,

906181, granted Dec. 8, 1908.

“Structural Analysis of Multi Plate

8. William Lautenschlager, Friction

Clutch”, International Journal of

Clutch, US 1439314, granted Dec.

Computer Trends and

19, 1922.

Technology(IJCTT), Volume 4

9. S Natsumeda, T Miyoshi.

Issue 7-July 2014. [8] T.K.

Numerical simulation of

Garrett,K.Newton,W.Steeds,The

engagement of paper based wet

Motor Vehicle,Thirdedition.

Available online: https://edupediapublications.org/journals/index.php/IJR P a g e | 5 3 71

International Journal of Research p-I SSN: 2 3 4 8 -6 8 4 8

e-I SSN: 2 3 4 8 -7 9 5 X

Available at https://edupediapublications.org/journals

Vol ume 0 3 I s s ue 1 4

O c tober 2 0 1 6

AUTHOR’S PROFILE:

V. Madhu Kumar, Pg Scholar in

Department of Mechanical Engineering

from Brilliant Grammer School

Educational Society's Group Of

Institutions

Ms. K. Lohith Jwalanthi

Associate Professor

M.TECH cad/cam

Brilliant Grammer School Educational

Society's Group Of Institutions,

Abdullapur,Hayathnagar,Hyderabad,Rr

Dist-501505.

Available online: https://edupediapublications.org/journals/index.php/IJR P a g e | 5 3 72

You might also like

- Solution Manual For Theory and Design For Mechanical Measurements 6th Edition Richard S Figliola Donald e BeasleyDocument20 pagesSolution Manual For Theory and Design For Mechanical Measurements 6th Edition Richard S Figliola Donald e BeasleyLoriWilliamsonoqabx98% (46)

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingFrom EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingRating: 4.5 out of 5 stars4.5/5 (9)

- Module 1Document32 pagesModule 1abhishek bsNo ratings yet

- Life 2e BrE Inter SB U01AB Day-1Document29 pagesLife 2e BrE Inter SB U01AB Day-1Quỳnh NhưNo ratings yet

- My SMART Goal UK - Big Life JournalDocument6 pagesMy SMART Goal UK - Big Life Journalacmc100% (2)

- Multi Clutch Project Report CoepDocument28 pagesMulti Clutch Project Report CoepStalk Gamer0% (2)

- Keshav Jangir Seminar-1Document33 pagesKeshav Jangir Seminar-1video songNo ratings yet

- 2 Malleshwar Rao 3 Sandhya Girish FinalDocument14 pages2 Malleshwar Rao 3 Sandhya Girish FinalPrateek DhamijaNo ratings yet

- Clutch Assembly Modeling and Dynamic Analysis: Gowtham ModepalliDocument6 pagesClutch Assembly Modeling and Dynamic Analysis: Gowtham ModepalliLại Thế KhánhNo ratings yet

- Final Project Design of Machine Elements IIDocument27 pagesFinal Project Design of Machine Elements IIScribdTranslationsNo ratings yet

- Rover With Rocker-Bogie Linkage Mounted With An Ultrasonic Sensor and Bluetooth ModuleDocument5 pagesRover With Rocker-Bogie Linkage Mounted With An Ultrasonic Sensor and Bluetooth Moduleshaik roshanNo ratings yet

- GEARS FUNdaMENTALS of Design Topic 6 PDFDocument62 pagesGEARS FUNdaMENTALS of Design Topic 6 PDFCristina Andreea CrissyNo ratings yet

- Keshav Jangir Seminar Front PageDocument39 pagesKeshav Jangir Seminar Front Pagevideo songNo ratings yet

- Chapter 2 Clutches Upload Rev1Document11 pagesChapter 2 Clutches Upload Rev1Weekly ExposureNo ratings yet

- Chapter ThreeDocument29 pagesChapter ThreeAbel OmweriNo ratings yet

- 1582887084-UI - 01 - 12. MechanismsDocument6 pages1582887084-UI - 01 - 12. MechanismsGeorgiana LazarNo ratings yet

- Ravikumar 2020 IOP Conf. Ser. Mater. Sci. Eng. 988 012043Document15 pagesRavikumar 2020 IOP Conf. Ser. Mater. Sci. Eng. 988 012043ko koNo ratings yet

- Fea Project (BG and LV)Document5 pagesFea Project (BG and LV)Zaman SuhailNo ratings yet

- ST1503 020Document7 pagesST1503 020MainãNo ratings yet

- Automatic Electromagnetic ClutchDocument15 pagesAutomatic Electromagnetic Clutchtapas_kbNo ratings yet

- F 201503291427610130Document8 pagesF 201503291427610130KirtiPadhiyarNo ratings yet

- "ROCKER BOGIE SUSPENSION SYSTEM" Ijariie5476Document6 pages"ROCKER BOGIE SUSPENSION SYSTEM" Ijariie5476Kanna MonishNo ratings yet

- ShaikJohnBhasha HariSankarVanka 50Document7 pagesShaikJohnBhasha HariSankarVanka 50Vignesan MechNo ratings yet

- Report On CLUTCH VIJAY KALEDocument21 pagesReport On CLUTCH VIJAY KALEChinmay AlandkarNo ratings yet

- Brakes, Clutch and CoplingDocument35 pagesBrakes, Clutch and CoplingJohnNo ratings yet

- Mechanisms Notes 2012Document12 pagesMechanisms Notes 2012kookwfNo ratings yet

- Design and Fabrication of Elliptical Trammel Using Perfomance Analysis of Reciprocating PumpDocument13 pagesDesign and Fabrication of Elliptical Trammel Using Perfomance Analysis of Reciprocating PumpAkhil MetlaNo ratings yet

- Design, Fabrication AND Analysis OF Rocker Bogie Mechanism: Mukt Shabd Journal ISSN NO: 2347-3150Document15 pagesDesign, Fabrication AND Analysis OF Rocker Bogie Mechanism: Mukt Shabd Journal ISSN NO: 2347-3150Tejas PrakashNo ratings yet

- Title: Design and Analysis of Gearless Transmission SystemDocument6 pagesTitle: Design and Analysis of Gearless Transmission SystemLokeshNo ratings yet

- Electromagnetic Clutch System Full Seminar Report 4537Document30 pagesElectromagnetic Clutch System Full Seminar Report 4537Lalit Tanan100% (1)

- Development and Fabrication of Multi-Purpose Machine: Praveen Karanam, Karthik A.V., Akshay S Bhat, Swaroop H.P., GaneshDocument6 pagesDevelopment and Fabrication of Multi-Purpose Machine: Praveen Karanam, Karthik A.V., Akshay S Bhat, Swaroop H.P., GaneshBADINEHALSANDEEPNo ratings yet

- Can CrusherDocument42 pagesCan CrusherParveen Jaat100% (2)

- Vibrations of Cracked RotorsDocument4 pagesVibrations of Cracked RotorsEditor IJRITCCNo ratings yet

- Modeling and Fatigue Analysis of Metal Matrix Composite Cam Shaft Using Finite Element AnalysisDocument10 pagesModeling and Fatigue Analysis of Metal Matrix Composite Cam Shaft Using Finite Element AnalysissamaNo ratings yet

- JETIR1906R84Document10 pagesJETIR1906R84Vignesan MechNo ratings yet

- A Study of Bearing and Its Types: April 2015Document9 pagesA Study of Bearing and Its Types: April 2015Ganta MaheshNo ratings yet

- LINK Shop ExerciseDocument15 pagesLINK Shop ExerciseNicole MilanNo ratings yet

- A Roller Chain Drive Model Including Contact With Guide-BarsDocument18 pagesA Roller Chain Drive Model Including Contact With Guide-BarsPietroNo ratings yet

- Basic TechDocument28 pagesBasic Techoby83.oooNo ratings yet

- Report Screw Jack (1) TDocument47 pagesReport Screw Jack (1) TAshish Sharma80% (5)

- Automatic Drainage Cleaning SystemDocument3 pagesAutomatic Drainage Cleaning Systemrock starNo ratings yet

- A Roller Chain Drive Model Including Contact With Guide-BarsDocument18 pagesA Roller Chain Drive Model Including Contact With Guide-BarsTrúc LinhhNo ratings yet

- Design and Fabrication of Box Transport Mechanism PDFDocument5 pagesDesign and Fabrication of Box Transport Mechanism PDFBharathNo ratings yet

- Parative Study On Flexible Type of ClutchesDocument6 pagesParative Study On Flexible Type of ClutchesSina ShourakiNo ratings yet

- Design and Development of Box Shifting Mechanism Using Gearless Power Transmission System1Document5 pagesDesign and Development of Box Shifting Mechanism Using Gearless Power Transmission System1International Journal of Innovative Science and Research TechnologyNo ratings yet

- A 3D-Printed Wheel With Constant Mass and Variable Moment of Inertia For Lab and DemonstrationDocument4 pagesA 3D-Printed Wheel With Constant Mass and Variable Moment of Inertia For Lab and DemonstrationDiogo LacerdaNo ratings yet

- Annasaheb Dange College of Engineering and Technology, AshtaDocument10 pagesAnnasaheb Dange College of Engineering and Technology, AshtaDipak BhagatNo ratings yet

- Gear Train ExperimentDocument8 pagesGear Train ExperimentRaza MutahirNo ratings yet

- Reverse Gear Mechanism For Handicapped PersonDocument4 pagesReverse Gear Mechanism For Handicapped PersonKoushik VimalanNo ratings yet

- Design and Analysis of Lower Control Arm of Suspension SystemDocument9 pagesDesign and Analysis of Lower Control Arm of Suspension SystemDavid Emanuel Gómez VidalNo ratings yet

- Analysis of The Single Toggle Jaw Crusher KinematicsDocument36 pagesAnalysis of The Single Toggle Jaw Crusher KinematicsCarlos Ediver Arias RestrepoNo ratings yet

- Coupled Structual Thermal Analysis of Disc BrakeDocument15 pagesCoupled Structual Thermal Analysis of Disc BrakeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Shape Separation of ParticlesDocument10 pagesShape Separation of Particlesبلال بن عميرهNo ratings yet

- TOMM ReportDocument10 pagesTOMM ReportMadhur WaghNo ratings yet

- Microproject Plan B FormatDocument7 pagesMicroproject Plan B FormatKaustubh NaikNo ratings yet

- Underwater Stingray Mechanism BotDocument3 pagesUnderwater Stingray Mechanism BotInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Gear Train PDFDocument10 pagesGear Train PDFABHIJITNo ratings yet

- Third Term jss2 Basic Technology - 081916Document25 pagesThird Term jss2 Basic Technology - 081916John EgbongNo ratings yet

- Circular 38-23 - 16032023Document1 pageCircular 38-23 - 16032023PSGNo ratings yet

- 1 07 958 007Document1 page1 07 958 007PSGNo ratings yet

- Liberty Galati Requirements For Execution New Sparts - Bolt - 1.07.958.006Document4 pagesLiberty Galati Requirements For Execution New Sparts - Bolt - 1.07.958.006PSGNo ratings yet

- Revised1 Notification Annexure CDocument6 pagesRevised1 Notification Annexure CPSGNo ratings yet

- Pre RequisitesDocument1 pagePre RequisitesPSGNo ratings yet

- Wa0006.Document14 pagesWa0006.PSGNo ratings yet

- Name Pasmanan D SH VG Ti1: Continuous, Ii. Insotatonal o SotationalDocument3 pagesName Pasmanan D SH VG Ti1: Continuous, Ii. Insotatonal o SotationalPSGNo ratings yet

- Your Selection For Personal Interview at Schneider Electric India PVT Ltd. Ahmednagar (Venue - Govt Poly Ahmednagar Campus) 12th May 2022 at 9.00 AmDocument1 pageYour Selection For Personal Interview at Schneider Electric India PVT Ltd. Ahmednagar (Venue - Govt Poly Ahmednagar Campus) 12th May 2022 at 9.00 AmPSGNo ratings yet

- OD124880239808548000Document1 pageOD124880239808548000PSGNo ratings yet

- Checklist - Turning Client To Lateral or Prone PositionDocument3 pagesChecklist - Turning Client To Lateral or Prone PositionNorhaina AminNo ratings yet

- Davis - Mathematics of Matrices PDFDocument366 pagesDavis - Mathematics of Matrices PDFRafael Garcia100% (1)

- Notes - Introduction To I/O PsychologyDocument30 pagesNotes - Introduction To I/O PsychologyMARIA SABINA BIANCA LIM UY100% (2)

- Kundalini YogaDocument153 pagesKundalini Yogaprajjwal singhNo ratings yet

- Service Quality Analysis of SBIDocument38 pagesService Quality Analysis of SBIAkhil BhatiaNo ratings yet

- Grammar ManualDocument130 pagesGrammar ManualJahnaviNo ratings yet

- Villains & Vigilantes Character TemplatesDocument9 pagesVillains & Vigilantes Character TemplatesLink PelcherNo ratings yet

- Information Management Systems, ObstetricalDocument12 pagesInformation Management Systems, ObstetricalLee ThoongNo ratings yet

- The Heart of Memory by Alison Strobel, ExcerptDocument49 pagesThe Heart of Memory by Alison Strobel, ExcerptZondervanNo ratings yet

- Practice 9.đáDocument5 pagesPractice 9.đáNguyễn Vân QuỳnhhNo ratings yet

- Steps: To Personal EvangelismDocument20 pagesSteps: To Personal EvangelismDwayne Bob LerionNo ratings yet

- KPK fsc2 ch02 - NotesDocument33 pagesKPK fsc2 ch02 - NotesShujahatNo ratings yet

- I. Objectives: PE10PF-Ia-h-39Document3 pagesI. Objectives: PE10PF-Ia-h-39Ken Genece LlanesNo ratings yet

- Bonding CompositeDocument210 pagesBonding CompositeDinesh KumarNo ratings yet

- ICT-Pedagogy Integration in MathematicsDocument11 pagesICT-Pedagogy Integration in MathematicsKaren Faye LagundayNo ratings yet

- Understanding The Gender Pay Gap: Women in Business and ManagementDocument8 pagesUnderstanding The Gender Pay Gap: Women in Business and Managementmostafa aliNo ratings yet

- Mio Amore Registration Form (1) - 1Document4 pagesMio Amore Registration Form (1) - 1Anish ChakrabortyNo ratings yet

- Accessories BOQ For HP, MP, LP Steam+CondensateDocument14 pagesAccessories BOQ For HP, MP, LP Steam+Condensatefakir mohammadNo ratings yet

- WF D02A Energy MeterDocument10 pagesWF D02A Energy MeterfioNo ratings yet

- Prashant Pandey Roll No 57 FinalDocument87 pagesPrashant Pandey Roll No 57 FinalSMF022VANSH JAINNo ratings yet

- A Study On Effective Cash Management System Performance in Abc Techno Labs India Private LimitedDocument8 pagesA Study On Effective Cash Management System Performance in Abc Techno Labs India Private LimitedBabasaheb JawalgeNo ratings yet

- (VigChr Supp 115) Lenka Karfíková - Grace and The Will According To Augustine 2012 PDFDocument443 pages(VigChr Supp 115) Lenka Karfíková - Grace and The Will According To Augustine 2012 PDFNovi Testamenti FiliusNo ratings yet

- Behavior of AAC Infilled RC Frame Under Lateral Loading: January 2014Document12 pagesBehavior of AAC Infilled RC Frame Under Lateral Loading: January 2014PREMALATHA JNo ratings yet

- Lesson 3Document30 pagesLesson 3Ellaine Grace Delima GurroNo ratings yet

- 47 01 000 - CenDocument54 pages47 01 000 - CenRicardo Vitoriano100% (2)

- Role of MNC in IndiaDocument41 pagesRole of MNC in IndiaKhundongbam SureshNo ratings yet

- Chassis Family: MX1 MX2 MX3 MX4 MX5 MX6 MX7 MX8 MX10 MX12 Mx5ZDocument7 pagesChassis Family: MX1 MX2 MX3 MX4 MX5 MX6 MX7 MX8 MX10 MX12 Mx5ZchepimancaNo ratings yet