Professional Documents

Culture Documents

Gsminiplan 3

Gsminiplan 3

Uploaded by

Lucas RamirezCopyright:

Available Formats

You might also like

- Tri-Horse Builders PlansDocument12 pagesTri-Horse Builders PlansEucap Mdz97% (33)

- Guitar Inside Mold - Top View 1937 Hauser Classical Guitar ShapeDocument1 pageGuitar Inside Mold - Top View 1937 Hauser Classical Guitar ShapeDaniel Garfo100% (3)

- Squier Setup ManualDocument2 pagesSquier Setup ManualFrank Boz100% (1)

- Kodachrome GroundplanDocument1 pageKodachrome Groundplanapi-319390606No ratings yet

- Trapezoidal Neck Strandberg US20130186254A1Document10 pagesTrapezoidal Neck Strandberg US20130186254A1Percy Stanbury Malaga100% (1)

- Building A 5 String BanjoDocument8 pagesBuilding A 5 String BanjoDimitris BasiotisNo ratings yet

- Top Plate Brace Layouts: Classical Guitar Plan #3Document1 pageTop Plate Brace Layouts: Classical Guitar Plan #3Lutcharguitwaira LibreNo ratings yet

- Top Plate Brace Layouts: Classical Guitar Plan #3Document1 pageTop Plate Brace Layouts: Classical Guitar Plan #3Lutcharguitwaira LibreNo ratings yet

- 000plan 3Document1 page000plan 3BeppeNo ratings yet

- GD-50072 - Spec 3Document1 pageGD-50072 - Spec 3jnordmanNo ratings yet

- GD-50072 SpecDocument1 pageGD-50072 SpecjnordmanNo ratings yet

- GD-50060 SpecDocument1 pageGD-50060 SpecjnordmanNo ratings yet

- GD-50060 SpecDocument1 pageGD-50060 SpecjnordmanNo ratings yet

- GD-50060 - Spec 2Document1 pageGD-50060 - Spec 2jnordmanNo ratings yet

- ME HW5 Mohammed Ahmed Tahhan 392027113 Layout4Document1 pageME HW5 Mohammed Ahmed Tahhan 392027113 Layout4engineer.mohammedtahhanNo ratings yet

- Roof Plan - UNDPDocument1 pageRoof Plan - UNDPFatenNo ratings yet

- Produced by An Autodesk Student VersionDocument1 pageProduced by An Autodesk Student VersionIulian NgiNo ratings yet

- BIELA ModelZOOM PDFDocument1 pageBIELA ModelZOOM PDFIulian NgiNo ratings yet

- VDS MasterplanDocument1 pageVDS MasterplanSamudrala SreepranaviNo ratings yet

- 06 Uke12tenorplanformsDocument1 page06 Uke12tenorplanformsarantxa16No ratings yet

- Week-1 Practice: 21K61A0117 Sai DeepikaDocument1 pageWeek-1 Practice: 21K61A0117 Sai DeepikajnanendraNo ratings yet

- A B C E F H G: Barbacoa Terraza BARDocument1 pageA B C E F H G: Barbacoa Terraza BARFrida LlerenaNo ratings yet

- Site Image MapDocument1 pageSite Image MapReenaNo ratings yet

- 2-Wi Nding.. 64.7Document1 page2-Wi Nding.. 64.7MICHAEL MEDINA FLORESNo ratings yet

- SK1528 Rook PDFDocument1 pageSK1528 Rook PDFInform7105No ratings yet

- GraphsDocument8 pagesGraphsPuneeth kumar j kNo ratings yet

- Week-1 Practice: 21K61A0111 G.Sai DeepikaDocument1 pageWeek-1 Practice: 21K61A0111 G.Sai DeepikajnanendraNo ratings yet

- E - Manual - 18x72 TRC - 20122010Document3 pagesE - Manual - 18x72 TRC - 20122010Edward LarensNo ratings yet

- Boeing P-26 PeashooterDocument1 pageBoeing P-26 Peashootermohamed sidkyNo ratings yet

- C Brand FX Body Company, INC. 2012 F-73-00-04 Rev:03Document1 pageC Brand FX Body Company, INC. 2012 F-73-00-04 Rev:03Alan TrejoNo ratings yet

- TD - 148018 - Essence SH-3232 - en - enDocument1 pageTD - 148018 - Essence SH-3232 - en - enTony ParkNo ratings yet

- Chikalaguriki 100Document1 pageChikalaguriki 100VB665No ratings yet

- B400 B700 ManualDocument2 pagesB400 B700 ManualMultiservicios aqualectNo ratings yet

- 2 X 48 No Weld GrinderDocument4 pages2 X 48 No Weld GrinderJoão Costa LemosNo ratings yet

- Farmland DimensionsDocument1 pageFarmland DimensionsKumar KingslyNo ratings yet

- Contoh Form AbsensiDocument23 pagesContoh Form AbsensiFeronika KurniaNo ratings yet

- 1:3 1:3 Extended Retracted: Cvl1000 / Cvl1500 (No Manual Override) - Specification SheetDocument1 page1:3 1:3 Extended Retracted: Cvl1000 / Cvl1500 (No Manual Override) - Specification SheetDaniel Camargo PérezNo ratings yet

- Back Plate Layout & Brace Layout: Classical Guitar Plan #3Document1 pageBack Plate Layout & Brace Layout: Classical Guitar Plan #3Lutcharguitwaira LibreNo ratings yet

- Bulkhead BinderDocument114 pagesBulkhead BinderWilliam ProvidoNo ratings yet

- CE013 - CE31S3 - Plate 2 - FELICIANO, Alberto LiclicanDocument1 pageCE013 - CE31S3 - Plate 2 - FELICIANO, Alberto Liclicanqalfeliciano01No ratings yet

- Plano EstructurasDocument1 pagePlano EstructurasFelipe ClarosNo ratings yet

- Historico PIB MexicoDocument1 pageHistorico PIB MexicoJUAN SINMIEDONo ratings yet

- 9 Kids Room AA 2403Document1 page9 Kids Room AA 2403priyankaNo ratings yet

- Structural Inspection Area QC01Document1 pageStructural Inspection Area QC01Mohd ELNo ratings yet

- Catalogues HoodsDocument2 pagesCatalogues HoodsVladimir CortezNo ratings yet

- Futuro Proyecto "San Valentin: Via ProyectadaDocument1 pageFuturo Proyecto "San Valentin: Via ProyectadaHanani Hernan Aguilar LoconiNo ratings yet

- A01 PDFDocument1 pageA01 PDFEdgardo Guevara EleraNo ratings yet

- A01 PDFDocument1 pageA01 PDFEdgardo Guevara EleraNo ratings yet

- Arbuda Aparrment Jatin BhaiDocument1 pageArbuda Aparrment Jatin BhaiSarthak DixitNo ratings yet

- Dre Voting Kiosk: Street Name, Suite Number City, State Zip Code 123.456.7890Document2 pagesDre Voting Kiosk: Street Name, Suite Number City, State Zip Code 123.456.7890Kakoy Lagusan EcobenNo ratings yet

- Tobacco FactsDocument2 pagesTobacco FactsstprepsNo ratings yet

- F16/FA16 INPUT F25/FA25 OUTPUT Ib10 Gearbox: Drawing NoDocument1 pageF16/FA16 INPUT F25/FA25 OUTPUT Ib10 Gearbox: Drawing NoHUNGNo ratings yet

- Duncan Kitchen DesignDocument10 pagesDuncan Kitchen DesignAmy AleshireNo ratings yet

- Cimentación OctavoDocument1 pageCimentación OctavoPaulaErazoPNo ratings yet

- Membaca Gambar TeknikDocument1 pageMembaca Gambar Teknikwahyubandono35No ratings yet

- Enviromag Datasheet Complete Revsd 08-4Document8 pagesEnviromag Datasheet Complete Revsd 08-4Abel VegaNo ratings yet

- E-03 Estructura: Centro Integral de Artes, ChapulliDocument1 pageE-03 Estructura: Centro Integral de Artes, Chapullikeila gonzálexNo ratings yet

- PT 0+000 Layout2Document1 pagePT 0+000 Layout2david.franco.pinheiroNo ratings yet

- Listening Answer Sheet-12Document1 pageListening Answer Sheet-12Kenzo KatarijiNo ratings yet

- Bahria Town: Produced by An Autodesk Educational ProductDocument1 pageBahria Town: Produced by An Autodesk Educational ProductJadoonNo ratings yet

- Fold Table All PartsDocument1 pageFold Table All PartsivanNo ratings yet

- Cont. On PR-252:PAB1 E 59'1" S 9'8" EL +18'9.9/16": Project NoDocument1 pageCont. On PR-252:PAB1 E 59'1" S 9'8" EL +18'9.9/16": Project NoThe 81No ratings yet

- One Bold Move a Day: Meaningful Actions Women Can Take to Fulfill Their Leadership and Career PotentialFrom EverandOne Bold Move a Day: Meaningful Actions Women Can Take to Fulfill Their Leadership and Career PotentialNo ratings yet

- Slte Aug2016Document84 pagesSlte Aug2016Cristian SNo ratings yet

- Explorer Guitar KitinstructionsDocument30 pagesExplorer Guitar KitinstructionsCorey WilliamsNo ratings yet

- Zakk Wylde Guitar MetodoDocument8 pagesZakk Wylde Guitar MetodoJosé Silvestre MontellanoNo ratings yet

- How To Set Up A Guitar Free GuideDocument38 pagesHow To Set Up A Guitar Free GuideAntonyNealeNo ratings yet

- User Manual: Downloaded From Manuals Search EngineDocument22 pagesUser Manual: Downloaded From Manuals Search EngineLuwissssNo ratings yet

- Master The Caged System For GuitarDocument11 pagesMaster The Caged System For GuitarLuis Cotrina VaraNo ratings yet

- Ibanez Bass AdjustDocument2 pagesIbanez Bass AdjustRosalba Maria Leal GiffoniNo ratings yet

- Repair Guitar NeckDocument5 pagesRepair Guitar NeckPetr PetrovNo ratings yet

- Carvin Jan2012 BassDocument10 pagesCarvin Jan2012 BassKing Maxwell DclxcviNo ratings yet

- RK - Catalog PDFDocument16 pagesRK - Catalog PDFfluidaimaginacionNo ratings yet

- Fender Electric Guitar ManualDocument32 pagesFender Electric Guitar Manualdeni_2013No ratings yet

- Full Diagonal Pentatonic EbookDocument27 pagesFull Diagonal Pentatonic Ebookaa100% (4)

- Lead Guitar TechniquesDocument47 pagesLead Guitar Techniquesteofrasto250% (2)

- Ukulele LessonsDocument38 pagesUkulele Lessonsapi-321836157No ratings yet

- Tommy Emmanuel Fingerstyle Guita MethodDocument25 pagesTommy Emmanuel Fingerstyle Guita MethodS. D.0% (1)

- Sigma Katalog 2013Document37 pagesSigma Katalog 2013fluidaimaginacionNo ratings yet

- 1989 Guild Stuart X-500Document6 pages1989 Guild Stuart X-500Betoguitar777No ratings yet

- Mayones Bass Manual enDocument12 pagesMayones Bass Manual enjankoduricNo ratings yet

- RBX170 eDocument4 pagesRBX170 ehuelcheNo ratings yet

- You Can Play Guitar: Beginner EbookDocument37 pagesYou Can Play Guitar: Beginner EbookmdhansenNo ratings yet

- A Note On The Sound Radiation From The Classical Guitar Influence of Energy Input Via The String Termination at The FretDocument4 pagesA Note On The Sound Radiation From The Classical Guitar Influence of Energy Input Via The String Termination at The FretAmaury Jamir Meza PérezNo ratings yet

- Squier Strat Pack and Bass Pack Owners ManualDocument12 pagesSquier Strat Pack and Bass Pack Owners Manualmartin_salineNo ratings yet

- Cellist and Cello Body PostureDocument6 pagesCellist and Cello Body PostureEthanNo ratings yet

- 1939 Gibson Super 400N: Instruments Here Instruments Previously Sold HereDocument6 pages1939 Gibson Super 400N: Instruments Here Instruments Previously Sold HereRudolf RijgersbergNo ratings yet

- Selecting Guitar Wood PDFDocument5 pagesSelecting Guitar Wood PDFZalNo ratings yet

- Bass Guitar For Dummies Cheat SheetDocument14 pagesBass Guitar For Dummies Cheat SheetRocio Barco100% (1)

- Cello DimensionDocument2 pagesCello DimensionChutchawan Ungern100% (1)

Gsminiplan 3

Gsminiplan 3

Uploaded by

Lucas RamirezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gsminiplan 3

Gsminiplan 3

Uploaded by

Lucas RamirezCopyright:

Available Formats

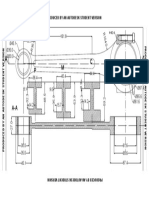

246.

6

9 23/32" 447.1

0" 17 19/32"

1.4 243.8 1.4

1/16" 9 19/32" 1/16"

86.1 80.7 75.6 86.2 118.5

3 13/32" 3 3/16" 2 31/32" 3 13/32" 4 21/32"

9/32"

7.0

246.6

9 23/32"

52.2 142.3 52.1

2 1/16" 5 19/32" 2 1/16"

Dark Line Indicates Outside

1/4"

6.2

Perimeter of Guitar. Light Line

Is Inside Of Sides.

12.3

5/32"

1/2"

4.3

1/16"

1.9

Dashed Lines Indicate Rough-Out

229.3 Line Of Brace Prior To Gluing To Top

9 1/32" Once Braces Have Been Glued, Scallop

3.1 223.1 3.2 According To The Curvature. Typical For

1/8" 8 25/32" 1/8" All Braces

D

C

B

9/32"

7.0

B 229.3

A

9 1/32"

51.7 125.9 51.7 Sand The Proper Back Arch On The

2 1/32" 4 31/32" 2 1/32" Bottom Of All The Back Braces. The

1/4"

6.6

Radius Should Be Exactly The Same

For All Back Bracing. This Is Best Marked To Cover Up The Center Seam Inside The Guitar Body And Give The

12.3

5/32"

Neck Block. This Is A Very

1/2"

With The Arch Template Joint Additional Strength Use A Strip Of Maple 3mm Thick. Run

4.4

Important Structural Element. Betwen The Braces And Round-Off As Shown. The Best Way To

1/16"

1.4

Construct From Vertical Grain Install This Is As One Long Piece And Carefully Cut And Chisel Out

Honduras Mahogany, Maple, Or The Channels For The Back Braces.

338.1 Same Species As Neck

13 5/16" Arch The Back Of The Guitar For Sound Reflectance Quality And To

8.8 320.4 8.8 Allow Some Tollerance For Humidity Changes. This Arch Should Be

11/32" 12 5/8" 11/32" Approximately 4 to 6mm Across The Wide Part Of The Back Plate

16.1

5/8"

14 13/32"

365.6

338.1

13 5/16"

Back Braces - Vertical And Fine

C 57.4

2 1/4"

223.4

8 25/32"

57.4

2 1/4"

Cedar Or Spruce #1 Quality. Cope

Out Ends Of Bracing.

3/16"

4.4

Back Material: Many Different Woods

13/32"

10.6

Can Be Used. For Bright Tones Go

1/8"

3.2

Back Block or Butt Block. Vertical Grain

With One Of The Rosewoods Such Honduras Mahogany, Maple or Other

1/8"

3.0

As Indian Rosewood or Brazilian Hardwood. Some Luthiers Shave This

Rosewood. Koa Is Bright As Is Zircote Block or Angle It Away From The Top

And Madagascar Rosewood. For As This Block Often Gives A Guitar A

Warm Tone Use Walnut. Most "Hump" In The Top And Can Cause

Traditional Acoustic Guitars Are Cracking.

358.3 Constructed From Indian Rosewood

14 3/32"

Or Mahogany. Some Great Rosewood

3.2 351.9 3.2 Sub-

1/8" 13 27/32" 1/8" stitues available now are Zebrawood,

Paduck and Bubinga

16.1

5/8"

358.3

14 3/32"

61.7 235.0 61.7

2 7/16" 9 1/4" 2 7/16"

5/32"

D

4.4

13/32"

3/32"

10.6

2.8

1/8"

3.5

Note: Make All The Back Bracing Longer Than It Needs To Be, Sand The Proper Back Arch On The

Leave Each Brace At Least 3/8" Long And Trim Back During Bottom Of All The Back Braces. The

Fitting Of The Back And Top Plates To The Guitar Sites. Radius Should Be Exactly The Same

For All Back Bracing. This Is Best Marked

With The Arch Template

Back Plate Layout & Brace Layout

Finished Back Plate: This back plate was glued up using the GoBoard Clamping Shaping The Back Arch On The Sides: Place the side contour template on each Finished Box: This photo shows the instrument box completely assembled, sanded,Fitting The Neck: After the body is constructed as in the photo on the left, it is Fitting The Neck 2: Prior to gluing the neck to the body, it is important to do a Headpiece Purfling and Binding: There are some tricks you can employ to get

Deck and Fiberglass Rods. The brace bottoms were arched with the Back Arch side and mark the back arch with a dry marker. and ready for the final step of the body construction - installation of the back plate.best to fit the neck to the body of the instrument. This allows the builder to make final check of the alignments. Install the neck and tighten it completely from inside the "perfect fit", when fitting and gluing these detailed bindings. If the curves are

Template together as one block and then cut apart on a band saw. Note how the channels are chiseled in the kerfed lining, ready to accept the backadjustment to the lateral and longitudinal axis and make appropriate adjustments the instrument body. Check the alignment in both directions. Also check the fit of rather sharp (as they were to the top of the headpiece here, it is necessary to pre-

This photo shows the sides placed in the inside form and blocked up about 1" with braces. to line the neck EXACTLY with the centerline of the top. Also measure the flatness the heel to the body. This should be a hairline joint. bend the purfling strip a bit. I did this on a hot pipe.

This method assures the builder that there will be a consistent arch across the small square shims. Place a pair of spreader jacks to fully clamp the sides into the of the fretboard surface of the neck to the top plate. This joint should be perfectly

length of the back plate. Also the center reinforcing strip was glued to the back in form and this will make the side fully conform to the inside form. When fitting the back, place the body inside an inside form and block the instrumentlevel and aligned. Make slight adjustments to the alignment by sanding the "cheeks" of the heel. A Also rather than mitering all the trims, it is far easier to butt them together. You will

one piece. Then the brace widths and positions were marked and cut with a razor up so the sides extend above the inside form at least 3/4" (19mm). I use pieces of 1" little bit goes a long way here and check your work often. never be able to detect this on a finished instrument. It also is a stronger joint and

saw. It is then easy to break the waste piece of the strip with a sharp chisel. The Use a sharp block plane to cut the sides down to the contour marks and follow up wood for this. The sides and kerfing then need to be shaped to accepted the archThis step is also important in that you can check the fit of the bolts to the neck and will resist pulling apart much better than a miter joint. Glue the purfling strips

braces were shaped after all the gluing was complete. with a sanding stick. After this step is complete, glue the head and tail blocks into form of the back. For this step use a crown sanding jig (available free on our website).the fit of the mortise joint. Note that we extensively cover this in our Guitar and separately and carefully butt each and sand flush. When you are finished gluing

place and finally fit the kerfed linings and glue them into position. Lastly the channels are cut into the kerfed lining (refer to details on the first sheet forUkulele Construction Handbook. the purfling, glue the binding and butt the joints in a similar manner. Sand flush.

more information on this).

Note For Detailed Guitar & Uke Construction Instructions

Refer To Our Book "Guitar & Ukulele Construction

Handbook @ http://shopglss.com

This Drawing or Drawings Are To Used For One Use Only Sheet Number

Date: Jan. 8, 2014

Georgia Luthier Supply

And Not Reproduced For Any Other Purpose Than

Construction Of This Particular Instrument, and a One Time

Gs4

Reproduction Only is Allowed Revisions: Dec 13, 2013

GS Mini Guitar Plan

Reproduction, Distribution or Sales For Any Other Use Is

Strictly Prohibited And Falls Under U.S Copyright Laws For

David VerBurg AIA c 2013 Unless Noted Otherwise,

This Sheet Size Is Metric A0 Size Overall Size is 1189mm x These Plans Are Drawing

841mm With 15mm Borders On All Sides. For USA Full Scale. They Are

Customers Print On Architectural "E" (36" x 48") Without Labeled in mm and

Resizing For 1:1 Printout.

Fractional Inches

You might also like

- Tri-Horse Builders PlansDocument12 pagesTri-Horse Builders PlansEucap Mdz97% (33)

- Guitar Inside Mold - Top View 1937 Hauser Classical Guitar ShapeDocument1 pageGuitar Inside Mold - Top View 1937 Hauser Classical Guitar ShapeDaniel Garfo100% (3)

- Squier Setup ManualDocument2 pagesSquier Setup ManualFrank Boz100% (1)

- Kodachrome GroundplanDocument1 pageKodachrome Groundplanapi-319390606No ratings yet

- Trapezoidal Neck Strandberg US20130186254A1Document10 pagesTrapezoidal Neck Strandberg US20130186254A1Percy Stanbury Malaga100% (1)

- Building A 5 String BanjoDocument8 pagesBuilding A 5 String BanjoDimitris BasiotisNo ratings yet

- Top Plate Brace Layouts: Classical Guitar Plan #3Document1 pageTop Plate Brace Layouts: Classical Guitar Plan #3Lutcharguitwaira LibreNo ratings yet

- Top Plate Brace Layouts: Classical Guitar Plan #3Document1 pageTop Plate Brace Layouts: Classical Guitar Plan #3Lutcharguitwaira LibreNo ratings yet

- 000plan 3Document1 page000plan 3BeppeNo ratings yet

- GD-50072 - Spec 3Document1 pageGD-50072 - Spec 3jnordmanNo ratings yet

- GD-50072 SpecDocument1 pageGD-50072 SpecjnordmanNo ratings yet

- GD-50060 SpecDocument1 pageGD-50060 SpecjnordmanNo ratings yet

- GD-50060 SpecDocument1 pageGD-50060 SpecjnordmanNo ratings yet

- GD-50060 - Spec 2Document1 pageGD-50060 - Spec 2jnordmanNo ratings yet

- ME HW5 Mohammed Ahmed Tahhan 392027113 Layout4Document1 pageME HW5 Mohammed Ahmed Tahhan 392027113 Layout4engineer.mohammedtahhanNo ratings yet

- Roof Plan - UNDPDocument1 pageRoof Plan - UNDPFatenNo ratings yet

- Produced by An Autodesk Student VersionDocument1 pageProduced by An Autodesk Student VersionIulian NgiNo ratings yet

- BIELA ModelZOOM PDFDocument1 pageBIELA ModelZOOM PDFIulian NgiNo ratings yet

- VDS MasterplanDocument1 pageVDS MasterplanSamudrala SreepranaviNo ratings yet

- 06 Uke12tenorplanformsDocument1 page06 Uke12tenorplanformsarantxa16No ratings yet

- Week-1 Practice: 21K61A0117 Sai DeepikaDocument1 pageWeek-1 Practice: 21K61A0117 Sai DeepikajnanendraNo ratings yet

- A B C E F H G: Barbacoa Terraza BARDocument1 pageA B C E F H G: Barbacoa Terraza BARFrida LlerenaNo ratings yet

- Site Image MapDocument1 pageSite Image MapReenaNo ratings yet

- 2-Wi Nding.. 64.7Document1 page2-Wi Nding.. 64.7MICHAEL MEDINA FLORESNo ratings yet

- SK1528 Rook PDFDocument1 pageSK1528 Rook PDFInform7105No ratings yet

- GraphsDocument8 pagesGraphsPuneeth kumar j kNo ratings yet

- Week-1 Practice: 21K61A0111 G.Sai DeepikaDocument1 pageWeek-1 Practice: 21K61A0111 G.Sai DeepikajnanendraNo ratings yet

- E - Manual - 18x72 TRC - 20122010Document3 pagesE - Manual - 18x72 TRC - 20122010Edward LarensNo ratings yet

- Boeing P-26 PeashooterDocument1 pageBoeing P-26 Peashootermohamed sidkyNo ratings yet

- C Brand FX Body Company, INC. 2012 F-73-00-04 Rev:03Document1 pageC Brand FX Body Company, INC. 2012 F-73-00-04 Rev:03Alan TrejoNo ratings yet

- TD - 148018 - Essence SH-3232 - en - enDocument1 pageTD - 148018 - Essence SH-3232 - en - enTony ParkNo ratings yet

- Chikalaguriki 100Document1 pageChikalaguriki 100VB665No ratings yet

- B400 B700 ManualDocument2 pagesB400 B700 ManualMultiservicios aqualectNo ratings yet

- 2 X 48 No Weld GrinderDocument4 pages2 X 48 No Weld GrinderJoão Costa LemosNo ratings yet

- Farmland DimensionsDocument1 pageFarmland DimensionsKumar KingslyNo ratings yet

- Contoh Form AbsensiDocument23 pagesContoh Form AbsensiFeronika KurniaNo ratings yet

- 1:3 1:3 Extended Retracted: Cvl1000 / Cvl1500 (No Manual Override) - Specification SheetDocument1 page1:3 1:3 Extended Retracted: Cvl1000 / Cvl1500 (No Manual Override) - Specification SheetDaniel Camargo PérezNo ratings yet

- Back Plate Layout & Brace Layout: Classical Guitar Plan #3Document1 pageBack Plate Layout & Brace Layout: Classical Guitar Plan #3Lutcharguitwaira LibreNo ratings yet

- Bulkhead BinderDocument114 pagesBulkhead BinderWilliam ProvidoNo ratings yet

- CE013 - CE31S3 - Plate 2 - FELICIANO, Alberto LiclicanDocument1 pageCE013 - CE31S3 - Plate 2 - FELICIANO, Alberto Liclicanqalfeliciano01No ratings yet

- Plano EstructurasDocument1 pagePlano EstructurasFelipe ClarosNo ratings yet

- Historico PIB MexicoDocument1 pageHistorico PIB MexicoJUAN SINMIEDONo ratings yet

- 9 Kids Room AA 2403Document1 page9 Kids Room AA 2403priyankaNo ratings yet

- Structural Inspection Area QC01Document1 pageStructural Inspection Area QC01Mohd ELNo ratings yet

- Catalogues HoodsDocument2 pagesCatalogues HoodsVladimir CortezNo ratings yet

- Futuro Proyecto "San Valentin: Via ProyectadaDocument1 pageFuturo Proyecto "San Valentin: Via ProyectadaHanani Hernan Aguilar LoconiNo ratings yet

- A01 PDFDocument1 pageA01 PDFEdgardo Guevara EleraNo ratings yet

- A01 PDFDocument1 pageA01 PDFEdgardo Guevara EleraNo ratings yet

- Arbuda Aparrment Jatin BhaiDocument1 pageArbuda Aparrment Jatin BhaiSarthak DixitNo ratings yet

- Dre Voting Kiosk: Street Name, Suite Number City, State Zip Code 123.456.7890Document2 pagesDre Voting Kiosk: Street Name, Suite Number City, State Zip Code 123.456.7890Kakoy Lagusan EcobenNo ratings yet

- Tobacco FactsDocument2 pagesTobacco FactsstprepsNo ratings yet

- F16/FA16 INPUT F25/FA25 OUTPUT Ib10 Gearbox: Drawing NoDocument1 pageF16/FA16 INPUT F25/FA25 OUTPUT Ib10 Gearbox: Drawing NoHUNGNo ratings yet

- Duncan Kitchen DesignDocument10 pagesDuncan Kitchen DesignAmy AleshireNo ratings yet

- Cimentación OctavoDocument1 pageCimentación OctavoPaulaErazoPNo ratings yet

- Membaca Gambar TeknikDocument1 pageMembaca Gambar Teknikwahyubandono35No ratings yet

- Enviromag Datasheet Complete Revsd 08-4Document8 pagesEnviromag Datasheet Complete Revsd 08-4Abel VegaNo ratings yet

- E-03 Estructura: Centro Integral de Artes, ChapulliDocument1 pageE-03 Estructura: Centro Integral de Artes, Chapullikeila gonzálexNo ratings yet

- PT 0+000 Layout2Document1 pagePT 0+000 Layout2david.franco.pinheiroNo ratings yet

- Listening Answer Sheet-12Document1 pageListening Answer Sheet-12Kenzo KatarijiNo ratings yet

- Bahria Town: Produced by An Autodesk Educational ProductDocument1 pageBahria Town: Produced by An Autodesk Educational ProductJadoonNo ratings yet

- Fold Table All PartsDocument1 pageFold Table All PartsivanNo ratings yet

- Cont. On PR-252:PAB1 E 59'1" S 9'8" EL +18'9.9/16": Project NoDocument1 pageCont. On PR-252:PAB1 E 59'1" S 9'8" EL +18'9.9/16": Project NoThe 81No ratings yet

- One Bold Move a Day: Meaningful Actions Women Can Take to Fulfill Their Leadership and Career PotentialFrom EverandOne Bold Move a Day: Meaningful Actions Women Can Take to Fulfill Their Leadership and Career PotentialNo ratings yet

- Slte Aug2016Document84 pagesSlte Aug2016Cristian SNo ratings yet

- Explorer Guitar KitinstructionsDocument30 pagesExplorer Guitar KitinstructionsCorey WilliamsNo ratings yet

- Zakk Wylde Guitar MetodoDocument8 pagesZakk Wylde Guitar MetodoJosé Silvestre MontellanoNo ratings yet

- How To Set Up A Guitar Free GuideDocument38 pagesHow To Set Up A Guitar Free GuideAntonyNealeNo ratings yet

- User Manual: Downloaded From Manuals Search EngineDocument22 pagesUser Manual: Downloaded From Manuals Search EngineLuwissssNo ratings yet

- Master The Caged System For GuitarDocument11 pagesMaster The Caged System For GuitarLuis Cotrina VaraNo ratings yet

- Ibanez Bass AdjustDocument2 pagesIbanez Bass AdjustRosalba Maria Leal GiffoniNo ratings yet

- Repair Guitar NeckDocument5 pagesRepair Guitar NeckPetr PetrovNo ratings yet

- Carvin Jan2012 BassDocument10 pagesCarvin Jan2012 BassKing Maxwell DclxcviNo ratings yet

- RK - Catalog PDFDocument16 pagesRK - Catalog PDFfluidaimaginacionNo ratings yet

- Fender Electric Guitar ManualDocument32 pagesFender Electric Guitar Manualdeni_2013No ratings yet

- Full Diagonal Pentatonic EbookDocument27 pagesFull Diagonal Pentatonic Ebookaa100% (4)

- Lead Guitar TechniquesDocument47 pagesLead Guitar Techniquesteofrasto250% (2)

- Ukulele LessonsDocument38 pagesUkulele Lessonsapi-321836157No ratings yet

- Tommy Emmanuel Fingerstyle Guita MethodDocument25 pagesTommy Emmanuel Fingerstyle Guita MethodS. D.0% (1)

- Sigma Katalog 2013Document37 pagesSigma Katalog 2013fluidaimaginacionNo ratings yet

- 1989 Guild Stuart X-500Document6 pages1989 Guild Stuart X-500Betoguitar777No ratings yet

- Mayones Bass Manual enDocument12 pagesMayones Bass Manual enjankoduricNo ratings yet

- RBX170 eDocument4 pagesRBX170 ehuelcheNo ratings yet

- You Can Play Guitar: Beginner EbookDocument37 pagesYou Can Play Guitar: Beginner EbookmdhansenNo ratings yet

- A Note On The Sound Radiation From The Classical Guitar Influence of Energy Input Via The String Termination at The FretDocument4 pagesA Note On The Sound Radiation From The Classical Guitar Influence of Energy Input Via The String Termination at The FretAmaury Jamir Meza PérezNo ratings yet

- Squier Strat Pack and Bass Pack Owners ManualDocument12 pagesSquier Strat Pack and Bass Pack Owners Manualmartin_salineNo ratings yet

- Cellist and Cello Body PostureDocument6 pagesCellist and Cello Body PostureEthanNo ratings yet

- 1939 Gibson Super 400N: Instruments Here Instruments Previously Sold HereDocument6 pages1939 Gibson Super 400N: Instruments Here Instruments Previously Sold HereRudolf RijgersbergNo ratings yet

- Selecting Guitar Wood PDFDocument5 pagesSelecting Guitar Wood PDFZalNo ratings yet

- Bass Guitar For Dummies Cheat SheetDocument14 pagesBass Guitar For Dummies Cheat SheetRocio Barco100% (1)

- Cello DimensionDocument2 pagesCello DimensionChutchawan Ungern100% (1)