Professional Documents

Culture Documents

The Royal Society

The Royal Society

Uploaded by

P. R. SREENIVASANOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Royal Society

The Royal Society

Uploaded by

P. R. SREENIVASANCopyright:

Available Formats

Discussion

Author(s): M. E. Hargreaves, A. Kelly, J. G. Ball, D. McLean, R. W. K. Honeycombe, James

Menter, J. F. Lancaster, K. E. Easterling and E. R. Petty

Source: Philosophical Transactions of the Royal Society of London. Series A, Mathematical and

Physical Sciences, Vol. 282, No. 1307, Rosenhain Centenary Conference: The Contribution of

Physical Metallurgy to Engineering Practice (Jul. 8, 1976), pp. 471-477

Published by: The Royal Society

Stable URL: http://www.jstor.org/stable/74560 .

Accessed: 08/05/2014 14:13

Your use of the JSTOR archive indicates your acceptance of the Terms & Conditions of Use, available at .

http://www.jstor.org/page/info/about/policies/terms.jsp

.

JSTOR is a not-for-profit service that helps scholars, researchers, and students discover, use, and build upon a wide range of

content in a trusted digital archive. We use information technology and tools to increase productivity and facilitate new forms

of scholarship. For more information about JSTOR, please contact support@jstor.org.

The Royal Society is collaborating with JSTOR to digitize, preserve and extend access to Philosophical

Transactions of the Royal Society of London. Series A, Mathematical and Physical Sciences.

http://www.jstor.org

This content downloaded from 169.229.32.137 on Thu, 8 May 2014 14:13:18 PM

All use subject to JSTOR Terms and Conditions

GENERAL DISCUSSION 471

not materials. Most of the science of materials, when it has been concerned with applications,

has been aimed at new alloys, improvements by heat-treatment, new microstructures such as

fibre-reinforcement, and new fabrication processes. What we may have overlooked is that there

is a potential new science, hardly developed yet but of direct relevance to the engineer, which

is the science of the performance of materials in engineering service. Perhaps the best example

of this is fracture mechanics, developed from A. A. Griffith's pioneering scientific investigations

into the nature of brittle cracks, which has now grown into a standard practice in engineering

design, based on the requirement that the material in an engineering component should have

a minimum fracture toughness, the value of which is governed by the geometry of the com-

ponent and the conditions of its service.

Needfor a scienceof materialsin service

If it were possible to deliver to the engineer various design procedures as explicit as this, for

dealing with other problems of materials in service - such as metal fatigue, stress-corrosion

cracking, or fretting failure - physical metallurgy and materials science would then be able

to make new great contributions to engineering practice. But we are still a long way from

achieving this. The necessary science is not yet there.

Many research metallurgists accept this but then go on to delve more deeply into the basic

atomic processes of fatigue, or corrosion, etc. Admittedly, we do not yet have a complete under-

standing, at the atomic level, of the above complex forms of failure in engineering materials,

but it may be that such an atomic understanding will not help to solve the practical problem

and that the more important thing that is missing at the present time is a rigorous and sophisti-

cated applied science of the uses and service of materials. Let us remember that the application

of fracture mechanics does not depend on atomic concepts but on an understanding of

the mechanics of a crack in a medium characterized only by its general elastic properties

and its measured work of fracture. Similarly, from the practical point of view, the most im-

portant scientific discovery about metal fatigue was made long ago, i.e. that this is a type of

plastic failure at the surface. A simple knowledge of this alone leads to many useful points in

practice, e.g. the importance of hard surfaces, avoidance of soft zones, and minimization of

tensile stresses in the surface.

I believe that there is great scope now for taking the existing 'pure' science of materials, as

we already know it, and building from it a large new applied science of the performance of

materials in service, one that will enable the engineer to get the best out of the materials avail-

able to him, even to the extent of encouraging him to adapt and transform his traditional design

and constructional procedures to suit the properties of these materials, and to ensure that he will

not be disappointed in practice through the unwonted failure of his constructions.

I believe that one of the most exciting challenges now, to the educator in the materials field,

is to establish and teach to engineers a 'science of materials in service', comparable to the quite

different 'science of materials for service' which he now teaches to metallurgists and materials

scientists.

Discussion (Chairman M. E. HARGREAVES(MelbourneUniversity))

A. KELLY (National Physical Laboratory)

For a few more days I can speak as a user, rather than as a producer of trained metallurgists.

I want to make a point which I have not yet heard made in this discussion; I want to approach

This content downloaded from 169.229.32.137 on Thu, 8 May 2014 14:13:18 PM

All use subject to JSTOR Terms and Conditions

472 GENERAL DISCUSSION

the question of motivation, not in terms of personal ambition of the student as Sir Alan (Keynote)

approached it, but in terms of a more altruistic motivation which I think is more important,

to the young nowadays. One of the great motivations for people doing engineering is the pull

of creativity; the joy of making things; this can be appreciated by the architect or by any of

us who try to draw things. There is a real attraction in engineering for the creativeness of a man.

Science I believe is motivated by inquisitiveness and so, if one accepts that definition of science,

metallurgy is in a very peculiar place, shared only by one other science of which I know.

Consider as you look outside yourself, the stars, the earth you stand on, the rocks underneath,

there is perhaps a fluid core in the middle of the earth, there are living things upon this planet -

those are things a scientist studies, and none of those was made by man. The difference I think

is that metallurgy arose to look at synthetic things. Now that carries with it a very important

qualification. Astronomy may be limitless, geology less so, biology probably almost as limitless

as astronomy. Metallurgy is not, because the metallurgist looks at synthetic things and those

man-made things are made - why? Because the engineer wishes to have them to make other

things. On the whole we support a metallurgist because his science supports the engineer.

Now there are two consequences from this which are peculiar to our subject. One, if the

young are less motivated to do engineering, then clearly they are less motivated to follow the

subjects which support engineering. The second is that since the subject is limited, it does not

have the horizons of biology, nor yet of geology, or geophysics. Its (metallurgy's) very own

success removes a need for more of us. We have seen in this conference, quite brilliantly,

I think, although hedged by details that we do not understand, magnificent achievements.

The steel men have told us that they very nearly understand all the factors of that once complex

and invisible microstructure; that black box. They can now tell us what are most of the factors

involved in producing a strong steel. That success removes the mystery, and once a subject

loses the challenge of mystery, it may go the way of other worked-out disciplines.

We are all young as scientists. We are not yet used to the rise and subsequent decay of once-

useful and hence fashionable fields of enquiry.

That being said, I see three routes which this corpus of knowledge embracing thermo-

dynamics, microstructure and mechanics, which we call metallurgy, can follow. One of these

has been chosen by Sir Alan and that is the last one I would list; it is to support the engineer

by producing a prediction, and that prediction will be best used in the forms of constitutive equa-

tions. But there are two other routes and, depending on the funding and societal influences (as

Cohen calls them) there is still a pure road. That corpus of knowledge has much to say to the

geologist, to the person studying planetary structure, particularly the cold planets. It has much

to say to the biologists and that is happening in part (e.g. in biomechanics). So there is still

a pure road for that corpus of knowledge to follow, and then there is an intermediate one

between those two and that brings me to what is the other subject like metallurgy. The answer

of course is polymer science. Again a man-made material, but several years behind us in the

provision of the microscopic techniques which provide means of unravelling microstructure.

Polymer science may join with metallurgy and continue in much the same way as we have seen

metallurgy develop.

J. G. (ImperialCollege, London)

BALL

I would agree, as a result of direct experience, that it is not a lack of knowledge in schools

which results in a lack of students. I think we have to live with such ignorance or such

This content downloaded from 169.229.32.137 on Thu, 8 May 2014 14:13:18 PM

All use subject to JSTOR Terms and Conditions

GENERAL DISCUSSION 473

knowledge as exists and I do not think we can much influence the situation. If we look back to the

time when we were on the upward grade of recruiting, in the mid 1960s, the factors influencing

the flow of students included an overspill from the pure science departments and a desire of

many students to keep up their maths, physics and chemistry by taking a subject which included

all of these branches of science. Many recruits came because of family connections and there

were also people who were intrinsically interested in the subject. In recent times I think that

all of these influences have diminished, even the one of family connections and intrinsic interest

in the subject. Certainly we no longer get the overspill from pure science or engineering depart-

ments because they themselves are looking for entrants. I think Sir Alan has analysed some

of the reasons why people go into pure science rather than into our subjects.

What worries me is that not very long ago we considered it to be an absolute necessity, for the

students on entry to have a competence in all three basic sciences and that still is expressed in

most propsectus', but on the whole it is a forlorn hope that all our students will be prepared in

this way. It seems now that our requirement for breadth of scientific understanding is a deter-

rent to entry into the subject and I do not know what we can do about it.

I feel the situation is going to get worse. The trends of sixth form studies are towards

scattered A level subjects, and we might have to be dealing with people coming in with one A

level. Such trends are also likely to reflect a lack of rigour in teaching which we have seen

developing already. I do not feel that we are collectively approaching this problem, and I think

we should be doing so.

D. MCLEAN (National PhysicalLaboratory)

In connection with the development of a science of engineering strength, or performance as

Sir Alan (Keynote) calls it, I would like to make three remarks. First, to accomplish such

a development material scientists must move on from their preoccupation with uniaxial testing

under very constant conditions - constant load, constant temperature and so on - and study

the behaviour of materials under conditions which epitomise those of engineering service, such

as under multi-axial stress, variable load, combinations of conditions etc. To some extent this

involves going over the work which engineers did about the turn of the century and expanding

it to suit modern conditions with the outlook of a modern materials scientist. Secondly, it is

easier for materials scientists to learn engineering than the reverse, the reason being that a lot

of engineering is well codified, is well digested, well condensed and well written up in text books.

Quantitative materails science, on the other hand, is quite a young science which has de-

veloped during the last 25 years, and is not nearly so well digested and well written-up in text

books. Thirdly, the time for such a development is ripe, partly because the problems for which

engineers have to design are so complicated that what we might call the existing empirical

methods are often unsatisfactory. I think there is a parallel with the relation that existed a century

and a half ago between elastic science and engineering, in that the science of elasticity had

then been developed by Coulomb, Poisson, Young and others, and had just begun to reach

engineers, whose constructions eventually gained immensely. However, the process of being

assimilated by the engineers took a very long time. Realization of the parallel should help to

shorten the delay in the application to engineering design of quantitative materials science, to

produce a science of engineering strength.

This content downloaded from 169.229.32.137 on Thu, 8 May 2014 14:13:18 PM

All use subject to JSTOR Terms and Conditions

474 GENERAL DISCUSSION

R. W. K. HONEYCOMBE(CambridgeUniversity)

Much has been said about the present day student and civilization by Sir Alan (Keynote)

and others, but I would like to make one point about the modern student that I think points to

a paradox, and that is, despite the challenges to authority, students are, on the whole, more

dedicated to service of the community. There is a greater social awareness among students

these days, than say, 20 years ago. Now this means that students want to do work which is

clearly of need to the community, for example, they are prepared more readily to embark on

applied science if they have the opportunity. They no longer automatically travel the road of

pure science as a first choice. I have talked to many students in Cambridge who have reached

the end of their second year, when they have to choose what to do in Part 2, their final under-

graduate year. I find out from them why they often change from physics to metallurgy, and the

answer is very frequently that they want to do a subject which has direct relevance to the com-

munity at large. If this is so, why are the numbers of applied scientists falling in many places ?

At Cambridge we are suffering much less, so I conclude that we must attribute some of the

blame to the mechanics by which the options are presented to students. The students become

aware of applied science not at school, but by the time they reach the middle of their University

courses, which is the most appropriate time they have for making a decision whether to be an

applied or a pure scientist. I think the conclusion from such observations is that we must

displace this decision from the sixth form at schools. Sir Alan has suggested one way of delaying

the decision namely until after the first degree. In ideal circumstances that would be the answer,

as it was in the States for many years, where many of their distinguished applied scientists were

originally pure scientists. However it seems to me that we cannot afford, at the moment at

least, to have as the main route to technology a first degree in pure science followed by further

training in applied science, furthermore, we might lose people in the transition. We have got

to structure more courses in a way to encourage a good entry of scientists, and allow tech-

nological options to be decided on in mid-course involving a smooth transition from pure to

applied science.

SIR JAMES MENTER, TREAS.R.S.

Bilby (discussion 4) remarked that the areas of science and technology we are dealing with

here can be tackled only through large teams from a variety of disciplines working together.

Speaking as an employer of substantial numbers of graduates I can confirm that but wish to

point out that this sytem of working through committees and the like is forced on us by the

intense specialization of the individual and, with a relative scarcity of graduates with the

ability to comprehend a variety of disciplines, design and project work tends to be hindered by

all the well known shortcomings of the committee system. I am therefore attracted to Sir Alan

Cottrell's idea (Keynote) for creating large schools of science (and presumably also engineering)

in Universities where students can study a selection of specialist disciplines in some depth.

This system has greater potential than existing arrangements for producing a greater proportion

of people with broader competence, having the character of the Prince Charming to which

I referred in my talk.

This content downloaded from 169.229.32.137 on Thu, 8 May 2014 14:13:18 PM

All use subject to JSTOR Terms and Conditions

GENERAL DISCUSSION 475

J. F. LANCASTER (Kellogg InternationalCorporation)

The hydrocarbon processing industry is a major consumer of fabricated products and, in

the United Kingdom, if we make proper use of North Sea oil and gas, will become increasingly

important in this respect during the next few decades. It is therefore essential that metallurgists,

both in the academic and in the practical fields, understand and respond to the particular

metallurgical needs of these industries.

Although the industry's problems are common to those of the engineering industry as a whole,

special considerations arise in the specification and construction of the process equipment itself,

where inflammable and sometimes toxic fluids are handled and processed. To keep up proper

standards of safety in this area required the appropriate techniques of material selection, of

quality assurance in manufacture and of operation and maintenance of equipment. It says much

for the diligence of all concerned in this industry that the safety record is so good. For example,

in the chemical industry the number of fatal accidents per employee is 3.5 per 108 h as com-

pared with 4.0 x 108 for British industry as a whole, 40 x 108 in coalmining, and so forth.

There is, of course, considerable incentive to maintain or improve such high safety standards,

quite apart from concern for the safety of individuals. The scale of single stream process units

increases with time, and incidents that can lead to an unsafe situation may also lead to periods

of increasingly costly downtime. Major incidents, such as the Flixborough disaster, also have

an unfavourable political effect on the industry, making it more difficult to obtain suitable sites

for process units and potentially attracting restrictive legislation regardless of the fact that the

industry's general level of safety is good.

Metallurgists and materials engineers can make an important contribution to safety in hydro-

carbon processing. Not all unsafe incidents are caused by metallurgical defects: indeed, the

majority of such incidents are complex in origin and it is rare to be able to isolate a single well-

defined cause. Nevertheless, the failure of a piece of metallic equipment is a feature of most

accidents and it is most important to ensure that both materials and fabrication are to standards

that are sufficiently high to exclude the metallurgical factor as a primary cause of failure.

This is an easy generalization to make. It is more difficult to define precisely what steps

should be taken in metallurgical education, research and development to promote higher

standards of reliability in this field. To do so wouldc require much better information about

failures than we presently have. Nevertheless, I think the metallurgical profession might

profitably give attention to the problem of training in materials engineering.

Materials engineers in the hydrocarbon processing industry are usually metallurgists, chemi-

cal enginers or mechanical engineers who have elected to specialize in materials. On-the-job

training is the normal rule, but it is not particularly easy to acquire the necessary information.

This is especially the case with material selection. Chemical engineers are sometimes given a

course in this subject, but it is at present tending to be crowded out of the syllabus. It is not, so

far as I know, included in any of our undergraduate courses in metallurgy, nor are there any

short courses available in material selection in the United Kingdom. Furthermore, there is no

worth-while textbook on the subject. With the exception of the lectures included in corrosion

courses organized by such bodies as U.M.I.S.T. and the City University, the materials engineer

must learn his trade as best he can, obtaining information about the experience of others,

mainly from U.S. journals, such as Corrosion,Materials Protectionand HydrocarbonProcessing.

The process industries do not at present employ mnanymaterials engineers but the demand

This content downloaded from 169.229.32.137 on Thu, 8 May 2014 14:13:18 PM

All use subject to JSTOR Terms and Conditions

476 GENERAL DISCUSSION

for such technologists is going to increase in the future. It might be profitable, therefore, for the

metallurgical profession to consider how a better transmission and exchange of information on

materials engineering and materials selection can be achieved.

The following two contributions were written after the meeting:

K. E. EASTERLING(University of Lulea, Sweden)

Of five technological universities in Sweden, four have departments of engineering materials,

i.e. for the teaching of engineers with specialization in materials, and there is only one depart-

ment of physical metallurgy. Thus the important interaction between engineers and materials

specialists is strongly recognized. Engineers in most cases follow general engineering courses

in the first two years an specialize

s in the area of their hoie n the

offinal two years. Every

individual course is followed directly by an examination, so there is not a general examination

session covering a whole year's work. There are no honours degree systems (as followed in

Britain); the philosophy here is that graduation engineers have all broadly acquired the

standards expected of the school concerned, and as such start out on their careers on a more or

less equal basis. On the other hand, individual examinations are graded, so some recognition is

made of talent.

E. R. PETTY(National Institutefor Higher Education,Limerick,Ireland)

We should remember that the word 'generalist' has come about to some extent because of

the particular historical way in which we have packaged knowledge. Were we to start reorgan-

izing the information available to mankind we might well never use the words metallurgy,

polymer technology, production engineer. In fact, words like chemical engineer or systems

engineer might well say it all. Or possibly, different groupings of topics might be more appro-

priate and we might talk of departments of tribology or thermodynamics. In view of the cries

from industry and the ways in which Britain has fallen behind in the technological race, the

time is probably long past that we should have stormed the barricades between rigid discipliness.

Further advantages of the broader degree scheme are related to the greater breadth of topics

being taken at G.C.E. A level these days and also the necessity to give students more time to

make up their minds about a chosen career path.

One major criticism of the generalist approach is based on an implied reduction of intellec-

tual level - the so-called 'depth' of treatment. In the system proposed this may be readily

avoided by cutting down on the total number of pieces of information considered - after all any

degree scheme in however 'narrow' a subject can no longer hope to pack in the total sum of

human knowledge in the field, so a selection is always necessary. In the generalist approach one

simply broadens the range of options from which the selection is made. While on the topic of

depth, it has always been my experience that students find it more difficult to assimilate and

correlate material from diverse fields than to go more deeply into one specialist area. Deeper

specialization can always come about through continuing education, either formally or during

normal self-education at the place of work.

At the National Institute for Higher Education we have set up such a system of education.

Being a new educational establishment we are not bound by tradition and, while this has many

disadvantages, it does allow us the freedom to experiment with new ideas. One of these is the

setting up of a degree programme in Materials and Industrial Engineering administered by an

This content downloaded from 169.229.32.137 on Thu, 8 May 2014 14:13:18 PM

All use subject to JSTOR Terms and Conditions

GENERAL DISCUSSION 477

interdisciplinary committee with rpresentatives from Business Studies, European Studies,

Electronics and Mathematics as well as the engineers. We have produced a four year sandwich-

type course (ten academic terms plus a total of 12 months in industry) with the first two years

devoted to basic science and engineering. The two final years cover a range of elective topics

many of which are sequential and interrelated.

This content downloaded from 169.229.32.137 on Thu, 8 May 2014 14:13:18 PM

All use subject to JSTOR Terms and Conditions

You might also like

- Qaisra Shahraz - A Pair of JeansDocument3 pagesQaisra Shahraz - A Pair of Jeansmonkey3333389% (19)

- Berk Sop PDFDocument2 pagesBerk Sop PDFKhadsaar Singh100% (1)

- Greenbook Research Industry Trends Report 2020Document126 pagesGreenbook Research Industry Trends Report 2020Paul KendallNo ratings yet

- 1 Novacron S OverviewDocument3 pages1 Novacron S OverviewsaskoNo ratings yet

- Art. 1474 - PRICEDocument4 pagesArt. 1474 - PRICEjamaica_maglinteNo ratings yet

- (ME 8) MSEME - Module 01Document7 pages(ME 8) MSEME - Module 01Night RaidNo ratings yet

- Bahasa Inggris: Universitas Muslim Indonesia Teknik Arsitektur 2018Document7 pagesBahasa Inggris: Universitas Muslim Indonesia Teknik Arsitektur 2018Andi Ulmu FaraditaNo ratings yet

- Strength of Materials - 1 - IntroductionDocument20 pagesStrength of Materials - 1 - IntroductionPaul DumitruNo ratings yet

- JEE125 MaterialsTechnology 2021 Lecture NotesDocument420 pagesJEE125 MaterialsTechnology 2021 Lecture NotesCarlene ToaNo ratings yet

- Materials Science (An Introduction)Document72 pagesMaterials Science (An Introduction)drspanwarNo ratings yet

- STUDY PLAN For Chemical EngineeringDocument3 pagesSTUDY PLAN For Chemical Engineeringyusuf abdulazizNo ratings yet

- Comments On The Application of Physics To Metallurgy: Articles You May Be Interested inDocument13 pagesComments On The Application of Physics To Metallurgy: Articles You May Be Interested inRizwan HassanNo ratings yet

- Nanomaterials and ApplicationsDocument174 pagesNanomaterials and ApplicationsRock mondalNo ratings yet

- Materials Science 3 PDFDocument15 pagesMaterials Science 3 PDFdileepchouhan16No ratings yet

- Week 9 (18-04-2024) - Sample ProblemsDocument11 pagesWeek 9 (18-04-2024) - Sample ProblemsPalasri DharNo ratings yet

- MYSOP - CornellDocument2 pagesMYSOP - CornellPankajMahajanNo ratings yet

- Structural Materials Properties and Selection-Springer International Publishing 2019 José AntonioDocument375 pagesStructural Materials Properties and Selection-Springer International Publishing 2019 José AntonioMARIA FERNANDA BETANCOURT SOTO100% (1)

- A Challenge To Concretors: by Adam NevilleDocument6 pagesA Challenge To Concretors: by Adam NevilleErika SotoNo ratings yet

- (Graduate Texts in Physics) Henri Alloul (Auth.) - Introduction To The Physics of Electrons in Solids-Springer-Verlag Berlin Heidelberg (2011) PDFDocument644 pages(Graduate Texts in Physics) Henri Alloul (Auth.) - Introduction To The Physics of Electrons in Solids-Springer-Verlag Berlin Heidelberg (2011) PDFNicusorIacob100% (1)

- The Century of MetamaterialsDocument4 pagesThe Century of MetamaterialsPratik AvhadNo ratings yet

- Pom AssignmentDocument7 pagesPom AssignmentMazlin AzuraNo ratings yet

- Materials Science: Notable EncyclopedicDocument13 pagesMaterials Science: Notable EncyclopedicMadhu DasariNo ratings yet

- Lectura 1 Fisica-IngieneriaDocument5 pagesLectura 1 Fisica-IngieneriaDYLAN THOMAS AVENDAÑO MORENONo ratings yet

- Coleman Formal Research Proposal and PlanDocument7 pagesColeman Formal Research Proposal and Planapi-533949767No ratings yet

- Lesson 1-Introduction To Material ScienceDocument5 pagesLesson 1-Introduction To Material Sciencemerooney desanchesNo ratings yet

- UntitledDocument574 pagesUntitledXI CHENNo ratings yet

- Mme 312 AssignmentDocument5 pagesMme 312 AssignmentFaruqNo ratings yet

- Joesbury A 2015Document271 pagesJoesbury A 2015Son NguyenNo ratings yet

- OPENING REMARKS - 1959 - Advances in Mass SpectrometryDocument2 pagesOPENING REMARKS - 1959 - Advances in Mass SpectrometryLeandroFuentesMedinaNo ratings yet

- Module 1 IT3Document6 pagesModule 1 IT3Nosreffej LaraNo ratings yet

- Research Paper Topics Structural EngineeringDocument4 pagesResearch Paper Topics Structural Engineeringpntrxjwgf100% (1)

- Ens 131 Material Science Bsce1Document17 pagesEns 131 Material Science Bsce1Hazel AbogadaNo ratings yet

- Full Download Book High Entropy Alloys 2Nd Edition PDFDocument41 pagesFull Download Book High Entropy Alloys 2Nd Edition PDFrichard.lamar761100% (30)

- Biomateriales General.Document9 pagesBiomateriales General.qcmyskr7y5No ratings yet

- Materials Science & Engineering Lecture Notes (Unit 1)Document19 pagesMaterials Science & Engineering Lecture Notes (Unit 1)baakaruopdeng50No ratings yet

- Messler2004 1Document26 pagesMessler2004 1Deepak SharmaNo ratings yet

- Final Copy 2019-10-01 Best J PHDDocument168 pagesFinal Copy 2019-10-01 Best J PHDcauchyjohn0No ratings yet

- Bookmatter EngineeredCementitiousCompositDocument15 pagesBookmatter EngineeredCementitiousCompositJayaguru CNo ratings yet

- Materials Sceince and TechnologyDocument18 pagesMaterials Sceince and TechnologyRajareddyDuddekuntaNo ratings yet

- The NSF Recognizes Great Talent: Tech TodayDocument5 pagesThe NSF Recognizes Great Talent: Tech TodaySalsa_Picante_BabyNo ratings yet

- Introduction NotesDocument17 pagesIntroduction Notestemwani324No ratings yet

- MaterialsDocument71 pagesMaterialsMarzena Madej100% (1)

- Material Science AnasDocument6 pagesMaterial Science AnasReal MadridNo ratings yet

- Modern Scholar TMS Understanding Nanotechnology 2011Document106 pagesModern Scholar TMS Understanding Nanotechnology 2011spiderman86100% (2)

- Material ScienceDocument3 pagesMaterial Scienceksb9790No ratings yet

- Nano Technology: Utkal UniversityDocument33 pagesNano Technology: Utkal UniversityShradha SubhadarshineeNo ratings yet

- Research Papers On NanotechnologyDocument6 pagesResearch Papers On Nanotechnologyphjaehhkf100% (1)

- Architecture and Its Close Relationship With PhysicsDocument7 pagesArchitecture and Its Close Relationship With PhysicsMarco AponteNo ratings yet

- Direction: After Reading and Understanding All The Materials. Please Answer TheDocument4 pagesDirection: After Reading and Understanding All The Materials. Please Answer TheLUMA-AS, Gerald P.No ratings yet

- Handouts No. 1-ADocument4 pagesHandouts No. 1-ANicole PerochoNo ratings yet

- Metallurgy Thesis TopicsDocument6 pagesMetallurgy Thesis Topicsdwr11wf4100% (1)

- ebook download (Original PDF) Transmaterial Next: A Catalog of Materials that Redefine Our Future all chapterDocument43 pagesebook download (Original PDF) Transmaterial Next: A Catalog of Materials that Redefine Our Future all chapterelegiwremir100% (1)

- CBR Material TeknikDocument11 pagesCBR Material TeknikTV SHOWNo ratings yet

- Dissertation Topics in Geotechnical EngineeringDocument4 pagesDissertation Topics in Geotechnical EngineeringPayToWritePaperCanada100% (1)

- Torraca, G. Materials Sciencie Architectural Conservation. 2009Document206 pagesTorraca, G. Materials Sciencie Architectural Conservation. 2009Trinidad Pasíes Arqueología-ConservaciónNo ratings yet

- Full Download Book Recrystallization and Related Annealing Phenomena PDFDocument41 pagesFull Download Book Recrystallization and Related Annealing Phenomena PDFgeorge.berger158100% (29)

- Soft Materials in Technology and BiologyDocument62 pagesSoft Materials in Technology and Biologyironmonkey00No ratings yet

- Thermo-Oxidative Ageing of ElastomersDocument172 pagesThermo-Oxidative Ageing of Elastomerssandrine guerinNo ratings yet

- Particle and Continuum Aspects of Mesomechanics: Mesomechanics 2007From EverandParticle and Continuum Aspects of Mesomechanics: Mesomechanics 2007No ratings yet

- Aging, Shaking, and Cracking of Infrastructures: From Mechanics to Concrete Dams and Nuclear StructuresFrom EverandAging, Shaking, and Cracking of Infrastructures: From Mechanics to Concrete Dams and Nuclear StructuresNo ratings yet

- Approximating Perfection: A Mathematician's Journey into the World of MechanicsFrom EverandApproximating Perfection: A Mathematician's Journey into the World of MechanicsRating: 3 out of 5 stars3/5 (1)

- America's Relation To The Advance of Science (Science, Vol. 1, Issue 1) (1895)Document6 pagesAmerica's Relation To The Advance of Science (Science, Vol. 1, Issue 1) (1895)P. R. SREENIVASANNo ratings yet

- INDIGENOUS VISION - PEOPLES OF INDIA ATTITUDES TO THE ENVIRONMENT - EDITORIAL - Homage To Earth (B. K. ROY BURMAN) (1992)Document11 pagesINDIGENOUS VISION - PEOPLES OF INDIA ATTITUDES TO THE ENVIRONMENT - EDITORIAL - Homage To Earth (B. K. ROY BURMAN) (1992)P. R. SREENIVASANNo ratings yet

- Consciousness and The Physical WorldDocument200 pagesConsciousness and The Physical WorldP. R. SREENIVASANNo ratings yet

- Classical Zero-Point Radiation and Relativity - The Problem of Atomic Collapse Revisited (2015) - by Timothy H. BoyerDocument15 pagesClassical Zero-Point Radiation and Relativity - The Problem of Atomic Collapse Revisited (2015) - by Timothy H. BoyerP. R. SREENIVASANNo ratings yet

- Biographical Meomirs, Robert Hanbury Brown 1916-2002 - Australian Academy of Science-By J. Davis, B. Lovell (2002)Document28 pagesBiographical Meomirs, Robert Hanbury Brown 1916-2002 - Australian Academy of Science-By J. Davis, B. Lovell (2002)P. R. SREENIVASANNo ratings yet

- Is The Universe Planned - (W.F.G. Swann) (1953)Document20 pagesIs The Universe Planned - (W.F.G. Swann) (1953)P. R. SREENIVASANNo ratings yet

- A. Rupert Hall - If This Be Magic. (Nature, Vol. 369, Issue 6482) (1994)Document1 pageA. Rupert Hall - If This Be Magic. (Nature, Vol. 369, Issue 6482) (1994)P. R. SREENIVASANNo ratings yet

- Nuclear Magnetic ResonanceDocument81 pagesNuclear Magnetic ResonanceP. R. SREENIVASANNo ratings yet

- Hamblin, Jacob Darwin - Arming Mother Nature - The Birth of Catastrophic Environmentalism - (2017)Document309 pagesHamblin, Jacob Darwin - Arming Mother Nature - The Birth of Catastrophic Environmentalism - (2017)P. R. SREENIVASANNo ratings yet

- Patterns of Discovery - N. R. Hanson, (Cambridge University Press 1958. Ix-2411 P. 30s) (Nuclear Physics, Vol. 9, Issue 4) (1959)Document1 pagePatterns of Discovery - N. R. Hanson, (Cambridge University Press 1958. Ix-2411 P. 30s) (Nuclear Physics, Vol. 9, Issue 4) (1959)P. R. SREENIVASANNo ratings yet

- Artemis - Why It May Be The Last Mission For Nasa AstronautsDocument3 pagesArtemis - Why It May Be The Last Mission For Nasa AstronautsP. R. SREENIVASANNo ratings yet

- Peter Coles - The Rise and Fall of The Universe. Nature Volume 425, Pages127-128 (2003)Document2 pagesPeter Coles - The Rise and Fall of The Universe. Nature Volume 425, Pages127-128 (2003)P. R. SREENIVASANNo ratings yet

- F. C. Brown, The Physics of Solids - REVIEW in American Journal of Physics - Vol 35, No 10Document3 pagesF. C. Brown, The Physics of Solids - REVIEW in American Journal of Physics - Vol 35, No 10P. R. SREENIVASANNo ratings yet

- HerranRoqu2009 - Tracers of Modern TechnoscienceDocument9 pagesHerranRoqu2009 - Tracers of Modern TechnoscienceP. R. SREENIVASANNo ratings yet

- High Technology and Human Freedomby Lewis H. Lapham (The Library Quarterly, Vol. 57, Issue 1) (1987)Document3 pagesHigh Technology and Human Freedomby Lewis H. Lapham (The Library Quarterly, Vol. 57, Issue 1) (1987)P. R. SREENIVASANNo ratings yet

- A. Rupert Hall - Master Theses (Nature, Vol. 314, Issue 6010) (1985) PDFDocument1 pageA. Rupert Hall - Master Theses (Nature, Vol. 314, Issue 6010) (1985) PDFP. R. SREENIVASANNo ratings yet

- F. I. G. Rawlins, Methodology and Aesthetic Content in Natural ScienceDocument6 pagesF. I. G. Rawlins, Methodology and Aesthetic Content in Natural ScienceP. R. SREENIVASANNo ratings yet

- Honoré de Balzac - The Pleasures and Pains of CoffeeDocument4 pagesHonoré de Balzac - The Pleasures and Pains of CoffeeP. R. SREENIVASANNo ratings yet

- From Radioactivity To Nuclear Physics - Marie Curie and Lise MeitnerDocument11 pagesFrom Radioactivity To Nuclear Physics - Marie Curie and Lise MeitnerP. R. SREENIVASANNo ratings yet

- A. Rupert Hall - Quantum Leap - (Nature, Vol. 350, Issue 6313) (1991)Document1 pageA. Rupert Hall - Quantum Leap - (Nature, Vol. 350, Issue 6313) (1991)P. R. SREENIVASANNo ratings yet

- Kleppner, Daniel - Hanbury Brown's Steamroller (Physics Today, Vol. 61, Issue 8) (2008)Document2 pagesKleppner, Daniel - Hanbury Brown's Steamroller (Physics Today, Vol. 61, Issue 8) (2008)P. R. SREENIVASANNo ratings yet

- .. Armin Hermann, The Genesis of Quantum Theory (1899-1913)Document12 pages.. Armin Hermann, The Genesis of Quantum Theory (1899-1913)P. R. SREENIVASANNo ratings yet

- 1.1971819 - REVIEW of - Introduction To Atomic and Nuclear PhysicsDocument3 pages1.1971819 - REVIEW of - Introduction To Atomic and Nuclear PhysicsP. R. SREENIVASANNo ratings yet

- 1.4797036 - Julian Schwinger's Paradoxical LegacyDocument2 pages1.4797036 - Julian Schwinger's Paradoxical LegacyP. R. SREENIVASANNo ratings yet

- 1) Electrons and Waves - An Introduction To Atomic Physics (2) Matière Et AtomesDocument1 page1) Electrons and Waves - An Introduction To Atomic Physics (2) Matière Et AtomesP. R. SREENIVASANNo ratings yet

- Zhu, Xian-Kui, Leis, Brian N (2006) - Application of Constraint Corrected J-R Curves To Fracture Analysis of PipelinesDocument9 pagesZhu, Xian-Kui, Leis, Brian N (2006) - Application of Constraint Corrected J-R Curves To Fracture Analysis of PipelinesP. R. SREENIVASANNo ratings yet

- Zero Point Field (ZPF) Effects in The Interaction of The Ultra-Short Laser Pulses With MatterDocument5 pagesZero Point Field (ZPF) Effects in The Interaction of The Ultra-Short Laser Pulses With MatterP. R. SREENIVASANNo ratings yet

- Prof. Don Howard Einstein'sDocument3 pagesProf. Don Howard Einstein'sP. R. SREENIVASANNo ratings yet

- Consciousness and Space - by Colin McGinnDocument10 pagesConsciousness and Space - by Colin McGinnP. R. SREENIVASANNo ratings yet

- Oliveri-Gaglio - Wittgenstein, Turing, and Neural NetworksDocument22 pagesOliveri-Gaglio - Wittgenstein, Turing, and Neural NetworksP. R. SREENIVASANNo ratings yet

- PDF Medical Management of Thyroid Disease 3Rd Ed 3Rd Edition David S Cooper Ebook Full ChapterDocument53 pagesPDF Medical Management of Thyroid Disease 3Rd Ed 3Rd Edition David S Cooper Ebook Full Chapterrebecca.baez273100% (5)

- Land Titles and DeedsDocument1 pageLand Titles and DeedsIanLightPajaroNo ratings yet

- Group2 Non Executive ResultsDocument3 pagesGroup2 Non Executive ResultsGottimukkala MuralikrishnaNo ratings yet

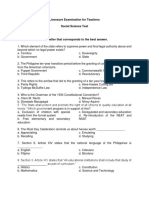

- Licensure Examination For TeachersDocument14 pagesLicensure Examination For Teachersonin saspaNo ratings yet

- Nemesis - TipsDocument2 pagesNemesis - TipsZoran StrajinNo ratings yet

- Broadwater Farm Estate - The Active CommunityDocument5 pagesBroadwater Farm Estate - The Active CommunitycvaggasNo ratings yet

- B412 TM Vol 1 Bell 412 EPDocument288 pagesB412 TM Vol 1 Bell 412 EPAri100% (1)

- Adetunji CVDocument5 pagesAdetunji CVAdetunji AdegbiteNo ratings yet

- B1.1-Self-Study Đã Sài XongDocument5 pagesB1.1-Self-Study Đã Sài XongVy CẩmNo ratings yet

- Highway Engineering I: Chapter Four Geometrical Design of HighwayDocument39 pagesHighway Engineering I: Chapter Four Geometrical Design of Highwaysirajt300No ratings yet

- Digital Image Processing - S. Jayaraman, S. Esakkirajan and T. VeerakumarDocument4 pagesDigital Image Processing - S. Jayaraman, S. Esakkirajan and T. VeerakumarBenedict IsaacNo ratings yet

- Emphatic Consonants Beyond Arabic: The Emergence and Proliferation of Uvular-Pharyngeal Emphasis in KumzariDocument54 pagesEmphatic Consonants Beyond Arabic: The Emergence and Proliferation of Uvular-Pharyngeal Emphasis in KumzariTwana1No ratings yet

- I Love Algorithms - Machine Learning CardsDocument6 pagesI Love Algorithms - Machine Learning CardsCarlos Manuel Ventura MatosNo ratings yet

- Curriculum OF Environmental Science BS/MS: (Revised 2013)Document120 pagesCurriculum OF Environmental Science BS/MS: (Revised 2013)Jamal Ud Din QureshiNo ratings yet

- Module 4Document5 pagesModule 4Engelbert RespuestoNo ratings yet

- Hemanth PHP Resume-1Document3 pagesHemanth PHP Resume-1hemanthjinnala777No ratings yet

- ProsidingDocument13 pagesProsidingAlfi Amalia S.E.I, M.E.INo ratings yet

- The Wexford Carol (Arr Victor C Johnson)Document13 pagesThe Wexford Carol (Arr Victor C Johnson)Macdara de BurcaNo ratings yet

- People vs. Asjali DigestDocument3 pagesPeople vs. Asjali DigestEmir Mendoza100% (1)

- RunEco EP600 Datasheet 2018Document2 pagesRunEco EP600 Datasheet 2018widnu wirasetiaNo ratings yet

- Wepik Strengthening Digital Defenses An in Depth Exploration of Cyber Security 20231121043209BlIPDocument12 pagesWepik Strengthening Digital Defenses An in Depth Exploration of Cyber Security 20231121043209BlIPsuchdev darshanNo ratings yet

- Mod Jeemain - GuruDocument31 pagesMod Jeemain - Guruparamarthasom1974No ratings yet

- Hanson Uk Cracked ConcreteDocument1 pageHanson Uk Cracked ConcreteAhmed Daahir AdenNo ratings yet

- Ax88796B With Ali M3602 Mcu Reference Schematic IndexDocument4 pagesAx88796B With Ali M3602 Mcu Reference Schematic IndexdistefanoNo ratings yet

- Vitamin ChatDocument9 pagesVitamin Chatnusdar20No ratings yet

- Real Exam 22.03.2024 (With Answers) - UpdatedDocument12 pagesReal Exam 22.03.2024 (With Answers) - Updatedtd090404No ratings yet