Professional Documents

Culture Documents

HG 225

HG 225

Uploaded by

Claudio Alvarado ArayaCopyright:

Available Formats

You might also like

- AZ-500 Book PDFDocument253 pagesAZ-500 Book PDFAldo SENo ratings yet

- FMC 120plus ValveDocument2 pagesFMC 120plus Valvefranz_aditya100% (3)

- Put An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamDocument8 pagesPut An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamjoseNo ratings yet

- Turnbuckle Eye To EyeDocument1 pageTurnbuckle Eye To EyeNed VasicNo ratings yet

- HG 226Document1 pageHG 226Konstantinos SynodinosNo ratings yet

- Jaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyDocument1 pageJaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyGustavo ArancibiaNo ratings yet

- Turnbuckle Jaw + JawDocument1 pageTurnbuckle Jaw + JawjoosuasinagaNo ratings yet

- Crosby G-257 PDFDocument1 pageCrosby G-257 PDFKonstantinos SynodinosNo ratings yet

- Jaw & Jaw TurnbucklesDocument1 pageJaw & Jaw TurnbucklesSavin TimofteNo ratings yet

- G-277 Cancamo CrosbyDocument1 pageG-277 Cancamo CrosbyDavid Borja HuarachiNo ratings yet

- Angular Contact Bearing SwivelsDocument1 pageAngular Contact Bearing SwivelsmeromikhaNo ratings yet

- Alloy Screw Pin Shackle G209ADocument1 pageAlloy Screw Pin Shackle G209ARony Prayitno SimeonNo ratings yet

- List - TBC SoftDocument1 pageList - TBC SoftadityadhNo ratings yet

- GemLock Submital Binder 1 - 2024 03 06 143033 - NtgyDocument21 pagesGemLock Submital Binder 1 - 2024 03 06 143033 - Ntgyjeferjoan.11No ratings yet

- Dextra - Marine Tie RodsDocument6 pagesDextra - Marine Tie Rodspangalengan zaxNo ratings yet

- CSI Spec Fiberglass PDFDocument5 pagesCSI Spec Fiberglass PDFSubash Bastola100% (1)

- Absolyte GP SpecsDocument20 pagesAbsolyte GP Specsarya permanaNo ratings yet

- Master Link A345Document1 pageMaster Link A345Hunnymijie NorNo ratings yet

- 11 CS Vibrating ScreensDocument4 pages11 CS Vibrating Screensfiliman219No ratings yet

- Suntech Thrust Pad Cata 18-19Document16 pagesSuntech Thrust Pad Cata 18-19ARKA technocorpNo ratings yet

- PT Bar Systems Brochure 17.05.29Document8 pagesPT Bar Systems Brochure 17.05.29SACHINNo ratings yet

- Crosby - HG-228 Jaw Jaw Turnbuckles SpecsDocument1 pageCrosby - HG-228 Jaw Jaw Turnbuckles SpecsSalmanNo ratings yet

- Absolyte Energy PDFDocument12 pagesAbsolyte Energy PDFIsrarul Haque AnsariNo ratings yet

- Absolyte GP PV Alt EnergyDocument12 pagesAbsolyte GP PV Alt EnergysasaNo ratings yet

- Correction To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsDocument2 pagesCorrection To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsTimNo ratings yet

- TurnbucklesDocument6 pagesTurnbucklesRonny Andalas100% (1)

- Crosby Bolt Type Shackles: Testing The LimitsDocument1 pageCrosby Bolt Type Shackles: Testing The LimitsStephen KokoNo ratings yet

- Crosby G-209R ROV ShackleDocument1 pageCrosby G-209R ROV ShacklenatNo ratings yet

- Struktur Conveyor & TowerDocument106 pagesStruktur Conveyor & Towersahnohilhami3512No ratings yet

- Clevis Grab Hook Crosby® A338 (Grade 80)Document1 pageClevis Grab Hook Crosby® A338 (Grade 80)CROSBYNo ratings yet

- CANAN Steel Deck Catalogue - 2023Document48 pagesCANAN Steel Deck Catalogue - 2023Clarice Lispector100% (1)

- Fire Sprinkler Pipe BrochureDocument8 pagesFire Sprinkler Pipe BrochureINGENIERIA8 FYSNo ratings yet

- Ssfly001465 en AqDocument2 pagesSsfly001465 en AqMike PowerNo ratings yet

- Rulman Kodlama NTN 106 119Document14 pagesRulman Kodlama NTN 106 119mustafa bulatNo ratings yet

- Bolt Capacities: Non-Preloaded Ordinary BoltsDocument1 pageBolt Capacities: Non-Preloaded Ordinary BoltsSelvasathaNo ratings yet

- The New Control Cable With Numbered Cores: Smaller, Lighter, With VDE-approvalDocument3 pagesThe New Control Cable With Numbered Cores: Smaller, Lighter, With VDE-approvaltwo travellerNo ratings yet

- BJ Model SV-5 Cement Retainer PDFDocument2 pagesBJ Model SV-5 Cement Retainer PDFmohammad teimuriNo ratings yet

- Crosby Wide Body ShacklesDocument1 pageCrosby Wide Body ShacklesPeter BarabasNo ratings yet

- Sling Saver ShackleDocument1 pageSling Saver ShackleFatihTufanNo ratings yet

- AbsolyteGP PDFDocument12 pagesAbsolyteGP PDFedin PopNo ratings yet

- NA2XSY 1 X (25-630) MM 3.6/6 KVDocument5 pagesNA2XSY 1 X (25-630) MM 3.6/6 KVMuhammad ArmiyaNo ratings yet

- NA2XSYDocument5 pagesNA2XSYВладимир УсольцевNo ratings yet

- 24 Crosby Shackle MetricDocument1 page24 Crosby Shackle MetricAsnawirNo ratings yet

- Sandvik FlangesDocument6 pagesSandvik FlangesMarcelene Justine DionisioNo ratings yet

- RB210Document27 pagesRB210afasdgNo ratings yet

- M11 MarineDocument12 pagesM11 MarineDiogo CidadeNo ratings yet

- GRC Kwik Couple Elbows GRC Conduit Elbows Nipples CouplingsDocument8 pagesGRC Kwik Couple Elbows GRC Conduit Elbows Nipples CouplingsJuanelo CruzNo ratings yet

- Shield Gate ValveDocument1 pageShield Gate ValveGopinath Sekar0% (1)

- CAT Buckets Technical SpecificationsDocument6 pagesCAT Buckets Technical SpecificationsEhab Attia SelimNo ratings yet

- Jc-557 Type 5610 TDS-FNL - LowresDocument7 pagesJc-557 Type 5610 TDS-FNL - LowresDaygoro RuizNo ratings yet

- GDEP - GD 2250T Continuous Duty - Spec Sheet - 2022Document2 pagesGDEP - GD 2250T Continuous Duty - Spec Sheet - 2022bayuNo ratings yet

- Fire Sprinkler Pipe BrochureDocument6 pagesFire Sprinkler Pipe BrochureFrankie ArrezaNo ratings yet

- 11 Series Internal Gear Slewing BearingDocument3 pages11 Series Internal Gear Slewing BearingAndre van GreunenNo ratings yet

- Quick Release Pins: Metric TableDocument1 pageQuick Release Pins: Metric Tableezequiel navarroNo ratings yet

- N2XYDocument5 pagesN2XYSamuel SantosNo ratings yet

- Static Grounding Reels: For Refueling or Hazardous AreasDocument2 pagesStatic Grounding Reels: For Refueling or Hazardous AreasCRISTIAN CMAILO CABALLERONo ratings yet

- 1.PL-Cendana Cove-20211204 - R0-InternalDocument3 pages1.PL-Cendana Cove-20211204 - R0-InternalKuntjoro HertantoNo ratings yet

- Eye Hook Clevis Hook: S-1316 Eye Hook Shur-Loc Hook Series With Positive Locking LatchDocument1 pageEye Hook Clevis Hook: S-1316 Eye Hook Shur-Loc Hook Series With Positive Locking LatchKonstantinos SynodinosNo ratings yet

- Case Studies For 125 Year Service Life Utilizing High Strength Low Chromium Reinforcing BarsDocument26 pagesCase Studies For 125 Year Service Life Utilizing High Strength Low Chromium Reinforcing BarsKY PengNo ratings yet

- Brochure - SIL PT BarDocument4 pagesBrochure - SIL PT Barprashant patilNo ratings yet

- Aluminum Structures: A Guide to Their Specifications and DesignFrom EverandAluminum Structures: A Guide to Their Specifications and DesignRating: 5 out of 5 stars5/5 (2)

- 2010 Drama For Life Festival - ProgrammeDocument13 pages2010 Drama For Life Festival - ProgrammeSA BooksNo ratings yet

- Q2 Mathematics 8 - Module 6Document19 pagesQ2 Mathematics 8 - Module 6Jose Carlos FernandezNo ratings yet

- Strain Index Scoring Sheet: Date: Task: Company: Supervisor: Dept: EvaluatorDocument1 pageStrain Index Scoring Sheet: Date: Task: Company: Supervisor: Dept: EvaluatorAngeline Henao BohorquezNo ratings yet

- Why Is Omkar Called As Pranav MantraDocument6 pagesWhy Is Omkar Called As Pranav Mantraami1577No ratings yet

- About Pets and AnimalsDocument5 pagesAbout Pets and AnimalsMatej JanakievNo ratings yet

- TW 05 ZhangDocument9 pagesTW 05 ZhangAhmed ELhefnawyNo ratings yet

- The Happy PrinceDocument3 pagesThe Happy PrinceLaurence UyNo ratings yet

- Alcuin of YorkDocument6 pagesAlcuin of YorkemeokeNo ratings yet

- A Corpus-Based Contrastive Study of Adverb + Verb Collocations in Chinese Learner English and Native Speaker EnglishDocument28 pagesA Corpus-Based Contrastive Study of Adverb + Verb Collocations in Chinese Learner English and Native Speaker EnglishMehwish AwanNo ratings yet

- Admission Letter CsabDocument1 pageAdmission Letter Csabsuraj mohantyNo ratings yet

- How To Size A Propeller ShaftDocument2 pagesHow To Size A Propeller ShaftJoão Henrique Volpini MattosNo ratings yet

- Reading 15 Analysis of Dividends and Share Repurchases - AnswersDocument31 pagesReading 15 Analysis of Dividends and Share Repurchases - AnswersNeerajNo ratings yet

- Lecture9 Memory OrganizationDocument32 pagesLecture9 Memory Organizationecevitmert1453No ratings yet

- Division - Memo - No. - 28s.2023 - CONTINUING FUNDDocument9 pagesDivision - Memo - No. - 28s.2023 - CONTINUING FUNDChard A. CañasNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 142, - , - : Bright Steel, Unalloyed, Cold DrawnDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 142, - , - : Bright Steel, Unalloyed, Cold Drawnbaskaran ayyapparajNo ratings yet

- Literature Review of Home Automation Using BluetoothDocument8 pagesLiterature Review of Home Automation Using BluetoothaflsodoamNo ratings yet

- Pipework Components - Definition and Selection of DN (Nominal Size) (ISO 6708:1995) Rörledningar - Nominell Storlek, DN (ISO 6708:1995)Document6 pagesPipework Components - Definition and Selection of DN (Nominal Size) (ISO 6708:1995) Rörledningar - Nominell Storlek, DN (ISO 6708:1995)Aliraza AlirazaNo ratings yet

- Delta Function and So OnDocument20 pagesDelta Function and So OnLionel TopperNo ratings yet

- 37mm Firework ProjectDocument5 pages37mm Firework ProjectK Scott Wyatt100% (1)

- Famous Filipino AthleteDocument5 pagesFamous Filipino AthleteSandara SarciaNo ratings yet

- 20 Must-Know Rocks Licks: Shuffle Lick 5Document3 pages20 Must-Know Rocks Licks: Shuffle Lick 5julyfriska100% (1)

- Group 70 - COMPONENT LOCATIONS - Mitsubishi Outlander III - Wiring DiagramsDocument19 pagesGroup 70 - COMPONENT LOCATIONS - Mitsubishi Outlander III - Wiring DiagramsandreslionNo ratings yet

- BARCOL Hardness Tester: Product InformationDocument2 pagesBARCOL Hardness Tester: Product InformationZulfikar MutaqinNo ratings yet

- Understanding The Self Syllabus 2nd Sem 2021-22Document7 pagesUnderstanding The Self Syllabus 2nd Sem 2021-22Mary Crisza RentoriaNo ratings yet

- Prinsip-Prinsip EkonomiDocument11 pagesPrinsip-Prinsip EkonomiRev AwNo ratings yet

- Stonhard Color Sheet Stonclad Fnlrev-1Document1 pageStonhard Color Sheet Stonclad Fnlrev-1Anonymous aii1ilNo ratings yet

- Is 5 8Document218 pagesIs 5 8andispotifyaccNo ratings yet

- Group 2 - The Basic Verb PhraseDocument12 pagesGroup 2 - The Basic Verb PhraseMuhammad FirnasNo ratings yet

- Ignou Assignment Wala Ehi 1 Solved Assignment 2018-19Document7 pagesIgnou Assignment Wala Ehi 1 Solved Assignment 2018-19NEW THINK CLASSES100% (1)

HG 225

HG 225

Uploaded by

Claudio Alvarado ArayaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HG 225

HG 225

Uploaded by

Claudio Alvarado ArayaCopyright:

Available Formats

Rigging_Metric.

fm Page 162 Tuesday, November 25, 2008 5:42 PM

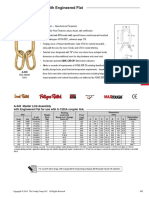

Hook & Eye Turnbuckles

HG-225 • End fittings are Quenched and Tempered, bodies heat treated by normalizing.

• Hot Dip galvanized steel.

• Turnbuckle eyes are forged elongated, by design, to maximize easy attachment in system

and minimize stress in the eye. For turnbuckles sizes 6 mm through 25.4 mm, a shackle one

size smaller can be reeved through eye.

• Turnbuckle hooks are forged with a greater cross sectional area that results in a stronger

hook with better fatigue properties.

• Crosby products meet or exceed all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements. Importantly, Crosby

products meet other critical performance requirements including fatigue life, impact

properties and material traceability, not addressed by ASME B30.26.

• TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY.

• Modified UNJ thread on end fittings for improved fatigue properties.

• Body has UNC threads.

• Lock Nuts available for all sizes (see page 170).

• Comprehensive end fitting data provided on pages 166 & 167.

• Fatigue Rated.

s e l k c u b n r u T e y E & k o o H

Meets the performance requirements of Federal

Specifications FF-T-791b, Type 1, Form 1 — CLASS

6,and ASTM F-1145, except for those provisions

required of the contractor. For additional infor-

mation, see page 391.

HG-225

Hook & Eye

Thread Working Dimensions

Diameter HG2 5 Load Weight (mm)

& Take Up HG-225 Limit Each E J K M N X

(mm) Stock No. (t)* (kg) A D Closed F Open Closed Open Closed R S Closed BB

† 6.35 x 102 1030636 .18 .14 6.35 11.2 42.3 32.3 296 195 312 211 20.6 8.64 44.6 103

† 7.94 x 114 1030654 .32 .23 7.94 12.7 50.7 38.1 343 229 363 248 24.1 11.2 55.8 116

† 9.53 x 152 1030672 .45 .36 9.53 14.2 57.8 44.7 434 282 458 306 28.7 13.5 62.9 155

12.7 x 152 1030690 .68 .82 12.7 16.5 89.7 57.9 497 345 528 376 35.8 18.0 90.4 153

12.7 x 305 1030734 .68 1.22 12.7 16.5 89.2 57.9 809 504 840 535 35.8 18.0 89.9 314

15.9 x 152 1030752 1.02 1.35 15.9 22.9 108 71.4 536 384 574 422 45.7 22.4 110 153

15.9 x 305 1030798 1.02 1.97 15.9 22.9 107 71.4 850 545 888 583 45.7 22.4 110 315

19.1 x 152 1030814 1.36 1.91 19.1 24.9 129 84.6 574 422 621 469 53.1 25.4 130 156

19.1 x 305 1030850 1.36 2.96 19.1 24.9 128 84.6 889 584 936 631 53.1 25.4 129 320

19.1 x 457 1030878 1.36 3.74 19.1 24.9 129 84.6 1194 737 1241 784 53.1 25.4 130 471

22.2 x 305 1030896 1.81 4.24 22.2 28.7 148 96.0 917 612 971 666 60.5 31.8 147 309

25.4 x 305 1030958 2.27 6.29 25.4 31.8 167 108 956 652 1018 713 76.2 36.3 165 309

* Proof Load is 2.5 times the Working Load Limit. Ultimate Load is 5 times the Working Load Limit.

† Mechanical Galvanized

162 Copyright © 2008 The Crosby Group, Inc.

All Rights Reserved

You might also like

- AZ-500 Book PDFDocument253 pagesAZ-500 Book PDFAldo SENo ratings yet

- FMC 120plus ValveDocument2 pagesFMC 120plus Valvefranz_aditya100% (3)

- Put An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamDocument8 pagesPut An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamjoseNo ratings yet

- Turnbuckle Eye To EyeDocument1 pageTurnbuckle Eye To EyeNed VasicNo ratings yet

- HG 226Document1 pageHG 226Konstantinos SynodinosNo ratings yet

- Jaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyDocument1 pageJaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyGustavo ArancibiaNo ratings yet

- Turnbuckle Jaw + JawDocument1 pageTurnbuckle Jaw + JawjoosuasinagaNo ratings yet

- Crosby G-257 PDFDocument1 pageCrosby G-257 PDFKonstantinos SynodinosNo ratings yet

- Jaw & Jaw TurnbucklesDocument1 pageJaw & Jaw TurnbucklesSavin TimofteNo ratings yet

- G-277 Cancamo CrosbyDocument1 pageG-277 Cancamo CrosbyDavid Borja HuarachiNo ratings yet

- Angular Contact Bearing SwivelsDocument1 pageAngular Contact Bearing SwivelsmeromikhaNo ratings yet

- Alloy Screw Pin Shackle G209ADocument1 pageAlloy Screw Pin Shackle G209ARony Prayitno SimeonNo ratings yet

- List - TBC SoftDocument1 pageList - TBC SoftadityadhNo ratings yet

- GemLock Submital Binder 1 - 2024 03 06 143033 - NtgyDocument21 pagesGemLock Submital Binder 1 - 2024 03 06 143033 - Ntgyjeferjoan.11No ratings yet

- Dextra - Marine Tie RodsDocument6 pagesDextra - Marine Tie Rodspangalengan zaxNo ratings yet

- CSI Spec Fiberglass PDFDocument5 pagesCSI Spec Fiberglass PDFSubash Bastola100% (1)

- Absolyte GP SpecsDocument20 pagesAbsolyte GP Specsarya permanaNo ratings yet

- Master Link A345Document1 pageMaster Link A345Hunnymijie NorNo ratings yet

- 11 CS Vibrating ScreensDocument4 pages11 CS Vibrating Screensfiliman219No ratings yet

- Suntech Thrust Pad Cata 18-19Document16 pagesSuntech Thrust Pad Cata 18-19ARKA technocorpNo ratings yet

- PT Bar Systems Brochure 17.05.29Document8 pagesPT Bar Systems Brochure 17.05.29SACHINNo ratings yet

- Crosby - HG-228 Jaw Jaw Turnbuckles SpecsDocument1 pageCrosby - HG-228 Jaw Jaw Turnbuckles SpecsSalmanNo ratings yet

- Absolyte Energy PDFDocument12 pagesAbsolyte Energy PDFIsrarul Haque AnsariNo ratings yet

- Absolyte GP PV Alt EnergyDocument12 pagesAbsolyte GP PV Alt EnergysasaNo ratings yet

- Correction To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsDocument2 pagesCorrection To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsTimNo ratings yet

- TurnbucklesDocument6 pagesTurnbucklesRonny Andalas100% (1)

- Crosby Bolt Type Shackles: Testing The LimitsDocument1 pageCrosby Bolt Type Shackles: Testing The LimitsStephen KokoNo ratings yet

- Crosby G-209R ROV ShackleDocument1 pageCrosby G-209R ROV ShacklenatNo ratings yet

- Struktur Conveyor & TowerDocument106 pagesStruktur Conveyor & Towersahnohilhami3512No ratings yet

- Clevis Grab Hook Crosby® A338 (Grade 80)Document1 pageClevis Grab Hook Crosby® A338 (Grade 80)CROSBYNo ratings yet

- CANAN Steel Deck Catalogue - 2023Document48 pagesCANAN Steel Deck Catalogue - 2023Clarice Lispector100% (1)

- Fire Sprinkler Pipe BrochureDocument8 pagesFire Sprinkler Pipe BrochureINGENIERIA8 FYSNo ratings yet

- Ssfly001465 en AqDocument2 pagesSsfly001465 en AqMike PowerNo ratings yet

- Rulman Kodlama NTN 106 119Document14 pagesRulman Kodlama NTN 106 119mustafa bulatNo ratings yet

- Bolt Capacities: Non-Preloaded Ordinary BoltsDocument1 pageBolt Capacities: Non-Preloaded Ordinary BoltsSelvasathaNo ratings yet

- The New Control Cable With Numbered Cores: Smaller, Lighter, With VDE-approvalDocument3 pagesThe New Control Cable With Numbered Cores: Smaller, Lighter, With VDE-approvaltwo travellerNo ratings yet

- BJ Model SV-5 Cement Retainer PDFDocument2 pagesBJ Model SV-5 Cement Retainer PDFmohammad teimuriNo ratings yet

- Crosby Wide Body ShacklesDocument1 pageCrosby Wide Body ShacklesPeter BarabasNo ratings yet

- Sling Saver ShackleDocument1 pageSling Saver ShackleFatihTufanNo ratings yet

- AbsolyteGP PDFDocument12 pagesAbsolyteGP PDFedin PopNo ratings yet

- NA2XSY 1 X (25-630) MM 3.6/6 KVDocument5 pagesNA2XSY 1 X (25-630) MM 3.6/6 KVMuhammad ArmiyaNo ratings yet

- NA2XSYDocument5 pagesNA2XSYВладимир УсольцевNo ratings yet

- 24 Crosby Shackle MetricDocument1 page24 Crosby Shackle MetricAsnawirNo ratings yet

- Sandvik FlangesDocument6 pagesSandvik FlangesMarcelene Justine DionisioNo ratings yet

- RB210Document27 pagesRB210afasdgNo ratings yet

- M11 MarineDocument12 pagesM11 MarineDiogo CidadeNo ratings yet

- GRC Kwik Couple Elbows GRC Conduit Elbows Nipples CouplingsDocument8 pagesGRC Kwik Couple Elbows GRC Conduit Elbows Nipples CouplingsJuanelo CruzNo ratings yet

- Shield Gate ValveDocument1 pageShield Gate ValveGopinath Sekar0% (1)

- CAT Buckets Technical SpecificationsDocument6 pagesCAT Buckets Technical SpecificationsEhab Attia SelimNo ratings yet

- Jc-557 Type 5610 TDS-FNL - LowresDocument7 pagesJc-557 Type 5610 TDS-FNL - LowresDaygoro RuizNo ratings yet

- GDEP - GD 2250T Continuous Duty - Spec Sheet - 2022Document2 pagesGDEP - GD 2250T Continuous Duty - Spec Sheet - 2022bayuNo ratings yet

- Fire Sprinkler Pipe BrochureDocument6 pagesFire Sprinkler Pipe BrochureFrankie ArrezaNo ratings yet

- 11 Series Internal Gear Slewing BearingDocument3 pages11 Series Internal Gear Slewing BearingAndre van GreunenNo ratings yet

- Quick Release Pins: Metric TableDocument1 pageQuick Release Pins: Metric Tableezequiel navarroNo ratings yet

- N2XYDocument5 pagesN2XYSamuel SantosNo ratings yet

- Static Grounding Reels: For Refueling or Hazardous AreasDocument2 pagesStatic Grounding Reels: For Refueling or Hazardous AreasCRISTIAN CMAILO CABALLERONo ratings yet

- 1.PL-Cendana Cove-20211204 - R0-InternalDocument3 pages1.PL-Cendana Cove-20211204 - R0-InternalKuntjoro HertantoNo ratings yet

- Eye Hook Clevis Hook: S-1316 Eye Hook Shur-Loc Hook Series With Positive Locking LatchDocument1 pageEye Hook Clevis Hook: S-1316 Eye Hook Shur-Loc Hook Series With Positive Locking LatchKonstantinos SynodinosNo ratings yet

- Case Studies For 125 Year Service Life Utilizing High Strength Low Chromium Reinforcing BarsDocument26 pagesCase Studies For 125 Year Service Life Utilizing High Strength Low Chromium Reinforcing BarsKY PengNo ratings yet

- Brochure - SIL PT BarDocument4 pagesBrochure - SIL PT Barprashant patilNo ratings yet

- Aluminum Structures: A Guide to Their Specifications and DesignFrom EverandAluminum Structures: A Guide to Their Specifications and DesignRating: 5 out of 5 stars5/5 (2)

- 2010 Drama For Life Festival - ProgrammeDocument13 pages2010 Drama For Life Festival - ProgrammeSA BooksNo ratings yet

- Q2 Mathematics 8 - Module 6Document19 pagesQ2 Mathematics 8 - Module 6Jose Carlos FernandezNo ratings yet

- Strain Index Scoring Sheet: Date: Task: Company: Supervisor: Dept: EvaluatorDocument1 pageStrain Index Scoring Sheet: Date: Task: Company: Supervisor: Dept: EvaluatorAngeline Henao BohorquezNo ratings yet

- Why Is Omkar Called As Pranav MantraDocument6 pagesWhy Is Omkar Called As Pranav Mantraami1577No ratings yet

- About Pets and AnimalsDocument5 pagesAbout Pets and AnimalsMatej JanakievNo ratings yet

- TW 05 ZhangDocument9 pagesTW 05 ZhangAhmed ELhefnawyNo ratings yet

- The Happy PrinceDocument3 pagesThe Happy PrinceLaurence UyNo ratings yet

- Alcuin of YorkDocument6 pagesAlcuin of YorkemeokeNo ratings yet

- A Corpus-Based Contrastive Study of Adverb + Verb Collocations in Chinese Learner English and Native Speaker EnglishDocument28 pagesA Corpus-Based Contrastive Study of Adverb + Verb Collocations in Chinese Learner English and Native Speaker EnglishMehwish AwanNo ratings yet

- Admission Letter CsabDocument1 pageAdmission Letter Csabsuraj mohantyNo ratings yet

- How To Size A Propeller ShaftDocument2 pagesHow To Size A Propeller ShaftJoão Henrique Volpini MattosNo ratings yet

- Reading 15 Analysis of Dividends and Share Repurchases - AnswersDocument31 pagesReading 15 Analysis of Dividends and Share Repurchases - AnswersNeerajNo ratings yet

- Lecture9 Memory OrganizationDocument32 pagesLecture9 Memory Organizationecevitmert1453No ratings yet

- Division - Memo - No. - 28s.2023 - CONTINUING FUNDDocument9 pagesDivision - Memo - No. - 28s.2023 - CONTINUING FUNDChard A. CañasNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 142, - , - : Bright Steel, Unalloyed, Cold DrawnDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 142, - , - : Bright Steel, Unalloyed, Cold Drawnbaskaran ayyapparajNo ratings yet

- Literature Review of Home Automation Using BluetoothDocument8 pagesLiterature Review of Home Automation Using BluetoothaflsodoamNo ratings yet

- Pipework Components - Definition and Selection of DN (Nominal Size) (ISO 6708:1995) Rörledningar - Nominell Storlek, DN (ISO 6708:1995)Document6 pagesPipework Components - Definition and Selection of DN (Nominal Size) (ISO 6708:1995) Rörledningar - Nominell Storlek, DN (ISO 6708:1995)Aliraza AlirazaNo ratings yet

- Delta Function and So OnDocument20 pagesDelta Function and So OnLionel TopperNo ratings yet

- 37mm Firework ProjectDocument5 pages37mm Firework ProjectK Scott Wyatt100% (1)

- Famous Filipino AthleteDocument5 pagesFamous Filipino AthleteSandara SarciaNo ratings yet

- 20 Must-Know Rocks Licks: Shuffle Lick 5Document3 pages20 Must-Know Rocks Licks: Shuffle Lick 5julyfriska100% (1)

- Group 70 - COMPONENT LOCATIONS - Mitsubishi Outlander III - Wiring DiagramsDocument19 pagesGroup 70 - COMPONENT LOCATIONS - Mitsubishi Outlander III - Wiring DiagramsandreslionNo ratings yet

- BARCOL Hardness Tester: Product InformationDocument2 pagesBARCOL Hardness Tester: Product InformationZulfikar MutaqinNo ratings yet

- Understanding The Self Syllabus 2nd Sem 2021-22Document7 pagesUnderstanding The Self Syllabus 2nd Sem 2021-22Mary Crisza RentoriaNo ratings yet

- Prinsip-Prinsip EkonomiDocument11 pagesPrinsip-Prinsip EkonomiRev AwNo ratings yet

- Stonhard Color Sheet Stonclad Fnlrev-1Document1 pageStonhard Color Sheet Stonclad Fnlrev-1Anonymous aii1ilNo ratings yet

- Is 5 8Document218 pagesIs 5 8andispotifyaccNo ratings yet

- Group 2 - The Basic Verb PhraseDocument12 pagesGroup 2 - The Basic Verb PhraseMuhammad FirnasNo ratings yet

- Ignou Assignment Wala Ehi 1 Solved Assignment 2018-19Document7 pagesIgnou Assignment Wala Ehi 1 Solved Assignment 2018-19NEW THINK CLASSES100% (1)