Professional Documents

Culture Documents

Results Methods Shore Tank No Properties Units Limits (A) : Jalan Yos Sudarso No.1 Pintu IV, Balikpapan - 76111

Results Methods Shore Tank No Properties Units Limits (A) : Jalan Yos Sudarso No.1 Pintu IV, Balikpapan - 76111

Uploaded by

Faizal NurCopyright:

Available Formats

You might also like

- Cambridge IGCSE Mathematics Core and Extended Workbook by Ric Pimentel, Terry Wall PDFDocument97 pagesCambridge IGCSE Mathematics Core and Extended Workbook by Ric Pimentel, Terry Wall PDFPrince Yug86% (22)

- Teachings in The Science of Osteopathy PDFDocument336 pagesTeachings in The Science of Osteopathy PDFAlex92% (13)

- Padi Peak Performance Buoyancy enDocument20 pagesPadi Peak Performance Buoyancy enPaolo Bocci100% (5)

- Exam C Manual PDFDocument2 pagesExam C Manual PDFJohnathan0% (1)

- RPT Maths Form 5 DLP 2022 - 2023Document16 pagesRPT Maths Form 5 DLP 2022 - 2023PETER WONG YUNG MING Moe50% (2)

- Unit 1 Test-Part 1 Reading: As A Young GirlDocument19 pagesUnit 1 Test-Part 1 Reading: As A Young GirlVictoria PhamNo ratings yet

- LNG TangguhDocument19 pagesLNG Tangguhapi-3759747100% (5)

- Rent-A-Movie Database Project: YOUR ASSIGNMENT (Deliverables Are Underlined)Document2 pagesRent-A-Movie Database Project: YOUR ASSIGNMENT (Deliverables Are Underlined)Miguel Flores FloresNo ratings yet

- Contribuciones de Leontief A La EconomíaDocument24 pagesContribuciones de Leontief A La EconomíaMargarita SepulvedaNo ratings yet

- Hollow LensDocument2 pagesHollow Lensapi-458747859No ratings yet

- FE MonitoringDocument1 pageFE MonitoringJezreel TolentinoNo ratings yet

- 3.D-017A Abandon Ship Drill Report Rev 0Document3 pages3.D-017A Abandon Ship Drill Report Rev 0Bataklanden MusicNo ratings yet

- 1.lifeboat 5 Yearly Cert 2022Document6 pages1.lifeboat 5 Yearly Cert 2022Lim LikweeNo ratings yet

- MT Griya Cirebon Aurora Samudera Perdana 30 Sep 2021Document135 pagesMT Griya Cirebon Aurora Samudera Perdana 30 Sep 2021intan nNo ratings yet

- Diving Work Permit FormDocument1 pageDiving Work Permit FormJorey FernanNo ratings yet

- Hindware Catalogue Compressed DLDocument146 pagesHindware Catalogue Compressed DLAyushiNo ratings yet

- Fire Extinguisher Inspection Check ListDocument2 pagesFire Extinguisher Inspection Check ListsravankotlasNo ratings yet

- Ua Uc DLCL 06 03 2024Document6 pagesUa Uc DLCL 06 03 2024Anvarsha SharafudheenNo ratings yet

- Countermeasure For SedimrnDocument8 pagesCountermeasure For SedimrnDwiNo ratings yet

- Industrial Training Report PDFDocument80 pagesIndustrial Training Report PDFRaman ChaudharyNo ratings yet

- Sanction MemoDocument32 pagesSanction MemoFahad ZulfiqarNo ratings yet

- Miscellaneous Tools Inspection Report (DPT) Page 1 of 1: Scope of Inspection Dye Penetrant Test On Ends & Full BodyDocument1 pageMiscellaneous Tools Inspection Report (DPT) Page 1 of 1: Scope of Inspection Dye Penetrant Test On Ends & Full BodyhamanjaloosNo ratings yet

- As Lo 2009Document1 pageAs Lo 2009nizzazaNo ratings yet

- Hse Master ChecklistDocument429 pagesHse Master ChecklistLantNo ratings yet

- IR Full SB 54 F R1.0 1 Buat NamasDocument21 pagesIR Full SB 54 F R1.0 1 Buat NamasIndra PujiantoNo ratings yet

- 1087 158386492 Fab's Exhibit List 4 Evidentiary Hearing On 10 4 22Document3 pages1087 158386492 Fab's Exhibit List 4 Evidentiary Hearing On 10 4 22larry-612445No ratings yet

- 42rle balveDocument7 pages42rle balveLalo Barajas GarciaNo ratings yet

- TQP-INSP-LAV-04 Monthly Eyewash InspectionDocument2 pagesTQP-INSP-LAV-04 Monthly Eyewash InspectionScribdTranslationsNo ratings yet

- NSRP Sdm2019 Hex ScheduleDocument2 pagesNSRP Sdm2019 Hex ScheduleThinh NguyenNo ratings yet

- Individual Performance Commitment and Review Form (Ipcrf) For Teacher I - IiiDocument8 pagesIndividual Performance Commitment and Review Form (Ipcrf) For Teacher I - IiiNida Viojan AbasoloNo ratings yet

- Hse Master ChecklistDocument541 pagesHse Master ChecklistVinay Tunge100% (2)

- 763 CTE Thal To Mirali Road (Section-5) : ConsultantDocument50 pages763 CTE Thal To Mirali Road (Section-5) : ConsultantKhuram IsmailNo ratings yet

- FEB 2023 - Eye Wash Station Monitoring SheetDocument3 pagesFEB 2023 - Eye Wash Station Monitoring SheetVigneshwaraNo ratings yet

- HC Progress Report 26 Mar 15Document4 pagesHC Progress Report 26 Mar 15Jayesh SolaskarNo ratings yet

- Modicare Cuckoo Air Purifier + 3 in 1 Filter Promotion April 2024Document3 pagesModicare Cuckoo Air Purifier + 3 in 1 Filter Promotion April 2024vikasbpl44No ratings yet

- Shackle Inspection Check List: Pt. Biro Klasifikasi Indonesia (Persero)Document5 pagesShackle Inspection Check List: Pt. Biro Klasifikasi Indonesia (Persero)kuncoro numpanguripNo ratings yet

- TDS r0 SignedDocument4 pagesTDS r0 SignedBhadresh KumbhaniNo ratings yet

- FHR Vox 2023 PDFDocument1 pageFHR Vox 2023 PDFEmmanuel ToretaNo ratings yet

- 54-Ch - Muhammad MusaDocument1 page54-Ch - Muhammad MusaMusa ChNo ratings yet

- 9120 Pi ENDocument2 pages9120 Pi ENAli AlsaidiNo ratings yet

- ER TC 47 PSC Checklist GuideDocument5 pagesER TC 47 PSC Checklist GuideAruljyothy PCNo ratings yet

- V-3111-002-A-709 - 2 Method Statement For Geoelectrical WorkDocument8 pagesV-3111-002-A-709 - 2 Method Statement For Geoelectrical WorkWidya PrasetyaNo ratings yet

- lul spc-lae-330272049-1-5-2014Document1 pagelul spc-lae-330272049-1-5-2014mahyarovNo ratings yet

- 西e押rtⅢ飢t調書⑲軌l蜘山肌: Div【Sion MemorandumDocument2 pages西e押rtⅢ飢t調書⑲軌l蜘山肌: Div【Sion MemorandumAdela PandoroNo ratings yet

- Thermodynamics of SolidsDocument2 pagesThermodynamics of SolidsAWNISH PRASAD SINGHNo ratings yet

- Certificate OF Inspection No.: ResultDocument13 pagesCertificate OF Inspection No.: ResultArif FuadiantoNo ratings yet

- 6mm Emicool Vision Cool Bronze +6mmAS + 6mm Vitralite ClearDocument1 page6mm Emicool Vision Cool Bronze +6mmAS + 6mm Vitralite ClearvigneshNo ratings yet

- Major Jobs Bar Chart - Shutdown July-23-1Document4 pagesMajor Jobs Bar Chart - Shutdown July-23-1priyajit sahooNo ratings yet

- How To Disassemble An Inflatable Boat in 3 Minutes INNOVOCEAN Inflatable Boat - YouTubeDocument1 pageHow To Disassemble An Inflatable Boat in 3 Minutes INNOVOCEAN Inflatable Boat - YouTubeniksa.ilovicNo ratings yet

- DSD Reply Letter - HBP1 Technical AuditDocument2 pagesDSD Reply Letter - HBP1 Technical AuditKa HoNo ratings yet

- Nylon Sling Inspection ChecklistDocument1 pageNylon Sling Inspection Checklistshamshad ahamedNo ratings yet

- EYEWASH DAILY INSPECTION CHECKLIST Insert Logo - MonthlyDocument2 pagesEYEWASH DAILY INSPECTION CHECKLIST Insert Logo - MonthlyMalik RizwanNo ratings yet

- TK-103-FGL-34 Holiday InspectionDocument1 pageTK-103-FGL-34 Holiday InspectionjoseNo ratings yet

- Executive Summary PTK-KJP Published 160524 PDFDocument41 pagesExecutive Summary PTK-KJP Published 160524 PDFGuido ContiniNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Ensco DS-7 Final Dive REPORTDocument88 pagesEnsco DS-7 Final Dive REPORTHadi SaifulAshuraNo ratings yet

- +baader Test Q Turret Eyepiece Set An Affordable Kit That Delivers e WilcoxDocument3 pages+baader Test Q Turret Eyepiece Set An Affordable Kit That Delivers e WilcoxJosip DASCOLINo ratings yet

- Punch List For Co2 Aug - 27Document2 pagesPunch List For Co2 Aug - 27Siriepathi SeetharamanNo ratings yet

- ACM - 1april2022Document1 pageACM - 1april2022ElvisNo ratings yet

- 7500 Specifications Style 2000 / 2100 SpecificationsDocument4 pages7500 Specifications Style 2000 / 2100 SpecificationsPham Phuong AnhNo ratings yet

- 3.1.1 Pengukuran OTDR (Tabel Rangkuman + Grafik) Bili-Bili 1480Document1 page3.1.1 Pengukuran OTDR (Tabel Rangkuman + Grafik) Bili-Bili 1480RUMAH PRINT MAKASSARNo ratings yet

- Brazilian Well Abandonment Guidelines - 2022 RevisionDocument13 pagesBrazilian Well Abandonment Guidelines - 2022 RevisionFrederico BarbosaNo ratings yet

- International Load Line Certificate: No SGI0/SLI/20200614231821-E4Document5 pagesInternational Load Line Certificate: No SGI0/SLI/20200614231821-E4vikas_etoNo ratings yet

- Juvenile Corals Underpin Coral Reef Carbonate Production After DisturbanceDocument11 pagesJuvenile Corals Underpin Coral Reef Carbonate Production After DisturbancerafislazzaNo ratings yet

- Lecture-2 Lifeboat Case StudyDocument8 pagesLecture-2 Lifeboat Case Studykhan asifNo ratings yet

- Monitoring FBHDocument12 pagesMonitoring FBHfadila halimNo ratings yet

- Class 3 4 KeyDocument12 pagesClass 3 4 Keyshivamsingh.fscNo ratings yet

- Ae 191 Lesson 1Document14 pagesAe 191 Lesson 1Erna DavidNo ratings yet

- Jungle Clear Compilation S14Document15 pagesJungle Clear Compilation S14Caio AnjosNo ratings yet

- Herodotus and The Emergence of The DemagDocument15 pagesHerodotus and The Emergence of The DemagKsenija BirmanacNo ratings yet

- Engl 316 Resume FinalDocument1 pageEngl 316 Resume Finalapi-466382256No ratings yet

- Eng Taas-08 Talmud Eser SefirotDocument63 pagesEng Taas-08 Talmud Eser Sefirotne0h_16_196547097No ratings yet

- FovizamDocument18 pagesFovizamMickey PierceNo ratings yet

- Production Unit - 4Document24 pagesProduction Unit - 4Goutham AppuNo ratings yet

- Slice: Safety Data SheetDocument7 pagesSlice: Safety Data Sheetzubair1951No ratings yet

- ImmigrationDocument4 pagesImmigrationJen AnnNo ratings yet

- Https Sis Cat Com Sisweb Sisweb Techdoc Techdoc Print Page 2Document4 pagesHttps Sis Cat Com Sisweb Sisweb Techdoc Techdoc Print Page 2Tshidiso LekalakalaNo ratings yet

- Project of SecurityDocument9 pagesProject of SecurityBerehe GezuNo ratings yet

- IELTS Writing Task1 TableDocument16 pagesIELTS Writing Task1 TableRakesh Kumar Sharma100% (1)

- The Yoga Sutras of Patanjali PDFDocument168 pagesThe Yoga Sutras of Patanjali PDFjhonprestonNo ratings yet

- 12 Chapter-6 Autumn FestivalDocument18 pages12 Chapter-6 Autumn FestivalSudipta Paul ShawliNo ratings yet

- Rand Oh Di So 22324668100220Document2 pagesRand Oh Di So 22324668100220Crystal RojasNo ratings yet

- Bubble Planner Uoi Where We Are in Place and TimeDocument10 pagesBubble Planner Uoi Where We Are in Place and TimeasimaNo ratings yet

- JSA Wet End or Dryer Bearing Inspection Paper MillDocument6 pagesJSA Wet End or Dryer Bearing Inspection Paper MillMlayeh MohamedNo ratings yet

- AI523 Data Sheet, 2, en USDocument12 pagesAI523 Data Sheet, 2, en USJozz LivelyNo ratings yet

- Burocco S3000 ManualDocument4 pagesBurocco S3000 ManualJose David Leon BetancourtNo ratings yet

- AP - LiabilitiesDocument4 pagesAP - LiabilitiesEarl Donne Cruz100% (4)

- The Plant Journal - 2023 - Selma Garc A - Engineering The Plant Metabolic System by Exploiting Metabolic RegulationDocument28 pagesThe Plant Journal - 2023 - Selma Garc A - Engineering The Plant Metabolic System by Exploiting Metabolic RegulationRodrigo ParolaNo ratings yet

- Year 6 Mco Lesson PlanDocument25 pagesYear 6 Mco Lesson PlanVanitha ThiagarajNo ratings yet

Results Methods Shore Tank No Properties Units Limits (A) : Jalan Yos Sudarso No.1 Pintu IV, Balikpapan - 76111

Results Methods Shore Tank No Properties Units Limits (A) : Jalan Yos Sudarso No.1 Pintu IV, Balikpapan - 76111

Uploaded by

Faizal NurOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Results Methods Shore Tank No Properties Units Limits (A) : Jalan Yos Sudarso No.1 Pintu IV, Balikpapan - 76111

Results Methods Shore Tank No Properties Units Limits (A) : Jalan Yos Sudarso No.1 Pintu IV, Balikpapan - 76111

Uploaded by

Faizal NurCopyright:

Available Formats

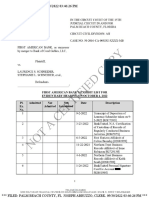

PT.

KILANG PERTAMINA INTERNASIONAL

REFINERY UNIT V - BALIKPAPAN

Jalan Yos Sudarso No.1 pintu IV, Balikpapan - 76111

Telp. (0542) 511000 - 5096, Email : Adm Eng & Dev RU V - Laboratory (mk.djuraidah@pertamina.com)

LOADING WORKING SHEET

Product : Avtur / Jet A-1 Report No. : 1062/2023

Vessel : MT.SEI PAKNING Date of Loading : June 26 , 2023

Shore Tank : P.1 , A.25 , P.31 , P.32 , P.2 Order No. : 0779/E15132/LO/VI/2023-S2

Port of Destination : TT WAYAME Ship's Tank No. : 1-2-4-5 P/S

Results

No Properties Units Limits (a) Methods Shore Tank Kontrol Muat

P.1 A.25 P.31 P.32 P.2 Pipa 914 3 Feet Selesai muat

1 Appearance

Clear, Bright and Clear, Bright and Clear, Bright and Clear, Bright and

Clear, Bright and Clear, Bright and Clear, Bright and Clear, Bright and

Clear, Bright and Visually free Visually free from solid Visually free from solid Visually free from Visually free from

Visually free from solid Visually free from solid Visually free from solid Visually free from solid

from solid matter and matter and matter and solid matter and solid matter and

Visual Appearance *) - undissolved water at ambient fuel

Visual matter and undissolved

undissolved water at undissolved water at

matter and undissolved matter and undissolved matter and undissolved

undissolved water at undissolved

water at ambient fuel water at ambient fuel water at ambient fuel water at ambient fuel

temperature ambient fuel ambient fuel ambient fuel water at ambient

temperature temperature temperature temperature

temperature temperature temperature fuel temperature

Colour Saybolt *) - Reported ASTM D156-15 +30 +26 +30 +28 +30 +17 '+30 +26

Particulate Contamination, or *) mg/L Max 1.0 ASTM D5452-20 0.5 0.5 0.5 0.5 0.5

Particulate Counts *) IP 565-13

≥ 4 µm (c) ISO Code Individual Reported Max 19 2678.7 19 3507 19 4290.2 19 1203.7 17 2064.2 18

≥ 6 µm (c) ISO Code

Channel Reported Max 17 599.8 16 788.7 17 1060.7 17 222.6 15 450.9 16

≥ 14 µm (c) ISO Code

Counts & ISO

Reported Max 14 34.3 12 20.3 13 129.4 14 24.8 12 41.5 13

≥ 21 µm (c) ISO Code Reported Reported 3.3 09 14.2 11 30 12 5.4 10 6.5 10

Code

≥ 25 µm (c) ISO Code Reported Reported 1.4 08 6.3 10 16.6 11 2.9 09 3.4 09

≥ 30 µm (c) ISO Code Reported Max 13 0.8 07 4.1 09 9.9 10 1.8 08 1.8 08

2 Composition

Total Acidity mg KOH/g Max 0.015 ASTM D3242 -11(2017) 0.001 0.003 0.008 0.005 0.003

Aromatic Hydrocarbon Types

Aromatics, or (f) % v/v Max. 25.0 ASTM D1319-20a Not Analyzed Not Analyzed Not Analyzed Not Analyzed Not Analyzed

Total Aromatics *) % v/v Max 26.5 ASTM D6379-21e1 14.81 6.89 17.00 9.63 12.35

Total Sulfur % m/m Max. 0.30 ASTM D2622-21 0.01 0.02 0.01 0.01 0.01

Sulfur Mercaptan, or (g) *) % m/m Max. 0.0030 ASTM D3227-16 0.0002 0.0014 0.0018 0.0017 0.0003

Doctor Test *) - Negative IP 30 Negative Positive Positive Positive Negative

Refining Components, at point of manufacture *) NONE

- Non Hydroprocessed Components % v/v Reported 0 26.81 17.71 22.09 0

- Mildly Hydroprocessed Components % v/v Reported Not Added Not Added Not Added Not Added Not Added

- Severely Hydroprocessed Components % v/v Reported 100 73.19 82.29 77.91 100

- Synthetic Components % v/v Reported (b) Not Added Not Added Not Added Not Added Not Added

3 Volatility

Distillation : ASTM D86-23

o Reported 145 149 147 146 147

- Initial Boiling Point C 146 146 146

- 10% vol. Recovery o

C Max 205.0 162.0 165.0 166.6 169.2 164.8 165.1 164.0 165.0

o Reported 195 196 198 201 197

- 50% vol. recovery C 197 198 196

o Reported 246 242 243 246 245

- 90% vol. recovery C 244 243 244

o Max 300.0 290.0 267.0 268.2 266.8 269.0

- Final Boiling Point C 268.5 266.0 269.0

- Residue % v/v Max 1.5 1.1 1.2 1.2 1.2 1.2 1.2 1.2 1.2

- Loss % v/v Max 1.5 1.2 1.2 1.2 1.0 1.2 1.2 1.2 1.2

o Min 38.0 IP 170-21 42.0 43.0 41.0 43.0 42.0

Flash Point Abel C 42.0 39.0 40.0

Density at 15 °C *) kg/m3 775.0 - 840.0 ASTM D4052-22 804.3 807.5 807.2 807.3 803.3 807.9 804.7 806.5

4 Fluidity

Freezing Point o

C Max minus 47.0 ASTM D2386-19 -57 -55 -50 -52 -58

Kinematic Viscosity at minus 20 oC mm2/s Max 8.000 ASTM D445-21e1 5.672 4.352 4.583 4.118 4.286

5 Combustion

Smoke Point, or mm Min 25.0 ASTM D1322-22 Not Analyzed Not Analyzed Not Analyzed Not Analyzed Not Analyzed

Smoke Point and mm Min 18.0 ASTM D1322-22 23.5 19.0 22.0 22 23

Naphtalenes *) % v/v Max 3.00 ASTM D1840 -22 1.72 1.63 2.30 1.79 1.12

Specific Energy MJ/kg Min 42.80 ASTM D3338-20a 43.27 43.36 43.28 43.21 43.32

6 Corrosion

Corrosion Copper Strip at 2 hrs / 100 °C Class Max Class 1 ASTM D130-19 Class 1 Class 1 Class 1 Class 1 Class 1

7 Thermal Stability, JFTOT ASTM D3241-20c

o Min. 260 260 260 260 260 260

Test Temperature Tube Rating C

(1) Tube Rating Visual (Annex B VTR), or Less than 3. No

- Peacock (P) or 1 1 1 1 1

Abnormal (A)

(2) Interferometric or Ellipsometric nm Max 85 Not Analyzed Not Analyzed Not Analyzed Not Analyzed Not Analyzed

Pressure Deferential mm Hg Max 25 3 3 3 3 3

8 Contaminants

Existent Gum mg/100 ml Max 7 ASTM D381-22 2 2 2 2 2

9 Water Separation Characteristics ASTM D3948-22

MSEP without SDA, or Rating Min 85 Not Analyzed Not Analyzed Not Analyzed Not Analyzed Not Analyzed

MSEP with SDA Rating Min 70 98 98 95 93 95

10 Conductivity

Electrical Conductivity pS/m 50 - 600 ASTM D2624-22 450 367 279 296 341 386 320 250

11 Lubricity :

Wear Scar Diameter mm Max 0.85 ASTM D5001-19e1 0.78 Not Analyzed Not Analyzed Not Analyzed 0.74

12 Additives

Static Dissipator Additives (RDE/A/621) *) mg/L Max 3 Calculated 0.62 1.05 0.43 0.55 0.5

Anti-Oxidant in Final Batch (RDE/A/606) *) mg/L Max 24 Calculated 21.11 4.46 16.25 20.74 12.61

Anti Oxidant for Hydroprocessed Component *) mg/L Max 24 Calculated Not Added Not Added Not Added Not Added Not Added

Metal Deactivator Additives *) mg/L Max 2.0 (d) Calculated Not Added Not Added Not Added Not Added Not Added

Lubricity Improver Additives *) mg/L (e) Calculated Not Added Not Added Not Added Not Added Not Added

Fuel System Icing Inhibitor *) % v/v 0.10 - 0.15 Calculated Not Added Not Added Not Added Not Added Not Added

Leak Detection Additives *) mg/kg Max 1.0 Calculated Not Added Not Added Not Added Not Added Not Added

Batch Number

Batch Volume

Sampling Method ASTM D4057-22

Date of Sampling 23.06.2023 17.06.2023 27.06.2023 29.06.23 30.06.2023

You might also like

- Cambridge IGCSE Mathematics Core and Extended Workbook by Ric Pimentel, Terry Wall PDFDocument97 pagesCambridge IGCSE Mathematics Core and Extended Workbook by Ric Pimentel, Terry Wall PDFPrince Yug86% (22)

- Teachings in The Science of Osteopathy PDFDocument336 pagesTeachings in The Science of Osteopathy PDFAlex92% (13)

- Padi Peak Performance Buoyancy enDocument20 pagesPadi Peak Performance Buoyancy enPaolo Bocci100% (5)

- Exam C Manual PDFDocument2 pagesExam C Manual PDFJohnathan0% (1)

- RPT Maths Form 5 DLP 2022 - 2023Document16 pagesRPT Maths Form 5 DLP 2022 - 2023PETER WONG YUNG MING Moe50% (2)

- Unit 1 Test-Part 1 Reading: As A Young GirlDocument19 pagesUnit 1 Test-Part 1 Reading: As A Young GirlVictoria PhamNo ratings yet

- LNG TangguhDocument19 pagesLNG Tangguhapi-3759747100% (5)

- Rent-A-Movie Database Project: YOUR ASSIGNMENT (Deliverables Are Underlined)Document2 pagesRent-A-Movie Database Project: YOUR ASSIGNMENT (Deliverables Are Underlined)Miguel Flores FloresNo ratings yet

- Contribuciones de Leontief A La EconomíaDocument24 pagesContribuciones de Leontief A La EconomíaMargarita SepulvedaNo ratings yet

- Hollow LensDocument2 pagesHollow Lensapi-458747859No ratings yet

- FE MonitoringDocument1 pageFE MonitoringJezreel TolentinoNo ratings yet

- 3.D-017A Abandon Ship Drill Report Rev 0Document3 pages3.D-017A Abandon Ship Drill Report Rev 0Bataklanden MusicNo ratings yet

- 1.lifeboat 5 Yearly Cert 2022Document6 pages1.lifeboat 5 Yearly Cert 2022Lim LikweeNo ratings yet

- MT Griya Cirebon Aurora Samudera Perdana 30 Sep 2021Document135 pagesMT Griya Cirebon Aurora Samudera Perdana 30 Sep 2021intan nNo ratings yet

- Diving Work Permit FormDocument1 pageDiving Work Permit FormJorey FernanNo ratings yet

- Hindware Catalogue Compressed DLDocument146 pagesHindware Catalogue Compressed DLAyushiNo ratings yet

- Fire Extinguisher Inspection Check ListDocument2 pagesFire Extinguisher Inspection Check ListsravankotlasNo ratings yet

- Ua Uc DLCL 06 03 2024Document6 pagesUa Uc DLCL 06 03 2024Anvarsha SharafudheenNo ratings yet

- Countermeasure For SedimrnDocument8 pagesCountermeasure For SedimrnDwiNo ratings yet

- Industrial Training Report PDFDocument80 pagesIndustrial Training Report PDFRaman ChaudharyNo ratings yet

- Sanction MemoDocument32 pagesSanction MemoFahad ZulfiqarNo ratings yet

- Miscellaneous Tools Inspection Report (DPT) Page 1 of 1: Scope of Inspection Dye Penetrant Test On Ends & Full BodyDocument1 pageMiscellaneous Tools Inspection Report (DPT) Page 1 of 1: Scope of Inspection Dye Penetrant Test On Ends & Full BodyhamanjaloosNo ratings yet

- As Lo 2009Document1 pageAs Lo 2009nizzazaNo ratings yet

- Hse Master ChecklistDocument429 pagesHse Master ChecklistLantNo ratings yet

- IR Full SB 54 F R1.0 1 Buat NamasDocument21 pagesIR Full SB 54 F R1.0 1 Buat NamasIndra PujiantoNo ratings yet

- 1087 158386492 Fab's Exhibit List 4 Evidentiary Hearing On 10 4 22Document3 pages1087 158386492 Fab's Exhibit List 4 Evidentiary Hearing On 10 4 22larry-612445No ratings yet

- 42rle balveDocument7 pages42rle balveLalo Barajas GarciaNo ratings yet

- TQP-INSP-LAV-04 Monthly Eyewash InspectionDocument2 pagesTQP-INSP-LAV-04 Monthly Eyewash InspectionScribdTranslationsNo ratings yet

- NSRP Sdm2019 Hex ScheduleDocument2 pagesNSRP Sdm2019 Hex ScheduleThinh NguyenNo ratings yet

- Individual Performance Commitment and Review Form (Ipcrf) For Teacher I - IiiDocument8 pagesIndividual Performance Commitment and Review Form (Ipcrf) For Teacher I - IiiNida Viojan AbasoloNo ratings yet

- Hse Master ChecklistDocument541 pagesHse Master ChecklistVinay Tunge100% (2)

- 763 CTE Thal To Mirali Road (Section-5) : ConsultantDocument50 pages763 CTE Thal To Mirali Road (Section-5) : ConsultantKhuram IsmailNo ratings yet

- FEB 2023 - Eye Wash Station Monitoring SheetDocument3 pagesFEB 2023 - Eye Wash Station Monitoring SheetVigneshwaraNo ratings yet

- HC Progress Report 26 Mar 15Document4 pagesHC Progress Report 26 Mar 15Jayesh SolaskarNo ratings yet

- Modicare Cuckoo Air Purifier + 3 in 1 Filter Promotion April 2024Document3 pagesModicare Cuckoo Air Purifier + 3 in 1 Filter Promotion April 2024vikasbpl44No ratings yet

- Shackle Inspection Check List: Pt. Biro Klasifikasi Indonesia (Persero)Document5 pagesShackle Inspection Check List: Pt. Biro Klasifikasi Indonesia (Persero)kuncoro numpanguripNo ratings yet

- TDS r0 SignedDocument4 pagesTDS r0 SignedBhadresh KumbhaniNo ratings yet

- FHR Vox 2023 PDFDocument1 pageFHR Vox 2023 PDFEmmanuel ToretaNo ratings yet

- 54-Ch - Muhammad MusaDocument1 page54-Ch - Muhammad MusaMusa ChNo ratings yet

- 9120 Pi ENDocument2 pages9120 Pi ENAli AlsaidiNo ratings yet

- ER TC 47 PSC Checklist GuideDocument5 pagesER TC 47 PSC Checklist GuideAruljyothy PCNo ratings yet

- V-3111-002-A-709 - 2 Method Statement For Geoelectrical WorkDocument8 pagesV-3111-002-A-709 - 2 Method Statement For Geoelectrical WorkWidya PrasetyaNo ratings yet

- lul spc-lae-330272049-1-5-2014Document1 pagelul spc-lae-330272049-1-5-2014mahyarovNo ratings yet

- 西e押rtⅢ飢t調書⑲軌l蜘山肌: Div【Sion MemorandumDocument2 pages西e押rtⅢ飢t調書⑲軌l蜘山肌: Div【Sion MemorandumAdela PandoroNo ratings yet

- Thermodynamics of SolidsDocument2 pagesThermodynamics of SolidsAWNISH PRASAD SINGHNo ratings yet

- Certificate OF Inspection No.: ResultDocument13 pagesCertificate OF Inspection No.: ResultArif FuadiantoNo ratings yet

- 6mm Emicool Vision Cool Bronze +6mmAS + 6mm Vitralite ClearDocument1 page6mm Emicool Vision Cool Bronze +6mmAS + 6mm Vitralite ClearvigneshNo ratings yet

- Major Jobs Bar Chart - Shutdown July-23-1Document4 pagesMajor Jobs Bar Chart - Shutdown July-23-1priyajit sahooNo ratings yet

- How To Disassemble An Inflatable Boat in 3 Minutes INNOVOCEAN Inflatable Boat - YouTubeDocument1 pageHow To Disassemble An Inflatable Boat in 3 Minutes INNOVOCEAN Inflatable Boat - YouTubeniksa.ilovicNo ratings yet

- DSD Reply Letter - HBP1 Technical AuditDocument2 pagesDSD Reply Letter - HBP1 Technical AuditKa HoNo ratings yet

- Nylon Sling Inspection ChecklistDocument1 pageNylon Sling Inspection Checklistshamshad ahamedNo ratings yet

- EYEWASH DAILY INSPECTION CHECKLIST Insert Logo - MonthlyDocument2 pagesEYEWASH DAILY INSPECTION CHECKLIST Insert Logo - MonthlyMalik RizwanNo ratings yet

- TK-103-FGL-34 Holiday InspectionDocument1 pageTK-103-FGL-34 Holiday InspectionjoseNo ratings yet

- Executive Summary PTK-KJP Published 160524 PDFDocument41 pagesExecutive Summary PTK-KJP Published 160524 PDFGuido ContiniNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Ensco DS-7 Final Dive REPORTDocument88 pagesEnsco DS-7 Final Dive REPORTHadi SaifulAshuraNo ratings yet

- +baader Test Q Turret Eyepiece Set An Affordable Kit That Delivers e WilcoxDocument3 pages+baader Test Q Turret Eyepiece Set An Affordable Kit That Delivers e WilcoxJosip DASCOLINo ratings yet

- Punch List For Co2 Aug - 27Document2 pagesPunch List For Co2 Aug - 27Siriepathi SeetharamanNo ratings yet

- ACM - 1april2022Document1 pageACM - 1april2022ElvisNo ratings yet

- 7500 Specifications Style 2000 / 2100 SpecificationsDocument4 pages7500 Specifications Style 2000 / 2100 SpecificationsPham Phuong AnhNo ratings yet

- 3.1.1 Pengukuran OTDR (Tabel Rangkuman + Grafik) Bili-Bili 1480Document1 page3.1.1 Pengukuran OTDR (Tabel Rangkuman + Grafik) Bili-Bili 1480RUMAH PRINT MAKASSARNo ratings yet

- Brazilian Well Abandonment Guidelines - 2022 RevisionDocument13 pagesBrazilian Well Abandonment Guidelines - 2022 RevisionFrederico BarbosaNo ratings yet

- International Load Line Certificate: No SGI0/SLI/20200614231821-E4Document5 pagesInternational Load Line Certificate: No SGI0/SLI/20200614231821-E4vikas_etoNo ratings yet

- Juvenile Corals Underpin Coral Reef Carbonate Production After DisturbanceDocument11 pagesJuvenile Corals Underpin Coral Reef Carbonate Production After DisturbancerafislazzaNo ratings yet

- Lecture-2 Lifeboat Case StudyDocument8 pagesLecture-2 Lifeboat Case Studykhan asifNo ratings yet

- Monitoring FBHDocument12 pagesMonitoring FBHfadila halimNo ratings yet

- Class 3 4 KeyDocument12 pagesClass 3 4 Keyshivamsingh.fscNo ratings yet

- Ae 191 Lesson 1Document14 pagesAe 191 Lesson 1Erna DavidNo ratings yet

- Jungle Clear Compilation S14Document15 pagesJungle Clear Compilation S14Caio AnjosNo ratings yet

- Herodotus and The Emergence of The DemagDocument15 pagesHerodotus and The Emergence of The DemagKsenija BirmanacNo ratings yet

- Engl 316 Resume FinalDocument1 pageEngl 316 Resume Finalapi-466382256No ratings yet

- Eng Taas-08 Talmud Eser SefirotDocument63 pagesEng Taas-08 Talmud Eser Sefirotne0h_16_196547097No ratings yet

- FovizamDocument18 pagesFovizamMickey PierceNo ratings yet

- Production Unit - 4Document24 pagesProduction Unit - 4Goutham AppuNo ratings yet

- Slice: Safety Data SheetDocument7 pagesSlice: Safety Data Sheetzubair1951No ratings yet

- ImmigrationDocument4 pagesImmigrationJen AnnNo ratings yet

- Https Sis Cat Com Sisweb Sisweb Techdoc Techdoc Print Page 2Document4 pagesHttps Sis Cat Com Sisweb Sisweb Techdoc Techdoc Print Page 2Tshidiso LekalakalaNo ratings yet

- Project of SecurityDocument9 pagesProject of SecurityBerehe GezuNo ratings yet

- IELTS Writing Task1 TableDocument16 pagesIELTS Writing Task1 TableRakesh Kumar Sharma100% (1)

- The Yoga Sutras of Patanjali PDFDocument168 pagesThe Yoga Sutras of Patanjali PDFjhonprestonNo ratings yet

- 12 Chapter-6 Autumn FestivalDocument18 pages12 Chapter-6 Autumn FestivalSudipta Paul ShawliNo ratings yet

- Rand Oh Di So 22324668100220Document2 pagesRand Oh Di So 22324668100220Crystal RojasNo ratings yet

- Bubble Planner Uoi Where We Are in Place and TimeDocument10 pagesBubble Planner Uoi Where We Are in Place and TimeasimaNo ratings yet

- JSA Wet End or Dryer Bearing Inspection Paper MillDocument6 pagesJSA Wet End or Dryer Bearing Inspection Paper MillMlayeh MohamedNo ratings yet

- AI523 Data Sheet, 2, en USDocument12 pagesAI523 Data Sheet, 2, en USJozz LivelyNo ratings yet

- Burocco S3000 ManualDocument4 pagesBurocco S3000 ManualJose David Leon BetancourtNo ratings yet

- AP - LiabilitiesDocument4 pagesAP - LiabilitiesEarl Donne Cruz100% (4)

- The Plant Journal - 2023 - Selma Garc A - Engineering The Plant Metabolic System by Exploiting Metabolic RegulationDocument28 pagesThe Plant Journal - 2023 - Selma Garc A - Engineering The Plant Metabolic System by Exploiting Metabolic RegulationRodrigo ParolaNo ratings yet

- Year 6 Mco Lesson PlanDocument25 pagesYear 6 Mco Lesson PlanVanitha ThiagarajNo ratings yet