Professional Documents

Culture Documents

Welding Repair Procedure BHEL

Welding Repair Procedure BHEL

Uploaded by

Prabir PalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Repair Procedure BHEL

Welding Repair Procedure BHEL

Uploaded by

Prabir PalCopyright:

Available Formats

BHEL Tiruchirappalli, 620014, India.

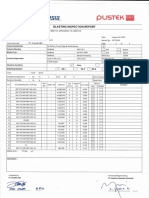

DOC No : CIP:613 Rev : 00

Quality Assurance Department Effective Date : 02/04/2013

CONTRACT INSPECTION PROCEDURE Page: 1 of 2

Background: It was reported from FES through email dated: 02/04/2013 that Coils failed at XXX

site.

Material Specification & Size:

Tube - SA213 T22 D 44.5x7.1mm

Tube - SA213 T91 D 44.5x5.6mm; D 44.5x5.7mm

Tube - SA 213 TP347H D 63.5x8.0mm

Roof Seal Band - SA387 Gr 22 Cl2 6x140.1x2060.3mm

Flexible male and Female connectors - SA351 Gr CH20

Reference Documents:

IBR

ASME Section I

Drg No: 0-11-095-00671, 0-11-095-00674, 0-11-095-00675, 0-11-095-00676, 2-11-095-06029.

Repair Procedure:

1. Obtain necessary approval from the Statutory Authorities as required.

2. Only IBR qualified welders shall be used.

3. Identify the panel coils which got failed.

0 0

4. All electrodes shall be baked at 300-350 C for 2 hour and maintained at 150 C till use.

5. Mark the failed tubes, roof seal bands and flexible male, female connectors and remove the defective

portions by cutting and / or grinding.

6. Based on the material combinations, parameters mentioned in the Table.1 to be followed for welding,

PWHT and NDT.

7. Wherever Gr 91 welding is involved, after completion of welding, allow the component to cool below

950C and commence PWHT immediately. All NDT shall be carried out after PWHT only.

0 0

8. Rate of heating and cooling shall not exceed 220 C/hr above 350 C for all the above PWHT cycles.

Documentation: Record the details of repair carried out with correlation to welder(s), heat treatment and

NDE reports.

Prepared By Reviewed and Approved By

Venkanna Rupani S. Selvarajan

You might also like

- Material Selection For A Rocket Fuel TankDocument9 pagesMaterial Selection For A Rocket Fuel TanksamNo ratings yet

- GD SP NDT 2Document47 pagesGD SP NDT 2AhmedNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: TEST CERTIFICATE (EN 10204.3.1)Document1 pageNingbo Dongxin High-Strength Nut Co.,Ltd: TEST CERTIFICATE (EN 10204.3.1)GLORIA MONSALVE SALAZARNo ratings yet

- Welder CTS2.0 NSQF-3Document40 pagesWelder CTS2.0 NSQF-3Prasanta DasNo ratings yet

- BV Specimen Certificate - Embarkation or Pilot LaddersDocument2 pagesBV Specimen Certificate - Embarkation or Pilot LaddersMeghna S I Shipping100% (1)

- S1450401-Execution and Inspection of Welding WorkDocument26 pagesS1450401-Execution and Inspection of Welding Workkeeoraon4No ratings yet

- Welding Distortion and Warpage: June 13, 2022 byDocument20 pagesWelding Distortion and Warpage: June 13, 2022 byArnab Goswami100% (1)

- QAP - Rubber liningBORLDocument1 pageQAP - Rubber liningBORLdada shaikNo ratings yet

- Welding Procedure Qualification Record: Welded ToDocument6 pagesWelding Procedure Qualification Record: Welded ToParis VNo ratings yet

- Parametros de SoldaduraDocument17 pagesParametros de SoldaduraBenjamin Alvarez MedinaNo ratings yet

- IGQ0811.100379 - Dye Penetrant Inspection According To API 6D - Rev2Document8 pagesIGQ0811.100379 - Dye Penetrant Inspection According To API 6D - Rev2Lili100% (1)

- Final Draft IRS M-39-2020Document27 pagesFinal Draft IRS M-39-2020sanoj kaushikNo ratings yet

- RedBus Ticket - TR6S26340861Document4 pagesRedBus Ticket - TR6S26340861tushar trivediNo ratings yet

- Report Blasting PDFDocument22 pagesReport Blasting PDFLord MobileNo ratings yet

- GW Air Cooled Handheld Laser Welder System ENDocument58 pagesGW Air Cooled Handheld Laser Welder System ENAleksander VassiljevNo ratings yet

- (First Revision) : Specification FOR Crane Rail SectionsDocument19 pages(First Revision) : Specification FOR Crane Rail SectionsNeo NaveenNo ratings yet

- Procedure Progress ISO 3834 2 PDFDocument3 pagesProcedure Progress ISO 3834 2 PDFKumar DNo ratings yet

- Peb Fabrication Project WorkDocument16 pagesPeb Fabrication Project Workmadhu krishnaNo ratings yet

- Saic W 2011Document3 pagesSaic W 2011munnaNo ratings yet

- Gauges and InstrumentsDocument14 pagesGauges and InstrumentsRatan Misra100% (1)

- Analysis of Cast Iron by Spark Atomic Emission Spectrometry: Standard Test Method ForDocument7 pagesAnalysis of Cast Iron by Spark Atomic Emission Spectrometry: Standard Test Method ForcommandoNo ratings yet

- 0268 - Company Profile of Joint Filler - Jolly Board Bitumen IDocument15 pages0268 - Company Profile of Joint Filler - Jolly Board Bitumen INalaka Santhajeewa100% (1)

- QC Welding Inspector NotesDocument26 pagesQC Welding Inspector NotesSohail Aziz Ahmad MalikNo ratings yet

- New QC MPR Format, Oct.22,09.11.2022Document14 pagesNew QC MPR Format, Oct.22,09.11.2022Devendra SinghNo ratings yet

- B - 8.6 - ZSS004 STD Spec For Fabrication Erection of PipingDocument23 pagesB - 8.6 - ZSS004 STD Spec For Fabrication Erection of PipingRajeswari MohantyNo ratings yet

- Metallic Material Specification: Title: AISI 8630 Mod Alloy Steel, 80 KSI Min Yield StrengthDocument5 pagesMetallic Material Specification: Title: AISI 8630 Mod Alloy Steel, 80 KSI Min Yield StrengthReginaldo SantosNo ratings yet

- Chase Testing PresentationDocument18 pagesChase Testing PresentationDiego Chavez0% (1)

- Vijay Resume 1Document5 pagesVijay Resume 1sathyajiNo ratings yet

- Iso 16162 2012 en PDFDocument6 pagesIso 16162 2012 en PDFSon NguyenNo ratings yet

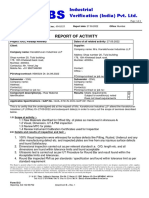

- Report of Activity - DTD 27.09.2022Document4 pagesReport of Activity - DTD 27.09.2022Dilip PatilNo ratings yet

- BS 8503-1Document17 pagesBS 8503-1HaiNo ratings yet

- Different Material STD ComparisionDocument15 pagesDifferent Material STD ComparisionKamal RajuNo ratings yet

- Chain Sling-Terminal 2Document4 pagesChain Sling-Terminal 2YasirNo ratings yet

- Maintenance Practices & Manual For POH of Schaku Couplers: 2019-20 8/1.0 October 2019Document55 pagesMaintenance Practices & Manual For POH of Schaku Couplers: 2019-20 8/1.0 October 2019carriage drawingNo ratings yet

- Pressure Test RecordDocument4 pagesPressure Test RecordhikmahNo ratings yet

- Indian Railways WeldingDocument9 pagesIndian Railways WeldingMohanNo ratings yet

- 823 (August, 2019)Document830 pages823 (August, 2019)SalikNo ratings yet

- Vorplex JHA Acid PickingDocument12 pagesVorplex JHA Acid PickingAmirHakimRusliNo ratings yet

- BS 1724 (Bronze Welding by Gas)Document24 pagesBS 1724 (Bronze Welding by Gas)nandi_scrNo ratings yet

- WELD-2008v05 Down To The WireDocument2 pagesWELD-2008v05 Down To The WirepeterNo ratings yet

- Awareness On en 15085Document5 pagesAwareness On en 15085SamsuNo ratings yet

- QMS - CA Exercise ISODocument3 pagesQMS - CA Exercise ISOBharat DigheNo ratings yet

- Welding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchDocument4 pagesWelding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchaNo ratings yet

- T-SS-SA-1166 - 120414 - Welding Process Control Procedure (SG2425-CST-007) Rev.0Document110 pagesT-SS-SA-1166 - 120414 - Welding Process Control Procedure (SG2425-CST-007) Rev.0Akansha SharmaNo ratings yet

- W14X26 BodegaDocument2 pagesW14X26 BodegaIvan PorrasNo ratings yet

- Saudi Aramco Oil Company: SECTION 03251 Construction, Expansion and Contraction JointsDocument6 pagesSaudi Aramco Oil Company: SECTION 03251 Construction, Expansion and Contraction Jointssaneela bibiNo ratings yet

- Eng052 20erw 000 Qa WQS 0015 000 - 01Document6 pagesEng052 20erw 000 Qa WQS 0015 000 - 01Mohammed ShehinNo ratings yet

- Mill CertDocument6 pagesMill Certharrys manaluNo ratings yet

- MTC Plate 6MM SS540Document2 pagesMTC Plate 6MM SS540Nofa Duta hitaNo ratings yet

- CNC Vertical Milling Machine: SuryaDocument4 pagesCNC Vertical Milling Machine: SuryaDesign PewbinderyNo ratings yet

- Certified Piping and Mechanical Quality Control (QC) InspectorDocument10 pagesCertified Piping and Mechanical Quality Control (QC) InspectorWilson NjangeNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- NDE Rev.1 July 2021Document145 pagesNDE Rev.1 July 2021luthfi otoy100% (1)

- NCR HistoryDocument2 pagesNCR HistoryAgam SehgalNo ratings yet

- Daytime Colorimetric Properties of Fluorescent Retroreflective Sheeting and Marking Materials For High Visibility Traffic Control and Personal Safety Applications Using 45°:normal GeometryDocument6 pagesDaytime Colorimetric Properties of Fluorescent Retroreflective Sheeting and Marking Materials For High Visibility Traffic Control and Personal Safety Applications Using 45°:normal GeometryEnriqueVeNo ratings yet

- Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)Document3 pagesMetal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)rohitNo ratings yet

- Asme Sections ListDocument1 pageAsme Sections ListShreekanthKannathNo ratings yet

- SOP - 03C Rev 1 Weld Shop PDFDocument9 pagesSOP - 03C Rev 1 Weld Shop PDFGohilakrishnan Thiagarajan100% (1)

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocument3 pagesTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanNo ratings yet

- TDC QapDocument69 pagesTDC QapKuppuraj ParamsivamNo ratings yet

- Scan 0016975Document4 pagesScan 0016975Prabir PalNo ratings yet

- Order 5000017228Document4 pagesOrder 5000017228Prabir PalNo ratings yet

- WPRM-51 (Bhel) 30.04.22 SignedDocument1 pageWPRM-51 (Bhel) 30.04.22 SignedPrabir PalNo ratings yet

- Img 20220705 0001Document1 pageImg 20220705 0001Prabir PalNo ratings yet

- Turbine Crosssection 24966 - HW-DG-445-STE-N003Document1 pageTurbine Crosssection 24966 - HW-DG-445-STE-N003Prabir PalNo ratings yet

- PE-DC-445-651-C001 R0 Reviewed 20210621Document19 pagesPE-DC-445-651-C001 R0 Reviewed 20210621Prabir PalNo ratings yet

- 2020 12 31 Balance Punch Points On COD - AS ON 31.12.2020WBPDCL DraftDocument2 pages2020 12 31 Balance Punch Points On COD - AS ON 31.12.2020WBPDCL DraftPrabir PalNo ratings yet

- 00 Letter For Reimburshment of Unit 3 Work After COD On PDCL RequestDocument13 pages00 Letter For Reimburshment of Unit 3 Work After COD On PDCL RequestPrabir PalNo ratings yet