Professional Documents

Culture Documents

A 12 FT Skiff - Free Boat Plans

A 12 FT Skiff - Free Boat Plans

Uploaded by

Ricardo DiasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A 12 FT Skiff - Free Boat Plans

A 12 FT Skiff - Free Boat Plans

Uploaded by

Ricardo DiasCopyright:

Available Formats

A 12 ft skiff

A 12' two sheet skiff

Yet another way of chopping up two sheets of plywood, to come up with a very easy-to-build, yet good looking and versatile 12 ft skiff.

This skiff follows the lines and building methods initially set up in the plans and building instructions for the Portuquese Style Dinghy and later in the 10 1/2 ft Skiff.

The design and building method is basically the same.

The boat sides are cut with straight cut edges, no lofting is needed.

The sides are bent around three mold frames and a transom, all of which stay in the finished boat. This is clearly a bigger boat than the Portuquese Style Dinghy or the 10 1/2 ft Skiff, so

real frames are needed for strength, rather than just pieces of batten to set the beam at frame positions.

The shape of the bottom panel is drawn using the assembled sides-frames-transom as a template.

See the detailed building instructions at the Portuquese Style Dinghy page.

A 12 ft skiff is about the maximum You can get out of two sheets of plywood, and still have the traditional skiff looks. Cutting the plywood for this boat You will be using about 91 % of the

surface area of two sheets of plywood. Very little waste, that is. Hardly enough for a pair of oar blades.

That's called "economical and ecological use of material" :-)

So, materialwise You couldn't get much more out of two sheets of plywood.

Here's the .hul file for this skiff.

The sides are cut out of one sheet of 1/4" plywood. Both sides will have one butt seam.

The plywood sheet standard in the following pictures is 122 cm x 244 cm = 48" x 96" = 4' x 8'. There are other "standard" plywood sizes, too, but this is probably the most common standard.

The transom and bottom are cut out of the other sheet. The transom is laminated out of two identical pieces, to get a stiffer result.

The bottom will have one butt seam, and needs to be patched at the very bow and on one side forward of the butt seam. Small pieces of plywood can be used for the patches, the patched

locations will end up under the chine glassfiber tapings, so they won't be visible in the finished boat.

Measurements for the sides.

And measurements for the frames and the transom.

The angle of the bow is 50 degrees, so cut the stem piece accordingly.

Resistance curves at 150 kg / 330 lbs total displacement

Rt (violet curve) = total resistance

Rv (red curve) = viscous resistance (friction)

Rw (blue curve) = wave forming resistance

Rh (pale blue curve) = resistance created by transom stern

Full speed scale = 4.0 m/s = 14.4 km/h = 9.0 mph = 7.8 knots

Two suggested seat positioning alternatives

The lengthwise balance point of the boat is at the mid frame B, so if the boat is mainly going to be used by a single person, the best location for the "main" rowing seat is with the seat rear

edge at the mid frame location.

A possible front rowing seat, and a rear passenger seat are suggested. These can be used with a crew of two.

The problem with this seating arrangement is that the optimum oar lengths are different for the main and front rowing positions. The optimum length for the main position is 225 cm / 7.5 ft,

and 195 cm / 6.5 ft for the front position.

Another possible seating arrangement, where there are two rowing seats with identical optimum oar lengths. When rowing alone the front seat would be best when rowing against the wind,

the middle seat would be best rowing with the wind or in sidewind.

The optimum oar length in this case is 210 cm / 7 ft.

Top of the page.

Back to main page.

You might also like

- Singapore Coc-1 Master Oral PreparationDocument195 pagesSingapore Coc-1 Master Oral Preparationcaptainkhan1977100% (14)

- Bonnie Two SailboatDocument18 pagesBonnie Two SailboatJim96% (27)

- Pirogue PlansDocument6 pagesPirogue Plansnative11247250% (2)

- Micro Auray PuntDocument9 pagesMicro Auray PuntAlphamatrix01No ratings yet

- "Subsport" Canoe & Kayak, June 2008Document5 pages"Subsport" Canoe & Kayak, June 2008samuelbass@comcast.netNo ratings yet

- Cargo Ship Safety Equipment SurveyDocument5 pagesCargo Ship Safety Equipment SurveyChamika Dilshan WickramawardenaNo ratings yet

- One Sheet Boat, - More Info On Boat Building - The PrismDocument26 pagesOne Sheet Boat, - More Info On Boat Building - The PrismJoe RowingNo ratings yet

- TFGDocument46 pagesTFGAlex Gigena50% (2)

- Duck SkiffDocument61 pagesDuck SkiffKay Pratt100% (2)

- 1588 English Galleon 1Document48 pages1588 English Galleon 1Lucian100% (4)

- Hull PlankingDocument3 pagesHull PlankingFellipe Silva Martins100% (4)

- A 15'8" Fishing Punt: Start of The DiscussionDocument21 pagesA 15'8" Fishing Punt: Start of The DiscussionArmando GumucioNo ratings yet

- Trixie 7 Dinghy - Study PlansDocument16 pagesTrixie 7 Dinghy - Study Planssaiga30894170% (1)

- Le Ptit GrosDocument10 pagesLe Ptit GrosKeith Williams100% (1)

- A Light Sculling Training Boat PDFDocument8 pagesA Light Sculling Training Boat PDFLuis BraulinoNo ratings yet

- PelicstudyDocument23 pagesPelicstudylulucf11No ratings yet

- Two DoriesDocument10 pagesTwo DoriesAlphamatrix01No ratings yet

- X Class ConstructionDocument21 pagesX Class Constructiontdfsks50% (2)

- Čamac Od KedraDocument58 pagesČamac Od KedraБ. А.No ratings yet

- Aquarail JetskiDocument6 pagesAquarail Jetskitony_williams_4No ratings yet

- Barton Skiff... 15ft 4in, by 4ft 8in, by 650lbs Displacement Outboard SkiffDocument9 pagesBarton Skiff... 15ft 4in, by 4ft 8in, by 650lbs Displacement Outboard SkiffStanlei FernandaNo ratings yet

- Julie Skiff NotesDocument4 pagesJulie Skiff NotesSorin DirjanNo ratings yet

- Canoe CatalogueDocument103 pagesCanoe CatalogueTom Ejerie100% (1)

- Vultee A-31 VengeanceDocument4 pagesVultee A-31 VengeanceAviation/Space History LibraryNo ratings yet

- Motor Boats & Launch CatalogueDocument98 pagesMotor Boats & Launch CatalogueDeganchileNo ratings yet

- Julie SkiffDocument4 pagesJulie SkiffDan100% (1)

- Blondie Sailboat Boat Plans John Bell Full ChapterDocument35 pagesBlondie Sailboat Boat Plans John Bell Full Chapterreynaldo.bailey262100% (7)

- Gee Bee Super SportsterDocument8 pagesGee Bee Super SportsterAviation/Space History LibraryNo ratings yet

- 'Blondie' (8'4" X 4'3") 2001-John Bell, Kennesaw, GA JMB-002Document13 pages'Blondie' (8'4" X 4'3") 2001-John Bell, Kennesaw, GA JMB-002Isaac Perez Garcia100% (1)

- Kastri 12: Study PlansDocument19 pagesKastri 12: Study PlansGEORGE KARYDIS0% (1)

- Study Plans 1 - S-16 N S-19Document23 pagesStudy Plans 1 - S-16 N S-19Joao CalinhoNo ratings yet

- Materials:: Geoff Burke L.L.BeanDocument4 pagesMaterials:: Geoff Burke L.L.BeantwinscrewcanoeNo ratings yet

- Building A Cedar-Strip Kayak: The Basics - SkyAboveUs PDFDocument38 pagesBuilding A Cedar-Strip Kayak: The Basics - SkyAboveUs PDFDrodaNo ratings yet

- 3sd Free Boat PlansDocument15 pages3sd Free Boat Plansleather_nun100% (1)

- Vintage Wood Boat Plans 1950sDocument123 pagesVintage Wood Boat Plans 1950ssjdarkman1930100% (5)

- ERCO 415-A ErcoupeDocument8 pagesERCO 415-A ErcoupeAviation/Space History LibraryNo ratings yet

- CatamaranDocument47 pagesCatamarannecatiygt100% (1)

- Wingsoul Easiest To Build Wing SailDocument18 pagesWingsoul Easiest To Build Wing Saillulucf11No ratings yet

- South Haven Dory PlansDocument9 pagesSouth Haven Dory PlansAlphamatrix01No ratings yet

- Module 4b Municipal Fishing BoatDocument5 pagesModule 4b Municipal Fishing BoatErine ContranoNo ratings yet

- How To Build Your First Surfboard by Stephen PirschDocument106 pagesHow To Build Your First Surfboard by Stephen PirschRichard SilvaNo ratings yet

- Woodworking TipsDocument602 pagesWoodworking Tipstrimadge100% (1)

- Bread and Butter Model Boat ConstructionDocument7 pagesBread and Butter Model Boat ConstructionindumarnicaraguaNo ratings yet

- Make Your Own Snowflake - A Rubber Band Powered Foam Plate Airplane - EndlessliftDocument191 pagesMake Your Own Snowflake - A Rubber Band Powered Foam Plate Airplane - Endlessliftlldkr276No ratings yet

- t3 Free PlansDocument46 pagest3 Free PlansDan100% (1)

- Jon Boat PlansDocument3 pagesJon Boat Planslm13700100% (2)

- Pico Light 1Document32 pagesPico Light 1manolislem100% (3)

- Sailing CanoeDocument2 pagesSailing CanoeFrenchwolf420No ratings yet

- How To Plank The Hull of A Sharp Bow Model ShipDocument22 pagesHow To Plank The Hull of A Sharp Bow Model Shiproman5791100% (2)

- Teacup SailboatDocument9 pagesTeacup SailboatJim100% (11)

- BlondieDocument21 pagesBlondieOmar Valencia CastillónNo ratings yet

- Hand PlanesDocument3 pagesHand PlanesDavid DonaldsonNo ratings yet

- Building A Wood Epoxy SharpieDocument12 pagesBuilding A Wood Epoxy SharpieAmy Rodriguez0% (2)

- Cuadro ChopperDocument121 pagesCuadro ChopperlabratzpyNo ratings yet

- Boat BuildingDocument66 pagesBoat BuildingJatsu AlbizuNo ratings yet

- Boat Building Simplified - Being a Practical Guide to the 'Ashcroft' Method of Building, Rowing, Sailing and Motor BoatsFrom EverandBoat Building Simplified - Being a Practical Guide to the 'Ashcroft' Method of Building, Rowing, Sailing and Motor BoatsRating: 1 out of 5 stars1/5 (1)

- Model Yachts and Boats: Their Designing, Making and SailingFrom EverandModel Yachts and Boats: Their Designing, Making and SailingNo ratings yet

- Prince of Persia WW FDocument112 pagesPrince of Persia WW FChandan SinghNo ratings yet

- Sailing Today With Yachts & Yachting - May 2023Document100 pagesSailing Today With Yachts & Yachting - May 2023CRISTINA ENENo ratings yet

- Types of Ships: Military Ships / Naval ShipsDocument3 pagesTypes of Ships: Military Ships / Naval ShipsbharathwajamechNo ratings yet

- The Basics of Sailing Hobie Cat 1Document15 pagesThe Basics of Sailing Hobie Cat 1olimpiu vesaNo ratings yet

- Canoeing: Araracap, Cachuela, Huerto, Nueva Arcena, Asahan, Loyola, SeguiroDocument34 pagesCanoeing: Araracap, Cachuela, Huerto, Nueva Arcena, Asahan, Loyola, SeguiroGreth NuevaNo ratings yet

- Introduction To Ship Load LinesDocument7 pagesIntroduction To Ship Load Linesนัทเดช เรืองสวนNo ratings yet

- The Mariner 125Document28 pagesThe Mariner 125Pat ReynoldsNo ratings yet

- Hull Fairring Lv1 and Lv2 by RhinoDocument11 pagesHull Fairring Lv1 and Lv2 by RhinoLe ChinhNo ratings yet

- First Row Second Row Third Row: Test: Operate Life Safing Appliances (Nautika)Document4 pagesFirst Row Second Row Third Row: Test: Operate Life Safing Appliances (Nautika)Akbar ZebuaNo ratings yet

- SeamanshipDocument5 pagesSeamanshipRachmat Hidayat Sapwari0% (1)

- Chandra Kirana Ship ParticularDocument1 pageChandra Kirana Ship ParticularRAHEL100% (1)

- Theseus - MinotaurosDocument11 pagesTheseus - MinotaurosMehmet BozkurtNo ratings yet

- Quantum 420 Tuning GuideDocument5 pagesQuantum 420 Tuning GuideNeo ZaoNo ratings yet

- Guidelines For Mumbai HarbourDocument10 pagesGuidelines For Mumbai HarbourVenugopal RajagopalNo ratings yet

- 67 Rhiann MarieDocument2 pages67 Rhiann MarieAlbertus HolbeinNo ratings yet

- BeachDocument3 pagesBeachElia MuñozNo ratings yet

- Lulu Mcnally Long CV 17Document3 pagesLulu Mcnally Long CV 17api-337543096No ratings yet

- 21-15th Century MarinersDocument2 pages21-15th Century Marinersapi-268362410No ratings yet

- Guide To Safe ScoutingDocument77 pagesGuide To Safe ScoutingtortdogNo ratings yet

- Nexus-Silva 2008 - English CatalogueDocument60 pagesNexus-Silva 2008 - English Cataloguejavi98745No ratings yet

- MGN 601 M MLC Crew Accommodation For Small Vessels of Less Than 200GT That Are Ordinarily Engaged in Commercial ActivitiesDocument10 pagesMGN 601 M MLC Crew Accommodation For Small Vessels of Less Than 200GT That Are Ordinarily Engaged in Commercial Activitiesaolaya14No ratings yet

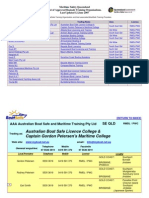

- PDF Boatsafe Approved Training ProvidersDocument22 pagesPDF Boatsafe Approved Training ProvidersNgaire TaylorNo ratings yet

- Product Sheet Expedition Cruise ShipDocument2 pagesProduct Sheet Expedition Cruise ShipPilar AlvarezNo ratings yet

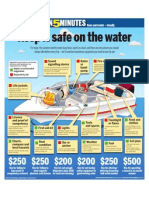

- Infographic: Boating SafetyDocument1 pageInfographic: Boating SafetyedsunonlineNo ratings yet

- Hollow City ExcerptDocument42 pagesHollow City ExcerptQuirk Books67% (3)

- Melville BenitoCereno&BillyBudd EnglishDocument90 pagesMelville BenitoCereno&BillyBudd EnglishMaria JoséNo ratings yet

- Lopez vs. DurueloDocument2 pagesLopez vs. DurueloKrizzia GojarNo ratings yet