Professional Documents

Culture Documents

Electrical Requirements: Referred To ANSI MC96.1. Immersed From 20 MM Min. To The Total Length of The Probe Sheath

Electrical Requirements: Referred To ANSI MC96.1. Immersed From 20 MM Min. To The Total Length of The Probe Sheath

Uploaded by

Carlos Omar Meza DonosoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical Requirements: Referred To ANSI MC96.1. Immersed From 20 MM Min. To The Total Length of The Probe Sheath

Electrical Requirements: Referred To ANSI MC96.1. Immersed From 20 MM Min. To The Total Length of The Probe Sheath

Uploaded by

Carlos Omar Meza DonosoCopyright:

Available Formats

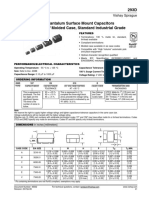

Component Specification for P/N: 1288207

Fluke Corporation Revision: 001

Part Type: Piercing Probe Thermocouple Assembly with Molded Connector Page 1 of 3

Thermocouple Type: T

1. ELECTRICAL REQUIREMENTS

All conditions and limits at 25 °C, 50 % RH, unless noted.

1.1 Sensing Temperature Range -196°C to 350°C

1.2 Output Per ANSI MC96.1-1982

1.3 Output Accuracy

Referred to ANSI MC96.1. Immersed

from 20 mm min. to the total length of

the probe sheath.

1.3.1 From -196°C to -150°C ±3%

1.3.2 From -150°C to -40°C ±2°C

1.3.3 From -40°C to 0°C ±1°C

1.3.4 From 0°C to 350°C ±1°C or ±0.75% of reading, whichever is

greater

1.4 Thermocouple Grounding Method Junction welded to sheath.

1.5 Time Constant 1.0 s max.

In 100 °C still water @ sea level pressure

1.6 Insulation Resistance

@ 500 VDC

1.6.1 Insulating Jacket to Either Plug Prong 100 MΩ min.

1.6.2 Insulating Jacket To Probe Sheath 100 MΩ min

1.7 Dielectric Withstanding Voltage 1000 VDC min.

Insulating Jacket to Either Plug Prong

2. MECHANICAL REQUIREMENTS

2.1 Assembly Materials

2.1.1 Thermocouple Material T-Type

2.1.2 Thermocouple Wire in Probe Sheath Per ANSI MC96.1-1982, AWG #24, solid,

and a Portion of the Handle Special Limits of Error,

2.1.3 Lead Wire, in the Rest of the Handle up to Extension Grade, Type TX, AWG #24,

the Point of Attachment to the Plug Prongs 7 strands of AWG #32, Special Limits of

Error, matched to the probe wire

2.1.4 Insulation

2.1.4.1 Thermoelements MGO Filled

2.1.4.2 Outer Jacket Gray PVC (Chroma E-80943A) extruded

around bare wire

2.1.5 Connector Plug Blue Hytrel 4776

2.1.6 Handle Gray Hytrel 5556 (Chroma E-80943A)

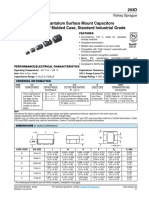

Component Specification for P/N: 1288207

Fluke Corporation Revision: 001

Page 2 of 3

2.1.7 Probe Sheath

2.1.7.1 Material 304 Stainless Steel

2.1.7.2 Diameter 0.125 tapered to 30° ± 5°

2.1.7.3 Insulating Material Magnesium Oxide

2.2 Markings (Plug), Molded in (+) (-) on one face and a 4 digit date code

(using the Fluke manufacturing date for the

last Friday of each month) on the opposite

face, see Figure 3.1

2.3 Dimensions See Figure 3.1

2.4 Probe Sheath Surface Finish 63 µinch rms, or better, per ASTM E235

2.5 Packaging Bulk

2.6 Probe Sheath Tip Protector Opaque plastic cap, removable

2.7 Cable 2 ties min., See Figure 3.1

3. ENVIRONMENTAL REQUIREMENTS

3.1 Continuous Operating Temperature

3.1.1 Probe Sheath -196°C to 350°C (-321°F to 662°F)

3.1.2 Probe Handle and Lead Wire -40°C to 125°C (-40°F to 257°F)

3.1.3 Connector -40°C to 71°C (-40°F to 160°F)

3.2 Pull Test Requirement Without Separation

3.2.1 Plug and Lead Wires 6 lb. min.

3.2.2 Handle and Probe Sheath 6 lb. min.

Component Specification for P/N: 1288207

Fluke Corporation Revision: 001

Page 3 of 3

Figure 3.1 - Dimensions,inches

∅ 1.230 ±.015

∅ .125

.094 INCH FOUR DIGIT DATE CODE

RAISED TO BE FLUSH WITH OVERALL

SURFACE AND CENTERED IN REC- .06

TANGULAR DETENT. 30° ±5°

.15

ORIENT DATE CODE AS SHOWN.

5555

4.00

.094 ±.13

+.002

-.003

.125 ±.002

.50 (centered)

.25

.62 REF.

.31

.31 .156

.156 .032 ±.002 ∅ .610 ±.015

10.75

±1.50

.313 1

3.72

R REF.

2PL .480 -.505

∅ .730 ±.020

+ −

.77

3.0

±.5

48.0

+3.0, -0.0

UNCOILED

NOTES:

1. TOLERANCE FOR THIS DIMENSION APPLIES WHEN PIN WIDTHS ARE AT MAXIMUM

MATERIAL CONDITION. TOLERANCE INCREASES IN ACCORD WITH PIN WIDTH.

2. TOLERANCES UNLESS NOTED: .XXX=±.005

.XX=±.01

You might also like

- Schindler 5500/5500S/5400-Rel.02: EN81-1 Commissioning Manual K 40700039 - 12 Edition 02-2016Document96 pagesSchindler 5500/5500S/5400-Rel.02: EN81-1 Commissioning Manual K 40700039 - 12 Edition 02-2016George Pontoni100% (13)

- Electrical Schematic With EMCP IIDocument4 pagesElectrical Schematic With EMCP IIAnonymous uEt1sNhU7l89% (19)

- Derbi Senda Service Manual DRD ModelDocument71 pagesDerbi Senda Service Manual DRD ModelChris Ranger Richardson83% (6)

- SH-005058-UM-6-455N User Manual - (PAxxxx)Document16 pagesSH-005058-UM-6-455N User Manual - (PAxxxx)Med Hédi BANNANI100% (1)

- Tacuma. EcmDocument105 pagesTacuma. EcmFelix VelasquezNo ratings yet

- Codigos de SMD CapasitoresDocument26 pagesCodigos de SMD CapasitoresHugo Roberto RibeiroNo ratings yet

- Product Datasheet 3523. : Ring Terminals With Insulation SupportDocument2 pagesProduct Datasheet 3523. : Ring Terminals With Insulation SupportFrancisco RamirezNo ratings yet

- Datasheet ThermistorDocument6 pagesDatasheet Thermistorkhoiru zadditNo ratings yet

- P9 JT Thermistor 1621687Document2 pagesP9 JT Thermistor 1621687ArafetNo ratings yet

- 1N5342 THRU 1N5388: 5W Silicon Planar Zener Diodes Features DO-15Document3 pages1N5342 THRU 1N5388: 5W Silicon Planar Zener Diodes Features DO-15DennisSendoyaNo ratings yet

- Photodarlington Optocoupler: Parameter Min. Typ. Max. Unit Condition EmitterDocument2 pagesPhotodarlington Optocoupler: Parameter Min. Typ. Max. Unit Condition EmitterJuan CarlosNo ratings yet

- Strain Gauge For Extreme Temperatures LC61Document2 pagesStrain Gauge For Extreme Temperatures LC61TenshiJNo ratings yet

- Ferrites and Accessories: U 93/76/30 With I 93/28/30 CoreDocument9 pagesFerrites and Accessories: U 93/76/30 With I 93/28/30 Corekrassi62No ratings yet

- Shielded Power Inductors - MOS6020Document2 pagesShielded Power Inductors - MOS6020mauricio alfonsoNo ratings yet

- F0a7c Compal LA-A994p r1.0 2014Document4 pagesF0a7c Compal LA-A994p r1.0 2014google manNo ratings yet

- Vishay 293D107X9016D2TE3 DatasheetDocument9 pagesVishay 293D107X9016D2TE3 DatasheetAlejandro ChavarríaNo ratings yet

- Ds pv3560 en inDocument5 pagesDs pv3560 en inravisingh12911No ratings yet

- Specification For Approval: Shenzhen CND-TEK Industrial Co.,LtdDocument4 pagesSpecification For Approval: Shenzhen CND-TEK Industrial Co.,LtdLeonardo Armando RomeroNo ratings yet

- 1N5342 THRU 1N5388: 5W Silicon Planar Zener DiodesDocument2 pages1N5342 THRU 1N5388: 5W Silicon Planar Zener DiodesLeandroNo ratings yet

- A9784 BL CoilcraftDocument1 pageA9784 BL CoilcraftStreet fighterNo ratings yet

- Calmicaglas 2005 TDS PDFDocument2 pagesCalmicaglas 2005 TDS PDFjalilemadiNo ratings yet

- 30 AWG Cable DATA SheetDocument2 pages30 AWG Cable DATA SheetTuýp Phờ NờNo ratings yet

- Vishay 293D475X9025C2TE3 DatasheetDocument9 pagesVishay 293D475X9025C2TE3 DatasheetMiguel VNo ratings yet

- BFOU (I) 250VDocument5 pagesBFOU (I) 250VmmbtestappNo ratings yet

- Luckylight: 0805 Package Blue Chip LED Technical Data SheetDocument9 pagesLuckylight: 0805 Package Blue Chip LED Technical Data SheetWaltencirNo ratings yet

- Installation Manual Multi-Function PROTECTION RELAY GRE110, GRE120, GRE130Document22 pagesInstallation Manual Multi-Function PROTECTION RELAY GRE110, GRE120, GRE130Cecep Marfu100% (2)

- LEMI-120 User Manual SN 0347 - 0351 - 0352 - 0353 - 0356 - 0357 - 0359 - 0373 - 0380 - 0382Document14 pagesLEMI-120 User Manual SN 0347 - 0351 - 0352 - 0353 - 0356 - 0357 - 0359 - 0373 - 0380 - 0382Илья ЛозовскийNo ratings yet

- Effect of Laser Welding Parameters On The Heat Input and Weld-Bead ProfileDocument8 pagesEffect of Laser Welding Parameters On The Heat Input and Weld-Bead ProfileAlfiansyah DarmawanNo ratings yet

- Power Losses in Wound Components PDFDocument12 pagesPower Losses in Wound Components PDFPedNo ratings yet

- Ntcs0805E3..... T SMD 0805, Glass Protected NTC Thermistors: Vishay BccomponentsDocument4 pagesNtcs0805E3..... T SMD 0805, Glass Protected NTC Thermistors: Vishay Bccomponentsoctavinavarro8236No ratings yet

- 5.0Mm Infrared Emitting Diode 520E940CDocument4 pages5.0Mm Infrared Emitting Diode 520E940CRonald TucumanNo ratings yet

- 06 - Fire Resistant CablesDocument13 pages06 - Fire Resistant CablesmlutfimaNo ratings yet

- MNR 6045Document8 pagesMNR 60450kim chanNo ratings yet

- Calmicaglas 2005, 0409: A Constantia Iso AG CompanyDocument3 pagesCalmicaglas 2005, 0409: A Constantia Iso AG CompanyjalilemadiNo ratings yet

- Etd 34 17 11Document12 pagesEtd 34 17 11orkun burkayNo ratings yet

- 1N5342 Thru 1N5388Document3 pages1N5342 Thru 1N5388Juan Manuel Briones GarciaNo ratings yet

- MLCC Application Guide WalsinDocument10 pagesMLCC Application Guide WalsinmuasaobangcnNo ratings yet

- Installation Instructions: Dental X-RayDocument23 pagesInstallation Instructions: Dental X-Rayزكريا دبوانNo ratings yet

- KC 301198 1171686 PDFDocument2 pagesKC 301198 1171686 PDFDiego Felipe Gavilán RetamalesNo ratings yet

- DIN Receptacles: Specifications MaterialsDocument2 pagesDIN Receptacles: Specifications MaterialsDiego Felipe Gavilán RetamalesNo ratings yet

- InsulationDocument23 pagesInsulationFabio TemporiniNo ratings yet

- Typical Properties of Copper & AluminiumDocument5 pagesTypical Properties of Copper & AluminiumamoghnawatheNo ratings yet

- Ferrites and AccessoriesDocument11 pagesFerrites and AccessoriesAdel DechirNo ratings yet

- Raiden Cable DatasheetDocument4 pagesRaiden Cable Datasheetshaikhfaisalx81No ratings yet

- NTC Thermistor 438959Document5 pagesNTC Thermistor 438959Anonymous eL4Dsp1BaNo ratings yet

- Ferrites and Accessories: A Í Püééí A Í PüééíDocument6 pagesFerrites and Accessories: A Í Püééí A Í PüééíAhmad AlasadiNo ratings yet

- B57153S479MDocument14 pagesB57153S479Mcasa1233333No ratings yet

- Datasheet ThermistorDocument5 pagesDatasheet ThermistorwaniabuNo ratings yet

- Final Data SheetDocument18 pagesFinal Data SheetJesus PerezNo ratings yet

- 8414 NhuDocument10 pages8414 NhuAdemar FukeNo ratings yet

- Specifications: Shenzhen Sunlord Electronics Co., LTDDocument38 pagesSpecifications: Shenzhen Sunlord Electronics Co., LTDdabajiNo ratings yet

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuNo ratings yet

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuNo ratings yet

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuNo ratings yet

- Soft Termination Multilayer Ceramic Chip Capacitors Meritek: EaturesDocument10 pagesSoft Termination Multilayer Ceramic Chip Capacitors Meritek: EaturesStuxnetNo ratings yet

- RFOU-1kV Rev12Document13 pagesRFOU-1kV Rev12Ahmed H. HassanNo ratings yet

- PC 8B35 Ge Lexan PCDocument3 pagesPC 8B35 Ge Lexan PCbalu gunaNo ratings yet

- B41456 Capacitors With Screw TerminalsDocument10 pagesB41456 Capacitors With Screw TerminalsE-RegisNo ratings yet

- SLF7045Document2 pagesSLF7045鄭建銘(小銘)No ratings yet

- HV Cable StandardDocument2 pagesHV Cable StandardAlla Naveen KumarNo ratings yet

- CEM-1203 (42) Datasheet - Magnetic Buzzer - CUI Inc PDFDocument5 pagesCEM-1203 (42) Datasheet - Magnetic Buzzer - CUI Inc PDFLUDWINGNo ratings yet

- NTC M12 PDFDocument2 pagesNTC M12 PDFBinotto PerformanceNo ratings yet

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- 2011 Service Flex-Multi-Series mfl63744402 20120105132900Document87 pages2011 Service Flex-Multi-Series mfl63744402 20120105132900sajjad147No ratings yet

- KY5 MNTP 3 RNDocument40 pagesKY5 MNTP 3 RNJuan Carlos Trucios MitmaNo ratings yet

- Soniq Operating Manual E46Z11ADocument55 pagesSoniq Operating Manual E46Z11AAllan WilliamsNo ratings yet

- Display Panel Voltmeter DMS-40PC PDFDocument6 pagesDisplay Panel Voltmeter DMS-40PC PDFafonsomoutinhoNo ratings yet

- Operator'S Manual: TecumsehpowerDocument24 pagesOperator'S Manual: TecumsehpowerConar Anahera MacphersonNo ratings yet

- 11 - SsangYong-Korando - 2012 - EN - US - Manual - de - Taller - Carroceria - 29fc2980d5Document72 pages11 - SsangYong-Korando - 2012 - EN - US - Manual - de - Taller - Carroceria - 29fc2980d5Mateus FumuassucaNo ratings yet

- VFDManualDocument61 pagesVFDManualSix_PacmanNo ratings yet

- Corporate Identity Number (CIN) - U40109RJ2000SGC016483: S.N O. Name of Item Quantity (Approx)Document45 pagesCorporate Identity Number (CIN) - U40109RJ2000SGC016483: S.N O. Name of Item Quantity (Approx)Achint KumarNo ratings yet

- Pdtech Deltamaxx: Digital Loss Factor/Capacitance Analyzer and Partial Discharge Detector For Test Voltages Up To 50 KVDocument4 pagesPdtech Deltamaxx: Digital Loss Factor/Capacitance Analyzer and Partial Discharge Detector For Test Voltages Up To 50 KVmichael_forraNo ratings yet

- Bosch Motorsport - Lambda Sensor LSU 4.9Document3 pagesBosch Motorsport - Lambda Sensor LSU 4.9Tomasz ZawadzkiNo ratings yet

- TRENDCOM ManualDocument14 pagesTRENDCOM ManualAndrés Ain-ActiveNo ratings yet

- BETA - Catalog ET B1 - 2010 - enDocument620 pagesBETA - Catalog ET B1 - 2010 - enUsuario32No ratings yet

- Form 635100 - HeadDocument2 pagesForm 635100 - HeadrafaelNo ratings yet

- TM 55-1520-228-BD PDFDocument312 pagesTM 55-1520-228-BD PDFAnselmo Alvarez Gonzalez100% (1)

- Norstar DR5 ManualDocument287 pagesNorstar DR5 ManualmmchokiesNo ratings yet

- Installation / User Manual: Apsystems Yc600 MicroinverterDocument24 pagesInstallation / User Manual: Apsystems Yc600 MicroinverterCarlos BrancoNo ratings yet

- HP 5328A Service ManualDocument219 pagesHP 5328A Service ManualDragan LazicNo ratings yet

- 1 1 8 P Solderingpractice Optional FunlightDocument6 pages1 1 8 P Solderingpractice Optional Funlightapi-287488627No ratings yet

- DLL - Science 5 - Q3 - W6Document6 pagesDLL - Science 5 - Q3 - W6JEANY ANN HAYAGNo ratings yet

- DCS400 Service Manual PDFDocument70 pagesDCS400 Service Manual PDFDoDuyBacNo ratings yet

- WK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedDocument24 pagesWK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedРома БлошенкоNo ratings yet

- Electrical SafetyDocument10 pagesElectrical SafetyUrsula JohnsonNo ratings yet

- BLDG STD Spec 2004Document703 pagesBLDG STD Spec 2004PcEngNo ratings yet

- Volume and Select Control Panels: Installation Instruction SheetDocument2 pagesVolume and Select Control Panels: Installation Instruction SheetbenjarrayNo ratings yet

- Fiber Optic Cable and Connector Selection: 1. Define Environmental RequirementsDocument5 pagesFiber Optic Cable and Connector Selection: 1. Define Environmental RequirementsRyan ZamoraNo ratings yet