Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

15 viewsSpek Steelpipe0000

Spek Steelpipe0000

Uploaded by

Gerobak GayaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Site Preparation and Earth WorkDocument31 pagesSite Preparation and Earth WorkGerobak Gaya100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 8147ef4dd30b64968770d6e4e616bc39Document22 pages8147ef4dd30b64968770d6e4e616bc39Gerobak GayaNo ratings yet

- Slideshare DownloadDocument12 pagesSlideshare DownloadGerobak GayaNo ratings yet

- Brosur PC - Spun - Piles - Jan - 2011-WIKABETONDocument2 pagesBrosur PC - Spun - Piles - Jan - 2011-WIKABETONGerobak GayaNo ratings yet

- Drill Hole With SPTDocument4 pagesDrill Hole With SPTGerobak GayaNo ratings yet

- Sni 03 1727 1989 PembebananDocument31 pagesSni 03 1727 1989 PembebananGerobak GayaNo ratings yet

- Anchor BoltsDocument2 pagesAnchor BoltsGerobak GayaNo ratings yet

- I Section Wide Flange EUDocument2 pagesI Section Wide Flange EUGerobak GayaNo ratings yet

Spek Steelpipe0000

Spek Steelpipe0000

Uploaded by

Gerobak Gaya0 ratings0% found this document useful (0 votes)

15 views16 pagesOriginal Title

SPEK-STEELPIPE0000

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

15 views16 pagesSpek Steelpipe0000

Spek Steelpipe0000

Uploaded by

Gerobak GayaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 16

Jae

sey

043 Bs)

SWARNA SPIRAL WELDED PIPES

Since its founding in 1989, PT Swarna Baja

Pacific (SBP) has distinguished itself as one of

the few spiral welded pipe producers with an

annual production capacity exceeding 60,000 MT.

To cope with increasing demand nationwide,

Swarna Baja Pacific produces large quantities of

high strength pipes that are used for various

purposes including water-work, the transmission of

gas and steam, irrigation, the transmission

and supply of industrial water, chemical and

petroleum piping, and the transmission of various

kinds of fluids.

he company's facilities today include spiral pipe

‘mills and corrosion protection facilities in the form

of cement lining and coal tar-asbestos felt

wrapping and plastic tape coating which can

produce pipes of6"N.B. through 120"N.B. according

to the specifications of all major international

standards such as API, JIS, DIN, ASTM and all

others.

Swamars main products are as Tonows

1. Pipe piles

2, Transportation pipes for solids - liquids

8. Ordinary piping

4, Special piping

~ Line pipes and high pressure line pipes

~ Casing and Tubing

- Pressure Service

- Low and High Temperature Services

- Chemigal Industry Service

- Various Tanks

This booklet is intended to give you general

information on Swama Spiral welded pipes and

to help you select and specify the proper pipes

for your use.

CHARACTERISTICS

Higher safety

10 % more safety compared with longitudinally

welded pipes. Burst and explosion tests. show

that due to the helically wound seam and the high

toughness properties in the circumferential

direction - the spiral welded pipe has an inherently

higher satety margin against crack propagation.

Lower Production Cost

Our high-tech production units guarantee cost-

effective pipe manufacture : using relatively cheap

charging material, requiring fewer personnel

and a,low application of investment for maximum

commercial efficiency.

This even when small lot sizes of different

dimensions must be produced, as often

demanded by the market.

High Dimensional Accuracy

The Swama Baja Pacific 3-roller-forming system

and the continuous welding-gap control produces

pipes with a constant diameter, roundness and

straightness within extreme close tolerances over

the whole pipe length.

HOT ROLLED COIL.

3 FORMING ROLLERS: SL

SUBMERGED ARC WELDING

High Availability and Flexibility

Pipe can be manufactured in various sizes from

~ pipe diameters 6" N.B. to 120" N.B

- wall thickness 4 to 20 mm

any pipe length

- hot rolled stee! qualities up to x-60

Use of Quality Material Manufactured

through Integrated Process

For all spiral pipe products, the company uses

Quality Noop manufactured through an integrated

process under rigid quality control. The hoop.

therefore, can be satisfactorily processed into spiral-

welded pipe for any purpose.

Use of a Variety of Steels in

the Manufacture of pipe

Swarna's advarited production facilities can

produce pipe of various steel qualities, such as

low carbon steel, medium carbon steel (ASTM A

178-C, etc), high-strength steel (API 5 LX-60,

eic.) and low alloy steel, These steels meet the

specifications of all major international standards.

. MANUFACTURING PROCESS ®

VISUAL & DIMENSIONAL

INSPECTION

—@

X-RAY

FLUOROSCOPIC

INSPECTION

G

3

MACHINING

Rigid Quality Control and Inspection

Rigid quality contro! and inspection throughout

the integrated manufacturing process is carried

out from material to finished pipe.

Application of Non-Destructive Inspection

The weld is inspected by a variety of methods,

including ultrasonic, x-ray and hydrostatic. test

depending on the kind and use of pipe.

‘Adoption of Submerged Arc Welding

Method

Internal and extemal submerged arc welding

method manufactured by Lincoln Electric are

employed. The weld will be for spiral butt weld

joint, therefore, flawless, with no burning at all

Application of Lining and Coating

Modern equipment can apply corrosion protection

in the form of cement lining and coal tar-asbestos

felt wrapping and plastic tape coating,

END

IONING

SHOT BLASTING

TESTING INSIDE COATING

SPECIFICATIONS

Swarna Baja Paciic pipes manufactured by high.

tech spiral welding processes meet the physical,

dimensional and pressure requirements of all

major pipe specifications such as the following

international standards

API ‘American Petroleum Institute

ASA: American Standard Association

ASTM —: American Society for Testing &

Materials

AWWA: American Water Works Association

BSS British Standard Specification

DIN Deutsche Industrie Norm

JIS Japanese Industrial Standard

sil Standard Industri indonesia

All SBP pipes undergo strict quality control

inspection, including Hydrostatic Test, Dimensional

Test, Non-destructive Test (ultrasonic, radiographic

and fluores copic) and Destructive Test.

STEEL PIPE

Spirally weided 6" to 120° in diameter, 3 mm to 20

mm in thickness.

PIPE LINING

Cement, bitumen, coal tar, epoxy, zine.

PIPE COATING

Coaltar, bitumen, asbestos felt, fiber glass, epoxy,

zinc, concrete weight coating.

OUTSIDE COATING

& WRAPPING

FINISHED PRODUCTS

Aigid quality control fore "zero-inferfor goods" rate

To produce superior pipe of the highest possible

quality, Swarna Pipe utilizes the latest testing and

inspection facilities to monitor every stage of the

production process from raw materials to finished

product.

These tests include :

ULTRASONIC INSPECTION

Swarna Pipesare subjected to continuous ultrasonic

inspection. The ultrasonic equipment is checked

every’shift to demonstrate its effectiveness and

the inspection procedure. All ultrasonic indications

are subjected to radiographic examination.

X-RAY INSPECTION

Swarna Pipes are also inspected by radiological

methods tor a distance of 4 inches from each end of

each length of pipe in addition to the full length

ultrasonic and fluorescopic inspection.

QUALITY MANAGEMENT

VISUAL & DIMENSIONAL INSPECTION

‘Swamna’s quality contro! personnel visually inspect

all pipes for imperfections. The pipes are also

inspected for compliance with the tolerances on

dimensions and weights.

HYDROSTATIC TEST

Straight Jengths of Swama pressure pipes are

subjected to aninternal hydrostatic pressure testas

part of the regular mill inspection procedure. It is

‘customary to make hydrostatic pressure test at he

pressure required by the applicable standard,

HOLIDAY TEST

Coated pipes for water or oil are subjected to test to

detect pinholes and holidays or other damages to

coating using holiday detectors adjusted to provide

sufficient voltage to produce @ spark through a

pinhole in the coating.

PRAY PIVAL MANUPAGIUNING RANGE

2 Seco

244

OYMMZAQ-—-LA Crepes

TI +

T eee Taeelicge lai LE SLU Le

8 10 12 14 16 20 24 28 80 36 40 44 50 54 70 74 80 90 100 110 120

&

OUTSIDE DIAMETER eH

APPLICATIONS

Pipe Piles

Steel pipe piles from Swarna are ideal for

strengthening the foundation of construction projects

buili on weak grourid or with big loads.

Typical uses of stee! pipe piles are as follows

- Foundations for buildings, machines,

tanks, stadiums, ete.

Structural base for roads, railways,

bridges, solid cross-road docks,

floodgates, barriers cranes,etc

- Piles for preventing landslides. e

Line Pipe & OCTG

Line pi

natural gast

in various grades 0

x60)

OCTG (Oi! Country Tubular G

Structural Purposes

SBP manufactures a diverse array of pipes for both

structural and al purposes. General

structural pipes are utilized in general engineering

& construction works, in steel towers,and in oth

structural projects. Mechanical pipes are utilized

inly in the construction of items such as

inery and airplane

the demand,

le dimensions

P produces pipe in all

SL ATT

Pipes for Special Piping

steel pipe is used for special

eand Storage Tanks,

ing and Low & High

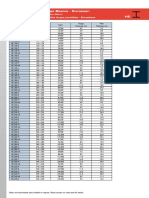

. STANDARD SIZES & WEIGHTS

A Sectan

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Site Preparation and Earth WorkDocument31 pagesSite Preparation and Earth WorkGerobak Gaya100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 8147ef4dd30b64968770d6e4e616bc39Document22 pages8147ef4dd30b64968770d6e4e616bc39Gerobak GayaNo ratings yet

- Slideshare DownloadDocument12 pagesSlideshare DownloadGerobak GayaNo ratings yet

- Brosur PC - Spun - Piles - Jan - 2011-WIKABETONDocument2 pagesBrosur PC - Spun - Piles - Jan - 2011-WIKABETONGerobak GayaNo ratings yet

- Drill Hole With SPTDocument4 pagesDrill Hole With SPTGerobak GayaNo ratings yet

- Sni 03 1727 1989 PembebananDocument31 pagesSni 03 1727 1989 PembebananGerobak GayaNo ratings yet

- Anchor BoltsDocument2 pagesAnchor BoltsGerobak GayaNo ratings yet

- I Section Wide Flange EUDocument2 pagesI Section Wide Flange EUGerobak GayaNo ratings yet