Professional Documents

Culture Documents

R02 Offer For Eddy Current Dyamometer With Controller - 12.06.2023

R02 Offer For Eddy Current Dyamometer With Controller - 12.06.2023

Uploaded by

Karthii AjuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R02 Offer For Eddy Current Dyamometer With Controller - 12.06.2023

R02 Offer For Eddy Current Dyamometer With Controller - 12.06.2023

Uploaded by

Karthii AjuCopyright:

Available Formats

Plot No. S-101, ‘S’ Block, M.I.D.C.

Bhosari,

Pune – 411 026 Maharashtra (India) Tel: +91-20-40717301

Email: info@dynomerk.in | Website: www.dynomerk.co.in

Quotation

To, Quotation No. Quotation Rev No.

Maheshwaree Mining Pvt Ltd, DMC/Maheshwaree/23.03.ECD.648/648 02

Kolkata. Enquiry No. Quotation Date.

648 13.06.2023

Kind Attn: Customer Email Id. Customer Phone No.

Mr. Karthick Aju

Karthick.aju@maheshwaree.com +91 98940 74789

Sub: Budgetary Offer for Engine Test Bed for load testing of servicing engines

Dear Sir,

This refers to your enquiry for Engine Test Bed for load testing of servicing engines.

Please find our Budgetary offer for the same.

Our offer comprises of:

Annexure I: Scope of Supply

Annexure II: Prices

Annexure III: Terms & Conditions

We trust that our offer is in line with your requirements.

Thanking you and assuring you of our best services at all times.

For Dynomerk Controls,

Rajesh Vaidya

Marketing Dept.

Mb. +91 99701 96143

Manufacturers of Engine & Vehicle Testing Dynamometers, Automotive component

Test Rigs, Data Acquisition & Control Software, Integration & Automation.

Page 1 of 9

Format No.: DMC/F/MKT/02/PNQ Rev No./Date:02/01.09.2022

Plot No. S-101, ‘S’ Block, M.I.D.C. Bhosari,

Pune – 411 026 Maharashtra (India) Tel: +91-20-40717301

Email: info@dynomerk.in | Website: www.dynomerk.co.in

Annexure I: Scope of Supply

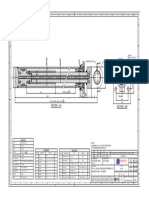

1. Eddy Current Dynamometer (EC-700)

Eddy Current Dynamometer EC-700

Maximum Power : 700 kW @ 3000 – 5000 rpm

Maximum Speed : 5000 Rpm

Maximum Torque : 2200 Nm @ 500 to 3000 rpm

Direction of rotation : Bi Directional

Fig. Eddy Current Dynamometer Assembly for Representation only

Basic Electromechanical Unit comprises of:

- 60 Teeth Gear Wheel for RPM Measurement

- Mounting arrangement for Load Cell and Magnetic Pick-up.

- Temperature Sensors to monitor Loss Plate Temperature.

- Temperature Sensors to monitor bearing Temperature

- Pressure Switch to ensure cooling water supply pressure.

- Flow switch to ensure cooling water flow.

- Suitable Adapter Plates for Cardon Shaft Coupling.

- Calibration kit

The construction comprises a casing to house the field coil and the cooling chambers

(Stator assembly). A thin spooked steel rotor revolves in the casing. The stator assembly

is mounted on a cast-base-frame supported by trunnion bearings.

When the excitation current is passed through the coil, a magnetic-flux field is formed.

An equal and opposite magnetic field is induced in the heat exchanger wall facing the

rotor & this field is of a pulsating form corresponding to the frequency of the passing

rotor spokes. This changing field produces eddy currents in the field, thus causing

retarding action to be imposed on the rotor. The magnetic flux lines developed in the rotor

Manufacturers of Engine & Vehicle Testing Dynamometers, Automotive component

Test Rigs, Data Acquisition & Control Software, Integration & Automation.

Page 2 of 9

Format No.: DMC/F/MKT/02/PNQ Rev No./Date:02/01.09.2022

Plot No. S-101, ‘S’ Block, M.I.D.C. Bhosari,

Pune – 411 026 Maharashtra (India) Tel: +91-20-40717301

Email: info@dynomerk.in | Website: www.dynomerk.co.in

are parallel to the axis and therefore the thickness of the rotor can be kept to minimize,

resulting in a low moment of inertia.

The function of water being passed through the cooling chambers is for heat dissipation

only and it does not come in contact with the rotor assembly. Hence, control of load

depends entirely on the level of excitation, and therefore fluctuations on the stability of

load absorption are minimum as water is used for cooling purpose only.

The dynamometer is Bi-directional, Dry-gap Type. In a dry gap unit, the only resistance

to movement of the rotor is that of bearing friction and the small effect of wind age. With

zero excitation, an almost no-load condition can be achieved over the entire speed range.

Dynamometer Safety Features:

The Dynamometer is provided with following Safety Features:

A pressure switch to monitor inlet water pressure.

A flow switch to monitor cooling water flow.

Two temperature sensors on either sides of heat exchanger of the dynamometer to

constantly guard the temperature of the cooling chambers and prevent overheating which

might occur due to insufficient water supply.

Two temperature sensors on either side of bearing housing to monitor bearing

temperature.

Provision is made to mount precision load-cell to sense Torque and 60 teeth wheel with

magnetic pick-up to sense the speed of the dynamometer.

Dynamometer cooling water flow rate: 200 Ltr/min (minimum)

The dynamometer inlet water temperature should be below 40C. At 40C

temperature of inlet water, if the dynamometer is being used to absorb power at its full

capacity, the minimum water-flow rate required is 200 litres / minute when Dynamometer

is used at 85% of its absorption capacity.

Cooling Water Pressure required: 1.5 Kg/cm² to 2.5 Kg/cm². [working range]

Load cell: Qty – 1 No.

(HBM make ‘S’ type with IKO mountings and MS Connector)

Precision grade, universal type.

Load Cell HBM Make

Model no – HBM S40A-1000 kgs

Range: 0 – 1000 Kg

Grade/Type: Precision Grade, Universal Type

Accuracy: ± 0.25% fsd

Output: 3.0 mV/V

Excitation voltage: 10 V

Magnetic Pick-up: Qty – 1 No.

Reluctance type made of plated MS body with alnico magnet for sensing, provided with

a 3-pin MS connector. The Coil impedance is 200 ohms approximately. The Output is

TTL (Square wave pulse output) at a distance of 2 mm from the gear teeth.

Manufacturers of Engine & Vehicle Testing Dynamometers, Automotive component

Test Rigs, Data Acquisition & Control Software, Integration & Automation.

Page 3 of 9

Format No.: DMC/F/MKT/02/PNQ Rev No./Date:02/01.09.2022

Plot No. S-101, ‘S’ Block, M.I.D.C. Bhosari,

Pune – 411 026 Maharashtra (India) Tel: +91-20-40717301

Email: info@dynomerk.in | Website: www.dynomerk.co.in

Magnetic Filter With Raw Water Pressure Dials, Qty – 1 No.

The Eddy Current Dynamometer works on the principle of the Eddy Currents and thus

has a Magnetic Field in which the rotor rotates. As a result, even very minute magnetic

particles present in the cooling water are attracted and get accumulated in the cooling

chambers. We will provide filter of suitable water flow rate capacity.

2. Dynamometer Controller 3 mode with RPM indicator

Operating modes

INT: In internal mode, operating control mode is selected internally and PID works as

per selection of mode & demand.

EXT: In external mode, operating control mode selection is done through external device

such as software and controller runs in I=C mode. PID control is done through DDC.

‘I= C’ Mode (Constant Excitation Current Mode): The exciting current supplied by the

control unit is independent of Dyno speed or torque. This mode is called as open loop

mode.

‘N=C’ Mode (Constant speed Mode): To control the engine with constant speed this

mode is used. This is a close loop mode where Dyno RPM is used as feedback. A high

dynamic ratio is obtained using PID control.

‘T=C’ Mode (Constant Current Mode): To control the engine with constant torque this

mode is used. This is a close loop mode where Dyno torque is used as feedback. A high

dynamic ratio is obtained using PID control.

RPM Indicator

Display : 0 to 5000 RPM

Accuracy : ± 1 RPM

Output : 0 to 10 VDC & Pulse output

3. Torque Indicator

This unit is housed in a 2U Sub-rack assembly.

The unit will have following features

Range : 0 – 2200 Nm

Excitation voltage output : 10 VDC

Feedback Output : 0 to 10 VDC

Zero & Span setting facility on front with potentiometer

Manufacturers of Engine & Vehicle Testing Dynamometers, Automotive component

Test Rigs, Data Acquisition & Control Software, Integration & Automation.

Page 4 of 9

Format No.: DMC/F/MKT/02/PNQ Rev No./Date:02/01.09.2022

Plot No. S-101, ‘S’ Block, M.I.D.C. Bhosari,

Pune – 411 026 Maharashtra (India) Tel: +91-20-40717301

Email: info@dynomerk.in | Website: www.dynomerk.co.in

4. Data Acquisition System (Qty – 01 no)

Temperature Sensors

Temperature Sensor – RTD – PT 100 (Nos –2)

Temperature Sensor – Thermocouple (nos – 1)

Pressure Sensors (4 Channel each)

Pressure Sensor (Nos: 3) (Make – Wika)

Panel for Pressure sensor mounting & Temperature sensors wiring

- This panel will accommodate the different terminal connections for the RTD

temperature sensors & Thermocouples.

- This will have the terminal connections and source adapters for pressure

transducers.

- All signal from Temperature sensors will be terminated inside panel and cables

from sensor panel will be connected to individual indicators on main Control panel

5. Temperature & Pressure Indicator

Temperature indicators

Temperature indicators for 2 RTD channels (Air intake & Coolant outlet) & 1

Thermocouple channel (Exhaust) will be supplied.

The indicators will accept signal from respective sensors and Display the parameter.

The indicator will have output from 0 to 10 VDC.

Pressure Indicators

Pressure Indicators for 3 channels (Air Intake, Lub oil & Fuel inlet) will be provided.

The indicators will have supply output voltage for pressure sensors & output of 0 to 10

VDC .

6. Universal Bed Plate

Universal Engine Mounting Test Bed

Universal Engine Mounting Test Bed for mounting different types of Engines. This Bed

provides X–Y–Z co-ordinates adjustment for matching centre–line of the Engine with

the Dynamometer.

It consists of

A Cast Iron T- slotted bed of size 1250 x 2000 mm,

2 Nos. of T-slotted steel rails,

6 Nos. of Screw columns,

6 Nos. of C.I. Hand-wheels for height adjustment,

Manufacturers of Engine & Vehicle Testing Dynamometers, Automotive component

Test Rigs, Data Acquisition & Control Software, Integration & Automation.

Page 5 of 9

Format No.: DMC/F/MKT/02/PNQ Rev No./Date:02/01.09.2022

Plot No. S-101, ‘S’ Block, M.I.D.C. Bhosari,

Pune – 411 026 Maharashtra (India) Tel: +91-20-40717301

Email: info@dynomerk.in | Website: www.dynomerk.co.in

T-bolts and nuts & Spanner etc.

X axis (Rail Length) is 1900 mm.

Adjustment along Y axis possible is 100 mm to 725 mm w.r.t. centre.

Adjustment along Z axis possible is 500 mm to 700 mm w.r.t. bottom

Overall Dimension in mm ‘Y’ Adjust in mm ‘Z’ Adjust in mm

Sr. No

Length Width Max Min Max Min

1 2020 1250 725 100 700 500

Details of Universal Bed Plate for Engine Mtg

Fig. Universal Bed Plate for Engine Mounting

7. Control panel

Control panel will be provided to house Dynamomet4er Controller unit, Torque Indicator,

Temperature Indicators & Pressure Indicators.

8. Installation material (Qty – 1 no)

- Installation material required to complete the installation.

- This will include, cable trays, conduits, wiring, hardware, flats, support for

mechanical structures, flow pipes, fittings.

- Wiring will be done in such a way that interference and noise will be minimized.

Manufacturers of Engine & Vehicle Testing Dynamometers, Automotive component

Test Rigs, Data Acquisition & Control Software, Integration & Automation.

Page 6 of 9

Format No.: DMC/F/MKT/02/PNQ Rev No./Date:02/01.09.2022

Plot No. S-101, ‘S’ Block, M.I.D.C. Bhosari,

Pune – 411 026 Maharashtra (India) Tel: +91-20-40717301

Email: info@dynomerk.in | Website: www.dynomerk.co.in

9. System Engineering, Design & Integration (Qty – 1 no)

- We will erect the system at our works, all control panel wiring & interfacing of

different instruments mounted in panel will be done. The system will be offered to

your representative for pre dispatch inspection.

Note: Hot firing and testing of Engine is not considered during PDI

10. Project Management & Documentation (Qty – 1 no)

- Our Engineer as a team leader will handle the entire project. He will correspond

with your representative from time to time for progress & status of the project as

well as to discuss & resolve any issues raised during manufacturing process.

11. Packing, Forwarding & Transport (Qty – 1 no)

- Equipment will be packed in standard packaging material, wooden boxes for safe

transport.

- Transport of material from DMC factory upto your plant will be done.

12. Installation & Commissioning (Qty – 01 no)

- This includes installation & commissioning charges of all the work.

- Trails & Proving.

- Training will be provided to the user.

Inclusions:

All the scope as mentioned above

Transport upto your plant at Kolkata

Customer Scope –

All Civil Work

Unloading & shifting of equipment to site.

Material handling equipments

Electrical supply near Control panel

Water supply arrangement and piping for Dyno & Magnetic Water filter

Exhaust Piping

Coolant, fuel, diesel, Compressed air supply etc Piping.

Work Permits and related Documents

Manufacturers of Engine & Vehicle Testing Dynamometers, Automotive component

Test Rigs, Data Acquisition & Control Software, Integration & Automation.

Page 7 of 9

Format No.: DMC/F/MKT/02/PNQ Rev No./Date:02/01.09.2022

Plot No. S-101, ‘S’ Block, M.I.D.C. Bhosari,

Pune – 411 026 Maharashtra (India) Tel: +91-20-40717301

Email: info@dynomerk.in | Website: www.dynomerk.co.in

Annexure II: Prices

Sr. Description Qty Price Total

No Price

1 Eddy Current Dynamometer (EC-700) with Loadcell, 1 21,17,707 21,17,707

Magnetic Pickup & Accessories

2 3 Mode Dynamometer Controller with RPM Indicator 1 3,30,000 3,30,000

3 Torque Indicator 1 28,800 28,800

4 Data Acquisition System with sensors & panel 1 9,00,000 9,00,000

5 Temperature & Pressure indicators 6 21,600 1,29,600

6 Universal Test Bed 1 9,00,000 9,00,000

7 Control Panel 1 96,000 96,000

8 Installation Material 1 2,40,000 2,40,000

9 System Engineering, Design & Integration 1 3,54,000 3,54,000

10 Project Management & Documentation 1

11 Packing, Forwarding & Transportation 1

12 Installation & Commissioning 1 2,40,000 2,40,000

Total 53,36,107

Total Cost of the Project: One Crore Twenty-Nine Lacs Eighty-Nine thousand seven

hundred rupees only.

Manufacturers of Engine & Vehicle Testing Dynamometers, Automotive component

Test Rigs, Data Acquisition & Control Software, Integration & Automation.

Page 8 of 9

Format No.: DMC/F/MKT/02/PNQ Rev No./Date:02/01.09.2022

Plot No. S-101, ‘S’ Block, M.I.D.C. Bhosari,

Pune – 411 026 Maharashtra (India) Tel: +91-20-40717301

Email: info@dynomerk.in | Website: www.dynomerk.co.in

Annexure III: Terms & Conditions

01. Validity 30 days from the date of quotation.

02. Delivery 16 - 18 weeks from the time of receipt of technically &

commercially clear Purchase Order.

03. Payment 50 % of Basic Amt as Advance

40 % of Basic Amt + 100 % GST after Pre Dispatch

Inspection against Proforma Invoice

10 % against completion of I&C

04. Goods and Service Tax (GST) IGST @ 18% or as Extra as Applicable, at the time of

supply

05. P & F Included

06. HSN & SAC Code HSN Code – 90318000

SAC Code - 998732

07. Transportation Included

08. Transit Insurance N.A.

09. Registration Details GSTIN: 27AAAFD8448D1ZJ.

10. Warranty/ Guarantee Against manufacturing defects only for 12 months

from the date of commissioning or 13 months from the

date of delivery whichever is earlier. All bought out

items will have warranty from respective supplier as

per supplier’s warranty clause. Liability of Dynomerk

Controls is restricted to replacement of faulty parts

.Dynomerk Controls will not be liable for

consequential damages.

We trust that our offer is in line with your requirements.

Thanking you & assuring our best services

For Dynomerk Controls,

Rajesh Vaidya

Marketing Dept.

Mb. +91 99701 96143

Manufacturers of Engine & Vehicle Testing Dynamometers, Automotive component

Test Rigs, Data Acquisition & Control Software, Integration & Automation.

Page 9 of 9

Format No.: DMC/F/MKT/02/PNQ Rev No./Date:02/01.09.2022

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Caltex Product CatalogueDocument34 pagesCaltex Product CatalogueAR YelNo ratings yet

- Quotation KTC Ekke 10 16 Ton KTCDocument4 pagesQuotation KTC Ekke 10 16 Ton KTCandraNo ratings yet

- RFQ - Motorized Traveling ChuteDocument17 pagesRFQ - Motorized Traveling ChuteBasabRajNo ratings yet

- Voltage Probe P5100A BNGEE010!3!2-2Document33 pagesVoltage Probe P5100A BNGEE010!3!2-2maniNo ratings yet

- Mass CIMD1 - 230503 - 202317Document3 pagesMass CIMD1 - 230503 - 202317Ajay KumarNo ratings yet

- TPL PDFDocument2 pagesTPL PDFbanit kumar hazraNo ratings yet

- Ensun CQ 21-22 00061Document1 pageEnsun CQ 21-22 00061sugunec2013No ratings yet

- Penawaran CV - Batara BayuDocument4 pagesPenawaran CV - Batara BayuMuhammad FarrasNo ratings yet

- Po - No - 2225 - TCS Indore Manibhadra Electricals PVT LTD RevDocument1 pagePo - No - 2225 - TCS Indore Manibhadra Electricals PVT LTD Revy8jkfz98m9No ratings yet

- Vibration Monitoring Crusher CoalDocument8 pagesVibration Monitoring Crusher CoalJay SantosNo ratings yet

- Larsen Toubro Purchase OrderDocument8 pagesLarsen Toubro Purchase OrderNilenduNo ratings yet

- 0006 - CQ 2021-22 - Chennai Analytical LabDocument1 page0006 - CQ 2021-22 - Chennai Analytical LabSaravana VelNo ratings yet

- Scope of Work NIT 9900217682 FinalDocument43 pagesScope of Work NIT 9900217682 Finalabhi_1mehrotaNo ratings yet

- PDF PO 246 Koel Care Oil 15W40 28.03.2024Document1 pagePDF PO 246 Koel Care Oil 15W40 28.03.2024Karthikeyan RajamanickamNo ratings yet

- Adobe Scan 15-Nov-2023Document6 pagesAdobe Scan 15-Nov-2023mussaermgmNo ratings yet

- SiemensDocument8 pagesSiemensivomNo ratings yet

- Arcelor Mittal Nippon Steel India (Am/Ns) Paradeep, Odisha Technical Specification FORDocument12 pagesArcelor Mittal Nippon Steel India (Am/Ns) Paradeep, Odisha Technical Specification FORBasabRajNo ratings yet

- 73 TukaramDocument2 pages73 TukaramAnita ChavanNo ratings yet

- RQF 10406905 RepsDocument11 pagesRQF 10406905 Repsdavid selekaNo ratings yet

- E+H 2009691644 RevDocument8 pagesE+H 2009691644 Revkahwooi88No ratings yet

- Theji TTMDocument3 pagesTheji TTMHemanth KumarNo ratings yet

- AD.224. MR - Sachin MalhotraDocument2 pagesAD.224. MR - Sachin MalhotraVikas BhadNo ratings yet

- MPEZ RAO Chhatarpur - Standard Purchase Order 32902,0 For 598833.11 INR Requires Your ApprovalDocument2 pagesMPEZ RAO Chhatarpur - Standard Purchase Order 32902,0 For 598833.11 INR Requires Your ApprovalnaveenNo ratings yet

- MPEZ RAO Chhatarpur - Standard Purchase Order 32902,0 For 598833.11 INR Requires Your ApprovalDocument2 pagesMPEZ RAO Chhatarpur - Standard Purchase Order 32902,0 For 598833.11 INR Requires Your ApprovalnaveenNo ratings yet

- 0006 - CQ 2021-22 - Chennai Analytical Lab-1Document1 page0006 - CQ 2021-22 - Chennai Analytical Lab-1Saravana VelNo ratings yet

- Cimec Technologies Private Limited: Shree Vinayak Concrete SolutionDocument3 pagesCimec Technologies Private Limited: Shree Vinayak Concrete SolutionRavindrakumar GajjarNo ratings yet

- Xerox - COD BOD TSS PHDocument3 pagesXerox - COD BOD TSS PHmukesh k2No ratings yet

- Technical DetailsDocument3 pagesTechnical DetailsRohit GoelNo ratings yet

- QuotationDocument2 pagesQuotationRajnish MauryaNo ratings yet

- MCK Kutty Engineers PVT LimitedDocument22 pagesMCK Kutty Engineers PVT LimitedMunthaqirNo ratings yet

- Weigh Bridge PDFDocument7 pagesWeigh Bridge PDFUmair Ft SteynNo ratings yet

- Radix - 633Document2 pagesRadix - 633Arjun BharambeNo ratings yet

- NTPC Limited: (A Government of India Enterprise)Document10 pagesNTPC Limited: (A Government of India Enterprise)Amit VijayvargiNo ratings yet

- Tube 50X25X2MMDocument1 pageTube 50X25X2MMkrishnalalNo ratings yet

- Sub:Procurement Of11Kv, 3 Core, Pvcarmoured Power Cables. Ref.: (I) Adv. No. 03/2016-17, Tender Si No019Document22 pagesSub:Procurement Of11Kv, 3 Core, Pvcarmoured Power Cables. Ref.: (I) Adv. No. 03/2016-17, Tender Si No019okman17No ratings yet

- The Executive Engineer, Public Health Division, EluruDocument24 pagesThe Executive Engineer, Public Health Division, EluruRaviteja ReddNo ratings yet

- 54102 PUMP (1)Document2 pages54102 PUMP (1)vinodkumarbalaga111No ratings yet

- Quote To Takii Seeds India Private Limited: 50Mm (2") Electromagnetic Flow MeterDocument2 pagesQuote To Takii Seeds India Private Limited: 50Mm (2") Electromagnetic Flow MetersunilNo ratings yet

- Shiva Alloys Mandi Gobindgarh - Met. Lab Eqpts.Document3 pagesShiva Alloys Mandi Gobindgarh - Met. Lab Eqpts.Mandeep SodhiNo ratings yet

- Arduino Based Tachometer Plus Speed ControlDocument41 pagesArduino Based Tachometer Plus Speed Controlujjwal mishra100% (1)

- FlowtechDocument2 pagesFlowtechvikramchowdaryNo ratings yet

- 920-Article Text-6483-1-10-20230926Document7 pages920-Article Text-6483-1-10-20230926kamutegar1No ratings yet

- 05 HIGHTENSION DOFs 12kV-24kV-36kV, 100ADocument2 pages05 HIGHTENSION DOFs 12kV-24kV-36kV, 100AAnkit SinghNo ratings yet

- Evoqua 1Document8 pagesEvoqua 1roman reignsNo ratings yet

- Vedantam - Semi AutomaticDocument1 pageVedantam - Semi AutomaticvishalNo ratings yet

- Test Certificate: CM/L-NO:5530357Document2 pagesTest Certificate: CM/L-NO:5530357pranav kariaNo ratings yet

- 041:DCS Qo:fr:v:2024Document4 pages041:DCS Qo:fr:v:2024Muhammad FarrasNo ratings yet

- Techno-Commercial OfferDocument6 pagesTechno-Commercial OfferharishNo ratings yet

- Simhadri Super Thermal Power ProjectDocument7 pagesSimhadri Super Thermal Power Projectvenkatesh bitraNo ratings yet

- QAP For Flow MeterDocument7 pagesQAP For Flow MeterhiyogsNo ratings yet

- Royal 056Document1 pageRoyal 056vaibhavpokale1997No ratings yet

- Material To Be Supplied by The MPMKVVCLDocument2 pagesMaterial To Be Supplied by The MPMKVVCLashi ashiNo ratings yet

- Work Order MAK Pump CompanyDocument3 pagesWork Order MAK Pump CompanyNouman AkhtarNo ratings yet

- Quote (PTT 24-25 022)Document1 pageQuote (PTT 24-25 022)Maiank Sri SinghNo ratings yet

- 10kw Ongrid Elevated 15kw Inverter G14Document5 pages10kw Ongrid Elevated 15kw Inverter G14Syed Zahoor SheraziNo ratings yet

- MPEZ RAO Chhatarpur - Standard Purchase Order 32905,0 For 284094.51 INR Requires Your ApprovalDocument2 pagesMPEZ RAO Chhatarpur - Standard Purchase Order 32905,0 For 284094.51 INR Requires Your ApprovalnaveenNo ratings yet

- QuotationDocument2 pagesQuotation92nikhilNo ratings yet

- PDFDocument34 pagesPDFSandeep Ardale100% (1)

- Techno-Commercial Offer For Supply of DPG and Flowmeter: Mohit Singh (9722101558)Document5 pagesTechno-Commercial Offer For Supply of DPG and Flowmeter: Mohit Singh (9722101558)Santhosh Reddy BNo ratings yet

- Submission of Vendor Proposal For AWSDocument5 pagesSubmission of Vendor Proposal For AWSSakshi SemwalNo ratings yet

- Line-40 - Ga-Rh-240128-Cyl-418 - Feed Tilt Cylinder - (125-50-290) - (MMPL) - R1Document1 pageLine-40 - Ga-Rh-240128-Cyl-418 - Feed Tilt Cylinder - (125-50-290) - (MMPL) - R1Karthii AjuNo ratings yet

- TNSTCDocument1 pageTNSTCKarthii AjuNo ratings yet

- Line-30 - Ga-Rh-240128-Cyl-417 - Boom Extension Cylinder - (80-50-1038) - (MMPL) - R1Document1 pageLine-30 - Ga-Rh-240128-Cyl-417 - Boom Extension Cylinder - (80-50-1038) - (MMPL) - R1Karthii AjuNo ratings yet

- MCN Resume Updated 22nd SepDocument3 pagesMCN Resume Updated 22nd SepKarthii AjuNo ratings yet

- Sos GainwellDocument4 pagesSos GainwellKarthii AjuNo ratings yet

- Asn To KolDocument1 pageAsn To KolKarthii AjuNo ratings yet

- Oil Analysis Offer - MMPL2Document2 pagesOil Analysis Offer - MMPL2Karthii AjuNo ratings yet

- Engine - Commissioning Check SheetDocument1 pageEngine - Commissioning Check SheetKarthii AjuNo ratings yet

- Quotation For Oil TestingDocument1 pageQuotation For Oil TestingKarthii AjuNo ratings yet

- Travel Request Form 2022Document1 pageTravel Request Form 2022Karthii AjuNo ratings yet

- Invoice HEGFD20220210335Document1 pageInvoice HEGFD20220210335Karthii AjuNo ratings yet

- Distribution Business Unit Cummins Field Service Report Deccan Sales and Services Private Limited (Indore)Document2 pagesDistribution Business Unit Cummins Field Service Report Deccan Sales and Services Private Limited (Indore)Karthii AjuNo ratings yet

- lh410 48 Technical Specifications EnglishDocument18 pageslh410 48 Technical Specifications EnglishKarthii AjuNo ratings yet

- Distribution Business Unit Cummins Field Service Report Deccan Sales and Services Private Limited (Indore)Document2 pagesDistribution Business Unit Cummins Field Service Report Deccan Sales and Services Private Limited (Indore)Karthii AjuNo ratings yet

- Holiday List 2023 - APPROVEDDocument1 pageHoliday List 2023 - APPROVEDKarthii AjuNo ratings yet

- AssessmentDocument19 pagesAssessmentKarthii AjuNo ratings yet

- EX110 Observation ReportDocument7 pagesEX110 Observation ReportKarthii AjuNo ratings yet

- Torque Specifications - Fasteners: Nut and Bolt Size, MM 280M or Better Torque, N M 280M or Better Torque, LB FTDocument1 pageTorque Specifications - Fasteners: Nut and Bolt Size, MM 280M or Better Torque, N M 280M or Better Torque, LB FTKarthii AjuNo ratings yet

- Hydraulic Room Drawing PDF 3 ColourDocument1 pageHydraulic Room Drawing PDF 3 ColourKarthii AjuNo ratings yet

- Attachment Parts For Starting Motor & AlternatorDocument6 pagesAttachment Parts For Starting Motor & AlternatorKarthii AjuNo ratings yet

- Camshaft and Timing Parts (Bus) Mercedes OM 904 LA: (Europa) (Engine)Document4 pagesCamshaft and Timing Parts (Bus) Mercedes OM 904 LA: (Europa) (Engine)Karthii AjuNo ratings yet

- Air Compressor (Bus) Mercedes OM 904 LA: (Europa) (Engine)Document11 pagesAir Compressor (Bus) Mercedes OM 904 LA: (Europa) (Engine)Karthii AjuNo ratings yet

- Application Systems: Powder DynamometersDocument6 pagesApplication Systems: Powder DynamometersKarthii AjuNo ratings yet

- Air Compressor Attachment PartsDocument5 pagesAir Compressor Attachment PartsKarthii AjuNo ratings yet

- List of Customers: ISO 9001:2015 Certified CertifiedDocument5 pagesList of Customers: ISO 9001:2015 Certified CertifiedKarthii AjuNo ratings yet

- Alternator (Bus) Mercedes OM 904 LA: (Europa) (Engine)Document21 pagesAlternator (Bus) Mercedes OM 904 LA: (Europa) (Engine)Karthii AjuNo ratings yet

- Gear Box Test SetupDocument20 pagesGear Box Test SetupKarthii AjuNo ratings yet

- Tandem DynamometersDocument5 pagesTandem DynamometersKarthii AjuNo ratings yet

- Electronic Parts Catalog - Option DetailDocument2 pagesElectronic Parts Catalog - Option DetailKarthii AjuNo ratings yet

- SVMX101 ILT Workbook - CORE 22.1 LightningDocument88 pagesSVMX101 ILT Workbook - CORE 22.1 LightningRygel OrionisNo ratings yet

- Object-Oriented Programming, C++ and Power System SimulationDocument10 pagesObject-Oriented Programming, C++ and Power System SimulationjasonkinNo ratings yet

- Assembly 1Document5 pagesAssembly 1Renpin LuoNo ratings yet

- UntitledDocument12 pagesUntitledBenedikta ArangkojaNo ratings yet

- IIOT For Production & MaintenanceDocument34 pagesIIOT For Production & Maintenancedheepmax100% (1)

- Parallel OperationDocument54 pagesParallel OperationGabriel Paco LunaNo ratings yet

- EPass2003 User Guide EDocument40 pagesEPass2003 User Guide ERodrigo DanielNo ratings yet

- AVM MTA Provisioning Guide v07 PDFDocument12 pagesAVM MTA Provisioning Guide v07 PDFMatija ColakovicNo ratings yet

- Blockchain Hands On TutorialDocument51 pagesBlockchain Hands On Tutorialagnelwaghela100% (1)

- Imajview PDFDocument2 pagesImajview PDFEsteban Colque RamosNo ratings yet

- MFJ-2389 Instruction ManualDocument8 pagesMFJ-2389 Instruction ManualMaria UrsuNo ratings yet

- Hpc-9ca-01-0002-2012 - STD - Numbering and Titling SpecificationDocument54 pagesHpc-9ca-01-0002-2012 - STD - Numbering and Titling SpecificationAli KayaNo ratings yet

- CNE 532 Computer Networks: L-T-P - (C) 3-0-2Document9 pagesCNE 532 Computer Networks: L-T-P - (C) 3-0-2VISHAL MISHRANo ratings yet

- NEOPLAN 75 YEARS Moving IdeasDocument20 pagesNEOPLAN 75 YEARS Moving IdeasDušan PetrovićNo ratings yet

- Anti Surge ControlDocument15 pagesAnti Surge Controlella arunNo ratings yet

- New Umbrella EntityDocument5 pagesNew Umbrella EntityKunwarbir Singh lohatNo ratings yet

- Tejas Bhandari Final ReportDocument77 pagesTejas Bhandari Final ReportPavan BarhateNo ratings yet

- PL Course FileDocument15 pagesPL Course FileparbhatvermaNo ratings yet

- T-Gage VDocument2 pagesT-Gage VRushikesh JoshiNo ratings yet

- Icassp40776 2020 9053737Document5 pagesIcassp40776 2020 9053737Prasad NizampatnamNo ratings yet

- Multimedia CommunicationDocument2 pagesMultimedia Communicationvinod kumar B VNo ratings yet

- Car - V2 Ie 1038959Document36 pagesCar - V2 Ie 1038959bogdanNo ratings yet

- Microelectronic CapsuleDocument20 pagesMicroelectronic CapsuleMouni BoomiReddyMounikaNo ratings yet

- UTStarcom NetRing TN705 2028Document2 pagesUTStarcom NetRing TN705 2028smithm007100% (1)

- Title Navigating The Evolving Landscape of Digital EvidenceDocument5 pagesTitle Navigating The Evolving Landscape of Digital Evidencelarebgul08No ratings yet

- E13100 0 09 10 - MaschR PDFDocument32 pagesE13100 0 09 10 - MaschR PDFGonzalo Alvarez100% (1)

- Raptor User's Manual PDFDocument152 pagesRaptor User's Manual PDFIchim NasuiNo ratings yet

- Sma 700UDocument2 pagesSma 700UAnonymous w5SJiLsNo ratings yet

- Exide Multifit Leisure Battery BrochureDocument8 pagesExide Multifit Leisure Battery BrochureTommaso ScigliuzzoNo ratings yet