Professional Documents

Culture Documents

Woven Geobag Up Technical Data Sheet

Woven Geobag Up Technical Data Sheet

Uploaded by

Sumit GuptaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Woven Geobag Up Technical Data Sheet

Woven Geobag Up Technical Data Sheet

Uploaded by

Sumit GuptaCopyright:

Available Formats

Page 47 of 106

CHAPTER – 1

1.0 GEO BAG/GABION :

1.01 GEO BAG- High performance woven geotextile bags, fabricated from ―Engineered Textile"

manufactured from 100% PP multifilament yarn by machine in cross direction, woven into stable network such that the yarn

retains their relative position. The fabric used for bags shall be(200 GSM)TFI 1200 or equivalent and meet the criteria given

under tech. spec. and have high UV resistance, inert to biological degradation and resistant to naturally encountered

chemicals like acids and alkalies.( Size 1.09M.x0.69M.)

PECIFICATIONS: Geo bags to be used in works must strictly confirm to the quality and specifications mentioned

below:

Technical Specifications of PP Multifilament Woven Geo textile Fabric for Geo Bag.

Test

Properties Unit Value Tolerance

Method

2

Mass per unit area ASTM D 5261 Gram/M 200 ± 2 (%)

Warp 55

Tensile Strength KN/M Minimum

Weft 40

IS 1969

Warp 25

Elongation at Break % Weft 25 Maximum

Puncture Resistance ASTM D 4833 N 700 Minimum

Warp 850

Trapezoidal Tear ASTM D 4533 N Minimum

Weft 600

Apparent Opening Size ASTM D 4751 Micron <75 Maximum

Water Permeability ASTM D 4491 L/M2/s 8 ±3

UV Resistance (%

strength Retained after

ASTM D 4355 % ≥75 Minimum

500 hrs exposure to

Outdoor weathering)

1. Only Manufacturer of Geotextile Fabric for Geotextile bag should take part in the Tender Process.

2. Manufacturer/Supplier must have a manufacturing unit of Geotextile Fabric for Geotextile bag Manufacturing License.

The firm should be registered with registrar of Firm and Industry Commissioner

3. Manufacturer/Supplier must have a facility for manufacturing woven geotextile fabric and stitching of woven geotextile

fabric into geotextile bag all together.

4. Manufacturer/Supplier must have an experience of supplying minimum 50000 PP Multifilament Woven Geotextile Bags

in a financial year to department of government of Uttar Pradesh.

5. Manufacturer/Supplier must have executed order of PP Multifilament Woven Geotextile bags to department of Govt of

Uttar Pradesh.

6. Manufacturer/Supplier must have in-house testing laboratories to perform the entire test specified for Geotextile bag.

Manufacture’s Test Certificate must be provided along with each lot of supply.

7. Manufacturer/Supplier should have ISO certification for producing Geotextile Fabrics

8. Manufacturer/Supplier must have In house facility to have printing on each Geotextile bag.

9. Each Geotextile bags supplied must be printed with Manufacturer’s name.

10. Manufacturer must include List of installed plant and machineries with full technical details for manufacturing Geotextile

Bags and Printing on Bags.

11. Successful bidder’s manufacturing plant may be inspected and verified about the mentioned capacity by departmental

engineer before agreement. Expense for the same will be borne by the manufacturer.

12. Materials to be used in works will be inspected at site on arrival, if defects of any kinds are noticed will be intimated to

Suppliers/Manufacturer. Failure to supply according to the specification may either entail forfeiture of security money or

curtail the aggremented rate.

13. Rate-The rates is inclusive of all admissible taxes including loading, unloading, transportation and other charges complete

upto destination and all taxes but Excluding GST. The income tax will be deducted as per rule. GST shall be paid extra by

the Department as per prevailing Govt. rules.

14. Consignee and paying authority- The Executive Engineer of concerned division as per scheduleed attached and specified in

the aggrement in normal situation extention of time will not be granted. If the Suppliers/ Manufacturer fails to supply the

materials within time, his security money will be forfeited and cancellation of the Aggrement may take place. Proceedings

for blacklisting of the firm will also be initiated.

RE-TENDER

PDF processed with CutePDF evaluation edition www.CutePDF.com

You might also like

- James Essinger - Jacquard's Web - How A Hand-Loom Led To The Birth of The Information Age (2007) PDFDocument314 pagesJames Essinger - Jacquard's Web - How A Hand-Loom Led To The Birth of The Information Age (2007) PDFМилош СтанојловићNo ratings yet

- Weaving CalculationsDocument12 pagesWeaving Calculationsrameshkothiya91% (54)

- The Geotextile Protection Layer For The Geomembrane Shall Be Made by A Needle Punching Process Using Staple Fibres and Should Have The Following Physical PropertiesDocument3 pagesThe Geotextile Protection Layer For The Geomembrane Shall Be Made by A Needle Punching Process Using Staple Fibres and Should Have The Following Physical PropertiesIr Ahmad AfiqNo ratings yet

- Appendix-C Specifications of Geosynthetic ProductsDocument104 pagesAppendix-C Specifications of Geosynthetic Productsambika prustyNo ratings yet

- Sample PVC Project SpecDocument8 pagesSample PVC Project SpecJULIONo ratings yet

- Esh M11P19 BDocument3 pagesEsh M11P19 Bjose luisNo ratings yet

- Polyethylene GeomembranesDocument18 pagesPolyethylene GeomembranesPalo DushiiNo ratings yet

- Spec Geo Bag PDFDocument1 pageSpec Geo Bag PDFBAMBANG IRAWANNo ratings yet

- ITEM 594.14010011 - Molded Rubber Fender Panel SystemDocument7 pagesITEM 594.14010011 - Molded Rubber Fender Panel Systemphd.meethaqNo ratings yet

- Fiberlon HDDocument2 pagesFiberlon HDMohamed AmeenNo ratings yet

- Non-Woven Geotextile As Per MORTH (PPGT - 150 GSM - Type-3) - TDSDocument1 pageNon-Woven Geotextile As Per MORTH (PPGT - 150 GSM - Type-3) - TDSSumit Gupta100% (1)

- Geo Fabric Filter BagDocument4 pagesGeo Fabric Filter BagAjju PatilNo ratings yet

- TDS Tuffpaulin PVC TarpDocument4 pagesTDS Tuffpaulin PVC TarpmukulsareenNo ratings yet

- Elastocoat C 6335-101Document4 pagesElastocoat C 6335-101Cristina AndronescuNo ratings yet

- Bituseal 1000-1200 (SKS)Document2 pagesBituseal 1000-1200 (SKS)khiem44No ratings yet

- D 119 - 78 ScanDocument4 pagesD 119 - 78 ScanJan BakosNo ratings yet

- Section 1. Practices and PrecautionsDocument23 pagesSection 1. Practices and PrecautionsrobinyNo ratings yet

- Controlled Volatility RTV Ablative Silicone: Description ApplicationDocument3 pagesControlled Volatility RTV Ablative Silicone: Description ApplicationLU CHUNHUINo ratings yet

- Belden P/N 50106F: Industrial CAT 6 F/UTPDocument2 pagesBelden P/N 50106F: Industrial CAT 6 F/UTPAsep heriyanaNo ratings yet

- Specification For Vertical Drains and Surcharge: 1.0 GeneralDocument13 pagesSpecification For Vertical Drains and Surcharge: 1.0 Generaljegatheesan777No ratings yet

- WSS M8P16 BDocument16 pagesWSS M8P16 Berik0007No ratings yet

- Product Data Sheet PP 200Document1 pageProduct Data Sheet PP 200AlonsoNo ratings yet

- Flexamat Spec SheetDocument5 pagesFlexamat Spec SheetJamesNo ratings yet

- Non Woven, Needle Punched, Staple FiberDocument2 pagesNon Woven, Needle Punched, Staple FiberAnonymous MAQrYFQDzVNo ratings yet

- Woven Geotextile SpecDocument5 pagesWoven Geotextile SpecMohammad Rafnie ArifNo ratings yet

- BPC Handrails, Caged Ladder & Structural 2010Document23 pagesBPC Handrails, Caged Ladder & Structural 2010sofyanshahNo ratings yet

- Specification For SleeveDocument6 pagesSpecification For SleevePipeline EngineerNo ratings yet

- Chapter 02Document39 pagesChapter 02Prakash Kumar NiralaNo ratings yet

- PolyflameDocument2 pagesPolyflameumn_mlkNo ratings yet

- Cat 6 BeldenDocument7 pagesCat 6 BeldenPT. Bali Cukup MandiriNo ratings yet

- CW 3130 - Supply and Installation of Geotextile Fabrics: December 2011 Division 4 - CW 3130 - R4Document5 pagesCW 3130 - Supply and Installation of Geotextile Fabrics: December 2011 Division 4 - CW 3130 - R4Dem DemNo ratings yet

- Prime Geo 550H..Document1 pagePrime Geo 550H..wpacadaNo ratings yet

- Conseal 250 Method Statement MEGASTARDocument4 pagesConseal 250 Method Statement MEGASTARKieboye AppahNo ratings yet

- Geogrid: Secugrid® Q (PES/PET)Document1 pageGeogrid: Secugrid® Q (PES/PET)Yassin Abd El AalNo ratings yet

- SikaWrap 930 GDocument3 pagesSikaWrap 930 GKevin Brandon ToledoNo ratings yet

- Brosur - PVD (GPVD704)Document2 pagesBrosur - PVD (GPVD704)Adriel ElezarNo ratings yet

- Scotchkote: Fusion-Bonded Epoxy Coating 206N LGDocument1 pageScotchkote: Fusion-Bonded Epoxy Coating 206N LGSohail TisekarNo ratings yet

- Titanpro 6531 MDocument1 pageTitanpro 6531 MErnesto CheguavaraNo ratings yet

- WSS M99P32 D1Document6 pagesWSS M99P32 D1jose luisNo ratings yet

- Construction Specification 495 GeotextileDocument5 pagesConstruction Specification 495 Geotextileathar abbasNo ratings yet

- Engineering Standards: Material Specification General GM222MDocument2 pagesEngineering Standards: Material Specification General GM222MFelipe De la cruzNo ratings yet

- Ac-700 SpecificationDocument10 pagesAc-700 SpecificationTarek Abuzene100% (1)

- Bitutect 3Document2 pagesBitutect 3mk779900mkNo ratings yet

- Macformer Tublar Type Mfm-IIIDocument1 pageMacformer Tublar Type Mfm-IIIDeny SuryantoNo ratings yet

- Geotex 4X4HF PDSDocument1 pageGeotex 4X4HF PDStranoNo ratings yet

- Polyflame Garden 1 & 2Document2 pagesPolyflame Garden 1 & 2mk779900mkNo ratings yet

- TDS-GEOPROTEC-GS3000S-22-01 Rev.01Document1 pageTDS-GEOPROTEC-GS3000S-22-01 Rev.01AMINNo ratings yet

- Pink Anti Static Bag BondlineDocument2 pagesPink Anti Static Bag Bondlineeky susilowatiNo ratings yet

- Humiseal 1R32 Conformal Coating English TdsDocument2 pagesHumiseal 1R32 Conformal Coating English TdsLee HitchensNo ratings yet

- 50105F Category 5e FTP Unarmoured CableDocument2 pages50105F Category 5e FTP Unarmoured CableAfinaNo ratings yet

- Ford WSS-M8P25-CDocument5 pagesFord WSS-M8P25-CPablo AnguianoNo ratings yet

- Poly GlasDocument2 pagesPoly Glasmk779900mkNo ratings yet

- Specification Concrete and Cmu Walls With BentoniteDocument8 pagesSpecification Concrete and Cmu Walls With BentoniteBaugh Graphic DesignNo ratings yet

- KLINGERSIL C-4430plus Data SheetDocument3 pagesKLINGERSIL C-4430plus Data SheetMichael PhamNo ratings yet

- Polyflame Garden - I & IIDocument2 pagesPolyflame Garden - I & IIAbdul Jaleel MohammedNo ratings yet

- Driscoplex 6500 Pe2708 / (Pe2406) Pipe: Pipe & Fittings Data SheetDocument2 pagesDriscoplex 6500 Pe2708 / (Pe2406) Pipe: Pipe & Fittings Data SheetmariannyNo ratings yet

- Kalyani Plastic Industries QT No 454 DT 12.10 PDFDocument4 pagesKalyani Plastic Industries QT No 454 DT 12.10 PDFMd AkramNo ratings yet

- Particular Spec For Geocell - Industrial Plots - East RailwayDocument4 pagesParticular Spec For Geocell - Industrial Plots - East RailwayThameem SharaafNo ratings yet

- SECTION 09980 Thin Film Polymer Floor Sealer Part 1 - General 1.01Document2 pagesSECTION 09980 Thin Film Polymer Floor Sealer Part 1 - General 1.01Eng CivilNo ratings yet

- PHONE - 503.692.5460 - FAX - 503.210.0602 - E-MAIL - ADDRESS - P.O. Box 100 9665 SW Tualatin-Sherwood Rd. Tualatin, Oregon 97062Document6 pagesPHONE - 503.692.5460 - FAX - 503.210.0602 - E-MAIL - ADDRESS - P.O. Box 100 9665 SW Tualatin-Sherwood Rd. Tualatin, Oregon 97062mohammed rafi shaikhNo ratings yet

- New Drain Board ProfileDocument25 pagesNew Drain Board ProfileSumit GuptaNo ratings yet

- Geostrap 2022Document26 pagesGeostrap 2022Sumit GuptaNo ratings yet

- Non-Woven Geotextile As Per MORTH (PPGT - 150 GSM - Type-3) - TDSDocument1 pageNon-Woven Geotextile As Per MORTH (PPGT - 150 GSM - Type-3) - TDSSumit Gupta100% (1)

- Paraweb BtraDocument6 pagesParaweb BtraSumit GuptaNo ratings yet

- Bid Mega 1Document55 pagesBid Mega 1Sumit GuptaNo ratings yet

- Specication of GeocompositeDocument6 pagesSpecication of GeocompositeSumit GuptaNo ratings yet

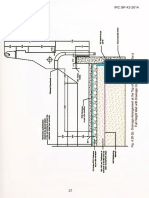

- 2 Drawing For Laying GeocompositDocument1 page2 Drawing For Laying GeocompositSumit GuptaNo ratings yet

- Warp Stop MotionDocument8 pagesWarp Stop MotionIlhamsNo ratings yet

- TNPL Chap5Document41 pagesTNPL Chap5sadhikbtech_91903923No ratings yet

- (Materiales) Productos CNFDocument18 pages(Materiales) Productos CNFNicolás Felipe Reyes CerdaNo ratings yet

- Dobby DesignDocument66 pagesDobby DesignSompad Shaha Razeb100% (1)

- Canada Customs TarrifDocument1,791 pagesCanada Customs TarrifnickNo ratings yet

- For Learners: First Quarter Week 1Document22 pagesFor Learners: First Quarter Week 1Naliene RamboNo ratings yet

- Knitting Terms and DefinitionDocument14 pagesKnitting Terms and DefinitionRakibul Hasan100% (1)

- An Investigation Into The Parameters of Terry Fabrics Regarding The ProductionDocument6 pagesAn Investigation Into The Parameters of Terry Fabrics Regarding The ProductionhawNo ratings yet

- Qbank FM II 2019-2020 EvenDocument4 pagesQbank FM II 2019-2020 EvenSivakumar KNo ratings yet

- Lectures Weft KnittingDocument78 pagesLectures Weft KnittingAfsana Afrin RummonNo ratings yet

- Arvind Internship, SantejDocument56 pagesArvind Internship, SantejShivani Rao0% (1)

- Sem 6Document51 pagesSem 6IndraniNo ratings yet

- (1.2c) Auxiliary Mechanism-Weft Fork (Side)Document10 pages(1.2c) Auxiliary Mechanism-Weft Fork (Side)sukanya prasadNo ratings yet

- Weaving Preparatory PDFDocument273 pagesWeaving Preparatory PDFmudit bhargavaNo ratings yet

- The Loom of Tradition: "Shawls As Artware"Document13 pagesThe Loom of Tradition: "Shawls As Artware"Sabrina SuptiNo ratings yet

- Filtration ExperimentDocument9 pagesFiltration ExperimentKoh Yung XinNo ratings yet

- BGMEA University of Fashion & Technology: Chapter: Introduction To Knit FabricDocument25 pagesBGMEA University of Fashion & Technology: Chapter: Introduction To Knit FabricRatul Hasan100% (1)

- Kajian Proses Dan Karakteristik Kain Tenun Serat Alami TANAMAN LIDAH MERTUA (Sansevieria Trifasciata P.)Document14 pagesKajian Proses Dan Karakteristik Kain Tenun Serat Alami TANAMAN LIDAH MERTUA (Sansevieria Trifasciata P.)bima wardanaNo ratings yet

- FMT Iippt 150302031306 ConversionDocument18 pagesFMT Iippt 150302031306 ConversionpoojaNo ratings yet

- Experiment No 1: Study On Yarn Path Diagram of A Shuttle Loom With Different PartsDocument13 pagesExperiment No 1: Study On Yarn Path Diagram of A Shuttle Loom With Different PartsRubel alamNo ratings yet

- Weave DesignDocument164 pagesWeave Designjayrock574765100% (1)

- 1923 Cotton Selvedge Tape For Electrical InsulationDocument8 pages1923 Cotton Selvedge Tape For Electrical InsulationKaushik SenguptaNo ratings yet

- Gate 1991-2000 Textile PapersDocument69 pagesGate 1991-2000 Textile Papersmohit100% (1)

- 18 Types of FABRIC WEAVES (An Overview) - Sew GuideDocument36 pages18 Types of FABRIC WEAVES (An Overview) - Sew GuideGOWTHAM CHANDRUNo ratings yet

- JURY FF - Manjusha Mary MathewsDocument51 pagesJURY FF - Manjusha Mary MathewsShobha MathewNo ratings yet

- WeavingDocument12 pagesWeavingPITTALA RAJKUMARNo ratings yet

- 1stQ - PIVOT4A LEARNER - S MATERIAL - BasketryG9 - 10Document31 pages1stQ - PIVOT4A LEARNER - S MATERIAL - BasketryG9 - 10Grace Mary JaoNo ratings yet

- Yarn Rate 04-01-2024Document4 pagesYarn Rate 04-01-2024muhammadzohaanqasimNo ratings yet