Professional Documents

Culture Documents

Installation Instructions N-1602

Installation Instructions N-1602

Uploaded by

alex maltezCopyright:

Available Formats

You might also like

- CONE VALVE Service ManualDocument30 pagesCONE VALVE Service ManualMathieu DouNo ratings yet

- A6GF1, A6LF1/2/3, A6MF1/2: Hyundai/KiaDocument1 pageA6GF1, A6LF1/2/3, A6MF1/2: Hyundai/Kiahidraulic100% (1)

- 1962-Burgmaster - Bench Model Turret Drilling and Tapping MachineDocument17 pages1962-Burgmaster - Bench Model Turret Drilling and Tapping Machinesalulai100% (3)

- Volvo Penta - Diagrama de Montagem - DPH PDFDocument1 pageVolvo Penta - Diagrama de Montagem - DPH PDFJorge Lopes100% (1)

- JENBACHERDocument457 pagesJENBACHERRaymundo Jimenez Herrera100% (1)

- GE MX-150 ManualDocument28 pagesGE MX-150 ManualCristian Munoz60% (5)

- 20 Watts TDA2005 Bridge Amplifier Project With Tone Control CircuitDocument10 pages20 Watts TDA2005 Bridge Amplifier Project With Tone Control CircuitMuhammad YousafNo ratings yet

- Merc7229 VBL InteractiveDocument1 pageMerc7229 VBL InteractiveMauricio Exequiel ChavezNo ratings yet

- n3135 RegulatorDocument2 pagesn3135 Regulatoryr5xrzgww8No ratings yet

- 23-3 Reminders ON THE USE OF Nibbler & Breakers: RunnmgDocument1 page23-3 Reminders ON THE USE OF Nibbler & Breakers: RunnmgPhan DungNo ratings yet

- Hoja Tecnica Control de NivelDocument3 pagesHoja Tecnica Control de NivelpawerxlNo ratings yet

- ServiceSchedule MD22Document3 pagesServiceSchedule MD22theo_swaranNo ratings yet

- FNH 5640-8340 Omm PDFDocument65 pagesFNH 5640-8340 Omm PDFan0th3r_0n3100% (1)

- Esc-Ecomat Service Check: Key To DrawingDocument2 pagesEsc-Ecomat Service Check: Key To DrawingЛеонид БеркоNo ratings yet

- GENERATOR Data SheetDocument1 pageGENERATOR Data Sheetshinki31000No ratings yet

- FW6A Manual CuerpoDocument11 pagesFW6A Manual CuerpoHenrry trespalaciosNo ratings yet

- Contact or Brochure CC SeriesDocument24 pagesContact or Brochure CC SeriesElizabethAguirreNo ratings yet

- TF 81SC VBL Interactive PDFDocument1 pageTF 81SC VBL Interactive PDFJUAN ENRIQUE TORRIJOS FLORESNo ratings yet

- Instrukciya Po Ustanovke Turbotajmera Hks Type 0Document2 pagesInstrukciya Po Ustanovke Turbotajmera Hks Type 0Álvaro AvilaNo ratings yet

- 04 ExDocument4 pages04 Exlone_anarchistNo ratings yet

- Hydraulic Force Control: Ser ManualDocument18 pagesHydraulic Force Control: Ser ManualDinh SangNo ratings yet

- Electric Devices: Name of PartsDocument30 pagesElectric Devices: Name of PartsAde HanggaraNo ratings yet

- Baldwin Vacuum Gage Kit IOMDocument1 pageBaldwin Vacuum Gage Kit IOMSMcNo ratings yet

- 510B Backhoe Loader: Engine PerformanceDocument5 pages510B Backhoe Loader: Engine PerformancebalajimetturNo ratings yet

- ESG2001C1-W Controller PDFDocument12 pagesESG2001C1-W Controller PDFRenato Matičević100% (1)

- Dayton Parallel Shaft High: Torque AC GearmotorsDocument12 pagesDayton Parallel Shaft High: Torque AC GearmotorsFelipe Ivan Escudero VidalNo ratings yet

- Transmission Functionalities 2014 enDocument3 pagesTransmission Functionalities 2014 enriqtorresNo ratings yet

- 570a PDFDocument3 pages570a PDFTamquadistu AlexNo ratings yet

- Jd570-A Motorgrader: Engine Performance Add Versatility WithDocument3 pagesJd570-A Motorgrader: Engine Performance Add Versatility WithTamquadistu AlexNo ratings yet

- Belt Power - : 3.5 KW - 5 KW - 230 V/50 HZDocument2 pagesBelt Power - : 3.5 KW - 5 KW - 230 V/50 HZMohamed ElfayomyNo ratings yet

- Captain Model EU 273 Stage V SmallDocument2 pagesCaptain Model EU 273 Stage V SmallDeep DaveNo ratings yet

- 10-12si Brush Holder ReplacementDocument1 page10-12si Brush Holder Replacementrogerc1894No ratings yet

- Honeywell ModutrolIVMotor M94 Iom D1190 632195Document12 pagesHoneywell ModutrolIVMotor M94 Iom D1190 632195Jonathan Basilio GomezNo ratings yet

- At-Dom24-58-At-Dom24 ManualDocument5 pagesAt-Dom24-58-At-Dom24 ManualJuanNo ratings yet

- 2017-06-29 BB1260 30 Ultra InstructionsEng GerV56Document31 pages2017-06-29 BB1260 30 Ultra InstructionsEng GerV56Vojislav CirkovicNo ratings yet

- Elite Series Full Sweep Electric Temperature Gauge: Installation InstructionsDocument4 pagesElite Series Full Sweep Electric Temperature Gauge: Installation InstructionsWalter PelegrinNo ratings yet

- STNC Pressostato PDFDocument1 pageSTNC Pressostato PDFyoga AGoyNo ratings yet

- Troubleshooting Single Engine Externally Regulated AlternatorsDocument1 pageTroubleshooting Single Engine Externally Regulated AlternatorsGana tpNo ratings yet

- SM 8Document27 pagesSM 8Steven BulckeNo ratings yet

- 2004 SR Johnson 2 Stroke 9.9, 15, 25, 30 HPDocument17 pages2004 SR Johnson 2 Stroke 9.9, 15, 25, 30 HPPaco Caballero SaorinNo ratings yet

- PDF Esquema Electrico c9 - CompressDocument1 pagePDF Esquema Electrico c9 - CompressPablo PorrasNo ratings yet

- One Touch Hydraulic Punch Clamp Operator's ManualDocument21 pagesOne Touch Hydraulic Punch Clamp Operator's Manualtrung vothaiNo ratings yet

- Installation Instructions: CascadeDocument2 pagesInstallation Instructions: CascadeIntercambio de ManualesNo ratings yet

- ESS2200Document4 pagesESS2200Rasith NimnaNo ratings yet

- EV Series: Instruction ManualDocument1 pageEV Series: Instruction ManualCarlos RasconNo ratings yet

- Manual Equipo Sonido RcaDocument31 pagesManual Equipo Sonido RcaCampo Elias QNo ratings yet

- Manual de Servico Kawasaki VN 800 Vulcan 1996 2004Document405 pagesManual de Servico Kawasaki VN 800 Vulcan 1996 2004Leonardo HalonNo ratings yet

- Global TLGDocument6 pagesGlobal TLGjoaofavioNo ratings yet

- HESOP. All-In-One Energy & Cost Saver. InfrastructuresDocument22 pagesHESOP. All-In-One Energy & Cost Saver. Infrastructuresરામ પ્રતાપNo ratings yet

- Manual PartesDocument164 pagesManual Partesoborda2769No ratings yet

- Standard - Automatic Defrost Freezer Models (: Service Data Sheet - 297299800Document2 pagesStandard - Automatic Defrost Freezer Models (: Service Data Sheet - 297299800Carmen Adriana Garcia MendozaNo ratings yet

- TeSys Brochure 2016Document8 pagesTeSys Brochure 2016nooruddinkhan1No ratings yet

- LW SeriesDocument8 pagesLW SeriesAbraham AutomationNo ratings yet

- VW Sharan 1997 WD EngDocument745 pagesVW Sharan 1997 WD Engkolea13579No ratings yet

- Braking System (Italien)Document42 pagesBraking System (Italien)Ahmed GhreebNo ratings yet

- TF-81SC VBL Interactive PDFDocument1 pageTF-81SC VBL Interactive PDFJULIAN ABRILNo ratings yet

- Kirloskar Electric Co LTD.: Price List For Ac MotorsDocument20 pagesKirloskar Electric Co LTD.: Price List For Ac MotorsAshishNo ratings yet

- Installation Instructions: Toyota FJ Cruiser 44545 75461 87412Document3 pagesInstallation Instructions: Toyota FJ Cruiser 44545 75461 87412uripssNo ratings yet

- Macurco Combustible Gas Detector: Methane, Propane or Hydrogen Gas DetectionDocument2 pagesMacurco Combustible Gas Detector: Methane, Propane or Hydrogen Gas Detectionadan maciasNo ratings yet

- Watts Radiant HydroNex Specification D-Series DHX PanelsDocument2 pagesWatts Radiant HydroNex Specification D-Series DHX Panelse-ComfortUSANo ratings yet

- Disconnector (With: InstallationDocument12 pagesDisconnector (With: InstallationUkesh ShresthaNo ratings yet

- Combo V24T Manual For EmailDocument4 pagesCombo V24T Manual For EmailJuan CamiloNo ratings yet

- Electrical OFFICE WAREHOUSE FREEWOOD - PERMIT 2 - Part3Document1 pageElectrical OFFICE WAREHOUSE FREEWOOD - PERMIT 2 - Part3David BarrientosNo ratings yet

- LTC 3805Document20 pagesLTC 3805AlphaNo ratings yet

- Technical Specification Rmu 33 KV Od RmuDocument9 pagesTechnical Specification Rmu 33 KV Od RmuBADRI VENKATESHNo ratings yet

- Sizing of Protective Earthing Conductor - Electrical Installation GuideDocument3 pagesSizing of Protective Earthing Conductor - Electrical Installation GuidevishalNo ratings yet

- NMOS and PMOS Transistors Operating Principle PDFDocument17 pagesNMOS and PMOS Transistors Operating Principle PDFSisay Fitwi0% (1)

- Hochiki Intrinsically Safe Compatible Sounder Control Module Installation InstructionsDocument4 pagesHochiki Intrinsically Safe Compatible Sounder Control Module Installation InstructionsAngel HernandezNo ratings yet

- Logic SelectivityDocument6 pagesLogic SelectivitymoosuhaibNo ratings yet

- IEC-E02-E01 Rev 4 Dec 2017 (A) Power System and Equip Design CalDocument19 pagesIEC-E02-E01 Rev 4 Dec 2017 (A) Power System and Equip Design Cal15150515715No ratings yet

- CEF04N6Document5 pagesCEF04N6Armel AtseNo ratings yet

- Dr. Eng. Mokh. Sholihul Hadi, S.T., M. EngDocument15 pagesDr. Eng. Mokh. Sholihul Hadi, S.T., M. EngBabangotekNo ratings yet

- BLDC Motor Control ThesisDocument4 pagesBLDC Motor Control Thesisafknkzkkb100% (2)

- Zener Diode As Voltage RegulatorDocument2 pagesZener Diode As Voltage RegulatorAMIT KUMAR SINGHNo ratings yet

- Short Circuit Withstand of Power CablesDocument42 pagesShort Circuit Withstand of Power CablesDheeraj Yadav100% (1)

- MDD3752 PDFDocument6 pagesMDD3752 PDFsonytel2No ratings yet

- ROTATORY CONVERTER 800kVADocument34 pagesROTATORY CONVERTER 800kVAFrancisco J. Rodriguez PermuyNo ratings yet

- Induction Type RelaysDocument8 pagesInduction Type RelayshilalsherNo ratings yet

- UTC 2SD1616/A NPN Epitaxial Silicon TransistorDocument4 pagesUTC 2SD1616/A NPN Epitaxial Silicon Transistornishatiwari82No ratings yet

- 64 2096pbf KNHuDWrv 2j6YLvwomDocument10 pages64 2096pbf KNHuDWrv 2j6YLvwomCh Jameel SidhuNo ratings yet

- Joule Thief Battery ChargerDocument7 pagesJoule Thief Battery ChargerAfshin NazemiNo ratings yet

- VFDs++for+HVAC+Application+ +Standard+or+PackagedDocument6 pagesVFDs++for+HVAC+Application+ +Standard+or+PackagedLuis MorenoNo ratings yet

- Price List DLGP 2016-NewDocument25 pagesPrice List DLGP 2016-NewRaden Pujakesuma100% (1)

- Catalogue 20200514 PDFDocument259 pagesCatalogue 20200514 PDFmrgreengenesNo ratings yet

- Design BasisDocument43 pagesDesign Basismurali0% (1)

- Symmetrical FaultsDocument134 pagesSymmetrical FaultsCaribNo ratings yet

- Form Pemeriksaan Genset: PT. MNA SerangDocument3 pagesForm Pemeriksaan Genset: PT. MNA Serangmd_anwarNo ratings yet

- 3x185 RMDocument5 pages3x185 RMjamilNo ratings yet

- Sss6n70a-Advanced Power MosfetDocument7 pagesSss6n70a-Advanced Power MosfetbmmostefaNo ratings yet

Installation Instructions N-1602

Installation Instructions N-1602

Uploaded by

alex maltezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Instructions N-1602

Installation Instructions N-1602

Uploaded by

alex maltezCopyright:

Available Formats

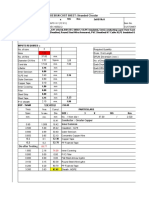

N1602-1 Alternator / N3118 Regulator

C. E. Niehoff & Co. OEM Wiring Connections

BRUSHLESS ALTERNATORS Dual or Single Voltage

Installation Instructions

DUAL VOLTAGE (28 V/14 V) applications

(see other side for single voltage):

1. Connect as shown on this page. Boots (2)

➛

Locknut, #10-24;

➛

➛

torque to 2.3 Nm / 20 lb.in. Locknut, 0.2500-20;

Washer

➛ ➛

➛ torque to 4 Nm / 35 lb.in.

➛ Washer

Regulator - AC terminal ➛ Regulator - IGN terminal

➛

Regulator

➛

➛

Boot

➛

➛ connectors

Vehicle

➛

harness Regulator - 14 V terminal

Washer

Nut, 0.3125-18 UNC-2B;

torque to 5.6 Nm / 50 lb.in.

Figure 1- N1602-1 Alternator Figure 1a - N3118 Regulator Wiring Connections

B+ connections on alternator

Bolt, 0.3750-16 UNC-2A; torque to 20 Nm / 15 lb.ft. when securing B+ cables. Both positive

cables must be connected together at battery positive potential when alternator is installed

in vehicle and during operation. Interconnect cable is part of vehicle cabling.

➛ ➛

Interconnect Lockwasher

Lockwasher ➛ cable

➛

➛ Washer

Washer

➛ ➛

Positive cable from vehicle

Positive cable

➛

from vehicle ➛ Secure alternator mounting

lug to vehicle using hard-

➛

ware specified by vehicle

➛

➛

manufacturer and torque

B– connections on alternator

B+ output terminals sufficient to withstand weight

Bolt, 0.3125-18 UNC-2A; torque to 9

➛

of alternator.

Nm / 80 lb. in. when securing B–

cables. Both ground cables must be

➛

MS21245-L12 nut;

connected to vehicle’s common ➛ torque to 163 Nm/

ground when alternator is installed in 120 lb. ft. when

➛

vehicle and during installing drive pulley.

operation.

Washer

Lock Washer Secure alternator mounting

➛

lugs to vehicle using hard-

Washer

➛

➛ ➛ ➛ ware specified by vehicle

manufacturer and torque

➛

Vehicle

harness sufficient to withstand weight

of alternator.

Figure 1b - B+ and B– Terminal Connections

Page 1 of 2 II0059A

SINGLE VOLTAGE (28 V) applications

(see other side for dual voltage):

1. Connect as shown on this page. Boots (2)

➛

Locknut, #10-24;

➛

➛

torque to 2.3 Nm / 20 lb.in. Locknut, 0.2500-20;

Washer

➛ ➛

➛ torque to 4 Nm / 35 lb.in.

➛ Washer

Regulator - AC terminal ➛ Regulator - IGN terminal

➛

Regulator

➛

➛

➛

➛ connectors

➛

Washer Regulator - 14 V terminal

Nut, 0.3125-18 UNC-2B;

torque to 5.6 Nm / 50 lb.in.

Figure 2- N1602-1 Alternator Figure 2a - N3118 Regulator Wiring Connections

B+ connections on alternator

Bolt, 0.3750-16 UNC-2A; torque to 20 Nm / 15 lb.ft. when securing B+ cables. Both positive

cables must be connected together at battery positive potential when alternator is installed

in vehicle and during operation. Interconnect cable is part of vehicle cabling.

➛ ➛

Interconnect Lockwasher

Lockwasher ➛ cable

➛

➛ Washer

Washer

➛ ➛

Positive cable from vehicle

Positive cable

➛

from vehicle ➛ Secure alternator mounting

lug to vehicle using hard-

➛

ware specified by vehicle

➛

➛

manufacturer and torque

B– connections on alternator

B+ output terminals sufficient to withstand weight

Bolt, 0.3125-18 UNC-2A; torque to 9

➛

of alternator.

Nm / 80 lb. in. when securing B–

cables. Both ground cables must be

➛

MS21245-L12 nut;

connected to vehicle’s common ➛ torque to 163 Nm/

ground when alternator is installed in 120 lb. ft. when

➛

vehicle and during installing drive pulley.

operation.

Washer

Lock Washer Secure alternator mounting

➛

lugs to vehicle using hard-

Washer

➛

➛ ➛ ➛ ware specified by vehicle

manufacturer and torque

➛

Vehicle

harness sufficient to withstand weight

of alternator.

Figure 2b - B+ and B– Terminal Connections

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

Page 2 of 2 II0059A

You might also like

- CONE VALVE Service ManualDocument30 pagesCONE VALVE Service ManualMathieu DouNo ratings yet

- A6GF1, A6LF1/2/3, A6MF1/2: Hyundai/KiaDocument1 pageA6GF1, A6LF1/2/3, A6MF1/2: Hyundai/Kiahidraulic100% (1)

- 1962-Burgmaster - Bench Model Turret Drilling and Tapping MachineDocument17 pages1962-Burgmaster - Bench Model Turret Drilling and Tapping Machinesalulai100% (3)

- Volvo Penta - Diagrama de Montagem - DPH PDFDocument1 pageVolvo Penta - Diagrama de Montagem - DPH PDFJorge Lopes100% (1)

- JENBACHERDocument457 pagesJENBACHERRaymundo Jimenez Herrera100% (1)

- GE MX-150 ManualDocument28 pagesGE MX-150 ManualCristian Munoz60% (5)

- 20 Watts TDA2005 Bridge Amplifier Project With Tone Control CircuitDocument10 pages20 Watts TDA2005 Bridge Amplifier Project With Tone Control CircuitMuhammad YousafNo ratings yet

- Merc7229 VBL InteractiveDocument1 pageMerc7229 VBL InteractiveMauricio Exequiel ChavezNo ratings yet

- n3135 RegulatorDocument2 pagesn3135 Regulatoryr5xrzgww8No ratings yet

- 23-3 Reminders ON THE USE OF Nibbler & Breakers: RunnmgDocument1 page23-3 Reminders ON THE USE OF Nibbler & Breakers: RunnmgPhan DungNo ratings yet

- Hoja Tecnica Control de NivelDocument3 pagesHoja Tecnica Control de NivelpawerxlNo ratings yet

- ServiceSchedule MD22Document3 pagesServiceSchedule MD22theo_swaranNo ratings yet

- FNH 5640-8340 Omm PDFDocument65 pagesFNH 5640-8340 Omm PDFan0th3r_0n3100% (1)

- Esc-Ecomat Service Check: Key To DrawingDocument2 pagesEsc-Ecomat Service Check: Key To DrawingЛеонид БеркоNo ratings yet

- GENERATOR Data SheetDocument1 pageGENERATOR Data Sheetshinki31000No ratings yet

- FW6A Manual CuerpoDocument11 pagesFW6A Manual CuerpoHenrry trespalaciosNo ratings yet

- Contact or Brochure CC SeriesDocument24 pagesContact or Brochure CC SeriesElizabethAguirreNo ratings yet

- TF 81SC VBL Interactive PDFDocument1 pageTF 81SC VBL Interactive PDFJUAN ENRIQUE TORRIJOS FLORESNo ratings yet

- Instrukciya Po Ustanovke Turbotajmera Hks Type 0Document2 pagesInstrukciya Po Ustanovke Turbotajmera Hks Type 0Álvaro AvilaNo ratings yet

- 04 ExDocument4 pages04 Exlone_anarchistNo ratings yet

- Hydraulic Force Control: Ser ManualDocument18 pagesHydraulic Force Control: Ser ManualDinh SangNo ratings yet

- Electric Devices: Name of PartsDocument30 pagesElectric Devices: Name of PartsAde HanggaraNo ratings yet

- Baldwin Vacuum Gage Kit IOMDocument1 pageBaldwin Vacuum Gage Kit IOMSMcNo ratings yet

- 510B Backhoe Loader: Engine PerformanceDocument5 pages510B Backhoe Loader: Engine PerformancebalajimetturNo ratings yet

- ESG2001C1-W Controller PDFDocument12 pagesESG2001C1-W Controller PDFRenato Matičević100% (1)

- Dayton Parallel Shaft High: Torque AC GearmotorsDocument12 pagesDayton Parallel Shaft High: Torque AC GearmotorsFelipe Ivan Escudero VidalNo ratings yet

- Transmission Functionalities 2014 enDocument3 pagesTransmission Functionalities 2014 enriqtorresNo ratings yet

- 570a PDFDocument3 pages570a PDFTamquadistu AlexNo ratings yet

- Jd570-A Motorgrader: Engine Performance Add Versatility WithDocument3 pagesJd570-A Motorgrader: Engine Performance Add Versatility WithTamquadistu AlexNo ratings yet

- Belt Power - : 3.5 KW - 5 KW - 230 V/50 HZDocument2 pagesBelt Power - : 3.5 KW - 5 KW - 230 V/50 HZMohamed ElfayomyNo ratings yet

- Captain Model EU 273 Stage V SmallDocument2 pagesCaptain Model EU 273 Stage V SmallDeep DaveNo ratings yet

- 10-12si Brush Holder ReplacementDocument1 page10-12si Brush Holder Replacementrogerc1894No ratings yet

- Honeywell ModutrolIVMotor M94 Iom D1190 632195Document12 pagesHoneywell ModutrolIVMotor M94 Iom D1190 632195Jonathan Basilio GomezNo ratings yet

- At-Dom24-58-At-Dom24 ManualDocument5 pagesAt-Dom24-58-At-Dom24 ManualJuanNo ratings yet

- 2017-06-29 BB1260 30 Ultra InstructionsEng GerV56Document31 pages2017-06-29 BB1260 30 Ultra InstructionsEng GerV56Vojislav CirkovicNo ratings yet

- Elite Series Full Sweep Electric Temperature Gauge: Installation InstructionsDocument4 pagesElite Series Full Sweep Electric Temperature Gauge: Installation InstructionsWalter PelegrinNo ratings yet

- STNC Pressostato PDFDocument1 pageSTNC Pressostato PDFyoga AGoyNo ratings yet

- Troubleshooting Single Engine Externally Regulated AlternatorsDocument1 pageTroubleshooting Single Engine Externally Regulated AlternatorsGana tpNo ratings yet

- SM 8Document27 pagesSM 8Steven BulckeNo ratings yet

- 2004 SR Johnson 2 Stroke 9.9, 15, 25, 30 HPDocument17 pages2004 SR Johnson 2 Stroke 9.9, 15, 25, 30 HPPaco Caballero SaorinNo ratings yet

- PDF Esquema Electrico c9 - CompressDocument1 pagePDF Esquema Electrico c9 - CompressPablo PorrasNo ratings yet

- One Touch Hydraulic Punch Clamp Operator's ManualDocument21 pagesOne Touch Hydraulic Punch Clamp Operator's Manualtrung vothaiNo ratings yet

- Installation Instructions: CascadeDocument2 pagesInstallation Instructions: CascadeIntercambio de ManualesNo ratings yet

- ESS2200Document4 pagesESS2200Rasith NimnaNo ratings yet

- EV Series: Instruction ManualDocument1 pageEV Series: Instruction ManualCarlos RasconNo ratings yet

- Manual Equipo Sonido RcaDocument31 pagesManual Equipo Sonido RcaCampo Elias QNo ratings yet

- Manual de Servico Kawasaki VN 800 Vulcan 1996 2004Document405 pagesManual de Servico Kawasaki VN 800 Vulcan 1996 2004Leonardo HalonNo ratings yet

- Global TLGDocument6 pagesGlobal TLGjoaofavioNo ratings yet

- HESOP. All-In-One Energy & Cost Saver. InfrastructuresDocument22 pagesHESOP. All-In-One Energy & Cost Saver. Infrastructuresરામ પ્રતાપNo ratings yet

- Manual PartesDocument164 pagesManual Partesoborda2769No ratings yet

- Standard - Automatic Defrost Freezer Models (: Service Data Sheet - 297299800Document2 pagesStandard - Automatic Defrost Freezer Models (: Service Data Sheet - 297299800Carmen Adriana Garcia MendozaNo ratings yet

- TeSys Brochure 2016Document8 pagesTeSys Brochure 2016nooruddinkhan1No ratings yet

- LW SeriesDocument8 pagesLW SeriesAbraham AutomationNo ratings yet

- VW Sharan 1997 WD EngDocument745 pagesVW Sharan 1997 WD Engkolea13579No ratings yet

- Braking System (Italien)Document42 pagesBraking System (Italien)Ahmed GhreebNo ratings yet

- TF-81SC VBL Interactive PDFDocument1 pageTF-81SC VBL Interactive PDFJULIAN ABRILNo ratings yet

- Kirloskar Electric Co LTD.: Price List For Ac MotorsDocument20 pagesKirloskar Electric Co LTD.: Price List For Ac MotorsAshishNo ratings yet

- Installation Instructions: Toyota FJ Cruiser 44545 75461 87412Document3 pagesInstallation Instructions: Toyota FJ Cruiser 44545 75461 87412uripssNo ratings yet

- Macurco Combustible Gas Detector: Methane, Propane or Hydrogen Gas DetectionDocument2 pagesMacurco Combustible Gas Detector: Methane, Propane or Hydrogen Gas Detectionadan maciasNo ratings yet

- Watts Radiant HydroNex Specification D-Series DHX PanelsDocument2 pagesWatts Radiant HydroNex Specification D-Series DHX Panelse-ComfortUSANo ratings yet

- Disconnector (With: InstallationDocument12 pagesDisconnector (With: InstallationUkesh ShresthaNo ratings yet

- Combo V24T Manual For EmailDocument4 pagesCombo V24T Manual For EmailJuan CamiloNo ratings yet

- Electrical OFFICE WAREHOUSE FREEWOOD - PERMIT 2 - Part3Document1 pageElectrical OFFICE WAREHOUSE FREEWOOD - PERMIT 2 - Part3David BarrientosNo ratings yet

- LTC 3805Document20 pagesLTC 3805AlphaNo ratings yet

- Technical Specification Rmu 33 KV Od RmuDocument9 pagesTechnical Specification Rmu 33 KV Od RmuBADRI VENKATESHNo ratings yet

- Sizing of Protective Earthing Conductor - Electrical Installation GuideDocument3 pagesSizing of Protective Earthing Conductor - Electrical Installation GuidevishalNo ratings yet

- NMOS and PMOS Transistors Operating Principle PDFDocument17 pagesNMOS and PMOS Transistors Operating Principle PDFSisay Fitwi0% (1)

- Hochiki Intrinsically Safe Compatible Sounder Control Module Installation InstructionsDocument4 pagesHochiki Intrinsically Safe Compatible Sounder Control Module Installation InstructionsAngel HernandezNo ratings yet

- Logic SelectivityDocument6 pagesLogic SelectivitymoosuhaibNo ratings yet

- IEC-E02-E01 Rev 4 Dec 2017 (A) Power System and Equip Design CalDocument19 pagesIEC-E02-E01 Rev 4 Dec 2017 (A) Power System and Equip Design Cal15150515715No ratings yet

- CEF04N6Document5 pagesCEF04N6Armel AtseNo ratings yet

- Dr. Eng. Mokh. Sholihul Hadi, S.T., M. EngDocument15 pagesDr. Eng. Mokh. Sholihul Hadi, S.T., M. EngBabangotekNo ratings yet

- BLDC Motor Control ThesisDocument4 pagesBLDC Motor Control Thesisafknkzkkb100% (2)

- Zener Diode As Voltage RegulatorDocument2 pagesZener Diode As Voltage RegulatorAMIT KUMAR SINGHNo ratings yet

- Short Circuit Withstand of Power CablesDocument42 pagesShort Circuit Withstand of Power CablesDheeraj Yadav100% (1)

- MDD3752 PDFDocument6 pagesMDD3752 PDFsonytel2No ratings yet

- ROTATORY CONVERTER 800kVADocument34 pagesROTATORY CONVERTER 800kVAFrancisco J. Rodriguez PermuyNo ratings yet

- Induction Type RelaysDocument8 pagesInduction Type RelayshilalsherNo ratings yet

- UTC 2SD1616/A NPN Epitaxial Silicon TransistorDocument4 pagesUTC 2SD1616/A NPN Epitaxial Silicon Transistornishatiwari82No ratings yet

- 64 2096pbf KNHuDWrv 2j6YLvwomDocument10 pages64 2096pbf KNHuDWrv 2j6YLvwomCh Jameel SidhuNo ratings yet

- Joule Thief Battery ChargerDocument7 pagesJoule Thief Battery ChargerAfshin NazemiNo ratings yet

- VFDs++for+HVAC+Application+ +Standard+or+PackagedDocument6 pagesVFDs++for+HVAC+Application+ +Standard+or+PackagedLuis MorenoNo ratings yet

- Price List DLGP 2016-NewDocument25 pagesPrice List DLGP 2016-NewRaden Pujakesuma100% (1)

- Catalogue 20200514 PDFDocument259 pagesCatalogue 20200514 PDFmrgreengenesNo ratings yet

- Design BasisDocument43 pagesDesign Basismurali0% (1)

- Symmetrical FaultsDocument134 pagesSymmetrical FaultsCaribNo ratings yet

- Form Pemeriksaan Genset: PT. MNA SerangDocument3 pagesForm Pemeriksaan Genset: PT. MNA Serangmd_anwarNo ratings yet

- 3x185 RMDocument5 pages3x185 RMjamilNo ratings yet

- Sss6n70a-Advanced Power MosfetDocument7 pagesSss6n70a-Advanced Power MosfetbmmostefaNo ratings yet