Professional Documents

Culture Documents

Article Critique Opm 633

Article Critique Opm 633

Uploaded by

Fatin Aqilah0 ratings0% found this document useful (0 votes)

57 views5 pagesOriginal Title

ARTICLE CRITIQUE OPM 633

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

57 views5 pagesArticle Critique Opm 633

Article Critique Opm 633

Uploaded by

Fatin AqilahCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

BACHELOR DEGREE IN OPERATION MANAGEMENT

(BA 244 - NBO9A)

SUSTAINABLE OPERATIONS MANAGEMENT

(OPM 633)

INDIVIDUAL ASSIGNMENT 1

ARTICLE CRITIQUE : SUSTAINABLE OPERATIONS

PREPARED BY : NOR FATIN AQILAH BINTI AMIR RASHID

2019649666

PREPARED FOR : MADAM FAIZATUL AKMAM BINTI

AMIRRUDIN

Journal of Business Economics (2021) 91:123–125

https://doi.org/10.1007/s11573-021-01034-z

EDITORIAL

Sustainable operations

Günter Fandel1 · Peter Letmathe2 · Thomas Stefan Spengler3 · Grit Walther4

Published online: 15 March 2021

© The Author(s) 2021

Sustainability is one of the mega topics of this century. Whether climate

change or resource efficiency sustainability is driving the transformation

of entire industries and has found its way into all scientific disciplines. It

is therefore only logical that social and environmental aspects of

production and logistics have been discussed in the business

management literature and in practice for many years now. The cur-

rent special issue reflects this development and covers a wide range of

topics in the research field of sustainable operations.

Production in particular is responsible for many environmental and

social impacts. This responsibility starts with the designing of global

value chains and the studying of heterogeneous environmental and

social standards applied. In this context, it is of great importance that

sustainability aspects are correctly documented and assessed. Only

then can such aspects be adequately considered in production planning

in order to ensure the preservation of resources as part of a circular

economy. These developments are associated with substantial changes

in corporate structures and routines that do not only lead to internal

changes but that also transform entire industries and markets. Hence,

these changes open up opportunities for new companies that position

social and environmental goals at the forefront of their activities. The

five papers included in this special issue cover such developments in

sustainable operations, addressing key aspects that are relevant to the

companies involved, to their supply chains, and to our society.

Petra Dickel, Monika Sienknecht, and Jacob Hörisch’s article, “The

early bird catches the worm: an empirical analysis of imprinting in

social entrepreneurship”, analyzes motivations and experiences that

may lead to social entrepreneurship. Their empirical study highlights

that childhood experiences in particular may be formative for later

entrepreneurs. Therefore, the authors recommend that aspects of

social entrepreneurship should be made more tangible in the upbringing

of children. Tim Gruchmann, Annika Mies, Thomas Neukirchen, and

Stefan Gold address social tensions in companies, which are related to

increasing automation and workplace design. Based on three case

studies and a mixed methods approach, the authors show that

performance and belonging aspects play critical roles in the redesigning

of workplaces as a result of technological change. During this change

process, paradox tensions between employees and human resource

managers may be subject to critical disputes and need to be resolved.

A circular economy requires used products and their resources to be

collected in order to preserve their value for further economic activities.

The corresponding collecting and processing costs play a crucial role

when configuring a collection system. In his article “On the influence of

collection cost on reverse channel configuration”, Jochen Gönsch

shows that manufacturers prefer collection by third parties and that they

need to organize their reverse supply chains accordingly.

Assessing the sustainability of global supply chains is an

extraordinarily complex problem, since ecological, economic, and social

aspects have to be considered simultaneously and in their interaction.

Christian Thies, Carsten Kieckhäfer, and Thomas Stefan Spengler show

in their paper “Activity analysis based modeling of global supply chains

for sustainability assessment” that spatial-based approaches can be

helpful when considering different supply chain configurations. The

approach is illustrated by the supply chain of lithiumion batteries.

The paper by Christian Scheller, Kerstin Schmidt, and Thomas Stefan

Spengler focuses on the interaction of recycling and production

activities of lithiumion batteries. The authors illustrate novel planning

approaches that take into account both forward and reverse material

flows. By analyzing five scenarios, the authors demonstrate that

recycling, remanufacturing, and reusing lithiumion batteries is

economically feasible and that centralized planning approaches can

increase the economic efficiency of manufacturing and recycling

companies.

Article Critique

This article show that sustainability is one of the mega issues of

this century. Whether it is climate change or resource efficiency,

sustainability is driving the transformation of entire industries and has

found its way into all scientific disciplines. So it is only logical that

social and ecological aspects of production and logistics have been

discussed in business management literature and in practice for many

years. This special issue takes this development into account and covers

a broad range of topics in the research field of sustainable

management. Production in particular is responsible for many

environmental and social impacts. This responsibility already starts

with the design of global value chains and the confrontation with

heterogeneous environmental and social standards. In this context, it is

of great importance that sustainability aspects are correctly

documented and evaluated. Only in this way can these aspects be

adequately taken into account in production planning to ensure

resource conservation within the framework of a circular economy.

These developments are associated with significant changes in

corporate structures and processes, which not only lead to internal

changes, but also change entire industries and markets. As a result,

these changes open up opportunities for new companies that place

social and ecological goals at the forefront of their actions. The five

articles in this special issue highlight such developments in the field of

sustainable business, addressing key aspects that are important for the

companies involved, their supply chains and our society.

The article by Petra Dickel, Monika Sienknecht and Jacob

Hoerisch, "The early bird catches the worm: an empirical analysis of

imprinting in social entrepreneurship," analyzes the motivations and

experiences that can lead to social entrepreneurship. Their empirical

study shows that childhood experiences in particular can be formative

for later entrepreneurs. Therefore, the authors recommend that aspects

of social entrepreneurship should be made more tangible in children's

education. Tim Gruchmann, Annika Mies, Thomas Neukirchen, and

Stefan Gold address social tensions in companies related to increasing

automation and workplace design. Using three case studies and a

mixed-methods approach, the authors show that performance and

affiliation aspects play a crucial role in the redesign of workplaces in

the wake of technological change. During this change process,

paradoxical tensions between workers and HR managers can be the

subject of critical disputes and need to be resolved.

A circular economy requires that used products and their

resources be collected to preserve their value for further economic

activity. When designing a collection system, the corresponding

collection and reprocessing costs play a decisive role. Jochen Goensch

shows in his article "On the influence of collection cost on reverse

channel configuration" that manufacturers prefer third party collection

and have to organize their reverse supply chains accordingly.

Assessing the sustainability of global supply chains is an

extraordinarily complex problem, as ecological, economic and social

aspects must be considered simultaneously and in their interplay.

Christian Thies, Carsten Kieckhaefer and Thomas Stefan Spengler

show in their paper "Activity analysis based modeling of global supply

chains for sustainability assessment" that spatial approaches can be

helpful when considering different supply chain configurations. The

approach is illustrated using the lithium-ion battery supply chain as an

example.

The paper by Christian Scheller, Kerstin Schmidt and Thomas

Stefan Spengler focuses on the interaction of recycling and production

activities of lithium-ion batteries. The authors illustrate novel planning

approaches that consider both forward and backward material flows.

By analyzing five scenarios, the authors show that recycling,

remanufacturing and reuse of lithiumion batteries are economically

feasible and that centralized planning approaches can increase the

economic efficiency of production and recycling companies.

You might also like

- Project Report On LakmeDocument53 pagesProject Report On LakmeOmita Johar69% (13)

- Sustainable Businesses in Developing Economies Socio Economic and Governance Perspectives Rajagopal Full ChapterDocument54 pagesSustainable Businesses in Developing Economies Socio Economic and Governance Perspectives Rajagopal Full Chaptertimothy.sherman331100% (9)

- Enabling Factors and Strategies For The Transition Toward A Circular Economy (CE)Document18 pagesEnabling Factors and Strategies For The Transition Toward A Circular Economy (CE)Nikola StojakovicNo ratings yet

- Literature Review On Environmental SustainabilityDocument5 pagesLiterature Review On Environmental SustainabilityafmzaxfmrdaameNo ratings yet

- Sustainability 10 02758 PDFDocument25 pagesSustainability 10 02758 PDFOviya VihaNo ratings yet

- Brief Overview On Circular Economy: by Mina Kobilarev, PHDDocument17 pagesBrief Overview On Circular Economy: by Mina Kobilarev, PHDNebojsa RedzicNo ratings yet

- Circular Economy in The Context of Sustainable DevelopmentDocument28 pagesCircular Economy in The Context of Sustainable DevelopmentmiskoscribdNo ratings yet

- DousasDocument3 pagesDousasMaaz KhanNo ratings yet

- Remanufacturing For The Circular Economy: An Examination of Consumer Switching BehaviorDocument15 pagesRemanufacturing For The Circular Economy: An Examination of Consumer Switching Behaviorberggren.nicoleNo ratings yet

- Stakeholder Management in Circular Economy Product Development in The Mining Industry - A Case StudyDocument15 pagesStakeholder Management in Circular Economy Product Development in The Mining Industry - A Case StudychevroletNo ratings yet

- Business Models For Circular Economy and Sustainable Development: The Case of Lease TransactionsDocument18 pagesBusiness Models For Circular Economy and Sustainable Development: The Case of Lease TransactionsTheresa BrownNo ratings yet

- 2018-Knowledge Sharing and Scientific Cooperation in The Design of Research-Based Policies - The Case of The Circular EconomyDocument37 pages2018-Knowledge Sharing and Scientific Cooperation in The Design of Research-Based Policies - The Case of The Circular EconomyBruna Silva SantosNo ratings yet

- Linear Economy Versus Circular Economy A ComparatiDocument4 pagesLinear Economy Versus Circular Economy A ComparatiElroy FransiskusNo ratings yet

- Economic and Environmental Packaging Sustainability: A Case StudyDocument10 pagesEconomic and Environmental Packaging Sustainability: A Case Studymn1938No ratings yet

- Circular EconomyDocument33 pagesCircular EconomyRodrigoNo ratings yet

- Towards Responsible and Sustainable Supply Chains - Innovation, Multi-Stakeholder Approach and GovernanceDocument29 pagesTowards Responsible and Sustainable Supply Chains - Innovation, Multi-Stakeholder Approach and GovernanceLauro SilapanNo ratings yet

- Avanzar en El Rigor Cuantitativo en La Literatura de La Economía CircularDocument12 pagesAvanzar en El Rigor Cuantitativo en La Literatura de La Economía CircularJoe BotelloNo ratings yet

- Research ProposalDocument9 pagesResearch ProposalAhmed MemonNo ratings yet

- A Practical and Analytic View On Legal Framework of Circular Economics As One of The Recent Economic Law Insights: A Comparative Legal StudyDocument26 pagesA Practical and Analytic View On Legal Framework of Circular Economics As One of The Recent Economic Law Insights: A Comparative Legal StudyNatalia Delgado GuerreroNo ratings yet

- Business Transitions: A Path To Sustainability: Annik Magerholm Fet EditorDocument269 pagesBusiness Transitions: A Path To Sustainability: Annik Magerholm Fet Editor9h8t7qhgdfNo ratings yet

- Circular EconomyDocument5 pagesCircular Economysong neeNo ratings yet

- Genovese, A. (2017)Document38 pagesGenovese, A. (2017)jose carlos fajardoNo ratings yet

- Accepted ManuscriptDocument18 pagesAccepted ManuscriptYASHASVI SHARMANo ratings yet

- Advances in The Circular Economy 2019 Resources Conservation and RecyclingDocument2 pagesAdvances in The Circular Economy 2019 Resources Conservation and RecyclingP_DaviesNo ratings yet

- The Spiral EconomyDocument10 pagesThe Spiral EconomyLucas LaureanoNo ratings yet

- Eco - Innovation and Circular Business Models As Drivers For A Circular Economy.Document20 pagesEco - Innovation and Circular Business Models As Drivers For A Circular Economy.Rocio Milagros Loli ValerioNo ratings yet

- Ethical ConcernsDocument10 pagesEthical ConcernsEmmanuel Alura YakubuNo ratings yet

- Sustainable Operations Research Based Assignment OnDocument11 pagesSustainable Operations Research Based Assignment Onssvarma09No ratings yet

- Industrial Ecology: From Wikipedia, The Free EncyclopediaDocument8 pagesIndustrial Ecology: From Wikipedia, The Free EncyclopediaSailaja Sankar SahooNo ratings yet

- 12 Liu Shuai 010 Guan Haoyun 018 Li Bowei 030Document10 pages12 Liu Shuai 010 Guan Haoyun 018 Li Bowei 030umaraccaNo ratings yet

- Circular Agri Food Economies: Business Models and Practices in The Potato IndustryDocument16 pagesCircular Agri Food Economies: Business Models and Practices in The Potato Industrydiu123No ratings yet

- Sustainable Product-Service Systems and Circular EDocument11 pagesSustainable Product-Service Systems and Circular EHanou HanouNo ratings yet

- Perspective of Business Models and Innovation For Sustainability Transition in HospitalsDocument19 pagesPerspective of Business Models and Innovation For Sustainability Transition in HospitalsHector JaramilloNo ratings yet

- Sustainable Manufacturing ThesisDocument5 pagesSustainable Manufacturing Thesisanashahwashington100% (1)

- 09+szczerbakDocument17 pages09+szczerbak.No ratings yet

- J Jclepro 2018 03 031Document25 pagesJ Jclepro 2018 03 031NAYAN PAULNo ratings yet

- Panel T09-P05 Session 4: 4 International Conference On Public Policy (ICPP4) June 26-28, 2019 - MontréalDocument26 pagesPanel T09-P05 Session 4: 4 International Conference On Public Policy (ICPP4) June 26-28, 2019 - Montréalshuvo barmanNo ratings yet

- 2021 Mapping The Social Dimension of The Circular EconomyDocument17 pages2021 Mapping The Social Dimension of The Circular EconomyLiliana Ale RuizNo ratings yet

- 978 3 319 92931 6 - 6Document16 pages978 3 319 92931 6 - 6draxina07No ratings yet

- Parida2019 PDFDocument19 pagesParida2019 PDFMohamed YehiaNo ratings yet

- CARDOSO EC CIRCULARDocument13 pagesCARDOSO EC CIRCULARPaulinaNo ratings yet

- Circular Economy Literature ReviewDocument5 pagesCircular Economy Literature Reviewafmabreouxqmrc100% (1)

- ZCOM - Volume 45 - Issue 1 - Pages 137-161Document25 pagesZCOM - Volume 45 - Issue 1 - Pages 137-161خديجة مصطفىNo ratings yet

- Implementing Sustainability Strategies in Networks and ClustersDocument177 pagesImplementing Sustainability Strategies in Networks and Clusterspham ngoc tuanNo ratings yet

- Dynamic Modeling and Econometrics in Economics and Finance: EditorsDocument229 pagesDynamic Modeling and Econometrics in Economics and Finance: Editorsاحمد صابرNo ratings yet

- Gibbs 2014Document21 pagesGibbs 2014daoh782No ratings yet

- 41 Twist V19i2p339Document9 pages41 Twist V19i2p339Gazanfer ERBAŞLARNo ratings yet

- Title 21 The Economics of Renewable Energy Transition Challenges and OpportunitiesDocument14 pagesTitle 21 The Economics of Renewable Energy Transition Challenges and OpportunitiesRENYJ FERNANDEZNo ratings yet

- A New Circular Business Model Typology For Creating Value From Agro WasteDocument11 pagesA New Circular Business Model Typology For Creating Value From Agro WasteKakiu Celis ToledoNo ratings yet

- Journal of Cleaner Production: Amir Rashid, Farazee M.A. Asif, Peter Krajnik, Cornel Mihai NicolescuDocument12 pagesJournal of Cleaner Production: Amir Rashid, Farazee M.A. Asif, Peter Krajnik, Cornel Mihai NicolescuDebashree DeNo ratings yet

- 5.sustainable Supply Chain Management - A Case Study at IKEADocument11 pages5.sustainable Supply Chain Management - A Case Study at IKEAechonNo ratings yet

- Business Model Innovation For Energy Transition in Household SectorDocument16 pagesBusiness Model Innovation For Energy Transition in Household SectorDavid TerrerosNo ratings yet

- Shopping Center PDFDocument8 pagesShopping Center PDFShaira ReyesNo ratings yet

- The Dematerialization Potential of Services and It: Futures Studies Methods PerspectivesDocument15 pagesThe Dematerialization Potential of Services and It: Futures Studies Methods PerspectivesRaghav BihaniNo ratings yet

- Eco Business ParkDocument10 pagesEco Business ParkJavier HerrerosNo ratings yet

- Microsoft Word-BackcastingfromDocument39 pagesMicrosoft Word-BackcastingfromFrancis Gabriel AbogNo ratings yet

- NCKH Paper VũDocument14 pagesNCKH Paper Vũhaidang13102003No ratings yet

- AJBM NovaisetalDocument11 pagesAJBM Novaisetalkhadijatul fatemaNo ratings yet

- Sustainable Innovation: The impact on the success of US large capsFrom EverandSustainable Innovation: The impact on the success of US large capsNo ratings yet

- Industrial Symbiosis for the Circular Economy: Operational Experiences, Best Practices and Obstacles to a Collaborative Business ApproachFrom EverandIndustrial Symbiosis for the Circular Economy: Operational Experiences, Best Practices and Obstacles to a Collaborative Business ApproachRoberta SalomoneNo ratings yet

- Circular Economy, Industrial Ecology and Short Supply ChainFrom EverandCircular Economy, Industrial Ecology and Short Supply ChainNo ratings yet

- Pham Le Thu Nga Hanoi University KM 9, Nguyen Trai ST., Thanh Xuan Dist., Hanoi Tel: (04) 3 5533560 Email: Ngaplt@hanu - Edu.vnDocument2 pagesPham Le Thu Nga Hanoi University KM 9, Nguyen Trai ST., Thanh Xuan Dist., Hanoi Tel: (04) 3 5533560 Email: Ngaplt@hanu - Edu.vnLan VuNo ratings yet

- Thesis Alex FlorianDocument209 pagesThesis Alex FlorianPratikNo ratings yet

- Thesis (Scribd)Document14 pagesThesis (Scribd)Shai Anne CortezNo ratings yet

- Soil + GisDocument7 pagesSoil + GisshivachandraNo ratings yet

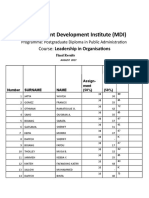

- Mdi Postgraduate Diploma Public Administration Results August 2017Document4 pagesMdi Postgraduate Diploma Public Administration Results August 2017Mr DamphaNo ratings yet

- The Latest Millennials (1995-2000) : Examining Within-Group Work EthicDocument16 pagesThe Latest Millennials (1995-2000) : Examining Within-Group Work EthicAhmad Syah PutraNo ratings yet

- Gender-and-Society-midterm CDocument8 pagesGender-and-Society-midterm CBALBIDO John LesterNo ratings yet

- Accuracy of Digital Impressions For Implant-Supported Complete-Arch ProsthesisDocument23 pagesAccuracy of Digital Impressions For Implant-Supported Complete-Arch ProsthesisValeria CrespoNo ratings yet

- Judging Criteria For Poster and Oral PresentationDocument2 pagesJudging Criteria For Poster and Oral PresentationRoland John MarzanNo ratings yet

- Weekly Schedule of MBA 2016 SIIIA Week 1Document12 pagesWeekly Schedule of MBA 2016 SIIIA Week 1aadinNo ratings yet

- Nursing StudentsDocument16 pagesNursing Studentsnhoj eca yabujNo ratings yet

- Study DesignsDocument166 pagesStudy DesignsIsmail QamarNo ratings yet

- Small Business Awareness and Adoption of State of The Art Technologies in Emerging and Developing Markets and Lessons From The COVID 19 PandemicDocument19 pagesSmall Business Awareness and Adoption of State of The Art Technologies in Emerging and Developing Markets and Lessons From The COVID 19 PandemickeithNo ratings yet

- Group 3 - Evaluating Selection Techniques and DecisionsDocument40 pagesGroup 3 - Evaluating Selection Techniques and Decisionsirishkate matugasNo ratings yet

- MANCOVA Workshop: - Please Open SPSSDocument45 pagesMANCOVA Workshop: - Please Open SPSSjohnbannyNo ratings yet

- EAPP Week 5Document7 pagesEAPP Week 5Niña Camille Arrozal David86% (7)

- EC - 2019 Telecoupling ResearchDocument13 pagesEC - 2019 Telecoupling ResearchAna PaulaNo ratings yet

- Paleoseismic TrenchingDocument16 pagesPaleoseismic TrenchingFadhel IrzaNo ratings yet

- Literature Review Newspaper IndustryDocument5 pagesLiterature Review Newspaper Industryzejasyvkg100% (1)

- Interpretations of Myth in Contemporary Architectural WritingDocument21 pagesInterpretations of Myth in Contemporary Architectural WritingAnonymous hbg8bn6HiNo ratings yet

- Hanley Et Al-2014-Journal of Applied Behavior AnalysisDocument21 pagesHanley Et Al-2014-Journal of Applied Behavior AnalysisEla AndreicaNo ratings yet

- Impact of Proactive Postsales Service and Cross-Selling Activities On Customer Churn and Service CallsDocument17 pagesImpact of Proactive Postsales Service and Cross-Selling Activities On Customer Churn and Service CallsHải YếnNo ratings yet

- International Space Station User's GuideDocument50 pagesInternational Space Station User's GuideBob Andrepont100% (1)

- Student's Manual: IntermediateDocument41 pagesStudent's Manual: IntermediateTalent SystemNo ratings yet

- British Tourist Authority Price Sensitivity of Tourism To BritainDocument132 pagesBritish Tourist Authority Price Sensitivity of Tourism To BritainLaura AndreeaNo ratings yet

- Creating Customer Engagement Via Mobile Apps-How Apps Usage DriveDocument48 pagesCreating Customer Engagement Via Mobile Apps-How Apps Usage DriveSasa SanandraNo ratings yet

- The Role of Research in Educational PlanningDocument24 pagesThe Role of Research in Educational PlanningsumaiyaqasimNo ratings yet

- Finals - ED01Document36 pagesFinals - ED01Personal AdminNo ratings yet

- Design of The Literature ReviewDocument62 pagesDesign of The Literature ReviewIkram AminaNo ratings yet