Professional Documents

Culture Documents

02 0TT em 1100 BM018 - 00

02 0TT em 1100 BM018 - 00

Uploaded by

maazouz radouaneOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 0TT em 1100 BM018 - 00

02 0TT em 1100 BM018 - 00

Uploaded by

maazouz radouaneCopyright:

Available Formats

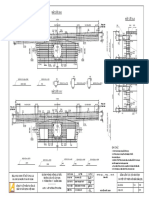

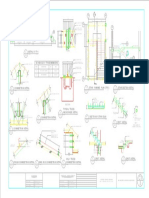

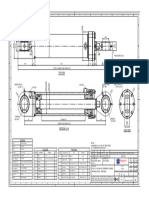

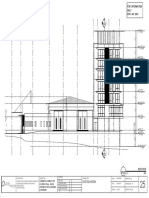

Plan Repérage

S5

S6 S3 S2

S4 S1

S7 Pr-1201

Pr-1282

PL10*225

Pr-1282

PL10*225

PL10*80 A

4 *Ø 18

50

50 55

65

75

70

130

5 5

70

75

130

2 *Ø 18 Pr-1224 Pr-1224 S9 A Pr-1224 Pr-1224

PL10*59 PL10*59 PL10*59 6 *Ø 22

PL10*59

S10 2616

S1 Pr-1337

S8 PL15*150

FRONT VIEW

Scale 1:10

S11 S12

Pr-1305

HE100A Pr-1224

Pr-1327 PL10*59

Pr-1336 2 *Ø 18 PL10*140

PL10*222 Pr-1340 Pr-1282

PL10*222 PL10*225

10

27

27

4 *Ø 18 40 105 Pr-1337

4 *Ø 18

2 *Ø 18 PL15*150

189

Pr-1056

145

145

2 *Ø 18 IPE270

36

36

53

36

36

4 *Ø 18

3 *Ø 22 Pr-1201 6 *Ø 22

PL10*80 Pr-1282

3 *Ø 22 Pr-1224

PL10*225 PL10*59

TOP VIEW

Scale 1:10

S13

S14 189 10

6 *Ø 22

60

140

75

75

Pr-1340

PL10*222

Pr-1327

PL10*140

Pr-1305

HE100A

SECTION A - A

Scale 1:10

ASSEMBLY MARK: BM018 - UNITS: 1 Weight= 211.5 Kg

3D VIEW

Scale 1:20 Pr-1056 1 IPE270 x 5378 mm. S275JR 179.2

Pr-1201 1 PL10*80 x 110 mm. S275JR 0.7

Pr-1224 4 PL10*59 x 246 mm. S275JR 4.4

Pr-1282 2 PL10*225 x 222 mm. S275JR 7.8

Pr-1305 1 HE100A x 186 mm. S275JR 2.9

Pr-1327 1 PL10*140 x 230 mm. S275JR 2.5

Pr-1336 1 PL10*222 x 346 mm. S275JR 4.2

Pr-1337 1 PL15*150 x 360 mm. S275JR 6.4

GENERAL NOTES Pr-1340 1 PL10*222 x 346 mm. S275JR 3.3

1.- ALL DIMENSIONS ARE IN MILLIMETERS. UNLESS INDICATED OTHERWISE. Pos. Qty. Denomination Material Standard Weight

2.- BEFORE WELDING PREHEAT THE EXCEEDING 25 mm THICK PARTS PROPERLY.

WEIGHT (KG.)

3.- ALL DIMENSIONS GIVEN IN THE LIST OF MATERIALS, ARE JUST FOR GUIDANCE. THIS DRAWING IS PROPERTY OF PHB WESERHÜTTE S. A.

THE DIMENSIONS GIVEN AT THE DRAWING, MUST ALWAYS PREVAIL. REPRODUCTION AND DIVULGATION FORBIDDEN 211.5

4.- ALL STEELS FOR SHAFTS C45E (F-114), 34CrMo4 (F-125), ETC. HAVE

TO BE SUPPLIED WITH NORMALIZED HEAT TREATMENT.

WHITHOUT WRITTEN PERMISSION.

001603-02-0TT-EM-1100-BM018_00 SCALE

STEEL STRUCTURE UP TO 12m LENGTH SHALL BE IN SINGLE PIECE WITHOUT ANY BUTT WELD JOINT. DRAWN 29/05/2020 M.A.V 1:10

ABOVE 12m LENGTH , "Z" BUTT WELD BY FULL PENETRATION BUTT WELDS AND GROUND FINISH, WITH SPLICE PLATE IS ALLOWED. CHECKED 29/05/2020 J. Diaz

TOLERANCES FOR LINEAR DIMENSIONS

DIN A1 594x841

SPLICING FOR BEAMS SHOULD BE DONE NEAR THE ONE-THIRD POINT OF THE BEAM SPAN (UNO). BATTEN PLATES AND LACING (UNLESS OTHERWISE SPECIFIED)

APPROVED 29/05/2020

J. L. Moral

FOR BUILT-UP SECTIONS SHALL BE WELDED. REF. PROJECT REF. CLIENT

OVER 1 5 30 120 400 1000 2000 >4000

BUTT WELD OF STEEL STRUCTURE SHALL BE "RT" TESTED BEFORE INSTALLATION OF SPLICE PLATE. JESA-Jrof DAP/TSP 001603

UP TO 5 30 120 400 1000 2000 4000

MECHANICAL 0.1 0.2 0.3 0.5 0.8 1.2 2 3 DRAWING NUMBER PHB SHEET

TT-02

STRUCTURAL 0.3 0.5 0.8 1.2 2 3 4 * 29-05-20 M.A.V FOR ISSUED 00 001603-02-0TT-EM-1100-BM018

ASSEMBLY MARK: BM018 CLIENT NUMBER REV.

* STANDARD ISO 13920 CLASS "A" WILL BE USED FOR DIMENSIONS LONGER

THAN 4000 mm IN WELDED STRUCTURES OR STRUCTURAL ASSEMBLIES DATE NAME MODIFICATION REV. 00

You might also like

- QC02001 BRC DRW SDW STR 06 Fe1 80203Document1 pageQC02001 BRC DRW SDW STR 06 Fe1 80203hbfbfkbf100% (1)

- Trumpf Slat Cleaner TSC1 ManualDocument26 pagesTrumpf Slat Cleaner TSC1 ManualMümin ÇimNo ratings yet

- B&K Amp Service ManualDocument16 pagesB&K Amp Service ManualPhantom GoatlordNo ratings yet

- 0sy.301.220.22a02 LVB-220W3Document1 page0sy.301.220.22a02 LVB-220W3ñdalskNo ratings yet

- Pub CopDocument13 pagesPub CopcheeNo ratings yet

- 052020 DTC -50Bi- Неофициальный отправительDocument9 pages052020 DTC -50Bi- Неофициальный отправительАндрей Солонович100% (5)

- Manual de Usuario Ups 10-20kva Ul - InglesDocument59 pagesManual de Usuario Ups 10-20kva Ul - Ingleswiiliam buitragpNo ratings yet

- Khoidaudam 2Document1 pageKhoidaudam 2tai taiNo ratings yet

- S18 S15 S9 S3: Ngcuh UNN H. THDocument1 pageS18 S15 S9 S3: Ngcuh UNN H. THtai taiNo ratings yet

- EXW-P008-0003-SE-CCC-DG-41050-011 - Rev CADocument1 pageEXW-P008-0003-SE-CCC-DG-41050-011 - Rev CAAbdul basithNo ratings yet

- Ramp 5Document1 pageRamp 5Enginer MineNo ratings yet

- SLO 50 SchematicDocument1 pageSLO 50 SchematicScott FreatisNo ratings yet

- Vestel 17mb110-r2 SCHDocument9 pagesVestel 17mb110-r2 SCHVasil StoyanovNo ratings yet

- 02 0TT em 1100 BM021 - 00Document1 page02 0TT em 1100 BM021 - 00maazouz radouaneNo ratings yet

- Plan Fondation Raoul KRDDocument1 pagePlan Fondation Raoul KRDaimé assogbaNo ratings yet

- Board 1Document1 pageBoard 1Soubhi SabbaghNo ratings yet

- BoardDocument1 pageBoardLAHCIENE ELHOUCINENo ratings yet

- Nepse Chart - Nepal Stock InformationDocument2 pagesNepse Chart - Nepal Stock InformationkabyaNo ratings yet

- 8-1-1-CWS325A2 (開機放電) - 複製Document1 page8-1-1-CWS325A2 (開機放電) - 複製adel allamNo ratings yet

- TimerDocument1 pageTimerВадим МкртчянNo ratings yet

- ULTEGRA Front Chainwheel FC-6600Document1 pageULTEGRA Front Chainwheel FC-6600jack87hornistNo ratings yet

- Ma5 TT01-ST05-1C259-4: Grid Location TT01-ST05-1C259-4 B-A/2-1/E Assembly Top Level: EL. +14.800Document1 pageMa5 TT01-ST05-1C259-4: Grid Location TT01-ST05-1C259-4 B-A/2-1/E Assembly Top Level: EL. +14.800Gandara SugandhiNo ratings yet

- A Camp 1Document1 pageA Camp 1aadishmoneNo ratings yet

- Ref 1 Out 6 In-5 GND 2 In+ 4 VCC 3 Ref 1 Out 6 in - 5 GND 2 In+ 4 VCC 3Document5 pagesRef 1 Out 6 In-5 GND 2 In+ 4 VCC 3 Ref 1 Out 6 in - 5 GND 2 In+ 4 VCC 3Bryan Felton100% (1)

- A S-3 Plan: W-1 2L-2x2x1/4 STRUTDocument1 pageA S-3 Plan: W-1 2L-2x2x1/4 STRUTKim MinjeongNo ratings yet

- SLR 145 BV15: F1 P1 G1 Q1 V20 K20Document1 pageSLR 145 BV15: F1 P1 G1 Q1 V20 K20Oleg KuryanNo ratings yet

- Benq Fp222w Power Supply SCHDocument5 pagesBenq Fp222w Power Supply SCHmsicoie1851No ratings yet

- Ibanez Ph99 SchematicDocument1 pageIbanez Ph99 SchematicOwen KalauNo ratings yet

- Typical 3Th - 13Th Floor Plan Waste Water Sanitary InstallationDocument1 pageTypical 3Th - 13Th Floor Plan Waste Water Sanitary InstallationAhmedNo ratings yet

- Ly01-Plan ViewDocument1 pageLy01-Plan Viewvu buianhvu.save1No ratings yet

- 02 0TT em 1100 BM001 - 00Document1 page02 0TT em 1100 BM001 - 00maazouz radouaneNo ratings yet

- Universidad Nacional de Colombia-Fac - Ing Empalmes Brayan C. AngaritaDocument1 pageUniversidad Nacional de Colombia-Fac - Ing Empalmes Brayan C. AngaritaBrayan AngaritaNo ratings yet

- PHFLrev 3Document1 pagePHFLrev 3Rauf MehdiyevNo ratings yet

- 4/20/2021 8:52:23 AM E:/PCB LONG KS/11. SUB 40 Class D/DATA LK/irs2092 v2.sch (Sheet: 1/1)Document1 page4/20/2021 8:52:23 AM E:/PCB LONG KS/11. SUB 40 Class D/DATA LK/irs2092 v2.sch (Sheet: 1/1)JaPan LifeNo ratings yet

- PKM 27 01 122 039Document1 pagePKM 27 01 122 039Rafael ObusanNo ratings yet

- Ocl 150 PDFDocument1 pageOcl 150 PDFsti mugaweleriNo ratings yet

- схема TP.VST59.PA502 PDFDocument7 pagesсхема TP.VST59.PA502 PDFFernando Guerrero100% (1)

- Front Side View 1: Mechanical Design, Fabrication & Testing of FiltersDocument4 pagesFront Side View 1: Mechanical Design, Fabrication & Testing of Filtersrifasarrifas123No ratings yet

- Ga HPHDocument1 pageGa HPHhanda ramadhanNo ratings yet

- KM Test FileDocument8 pagesKM Test FileprinttersNo ratings yet

- Precast GirdersDocument1 pagePrecast GirdersFriezt Lavoizer FialNo ratings yet

- Universitas Muhammadiyah Surakarta: Group Project 1: 10 Keterangan::: Digambar MM::: Satuan Ukuran SkalaDocument1 pageUniversitas Muhammadiyah Surakarta: Group Project 1: 10 Keterangan::: Digambar MM::: Satuan Ukuran SkalaWahid Arief AhNo ratings yet

- Toilet Block: Bihar Panchayat Strengthening ProjectDocument1 pageToilet Block: Bihar Panchayat Strengthening ProjectAr. Osama FirozNo ratings yet

- CBD-E 550-2500 + 1xCD212 - Right - C25036ECDC07 - C PDFDocument8 pagesCBD-E 550-2500 + 1xCD212 - Right - C25036ECDC07 - C PDFAhmed Nasr (By NAZRi)No ratings yet

- Line-20 - Ga-Rh-240127-Cyl-416 - Steering Cylinder - (100-50-422) - (MMPL) - R1Document1 pageLine-20 - Ga-Rh-240127-Cyl-416 - Steering Cylinder - (100-50-422) - (MMPL) - R1Karthii AjuNo ratings yet

- QC02001 BRC DRW SDW STR 06 Fe1 80204Document1 pageQC02001 BRC DRW SDW STR 06 Fe1 80204hbfbfkbfNo ratings yet

- Standard Drawing 1041 Step IronsDocument1 pageStandard Drawing 1041 Step IronsAmy LeNo ratings yet

- Rat Brain AtlasDocument11 pagesRat Brain AtlasLucas BühlerNo ratings yet

- Building 500 20517.83 SM: Parque Logistico LurinDocument1 pageBuilding 500 20517.83 SM: Parque Logistico LurinAndres Aceijas MuñozNo ratings yet

- ROFI160360 WDocument1 pageROFI160360 WchetanbakkerNo ratings yet

- Denah Pondasi Batu Kali Dan Sloef ARS-011: Sekolah Vokasi Universitas DiponegoroDocument20 pagesDenah Pondasi Batu Kali Dan Sloef ARS-011: Sekolah Vokasi Universitas DiponegorogalangNo ratings yet

- Canopy-02 Back Beam Fabrication-ModelDocument1 pageCanopy-02 Back Beam Fabrication-ModelnoufalNo ratings yet

- Circuit Schematic Loadmaster XP - PCB v4 Release ASRtJ7DajmDocument1 pageCircuit Schematic Loadmaster XP - PCB v4 Release ASRtJ7Dajm何青No ratings yet

- Midea EMCX2908 Microwave OvenDocument24 pagesMidea EMCX2908 Microwave OvenHumberto Souza ArrudaNo ratings yet

- Omnitronic Edp-700 Class DDocument3 pagesOmnitronic Edp-700 Class Dosman saraçNo ratings yet

- ELEVATIONSDocument4 pagesELEVATIONSKamlesh Kumar KarnaNo ratings yet

- R1 Donor Cut Tower: Waste Hexane Drum Item No. D-718Document1 pageR1 Donor Cut Tower: Waste Hexane Drum Item No. D-718NoppolNorasriNo ratings yet

- f18p01 m00 000 General ArrangementDocument1 pagef18p01 m00 000 General ArrangementAngga Purnama PutraNo ratings yet

- NLLT Cum01Document20 pagesNLLT Cum01tiep tranNo ratings yet

- EXW-P008-0003-SE-CCC-DG-41050-008 - Rev CADocument1 pageEXW-P008-0003-SE-CCC-DG-41050-008 - Rev CAAbdul basithNo ratings yet

- Assignment 1-First Floor PlanDocument1 pageAssignment 1-First Floor PlanFady Medhat FarahatNo ratings yet

- Esquema Sub InealDocument4 pagesEsquema Sub Inealtesye fofrNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredFrom EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredNo ratings yet

- Python ProgramsDocument12 pagesPython ProgramsvijayNo ratings yet

- Community Helper Coloring PagesDocument24 pagesCommunity Helper Coloring PagesJvier NathaleeNo ratings yet

- Hammad Hussian: Mass and Weight Gravitational Fields DensityDocument95 pagesHammad Hussian: Mass and Weight Gravitational Fields DensityRaiyaan BawanyNo ratings yet

- Quiz Ch. 6&7 Statistics & FractionsDocument2 pagesQuiz Ch. 6&7 Statistics & FractionsAkbar Suhendi TeacherNo ratings yet

- FIRST SUMMATIVE TEST IN MEDIA First QuarterDocument2 pagesFIRST SUMMATIVE TEST IN MEDIA First QuarterRhaieyee ElNo ratings yet

- Magill July 1998Document50 pagesMagill July 1998Malachy BrowneNo ratings yet

- RPT 2021 DLP Math Year 5 KSSR SemakanDocument16 pagesRPT 2021 DLP Math Year 5 KSSR SemakanShalini SuriaNo ratings yet

- F A 2 1 0 0 C V D R: Cockpit Voice and Data RecorderDocument2 pagesF A 2 1 0 0 C V D R: Cockpit Voice and Data RecorderJNo ratings yet

- OCPDDocument61 pagesOCPDyankurokuNo ratings yet

- Characteristics of AI Problems: Dr. K. LakshmiDocument4 pagesCharacteristics of AI Problems: Dr. K. LakshmiShanthi GanesanNo ratings yet

- EntreDocument66 pagesEntrejashley_janeNo ratings yet

- Tropical Cyclones: A Preparedness GuideDocument12 pagesTropical Cyclones: A Preparedness GuideMayeth MacedaNo ratings yet

- 2 - Skip - Nonlinear RegressionDocument41 pages2 - Skip - Nonlinear RegressionEmdad HossainNo ratings yet

- Barker Cultural Studies Chapter 1Document38 pagesBarker Cultural Studies Chapter 1Merima IbrisimovicNo ratings yet

- ch08 MOTIVATION - EMPOWERMENTDocument37 pagesch08 MOTIVATION - EMPOWERMENTEly HarunoNo ratings yet

- 14 NaiveBayes - Problem Statement ASSDocument14 pages14 NaiveBayes - Problem Statement ASSJose100% (1)

- Social Entrepeneurship Bootcamp SyllabusDocument7 pagesSocial Entrepeneurship Bootcamp SyllabusIsraelllNo ratings yet

- Trickle Up-Mali Case StudyDocument40 pagesTrickle Up-Mali Case StudyPoverty Outreach Working Group (POWG)No ratings yet

- IJTS, Numerical Investigation of Heat Transfer From A Plane Surface Due To Turbulent Annular Swirling Jet ImpingementDocument14 pagesIJTS, Numerical Investigation of Heat Transfer From A Plane Surface Due To Turbulent Annular Swirling Jet ImpingementIndrasis MitraNo ratings yet

- Service Manual: EPSON Stylus PHOTO 810/820Document146 pagesService Manual: EPSON Stylus PHOTO 810/820Алексей МаксимовNo ratings yet

- Aviation News - December 2015Document84 pagesAviation News - December 2015serge.pungweNo ratings yet

- Design Frameworks: Past, Present and FuturesDocument53 pagesDesign Frameworks: Past, Present and FuturesJames Piers Taylor100% (2)

- Effect of Road Expansion To The Local Household Lalitpur DistrictDocument8 pagesEffect of Road Expansion To The Local Household Lalitpur DistrictJoshua CenizaNo ratings yet

- Meditrack: Submitted ToDocument25 pagesMeditrack: Submitted ToDev GuptaNo ratings yet

- Solar HydrogenDocument184 pagesSolar HydrogenFortunato GarmendiaNo ratings yet

- Fin 604 AssignmentDocument3 pagesFin 604 AssignmentSiyao HuNo ratings yet