Professional Documents

Culture Documents

Final Poster - Biodegradeable Metallic Stents

Final Poster - Biodegradeable Metallic Stents

Uploaded by

McQuack ÁvilaCopyright:

Available Formats

You might also like

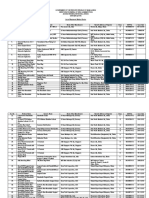

- Registered Medical Device - 08 - 03 - 20Document104 pagesRegistered Medical Device - 08 - 03 - 20Md. Shafi Newaz100% (1)

- Microstructural Aspects of Fracture by Dimpled RuptureDocument24 pagesMicrostructural Aspects of Fracture by Dimpled RuptureWylliam Diel WagnerNo ratings yet

- Bioactive Materials: SciencedirectDocument44 pagesBioactive Materials: SciencedirectAlicia Jara ChavezNo ratings yet

- Zinc-Based Biomaterials For Regeneration and Therapy: ReviewDocument14 pagesZinc-Based Biomaterials For Regeneration and Therapy: ReviewAndreaNo ratings yet

- Imidazoline Gemini Surfactants As Corrosion Inhibitors For Carbon Steel X70 in Nacl SolutionDocument8 pagesImidazoline Gemini Surfactants As Corrosion Inhibitors For Carbon Steel X70 in Nacl Solutiondivya vajpayeeNo ratings yet

- Selective Dissolution of Austenite in 304 by Bacterial ActivityDocument3 pagesSelective Dissolution of Austenite in 304 by Bacterial ActivityDavid Andres Cañas SuarezNo ratings yet

- A Review of The Application of AnodizatiDocument15 pagesA Review of The Application of AnodizatiMam MiyamiNo ratings yet

- Dex La Fontaine CJ98Document12 pagesDex La Fontaine CJ98jatan aminNo ratings yet

- Biocorrosion Towards Understanding Interactions Between Biofilms and Metals PDFDocument6 pagesBiocorrosion Towards Understanding Interactions Between Biofilms and Metals PDFIsabela BarretoNo ratings yet

- Pictorial Essay: Electrochemical Corrosion of Metal ImplantsDocument4 pagesPictorial Essay: Electrochemical Corrosion of Metal ImplantsYan HeNo ratings yet

- Corrosion BasicDocument500 pagesCorrosion BasicKing Sabi100% (1)

- Chapter 12 Biological Responses To Metal Debris and Metal IonsDocument11 pagesChapter 12 Biological Responses To Metal Debris and Metal IonsEmilio Eduardo ChoqueNo ratings yet

- Energy EnvironDocument37 pagesEnergy Environzedanabdallah4fbNo ratings yet

- Biesiekierski 2012Document9 pagesBiesiekierski 2012Diavolo RequiemNo ratings yet

- Effects of Different Parameters On Molybdenum Concentration in ZN MO MN AlloyDocument7 pagesEffects of Different Parameters On Molybdenum Concentration in ZN MO MN AlloyEditor IJTSRDNo ratings yet

- HOmogenous Deposition For Sodium Metal Batteries - Carbon - 2021Document13 pagesHOmogenous Deposition For Sodium Metal Batteries - Carbon - 2021viscairsyad96No ratings yet

- Modeling The Chemo-Mechanical Behavior of All-Solid-State Batteries: A ReviewDocument32 pagesModeling The Chemo-Mechanical Behavior of All-Solid-State Batteries: A Reviewthubten chogyelNo ratings yet

- Chapter BookDocument15 pagesChapter BookhrecioNo ratings yet

- Microporous Framework Membranes For Precise Moleculeion SeparationsDocument44 pagesMicroporous Framework Membranes For Precise Moleculeion SeparationsNing ZhangNo ratings yet

- Role of Microstructure in Sucker Rod String Failures in Oil Well ProductionDocument2 pagesRole of Microstructure in Sucker Rod String Failures in Oil Well ProductionJose Marval RodriguezNo ratings yet

- Girish Sir MG PaperDocument21 pagesGirish Sir MG PaperNileshTipanNo ratings yet

- Pnas 1600422113Document6 pagesPnas 1600422113gopi raandNo ratings yet

- Trouble With Paint Barrier CoatingsDocument15 pagesTrouble With Paint Barrier Coatingsravi00098100% (1)

- TextResJ79 (2009 No7) 645-51Document7 pagesTextResJ79 (2009 No7) 645-51Paulo UtargNo ratings yet

- Bioglass Composites: A Potential Material For Dental ApplicationDocument4 pagesBioglass Composites: A Potential Material For Dental ApplicationMario Misael Machado LòpezNo ratings yet

- Mechanical Properties of Powder Metallurgy Processed Biodegradable ZN Based Alloy For Biomedical ApplicationDocument6 pagesMechanical Properties of Powder Metallurgy Processed Biodegradable ZN Based Alloy For Biomedical ApplicationAsif AliNo ratings yet

- Adv Eng Mater - 2022 - Körber - Anisotropic Growth of The Primary Dendrite Arms in A Single Crystal Thin WalledDocument8 pagesAdv Eng Mater - 2022 - Körber - Anisotropic Growth of The Primary Dendrite Arms in A Single Crystal Thin WalledRATHIRAM NAIKNo ratings yet

- Role of Metal Dyshomeostasis in Alzheimer's Diseasew: MetallomicsDocument4 pagesRole of Metal Dyshomeostasis in Alzheimer's Diseasew: MetallomicsArchishman SarkarNo ratings yet

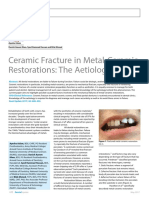

- Ceramic Fracture in Metal-Ceramic Restorations: The AetiologyDocument6 pagesCeramic Fracture in Metal-Ceramic Restorations: The AetiologyQamar IshfaqueNo ratings yet

- Biological Applications of Severely Plastically Deformed Nano-Grained Medical Devices: A ReviewDocument24 pagesBiological Applications of Severely Plastically Deformed Nano-Grained Medical Devices: A ReviewGopinath PerumalNo ratings yet

- Fiber Post Techniques For Anatomical Root Variations: FeatureDocument10 pagesFiber Post Techniques For Anatomical Root Variations: FeatureVictor LappostNo ratings yet

- (已压缩)1 s2.0 S2590006422001661 mainDocument22 pages(已压缩)1 s2.0 S2590006422001661 mainquea02No ratings yet

- Effect of Tempering On The Microstructure and Mechanical Properties of Low Carbon Low Alloy Martensitic SteelDocument6 pagesEffect of Tempering On The Microstructure and Mechanical Properties of Low Carbon Low Alloy Martensitic SteelMuhammad Rizki Ash-ShidiqNo ratings yet

- 2018Zinc-Based Alloys For Degradable Vascular Stent ApplicationsReviewDocument23 pages2018Zinc-Based Alloys For Degradable Vascular Stent ApplicationsReviewAlicia Jara ChavezNo ratings yet

- A Perpective On Corrion Inhinitor by BiofilmsDocument5 pagesA Perpective On Corrion Inhinitor by BiofilmsINRO IngeníeriaNo ratings yet

- Advances in Schiff Base and Its Coating On Metal Biomaterials, A ReviewDocument16 pagesAdvances in Schiff Base and Its Coating On Metal Biomaterials, A ReviewMarian Ferreira Baptista da SilvaNo ratings yet

- JFB 13 00164 v3Document20 pagesJFB 13 00164 v3Panaghie CatalinNo ratings yet

- A Review On Diatom Biosilicification and Their Adaptive Ability To Uptake Other Metals Into Their Frustules For Potential Application in Bone RepairDocument10 pagesA Review On Diatom Biosilicification and Their Adaptive Ability To Uptake Other Metals Into Their Frustules For Potential Application in Bone RepairGabriel CespedesNo ratings yet

- Mechanical Properties of Iron-Based Bulk Metallic GlassesDocument8 pagesMechanical Properties of Iron-Based Bulk Metallic Glassesunknown1711No ratings yet

- Effect of Heavy Metal On Fouling Behavior in Membrain BioreactorsDocument8 pagesEffect of Heavy Metal On Fouling Behavior in Membrain BioreactorsDavood BarzegariNo ratings yet

- Materials Today: ProceedingsDocument4 pagesMaterials Today: ProceedingsNileshTipanNo ratings yet

- New Interpretation of The Effect of Hydrogen On The Ion Distributions and Structure of Passive Films On Microalloyed SteelDocument9 pagesNew Interpretation of The Effect of Hydrogen On The Ion Distributions and Structure of Passive Films On Microalloyed Steel杨富强No ratings yet

- 2020 Metal Organic Frameworks History and Structural FeaturesDocument29 pages2020 Metal Organic Frameworks History and Structural FeaturesSARMAD TARIQ 0219No ratings yet

- What Is Corrosion?: Electrochemical Society Interface March 2006Document4 pagesWhat Is Corrosion?: Electrochemical Society Interface March 2006Behayle TerayeNo ratings yet

- Ceramic Fracture in Metal-Ceramic Restorations: The AetiologyDocument7 pagesCeramic Fracture in Metal-Ceramic Restorations: The AetiologySamNo ratings yet

- Experimental Study On Bacterial Concrete Amudhavalli.N.K. 1, Keerthana.K.2, Ranjani.A3Document3 pagesExperimental Study On Bacterial Concrete Amudhavalli.N.K. 1, Keerthana.K.2, Ranjani.A3GR DesignsNo ratings yet

- 6007 (JCI Rahmita Sari 2015)Document10 pages6007 (JCI Rahmita Sari 2015)Rahmita Sari RafdinalNo ratings yet

- Rsta 1980 0079Document14 pagesRsta 1980 0079Kay WhiteNo ratings yet

- DownloadDocument4 pagesDownloadSari Ramadhani MeutuahNo ratings yet

- SSW Ce LR PDFDocument9 pagesSSW Ce LR PDFankitniranjan1390No ratings yet

- What Is Corrosion?: Electrochemical Society Interface March 2006Document4 pagesWhat Is Corrosion?: Electrochemical Society Interface March 2006Jahzerah PoochieNo ratings yet

- Monolayer MBenes Prediction of Anode Materials For High-Performance Lithiumsodium Ion BatteriesDocument8 pagesMonolayer MBenes Prediction of Anode Materials For High-Performance Lithiumsodium Ion BatteriesunnisazureNo ratings yet

- Types of CorrosionDocument1 pageTypes of CorrosionprathapNo ratings yet

- (Asce) MT 1943-5533 0002560Document11 pages(Asce) MT 1943-5533 0002560Hizbawi SisayNo ratings yet

- Advanced Energy Materials - 2020 - LiuDocument24 pagesAdvanced Energy Materials - 2020 - Liu조창흠No ratings yet

- IUST v7n3p0 enDocument8 pagesIUST v7n3p0 enAzadeh AliabadiNo ratings yet

- ShawKelly 2006 WhatisCorrosionDocument4 pagesShawKelly 2006 WhatisCorrosionAldair FranciscoNo ratings yet

- Trends and Perspectives in Modification of Zirconium Oxide For Dental ProstheticDocument17 pagesTrends and Perspectives in Modification of Zirconium Oxide For Dental Prostheticelbanuswatri1980No ratings yet

- Bacterial Concrete and Effect of Differe PDFDocument8 pagesBacterial Concrete and Effect of Differe PDF18TPCV012 HARSHA BABU ENo ratings yet

- Srep 46343Document12 pagesSrep 46343פּואַ פּוגאַNo ratings yet

- Exercise Wheelchair - Eduardo Ávila - Antoni LopezDocument3 pagesExercise Wheelchair - Eduardo Ávila - Antoni LopezMcQuack ÁvilaNo ratings yet

- Labview Document PDFDocument9 pagesLabview Document PDFMcQuack ÁvilaNo ratings yet

- Gobernor de VelocidadDocument4 pagesGobernor de VelocidadMcQuack ÁvilaNo ratings yet

- Homework 5: Theory of Operation and Hardware Design NarrativeDocument8 pagesHomework 5: Theory of Operation and Hardware Design NarrativeMcQuack ÁvilaNo ratings yet

- Crimping and Deployment of Metallic and Polymeric Stents - Finite Element ModellingDocument10 pagesCrimping and Deployment of Metallic and Polymeric Stents - Finite Element ModellingMuhammad JamilNo ratings yet

- Evaluation of Coronary Stents A Review of Types, Materials, Processing Techniques, Design, and ProblemsDocument14 pagesEvaluation of Coronary Stents A Review of Types, Materials, Processing Techniques, Design, and ProblemsFellipe LavaquiNo ratings yet

- Coronary Stent RestenosisDocument808 pagesCoronary Stent RestenosisIonëlla MihaelaNo ratings yet

- Zinc Exhibits Ideal Physiological Corrosion Behavior For Bioabsorbable Stents (Bowen Et Al., Advanced Materials, 2013)Document18 pagesZinc Exhibits Ideal Physiological Corrosion Behavior For Bioabsorbable Stents (Bowen Et Al., Advanced Materials, 2013)Patrick BowenNo ratings yet

- 2018Zinc-Based Alloys For Degradable Vascular Stent ApplicationsReviewDocument23 pages2018Zinc-Based Alloys For Degradable Vascular Stent ApplicationsReviewAlicia Jara ChavezNo ratings yet

- Final Poster - Biodegradeable Metallic StentsDocument1 pageFinal Poster - Biodegradeable Metallic StentsMcQuack ÁvilaNo ratings yet

- Mechanical Behavior of Polymer-Based vs. Metallic-Based Bioresorbable StentsDocument12 pagesMechanical Behavior of Polymer-Based vs. Metallic-Based Bioresorbable StentsSiddharthan ArjunanNo ratings yet

- Bioresorbable Vascular Scaffold: (Advantages, Limitations and Future Directions)Document7 pagesBioresorbable Vascular Scaffold: (Advantages, Limitations and Future Directions)hafsaNo ratings yet

- When and How To Use BRS in BifurcationsDocument5 pagesWhen and How To Use BRS in BifurcationsRui FonteNo ratings yet

Final Poster - Biodegradeable Metallic Stents

Final Poster - Biodegradeable Metallic Stents

Uploaded by

McQuack ÁvilaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final Poster - Biodegradeable Metallic Stents

Final Poster - Biodegradeable Metallic Stents

Uploaded by

McQuack ÁvilaCopyright:

Available Formats

Biodegradable Metallic Stents

Master of biomedical Engineering - Biomaterials Project

Cinthia E. M. Kramer, Sergio Eduardo Ávila Pérez, Marc Rulló Besora

INTRODUCTION

1. Introduction 2. Biodegradable Stents - 3. Zn-based biodegradable stents 4. Discussion – 5. Conclusion

Coronary artery disease (CAD) is the third 2.1 Principle of the Biodegradability of metallic Stents 3.2 Properties 4. Discussion

leading cause of death worldwide. It is Using an essential transition metal of • Physiochemical Properties Functionality

characterized by a narrowing of the artery the human body for the stent, makes it

due to plaque deposits beneath the Zn-based alloys have low melting temperatures below The development of new generations of stents aims to improve mechanical properties,

bioresorbable. The degradation takes

endothelium, reduced blood flow, and 420 degrees, and low reactivity which is good for safety, biocompatibility, stability, reendothelialization and to reduce adverse effects

place due to a series of anodic and

insufficient nutrients and oxygen supply to manufacturing [7]. The molecular structure of the BM is such as restenosis, thrombosis, inflammation, neointimal hyperplasia, etc.

cathodic reactions on the BMs surface.

the cardiac muscle, which can lead to a bulk metallic glass (BMG): Multi component metallic These problems could be solved with biodegradable stents which showed a lot of

myocardial infarction or transient cerebral These depend on the composition of

alloys with disordered atomic distribution (glassy potential, wherefore its investigation is very senseful. But still drawbacks and challenges

ischemic attacks and stroke. the alloy, especially meaning the size

structure). The Metallic glasses are materials which have might arise when starting into clinical studies, as each individuum could react very

Figure 1.1: Coronary artery disease and distribution of local anodes

the properties of both metals and glasses, meaning differently. For instance, in some the stents could be degraded much faster or slower

This condition can be treated by employing fluoroscopic and/or endoscopic guidance (oxidation of less noble metal) and

metallic bonds but amorphous atomic orientation. than anticipated.

to place special devices called stents into the afflicted channel. [1] [2]. cathodes (reduction of more noble

[8][9][1] Its structure bring many advantages in the

Figure 1.1: Concept of degradation of metallic stent surface [5]. metal). [5]

mechanical properties and biological integrity as Production

Stents are hollow structures that are small, First the metal is oxidated and then forms the metal oxide, which is then dissolved by metallic glasses, have proven to show significantly As stated, before ideal alloys are being determined and investigated already e.g., Zn–

Figure 3.2.1: Atomic distribution,

complex, cylindrically and are constructed into a negative charged ions such as Cl- which are present in body fluids (see figure 1.1). better corrosion resistance compared to their amorph and crystalline [11] 0.5Mg extruded alloy shows a good combination of mechanical performance and

sequential ring with a sequence of struts and crystalline counterparts degradation rate. This alloy also showed good behavior in laser cutting tests as the

connecting parts.

2.2 Metallic biodegradable Biomaterials for Stent Applications

analysis found that neither grain coarsening nor texture modification occurred close to

• Mechanical Properties the laser cut edge. [7]

Property\Stent Mg-based Fe-based Zn-based

Aim: Keep the path of human arteries through the

body open. Biocompa- (-) Excessive release of (-) Corrosion products () Excess Zn in the The tensile strength of pure Zn is too low for stent applications, but in form of

tibility degradation products damage artery on a body is harmful to

metallic glass with additional Mg enhanced performance (see Figure 3.2.3).

• Properties of the ideal Stent [1] Figure 1.2: Stent placement procedure. [5] long term [5] vital organs

[Mustead] In general, metallic glasses are strong, ductile, malleable and brittle. Also

(+) electronegative (-) Disadvantages of (+) daily dose of Zn harder than steel, non-toxic and resist to wear stress and corrosion, they are easy

charge during permanent stents are release from stent is to shape and elastic enough to change form [8][9][5][1].

degradation → present. [7] significantly below

antithrombotic any risk [7] Zn–0.5Mg is the most promising material for stent applications with a good

potential [5] combination of strength, ductility, strain hardening exponent and an appropriate

rate of loss of mechanical integrity during degradation. [7]

Mechanical (-) Too short (< 6 (-) Too long [5] [6] () short – appropriate Figure 4.1: SEM images of Zn-0.5Mg tube cutted with laser cutter.[7]

Integrity months and unstable) [7]

Another obstacle is that laser micro cutting of Zn-Mg alloys requires inert gas

[5] [7]

conditions. The process gas O2 can be used with the conventional stent material

stainless steel. However, the use of O2 in Zn-Mg alloys leads to the formation of MgO in

Mechanical (+) Superior elastic (+) Main advantage: (-) too low, adding

the kerf, which acts as a refractory layer due to its high melting temperature, thus

properties moduli and tensile High radial strength alloying elements

strengths while because of and/or preventing the cutting process. [12].

Figure 1.3: Ideal stent property graphic. degrading [Udriste 108] high elastic modulus thermomechanical However, the Mg content in the alloy is very low, which is reflected in the study by

[6] refinement of grain Mostaed et al. has proven to be the most efficient. The formation of MgO inside the

• Properties of real Stents (-) Not strong enough size necessary [7] body is also unavoidable and does not impair the function of the stent. In addition, in

Figure 3.2.2: SEM images of Zn and Zn Alloys. Left: Zn (pure), middle: Zn-0.15Mg 0.15, right: Zn-0.5Mg. [7]

Common Stent Metals and Alloys [1] for the load-bearing the work of Demir et al. possible to preserve the chemical composition of a Mg-based

Iron (Fe), stainless steel (316L), Tantalum (Ta), Nitinol (Ni-Ti), Cobalt-Chromium (Co- applications stent by removing the oxidized zones by chemical etching. [12][7]

Cr), Magnesium (Mg), Platinum-Iridium (Pt-Ir) [5]

However, a problem that arises in the next production step, the chemical etching step,

is the inevitable reduction in thickness [12]. This could affect the mechanical

• Main Complications of Stent Placement Corrosion (-) Too fast and () Superior [1] (+) Between Mg and performance of the stent and therefore needs to be investigated and standardized to

Restenosis Stent Thrombosis Behaviour uncontrollable [5][1] Fe [7]

ensure the functionality of the stent.

The concern mentioned in the paper of Mostaed et. al on the impurities of industrial Zn

3. Zn-based biodegradable stents has yet to be proven as we were able to find 99.995% pure zinc from China for

US$1550-1700/ton while bulk stainless-steel costs around US$2000/ton. [7][13][14]

Most promising alloys are the Zn-Mg alloys as mechanical integrity and properties

can be enhanced with the additional component magnesium. Mg is well studied and

biocompatible, making it the perfect alloying element. The alloys are expected to 5. Conclusion

have superior mechanical properties while maintaining high biosafety. [7] Biodegradable stents are well on their way to entering clinical trials and are already

Figure 3.2.3: Zn and Zn Alloys mechanical property analysis. Left: Zn-Alloy HV alterations, right: Alterations of

showing great potential in vivo and in vitro in mammals. As their performance

Figure 1.4: Re-narrowing or blockage of a previously- Figure 1.5: Presence or formation of blood cots 3.1 Fabrication & manufacturing Youngs Modulus (YS), Ultimate tensile strength (UTS) and Elongation. [7] continues to improve with surface treatments and more alloys, these materials have

treated artery by coronary angioplasty [3] in a vessel or on stented area [4] great potential to change the gold standard of stainless-steel stents. From an economic

1. Production of the Biomaterial and functional point of view (see table in 3), the Zn-based stents appear very promising,

Zn and Mg are both melted at 500 ºC in Figure 3.1.1. SEM Images of the laser microcut since conventional production steps for Zn-based stents work, which facilitates their

cylindrical mold made of steel, inside a stents produced using Ar [12] entry into mass production.

resistance furnace, produces cast cylindrical • Biological Integrity

billets with a length and diameter of 80 mm and

Zn is an essential element in human

15 mm, respectively. [7] Then hardened at 350 ºC

Figure 1.6

for 48h in order to homogenize the cast nutrition and is the second most Acknowledgements

• Evolution of cardiovascular Stents [1] structure followed by water quenching. Then Figure 3.1.2. SEM Images of the laser microcut abundant metal element in the human

stents using Ar after chemical etching at 10 body. It plays a crucial role in cell [1] - Alexandru Scafa Udriste, Adelina-Gabriela Niculescu, Alexandru Mihai Grumezescu and Elisabeta

Bare Metal (BMS) Drug Eluting Stent (DES) Bioresorbable cylindrical rods are obtained by extrusion Badila 2021.

STENTS seconds. [12]

1986 2002 / 2008 2011 - Today around 300 degrees. The small tubes and the proliferation and in the immune and Cardiovascular Stents: A Review of Past, Current, and Emerging Devices

• Stainless steel (316L), Co-• Improved radial force • Temporary support stents precursors. with outer and inner nervous system. But excess and long- [2] - https://www.myupchar.com/en/disease/coronary-artery-disease

Cr, Pt-Ir, Ta, Ni-Ti and radiopacity (scaffold) diameters of 4 and 1.5 mm respectively. [7] term exposure to Zn is harmful to vital [3] - https://www.bostonscientific.com/en-US/medical-specialties/interventional-cardiology/coronary-

• Permanently implanted • Anti-inflammatory • Biocompatible, interventio ns/pci-product-portfolio/agent-ide-clinical-trial/understanding-isr-for-patients.html

organs such as the kidney, spleen,

Features

• Non-degradability • Elution of biodegradable polymers and [4] - https://www.ahajournals.org/doi/10.1161/01.ATV.0000255308.41576.ae

1. Stent Fabrication liver, brain and heart and interferes

• Prevents elastic recoil antiproliferative metallic materials Figure 3.1.3.SEM images of stents cut with Ar, taken [5] - Wei Yuan, Dandan Xia, Shuilin Wu, Yufeng Zheng, Zhenpeng Guan, Julietta V. Rau 2022. A review on

neointimal inhibitors • Reduce chronic Wires and tubes are the most widely used for in back scattered electron mode. [12] with the copper uptake. [7] current research status of the surface modification of Zn-based biodegradable metals

inflammation, restenosis, producing expandable and self-expanding Figure 3.2.4: Physiological roles of zinc. [10] [6] – Maryam Moravej and Diego Mantovani 2011. Biodegradeable Metals for Cardiovascular Stent

late stent thrombosis stents. But processing mini tubes for stents is Application: Interests and New Opportunities.

Experiments with rats showed that after 4.5 and 6 months in vivo, the corrosion [7] - E. Mostaed, M.Sikora-Jasinskaa, A. Mostaed, S.Loffredoa, A. G. Demira, B. Previtalia, D. Mantovanib, R.

• Currently in development not trivial and depends on the material used. It

• High rate of in-stent • Restenosis (rate less than products were primarily benign compacted zinc oxide interspersed in zinc Beanlandc, M. Vedania 2016. Novel Zn-based alloys for biodegradable stent applications: Design,

must have a good response to laser irradiation development and in vitro degradation

restenosis and late-stage BMS) carbonate. The same study showed that after partial degradation, they proved that

during strut cutting, and microstructural [8] - https://www.bulkmetallicglass.it/en/bulk-metallic-glass-blog/stent-innovative-bulk-metallic-glass-

thrombosis • Late stent thrombosis Zn has an antiproliferative effect, guarding against restenosis after stent

stability after laser cutting. [7][12] Figure 3.1.4. SEM images of the stent after laser

Problems

application/]

• Chronic inflammatory • More dual antiplatelet implantation [7].

?

microcutting and chemical etching. [12] [9] - https://padeepz.net/metallic-glasses

response therapy (DAPT) → more

•

Industrial processes are being adapted for the laser micro cutting stents, as this [10] - https://jps.biomedcentral.com/articles/10.1007/s12576-017-0521-4

Keep the stent as a bleeding However, any widely-used Zn-based alloys contain large amounts of Al, are

technique is most feasible. In the production cycle small diameter tubes are cut with a [11] - https://www.totalmateria.com/page.aspx?ID=CheckArticle&site=ktn&NM=485

foreign body throughout • Abnormal coronary therefore potentially toxic and unsuitable for bio applications. New biodegradable [12] – Demir, A.G., khan Previtali, B., Biffi, C.A., 2013. Fibre laser cutting and chemical etching of AZ31 for

the entire life. vasomotion Q-switched fibre laser (pulsed lasers with a high energy content) producing structures

Zn-based alloys with limited amounts of Al or other potentially harmful elements, manufacturing biodegraable stents. Adv. Mater. Sci. Eng., e692635, http://dx.doi.org/

shown in the figure. The last operation is chemical etching with an HNO3 ethanol 10.1155/2013/692635.

are of interest and crucial for stent application. [7]

Idea of Metallic Bioresorbable Stents: solution to clean the deposited spatter on the stent surface [12]. [13] - https://m.made-in-china.com/company-hbcongjin/productlist/group/631408695

[14] - https://www.alibaba.com/premium/stainless_steel.html

corrosion resistance and superior mechanical properties, maintaining a long-term

mechanical stability in vivo.

You might also like

- Registered Medical Device - 08 - 03 - 20Document104 pagesRegistered Medical Device - 08 - 03 - 20Md. Shafi Newaz100% (1)

- Microstructural Aspects of Fracture by Dimpled RuptureDocument24 pagesMicrostructural Aspects of Fracture by Dimpled RuptureWylliam Diel WagnerNo ratings yet

- Bioactive Materials: SciencedirectDocument44 pagesBioactive Materials: SciencedirectAlicia Jara ChavezNo ratings yet

- Zinc-Based Biomaterials For Regeneration and Therapy: ReviewDocument14 pagesZinc-Based Biomaterials For Regeneration and Therapy: ReviewAndreaNo ratings yet

- Imidazoline Gemini Surfactants As Corrosion Inhibitors For Carbon Steel X70 in Nacl SolutionDocument8 pagesImidazoline Gemini Surfactants As Corrosion Inhibitors For Carbon Steel X70 in Nacl Solutiondivya vajpayeeNo ratings yet

- Selective Dissolution of Austenite in 304 by Bacterial ActivityDocument3 pagesSelective Dissolution of Austenite in 304 by Bacterial ActivityDavid Andres Cañas SuarezNo ratings yet

- A Review of The Application of AnodizatiDocument15 pagesA Review of The Application of AnodizatiMam MiyamiNo ratings yet

- Dex La Fontaine CJ98Document12 pagesDex La Fontaine CJ98jatan aminNo ratings yet

- Biocorrosion Towards Understanding Interactions Between Biofilms and Metals PDFDocument6 pagesBiocorrosion Towards Understanding Interactions Between Biofilms and Metals PDFIsabela BarretoNo ratings yet

- Pictorial Essay: Electrochemical Corrosion of Metal ImplantsDocument4 pagesPictorial Essay: Electrochemical Corrosion of Metal ImplantsYan HeNo ratings yet

- Corrosion BasicDocument500 pagesCorrosion BasicKing Sabi100% (1)

- Chapter 12 Biological Responses To Metal Debris and Metal IonsDocument11 pagesChapter 12 Biological Responses To Metal Debris and Metal IonsEmilio Eduardo ChoqueNo ratings yet

- Energy EnvironDocument37 pagesEnergy Environzedanabdallah4fbNo ratings yet

- Biesiekierski 2012Document9 pagesBiesiekierski 2012Diavolo RequiemNo ratings yet

- Effects of Different Parameters On Molybdenum Concentration in ZN MO MN AlloyDocument7 pagesEffects of Different Parameters On Molybdenum Concentration in ZN MO MN AlloyEditor IJTSRDNo ratings yet

- HOmogenous Deposition For Sodium Metal Batteries - Carbon - 2021Document13 pagesHOmogenous Deposition For Sodium Metal Batteries - Carbon - 2021viscairsyad96No ratings yet

- Modeling The Chemo-Mechanical Behavior of All-Solid-State Batteries: A ReviewDocument32 pagesModeling The Chemo-Mechanical Behavior of All-Solid-State Batteries: A Reviewthubten chogyelNo ratings yet

- Chapter BookDocument15 pagesChapter BookhrecioNo ratings yet

- Microporous Framework Membranes For Precise Moleculeion SeparationsDocument44 pagesMicroporous Framework Membranes For Precise Moleculeion SeparationsNing ZhangNo ratings yet

- Role of Microstructure in Sucker Rod String Failures in Oil Well ProductionDocument2 pagesRole of Microstructure in Sucker Rod String Failures in Oil Well ProductionJose Marval RodriguezNo ratings yet

- Girish Sir MG PaperDocument21 pagesGirish Sir MG PaperNileshTipanNo ratings yet

- Pnas 1600422113Document6 pagesPnas 1600422113gopi raandNo ratings yet

- Trouble With Paint Barrier CoatingsDocument15 pagesTrouble With Paint Barrier Coatingsravi00098100% (1)

- TextResJ79 (2009 No7) 645-51Document7 pagesTextResJ79 (2009 No7) 645-51Paulo UtargNo ratings yet

- Bioglass Composites: A Potential Material For Dental ApplicationDocument4 pagesBioglass Composites: A Potential Material For Dental ApplicationMario Misael Machado LòpezNo ratings yet

- Mechanical Properties of Powder Metallurgy Processed Biodegradable ZN Based Alloy For Biomedical ApplicationDocument6 pagesMechanical Properties of Powder Metallurgy Processed Biodegradable ZN Based Alloy For Biomedical ApplicationAsif AliNo ratings yet

- Adv Eng Mater - 2022 - Körber - Anisotropic Growth of The Primary Dendrite Arms in A Single Crystal Thin WalledDocument8 pagesAdv Eng Mater - 2022 - Körber - Anisotropic Growth of The Primary Dendrite Arms in A Single Crystal Thin WalledRATHIRAM NAIKNo ratings yet

- Role of Metal Dyshomeostasis in Alzheimer's Diseasew: MetallomicsDocument4 pagesRole of Metal Dyshomeostasis in Alzheimer's Diseasew: MetallomicsArchishman SarkarNo ratings yet

- Ceramic Fracture in Metal-Ceramic Restorations: The AetiologyDocument6 pagesCeramic Fracture in Metal-Ceramic Restorations: The AetiologyQamar IshfaqueNo ratings yet

- Biological Applications of Severely Plastically Deformed Nano-Grained Medical Devices: A ReviewDocument24 pagesBiological Applications of Severely Plastically Deformed Nano-Grained Medical Devices: A ReviewGopinath PerumalNo ratings yet

- Fiber Post Techniques For Anatomical Root Variations: FeatureDocument10 pagesFiber Post Techniques For Anatomical Root Variations: FeatureVictor LappostNo ratings yet

- (已压缩)1 s2.0 S2590006422001661 mainDocument22 pages(已压缩)1 s2.0 S2590006422001661 mainquea02No ratings yet

- Effect of Tempering On The Microstructure and Mechanical Properties of Low Carbon Low Alloy Martensitic SteelDocument6 pagesEffect of Tempering On The Microstructure and Mechanical Properties of Low Carbon Low Alloy Martensitic SteelMuhammad Rizki Ash-ShidiqNo ratings yet

- 2018Zinc-Based Alloys For Degradable Vascular Stent ApplicationsReviewDocument23 pages2018Zinc-Based Alloys For Degradable Vascular Stent ApplicationsReviewAlicia Jara ChavezNo ratings yet

- A Perpective On Corrion Inhinitor by BiofilmsDocument5 pagesA Perpective On Corrion Inhinitor by BiofilmsINRO IngeníeriaNo ratings yet

- Advances in Schiff Base and Its Coating On Metal Biomaterials, A ReviewDocument16 pagesAdvances in Schiff Base and Its Coating On Metal Biomaterials, A ReviewMarian Ferreira Baptista da SilvaNo ratings yet

- JFB 13 00164 v3Document20 pagesJFB 13 00164 v3Panaghie CatalinNo ratings yet

- A Review On Diatom Biosilicification and Their Adaptive Ability To Uptake Other Metals Into Their Frustules For Potential Application in Bone RepairDocument10 pagesA Review On Diatom Biosilicification and Their Adaptive Ability To Uptake Other Metals Into Their Frustules For Potential Application in Bone RepairGabriel CespedesNo ratings yet

- Mechanical Properties of Iron-Based Bulk Metallic GlassesDocument8 pagesMechanical Properties of Iron-Based Bulk Metallic Glassesunknown1711No ratings yet

- Effect of Heavy Metal On Fouling Behavior in Membrain BioreactorsDocument8 pagesEffect of Heavy Metal On Fouling Behavior in Membrain BioreactorsDavood BarzegariNo ratings yet

- Materials Today: ProceedingsDocument4 pagesMaterials Today: ProceedingsNileshTipanNo ratings yet

- New Interpretation of The Effect of Hydrogen On The Ion Distributions and Structure of Passive Films On Microalloyed SteelDocument9 pagesNew Interpretation of The Effect of Hydrogen On The Ion Distributions and Structure of Passive Films On Microalloyed Steel杨富强No ratings yet

- 2020 Metal Organic Frameworks History and Structural FeaturesDocument29 pages2020 Metal Organic Frameworks History and Structural FeaturesSARMAD TARIQ 0219No ratings yet

- What Is Corrosion?: Electrochemical Society Interface March 2006Document4 pagesWhat Is Corrosion?: Electrochemical Society Interface March 2006Behayle TerayeNo ratings yet

- Ceramic Fracture in Metal-Ceramic Restorations: The AetiologyDocument7 pagesCeramic Fracture in Metal-Ceramic Restorations: The AetiologySamNo ratings yet

- Experimental Study On Bacterial Concrete Amudhavalli.N.K. 1, Keerthana.K.2, Ranjani.A3Document3 pagesExperimental Study On Bacterial Concrete Amudhavalli.N.K. 1, Keerthana.K.2, Ranjani.A3GR DesignsNo ratings yet

- 6007 (JCI Rahmita Sari 2015)Document10 pages6007 (JCI Rahmita Sari 2015)Rahmita Sari RafdinalNo ratings yet

- Rsta 1980 0079Document14 pagesRsta 1980 0079Kay WhiteNo ratings yet

- DownloadDocument4 pagesDownloadSari Ramadhani MeutuahNo ratings yet

- SSW Ce LR PDFDocument9 pagesSSW Ce LR PDFankitniranjan1390No ratings yet

- What Is Corrosion?: Electrochemical Society Interface March 2006Document4 pagesWhat Is Corrosion?: Electrochemical Society Interface March 2006Jahzerah PoochieNo ratings yet

- Monolayer MBenes Prediction of Anode Materials For High-Performance Lithiumsodium Ion BatteriesDocument8 pagesMonolayer MBenes Prediction of Anode Materials For High-Performance Lithiumsodium Ion BatteriesunnisazureNo ratings yet

- Types of CorrosionDocument1 pageTypes of CorrosionprathapNo ratings yet

- (Asce) MT 1943-5533 0002560Document11 pages(Asce) MT 1943-5533 0002560Hizbawi SisayNo ratings yet

- Advanced Energy Materials - 2020 - LiuDocument24 pagesAdvanced Energy Materials - 2020 - Liu조창흠No ratings yet

- IUST v7n3p0 enDocument8 pagesIUST v7n3p0 enAzadeh AliabadiNo ratings yet

- ShawKelly 2006 WhatisCorrosionDocument4 pagesShawKelly 2006 WhatisCorrosionAldair FranciscoNo ratings yet

- Trends and Perspectives in Modification of Zirconium Oxide For Dental ProstheticDocument17 pagesTrends and Perspectives in Modification of Zirconium Oxide For Dental Prostheticelbanuswatri1980No ratings yet

- Bacterial Concrete and Effect of Differe PDFDocument8 pagesBacterial Concrete and Effect of Differe PDF18TPCV012 HARSHA BABU ENo ratings yet

- Srep 46343Document12 pagesSrep 46343פּואַ פּוגאַNo ratings yet

- Exercise Wheelchair - Eduardo Ávila - Antoni LopezDocument3 pagesExercise Wheelchair - Eduardo Ávila - Antoni LopezMcQuack ÁvilaNo ratings yet

- Labview Document PDFDocument9 pagesLabview Document PDFMcQuack ÁvilaNo ratings yet

- Gobernor de VelocidadDocument4 pagesGobernor de VelocidadMcQuack ÁvilaNo ratings yet

- Homework 5: Theory of Operation and Hardware Design NarrativeDocument8 pagesHomework 5: Theory of Operation and Hardware Design NarrativeMcQuack ÁvilaNo ratings yet

- Crimping and Deployment of Metallic and Polymeric Stents - Finite Element ModellingDocument10 pagesCrimping and Deployment of Metallic and Polymeric Stents - Finite Element ModellingMuhammad JamilNo ratings yet

- Evaluation of Coronary Stents A Review of Types, Materials, Processing Techniques, Design, and ProblemsDocument14 pagesEvaluation of Coronary Stents A Review of Types, Materials, Processing Techniques, Design, and ProblemsFellipe LavaquiNo ratings yet

- Coronary Stent RestenosisDocument808 pagesCoronary Stent RestenosisIonëlla MihaelaNo ratings yet

- Zinc Exhibits Ideal Physiological Corrosion Behavior For Bioabsorbable Stents (Bowen Et Al., Advanced Materials, 2013)Document18 pagesZinc Exhibits Ideal Physiological Corrosion Behavior For Bioabsorbable Stents (Bowen Et Al., Advanced Materials, 2013)Patrick BowenNo ratings yet

- 2018Zinc-Based Alloys For Degradable Vascular Stent ApplicationsReviewDocument23 pages2018Zinc-Based Alloys For Degradable Vascular Stent ApplicationsReviewAlicia Jara ChavezNo ratings yet

- Final Poster - Biodegradeable Metallic StentsDocument1 pageFinal Poster - Biodegradeable Metallic StentsMcQuack ÁvilaNo ratings yet

- Mechanical Behavior of Polymer-Based vs. Metallic-Based Bioresorbable StentsDocument12 pagesMechanical Behavior of Polymer-Based vs. Metallic-Based Bioresorbable StentsSiddharthan ArjunanNo ratings yet

- Bioresorbable Vascular Scaffold: (Advantages, Limitations and Future Directions)Document7 pagesBioresorbable Vascular Scaffold: (Advantages, Limitations and Future Directions)hafsaNo ratings yet

- When and How To Use BRS in BifurcationsDocument5 pagesWhen and How To Use BRS in BifurcationsRui FonteNo ratings yet