Professional Documents

Culture Documents

Index 2013 Bioprocess-Engineering

Index 2013 Bioprocess-Engineering

Uploaded by

Carmen Hdz0 ratings0% found this document useful (0 votes)

22 views11 pagesThis document provides an index of terms related to bioprocess engineering and biotechnology. It lists over 200 terms alphabetically from "absolute filtration" to "wild type selection". Each term is briefly defined. The index covers topics such as microbial growth kinetics, enzyme kinetics, fermentation processes, downstream processing, and more. It serves as a reference guide for the key concepts and terminology used in bioprocess engineering.

Original Description:

Original Title

Index_2013_Bioprocess-Engineering

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an index of terms related to bioprocess engineering and biotechnology. It lists over 200 terms alphabetically from "absolute filtration" to "wild type selection". Each term is briefly defined. The index covers topics such as microbial growth kinetics, enzyme kinetics, fermentation processes, downstream processing, and more. It serves as a reference guide for the key concepts and terminology used in bioprocess engineering.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

22 views11 pagesIndex 2013 Bioprocess-Engineering

Index 2013 Bioprocess-Engineering

Uploaded by

Carmen HdzThis document provides an index of terms related to bioprocess engineering and biotechnology. It lists over 200 terms alphabetically from "absolute filtration" to "wild type selection". Each term is briefly defined. The index covers topics such as microbial growth kinetics, enzyme kinetics, fermentation processes, downstream processing, and more. It serves as a reference guide for the key concepts and terminology used in bioprocess engineering.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 11

Index

absolute filtration, 204 anaerobic fermentation, 58, 59,

acceleration phase, 106 62, 66, 142

activation energy of thermal death, anaerobic respiration, 22, 58, 59

192 anaplerotic reactions, 67

adaptive enzyme, 45, 48, anticodon, 41

106 aqueous two phase extraction, 229

adenosine phosphates, 34 archaebacteria, 9

ADP, 34, 54, 55, 57, 58, 61, 62, archea, 8, 9, 10, 15, 20

64, 65, 66, 68, 70 Arrhenius form, 192

adsorption, 87 ATP, 31, 34, 54, 55, 57, 58, 61,

adsorption isotherms, 229 62, 64, 65, 66, 67, 68,

aerobic respiration, 57, 58, 59, 74, 70, 72

98, 141, 142 axial dispersion, 200, 201, 202,

aerotolerant anaerobes, 59 203

affinity chromatography, 231

air sterilisation, 189, 190, 203 β-oxidation, 31, 62, 72

aldoses, 26 fats, 68–71

alkaline solution, 99 balanced growth, 109

alkanes, 71 batch culture, 11, 97, 98, 101,

allolactose, 47 102, 103, 104, 112, 123,

allosteric enzyme, 83 124, 140, 161

amino acids, 3, 21, 22, 31, 32, 33, batch enzyme reactor, 86

38, 42, 99, 100, 101, 113, batch filtration, 213–14

190, 231 batch process

AMP, 34, 48, 54 bubble density distribution,

amylases, 4, 30, 75 103

amylopectin, 28, 29 dependence of growth rate on

amylose, 28 substrate concentration,

anabolic pathways, 71–3 112–15

anabolism, 53 design equations, 101–16

235

Published by Woodhead Publishing Limited, 2013

Index

flask cultures in shaker oxygen transfer, 185–6

incubator on the lab bench, power requirements, 185

104 shear stress, 186

instrumented laboratory stirred constant mixing, 180–2

tank reactor, 105 flow regime, 182

microbial growth rate, 102–11 oxygen transfer, 181

batch growth curves, 110 power requirements, 180–1

characteristic microbial shear stress, 181–2

growth phases, 107 constant oxygen transfer rate,

effect of substrate 173–80

concentration on specific flow regime, 179–80

growth rate, 113 geometrically similar vessels,

exponential growth of single 175

bacterial cell, 107 mixing, 176–8

rate of substrate utilisation and power requirements, 174–6

product formation, 115–16 shear stress, 178–9

batch sterilisation, 193–9, 200, constant shear stress, 182–6

202 flow regime, 184–5

binomial nomenclature, 10 mixing, 184

biocatalysts, 75–96 oxygen transfer, 183–4

enzyme kinetics with inhibition, power requirements, 183

78–84 biotechnology, 1

enzyme kinetics with no biotransformation, 75

inhibition, 76–8 BIOX process, 4

enzyme reactors with bubble density distribution, 102

immobilised enzymes, buffering capacity, 22, 100

86–95

enzyme reactors with soluble CAP, 48

enzymes, 84–6 carbohydrates, 18, 21, 26–30, 31,

biodiesel, 20 59, 62, 71, 130, 148

bioprocess cellulose, 29

asepsis and sterility, 189–207 D-glucose conversion from

air filter sterilisation, 203–7 straight chain to pyranose

media and equipment heat form, 28

sterilisation, 190–203 families of D-aldoses and

bioprocess engineering, 1–6 ketoses, 27

bioprocess scale up, 171–87 starch, 29

constant flow regime, 185–7 sucrose, 28

mixing, 186 carbon, 99

236

Published by Woodhead Publishing Limited, 2013

Index

carbon metabolism, 53–74 centrifugation, 109, 213, 216,

anabolic pathways, 71–3 217, 219

fatty acid synthesis, 71–3 chemo-autotrophs, 19, 20

gluconeogenesis, 73 chemo-heterotrophs, 53,

catabolic pathways, 59–71 59, 98

β-oxidation of fats, 68–71 chromatography, 209, 211, 212,

glycolysis, 59–62 220, 229–32

schematic of β-oxidation of CLEA, 87

fats, 69 co-repressor, 47

schematic of glycolysis, 60 CoA, 35

schematic of tricarboxylic coagulation, 217

acid cycle, 63 codon, 41

tricarboxylic acid cycle, 62–8 coenzyme A, 35

energy generation, storage and competitive inhibition, 79, 80, 82

transfer, 54–9 complex media, 130

active groups NAD, FAD and compressibility, 215

CoQ reduction, 56 concentration polarisation, 226

electron transport chain or constitutive enzyme, 45, 48

oxidative phosphorylation, continuous culture, 12, 50, 97,

56 116, 117, 119, 120, 122,

energy release and 123, 129, 130, 134, 137,

sequestration, 54 138, 140, 142, 143, 160,

oxidative and substrate level 189

phosphorylation, 55–9 continuous filtration, 213

role of adenosine continuous operation, 12, 88, 116,

triphosphate, 54–5 117, 214

Carman-Kozeny equation, 214 continuous plug flow reactor, 88

catabolic pathways, 59–71 continuous process

catabolism, 18, 53, 59, 62 basic model equations

catabolite activator protein, 48 development, 117–27

cell concentration data, 109, 110 cell and substrate concentrations

cell counts, 110 with multiple feed

cell death rate, 132 concentration, 126

cell disintegration, 211, 219 cell and substrate concentrations

cell dry weight, 109, 110, 111 with single feed

cell rupture, 217–19 concentration, 125

cellulases, 29, 30 customised continuous culture

cellulose, 21, 28, 29, 59, 166, 226, configurations, 138–40

231 design equations, 116–40

237

Published by Woodhead Publishing Limited, 2013

Index

empirical deviations from degree of sterility, 193, 194, 196,

predictions of basic model 202

equations, 127–32 Del Factor, 193

laboratory scale bubble column deoxyribonucleic acid, 36

reactor, 118 desorption, 87

modified model equations diauxie effect, 48

incorporating endogenous dilution rate, 119, 120, 122, 123,

metabolism, 132–58 124, 125, 126, 127, 129,

modified model equations 130, 132, 133, 134, 135,

incorporating energy of 142

maintenance, 135–8 disaccharides, 28

simple continuous culture dispersion model, 201

system incorporating a DNA, 16, 36, 37, 38, 40, 41, 42,

CSTR, 119 43, 44, 45, 46, 49, 109,

wild type selection during 110

culture of genetically doubling time, 107, 108

modified organisms, 129 downstream processing, 209–32

continuous sterilisation, cell rupture and cell extract

199–203 separation, 217–19

continuous stirred tank reactor, cells and extracellular fluid

88, 116 separation, 213–17

CPFR, 88, 91, 92 microbial products recovery,

critical dilution rate, 125, 126, 212

127, 128, 130 potential recovery operations,

cross-linked enzyme aggregates, 87 211–13

CSTR, 88, 89, 91, 92, 116, 117, soluble products concentration

119, 120 and purification, 219–32

cyclic fed-batch, 144

cyclic fed-batch operation, 144 ‘e-fold’ generations, 108

cysteine, 31–2 Eadie–Hofstee relationship, 78,

114, 123

D-stereoisomers, 26 effectiveness factor, 95

Damköhler number, 201 electron transport chain, 56, 57

deacceleration phase, 112 electrophoresis, 211, 220, 232

death phase, 107, 111 endogenous metabolism, 98,

deep bed filtration, 189, 203, 204, 132–5, 137, 139, 142

206 endogenous respiration, 132

degree of sterilisation, 190, 196, endogenous respiration constant,

197, 199, 200, 201, 202 132

238

Published by Woodhead Publishing Limited, 2013

Index

energy generation, 10, 17, 34, 53, enzyme respression, 47

54–9, 59–71 enzyme retention, 86

energy of maintenance, 98, 135–8, enzyme–substrate complex, 83

142 enzyme–substrate–inhibitor

entrapment, 87 complex, 81, 83

environmental conditions, 221 enzyme synthesis, 44

enzyme activity, 44 enzymes

enzyme decay constant, 85 as biocatalysts, 75–96

enzyme factories, 13 enzyme kinetics with inhibition,

enzyme immobilisation, 87, 88 78–84

enzyme induction, 46 enzyme kinetics with no

enzyme-inhibitor complex, 79, 83 inhibition, 76–8

enzyme kinetics, 76, 78 enzyme reactors with

with inhibition, 78–84 immobilised enzymes,

competitive inhibition 86–95

kinetics, 79–81 enzyme reactors with soluble

mixed inhibition kinetics, enzymes, 84–6

82–4 Equation Solver in Excel, 167

uncompetitive inhibition eubacteria, 9

kinetics, 81–2 eukaryotes, 8, 12–15, 16, 17–18

with no inhibition, 76–8 cellular structure and metabolic

enzyme reactors, 76, 84, 86, 91, reactions sites, 17–18

92 intracellular structures, 16

with immobilised enzymes, microscopic morphology, 12–15

86–95 exponential growth phase, 106,

continuous enzyme processes 107, 109, 110, 111, 112,

with kinetically controlled 113

reaction, 88–92

continuous enzyme processes facultative anaerobes, 59

with transport controlled FAD, 34

reaction, 92–5 fatty acid synthesis, 71–3

CPFR schematic, 90 fatty acids, 20, 30, 31, 63, 68, 70,

CSTR schematic, 89 71, 72

immobilisation techniques, fed-batch bioprocess

86–8 design equations, 140–4

laboratory membrane reactor fed-batch culture, 97, 140, 141,

housing ceramic support for 142, 161, 189

enzyme immobilisation, 88 fed-batch process, 67

with soluble enzymes, 84–6 Fick’s Second Law, 154

239

Published by Woodhead Publishing Limited, 2013

Index

filter sterilisation, 203–7 continuous sterilisation,

filtration, 109, 189, 203, 204, 213, 199–203

214, 215, 216, 217, 219, dependence of thermal death

225, 227 and degradation rates on

final electron acceptor, 64, 147 temperature, 198

flavin adenine dinucleotide, 34 influence of sterilisation

flocculation, 217 temperature on sterilisation

flow regime, 172, 173, 176, 177, efficiency, 192

179–80, 182, 184–5, 185–7 kinetics, 190–3

fractional precipitation, 221 media and equipment, 190–203

fungi, 12–15 thermal destruction of

contaminating

gassing out procedure, 162, 166, microorganisms, 203

168 hemicellulose, 29

gel chromatography, 231 Henry’s Law, 159

gel filtration, 231 hierachical system, 8

gel regime, 226 high pressure homogenisation,

gene, 8, 44, 45, 46, 47, 48 217–18

generation time, 108, 109 HTST sterilisation, 198, 200

genetic engineering, 49, 50, 76 hydrocarbons, 21

genetic modification, 49–50

genetic regulation, 44–8 impeller tip speed, 178–9

geometric similarity, 172, 173, in situ product removal, 139

175, 177, 181 inducer, 46, 48, 101, 123, 141

geometrical similarity, 173 inertial impaction, 206

gluconeogenesis, 31, 67, 73 insulin, 4–5

glucose isomerase, 75 interfacial area per unit liquid

glycogen, 29, 73 volume, 94

glycolysis, 31, 59–62, 63, 65, 66, interfacial area per unit volume,

72 151, 152, 154, 155, 157

glyoxylate shunt, 67 ionic polymers, 223

GMO, 39, 50, 86, 101, iron, 99

129, 130

Gram negative, 17 ketones, 26, 28

Gram positive, 17 ketoses, 26

gravity sedimentation, 216–17

lac operon, 46, 47

heat sterilisation lacI, 47

batch sterilisation, 193–9 lactose, 28

240

Published by Woodhead Publishing Limited, 2013

Index

lag phase, 48, 106, 112 Michaelis–Menten equation, 77,

Latin binomial system, 10 78, 80, 81, 84, 85, 94, 95

Le Chatelier’s Principle, 82 Michaelis–Menten kinetics, 93

limiting substrate, 112, 113, 130 microbial kinetics

Lineweaver–Burk relationship, 78, batch, continuous and fed-batch

80, 82, 84, 114, 123 processes, 97–146

lipids, 30–1, 33, 130 batch process design equations,

liquid extraction, 220, 227–9 101–16

log penetration model, 204, 205, continuous process design

206 equations, 116–40

low dilution rate, 130, 131, 134, fed-batch bioprocess design

135, 137, 138, 139 equations, 140–4

LTLT sterilisation, 199 nutrient medium, 98–101

microbiology, 7–23

maintenance coefficient, 136 cellular structure and metabolic

maltose, 28 reactions sites, 15–18

mass transfer limitation, 87, 93, classification according to

95 carbon and energy

Matlab, 168 requirements, 18–20

mechanical rupture, 217 filamentous fungal colonies, 14

media sterilisation, 189, 190 intracellular structures of

membrane separation, 211, 220, prokaryotes and

224–7 eukaryotes, 16

metabolic macromolecules, 25–38 microorganisms, 8–15

carbohydrates, 26–30 nutrient requirements, 21–2

lipids, 30–1 schematic of classification

nucleosides, nucleotides and according to carbon and

nucleic acids, 33–8 energy requirements, 19

proteins, 31–3 the Phylogenetic Tree of Life, 9

metabolic pathways, 8, 25, 26, 30, microorganisms, 8–15

31, 33, 53, 190 microscopic morphology, 11–15

metabolism, 25, 48, 53, 54, 57, eukaryotes, 12–15

62, 63, 66, 99, 132, 133, filamentous fungal colonies,

134, 135, 137, 139, 142, 14

147, 163, 171, 190 prokaryotes, 11–12

methanogens, 20 taxonomy, 8–11

Methanopyrus, 10 mitochondria, 17, 68, 72

Michaelis–Menten constant, 77, mixed inhibition, 79, 82–4

81, 84 mixing, 66, 102, 117, 128, 142,

241

Published by Woodhead Publishing Limited, 2013

Index

160, 171, 172, 173, 176, nucleic acids, 33, 36–8, 99

177, 178, 180, 181, 182, nucleosides, 33–6

184, 186, 187, 224 nucleotides, 33–6, 37, 38, 40, 42,

mixing time, 176 44, 53, 54, 99

modified gassing out procedure, adenosine mono-, di- and

166 triphosphate, 35

molar flow rate of oxygen nicotinamide adenine

entering, 158 dinucleotide, flavin adenine

molar flow rate of oxygen exiting, dinucleotide and coenzyme

158–9 A, 36

molar flux, 151 parent purine and pyrimidine

molecular biology, 8, 39–51 compounds, 34

enzyme synthesis regulation, RNA and DNA, 37

45 nutrient medium, 21, 22, 97,

genetic modification, 49–50 98–101, 104, 117, 120,

genetic regulation, 44–8 141, 199

protein synthesis, 43

replication, 40–1 obligate aerobes, 58

transcription, 41 operator, 45, 46, 47

translation, 41–4 operon, 45, 46, 47, 48

molecular cloning, 49 OTR, 148, 149, 150, 151, 152,

molecular diffusion, 151 155, 156, 157, 158, 159,

Monod growth kinetics, 11, 13, 160, 161, 162, 164, 166,

108–9, 111, 121 173, 174

Monod Model, 112, 113, 114, OUR, 148, 158, 159, 164, 165,

120, 123, 129, 133, 136, 167

143, 147 overall volumetric mass transfer

monohydroxyaldehydes, 26 coefficient, 94

monohydroxyketones, 26 overall volumetric oxygen transfer

monosaccharides, 26 coefficient, 147–69

morphology, 7, 11, 12, 13, 14, oxidative phosphorylation, 56, 57,

111 58, 59, 62, 65, 147

mRNA, 41, 42, 43, 44, 45, 47, 48 oxygen, 99

oxygen limiting, 58

NAD+, 34 oxygen mass balance, 158

negative modulation, 83 oxygen probe, 161, 162

nicotinamide dinucleotide, 34 oxygen solubility, 147, 148, 150,

nitrogen, 22, 99–100 151, 156, 157, 159, 160,

non-competitive inhibition, 79, 84 161, 163

242

Published by Woodhead Publishing Limited, 2013

Index

oxygen transfer, 7, 21, 58, 102, palmitic acid, 70

117, 148, 149, 150, 161, Péclet number, 201

168, 171, 172, 174, 176, Penetration Theory, 149

178, 179, 181, 183–4, 185, penicillin amidase, 76

186, 187 peptidoglycan, 15

oxygen transfer coefficient, pharming, 49

152 phospholipids, 30

oxygen transfer limitation, 13, phosphorous, 100

172, 184 photo-autotrophs, 20

oxygen transfer rate, 147–69, 172, Phylogenetic Tree of Life, 9

173 plasmids, 16, 49

design equations, 149–57 polyhydroxyaldehydes, 28

bubble diameter and size polyhydroxyalkonates, 71

distribution in bubble polymerase chain reaction, 49

column reactor, 153 polypeptide, 31, 32, 41, 42, 43,

edge detection on original 44, 45

image and contrast polypeptide chains, 32

mapping of detected polysaccharides, 28

bubbles, 154 positive modulation, 83

possible resistances to oxygen potassium, 22

transfer according to precipitation, 87, 88, 220,

Two Film Theory model, 221–4

150 precise fractionation, 224

measurement, 157–68 pressure step procedure, 166, 167,

quantification under dynamic 168

conditions, 161–8 probe constant, 166, 167

dynamic methodologies prokaryotes, 8, 11–12, 15–17, 45,

assuming a negligible probe 111, 215, 216

response lag, 162–5 cellular structure and metabolic

dynamic methodologies reactions sites, 15–17

incorporating a probe intracellular structures, 16

response lag, 165–8 microscopic morphology, 11–12

oxygen concentration profile promoter, 45, 46, 47, 48

during the dynamic method proteins, 4, 15, 31–3, 38, 47, 99,

in a system with respiring 220, 221, 222, 223, 224,

cells, 163 229, 231, 232

quantification under steady state pseudo steady state, 143, 144

conditions, 158–61 PT, 149

oxygen utilisation rate, 147, 148 purification programme, 33, 209

243

Published by Woodhead Publishing Limited, 2013

Index

rate of thermal death, 191 slime layers, 16, 128, 215

reaction velocity, 76, 77, 80, 81, solvent extraction, 227–8,

84, 94, 95 229

recombinant DNA, 4, 5, 49 specific growth rate, 108, 109,

regulatory gene, 46 111, 112, 113, 114, 115,

replication, 11, 40–1, 107, 111 120, 122, 123, 126, 127,

repressor, 46, 47, 123 129, 147

repressor molecule, 46 spores, 11, 12, 13, 14

respiratory chain oxidation, 57 sporulation, 12

respiratory quotient, 142 SRT, 149

response lag, 161, 162, 165, 166, starch, 4, 28, 29, 30, 59, 75

167, 168 stationary phase, 107, 110, 111,

reverse osmosis, 225, 226, 227 229, 230

Reynolds number, 177, 179, 180, steady state, 89, 90, 120, 121,

182, 184, 185, 187, 201 123, 124, 125, 126,

ribonucleic acid, 36, 37, 41, 45, 127, 133, 136, 137, 138,

46, 47, 48, 109, 131 140, 143, 144, 152, 153,

ribosomes, 16, 17, 42, 46 154, 158, 159, 160, 161,

RQ, 142 201

rRNA, 42 stirred tank reactor, 102, 105

structural genes, 45, 46, 47, 48

salt precipitation, 222 substrate inhibition, 114

salting out, 222, 223 substrate level phosphorylation,

‘salting out’ constant, 222 55–9, 61, 64, 65, 67

‘salting out’ equation, 222 substrate limitation, 130, 131,

‘salting out’ technique, 222 141

saturation constant, 112 sucrose, 28

Sauter mean diameters, 152 Sulfolobus, 10

scale up criterion, 172, 173, 174, Surface Renewal Theory, 149

178, 179, 180, 181, 182,

183, 184, 185 thermal death, 191, 192, 193, 198,

secondary metabolites, 116, 138, 199, 200

140 thermal death rate constant, 191

sedimentation, 213, 216, 217 thermal degradation, 191, 193,

selective pressure of continuous 198, 199, 200, 201

culture, 130 Thiele modulus, 95

shear stress, 171, 172, 173, 176, transcription, 40, 41, 44, 45, 46,

178, 179, 181, 182, 183, 47, 48

184, 186, 187 translation, 40, 41, 42, 43, 45

244

Published by Woodhead Publishing Limited, 2013

Index

tricarboxylic acid cycle, 31, 35, ultrasound, 218

62–8, 64, 66, 67, 68, 70, uncompetitive inhibition, 79,

72 81–2, 84

triglycerides, 20

triplet code, 41, 42 wall growth, 128

tRNA, 41, 42, 43

Two Film Theory, 149 xylose isomerase, 4

ultrafiltration, 86, 219, 224, 225, yield coefficient, 115

226 yield constant, 124

245

Published by Woodhead Publishing Limited, 2013

You might also like

- Genetics Analysis and Principles 7Th Edition Brooker Full ChapterDocument51 pagesGenetics Analysis and Principles 7Th Edition Brooker Full Chapterwilliam.shaw138100% (20)

- Mitosis WorksheetDocument4 pagesMitosis WorksheetAmna Jamshed67% (3)

- Purification Table InstructionDocument1 pagePurification Table Instructionapi-3744715100% (3)

- Dna StructureDocument23 pagesDna Structureapi-315792432No ratings yet

- IndexDocument8 pagesIndexAli J. HojeijNo ratings yet

- 2 BackmatterDocument12 pages2 BackmatterAdam MihaiNo ratings yet

- Perfusion Cell Culture Process DevelopmentDocument5 pagesPerfusion Cell Culture Process DevelopmentPosh Arts and CraftsNo ratings yet

- 3561x IndxDocument8 pages3561x Indxjamaljamal20No ratings yet

- IndexDocument4 pagesIndexRui LiuNo ratings yet

- Index - 2020 - Hydrogen Biomass and BioenergyDocument7 pagesIndex - 2020 - Hydrogen Biomass and BioenergyLuiz Felipe Soares LopesNo ratings yet

- Reduction DisconectionDocument5 pagesReduction DisconectionGabriel FloresNo ratings yet

- A Textbook of Experimental Microbiology: June 2023Document294 pagesA Textbook of Experimental Microbiology: June 2023resonce2021No ratings yet

- Index - 2019 - Food Quality and Shelf LifeDocument10 pagesIndex - 2019 - Food Quality and Shelf LifeCherise TanNo ratings yet

- Index: - Linolenic Acid 236, 237-8 - Tocopherol 198-9Document10 pagesIndex: - Linolenic Acid 236, 237-8 - Tocopherol 198-9Raul tejadaNo ratings yet

- Index - 1992 - Introduction To Colloid and Surface ChemistryDocument9 pagesIndex - 1992 - Introduction To Colloid and Surface ChemistryAZUCENANo ratings yet

- Index 2017 Seaweed-PolysaccharidesDocument10 pagesIndex 2017 Seaweed-Polysaccharidesdanka0709No ratings yet

- 3 s2.0 B9780323910231100006 MainDocument8 pages3 s2.0 B9780323910231100006 Main7fkqx7zh7pNo ratings yet

- IndiceDocument10 pagesIndiceZander MctrevorNo ratings yet

- Index: See Also Essential Amino AcidsDocument12 pagesIndex: See Also Essential Amino AcidsAlejandro BoteroNo ratings yet

- 3 s2.0 B9780124402010500175 MainDocument4 pages3 s2.0 B9780124402010500175 MainHassan Funsho AkandeNo ratings yet

- HTTPS://WWW Scribd com/book/412445555/Compostable-Polymer-MaterialsDocument15 pagesHTTPS://WWW Scribd com/book/412445555/Compostable-Polymer-MaterialsAhmedabadNo ratings yet

- X IndexDocument8 pagesX Indexابراهيم القويعىNo ratings yet

- Index 1999 Molecular-Biology-TechniquesDocument6 pagesIndex 1999 Molecular-Biology-TechniquesANANo ratings yet

- Index - 2022 - Advances in Chemical ProteomicsDocument7 pagesIndex - 2022 - Advances in Chemical ProteomicsPœta OciosoNo ratings yet

- No Title Available - 2013 - Handbook of Biopolymers and Biodegradable PlasticsDocument16 pagesNo Title Available - 2013 - Handbook of Biopolymers and Biodegradable PlasticsJiankun YangNo ratings yet

- Index, Pages 245-256Document12 pagesIndex, Pages 245-256Saumya SinghNo ratings yet

- Index - 2021 - Advances in Organic FarmingDocument6 pagesIndex - 2021 - Advances in Organic FarmingPœta OciosoNo ratings yet

- Index 1994 Advanced Fiber Spinning TechnologyDocument5 pagesIndex 1994 Advanced Fiber Spinning TechnologyKavin MohanasundaramNo ratings yet

- Index 2019 Recent Developments in Applied Microbiology and BiochemistryDocument14 pagesIndex 2019 Recent Developments in Applied Microbiology and BiochemistryramamurthiNo ratings yet

- Subject IndexDocument8 pagesSubject Indexjubatus.libroNo ratings yet

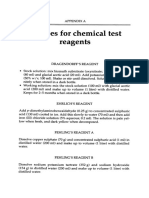

- Recipes For Chemical Test Reagents: ML) ML)Document15 pagesRecipes For Chemical Test Reagents: ML) ML)andyrojasNo ratings yet

- Index: Book - 6376.indb 249 9/4/13 4:08 PMDocument6 pagesIndex: Book - 6376.indb 249 9/4/13 4:08 PMFábio FernandesNo ratings yet

- Index: Advanced Modelling Techniques in Structural Design, First Edition. Feng FuDocument6 pagesIndex: Advanced Modelling Techniques in Structural Design, First Edition. Feng FuMahmoud AbbassNo ratings yet

- 3 s2.0 B9780123850997000334 MainDocument21 pages3 s2.0 B9780123850997000334 Mainsuraj kokareNo ratings yet

- Index: Cambridge Books Online © Cambridge University Press, 2009Document7 pagesIndex: Cambridge Books Online © Cambridge University Press, 2009Veronica B MarinaNo ratings yet

- Index: Alcaligenes, 28-9 See Also EthanolDocument7 pagesIndex: Alcaligenes, 28-9 See Also EthanolKeshavNo ratings yet

- Index: See Also Mush See Soap Base See Zeta PhaseDocument19 pagesIndex: See Also Mush See Soap Base See Zeta PhaseKunwar Apoorva SinghNo ratings yet

- 3 s2.0 B9781845692162500451 MainDocument19 pages3 s2.0 B9781845692162500451 MainAashu984No ratings yet

- Back MatterDocument8 pagesBack MatterZhixiang HuangNo ratings yet

- Subject IndexDocument10 pagesSubject IndexDelvia ElvindaNo ratings yet

- Index: Biomass Gasification and Pyrolysis. DOI: 10.1016/B978-0-12-374988-8.00021-0Document12 pagesIndex: Biomass Gasification and Pyrolysis. DOI: 10.1016/B978-0-12-374988-8.00021-0ThoharudinNo ratings yet

- Index - 2018 - Gasification of Waste MaterialsDocument7 pagesIndex - 2018 - Gasification of Waste MaterialsRibhu GautamNo ratings yet

- Food HygieneDocument22 pagesFood HygieneIvy AlbanielNo ratings yet

- 3 s2.0 B9780128027721180017 MainDocument16 pages3 s2.0 B9780128027721180017 MainPonyo NdutNo ratings yet

- Schizochytrium Limacinum PDFDocument23 pagesSchizochytrium Limacinum PDFSheila CabreraNo ratings yet

- Circular MCQ MergedDocument3 pagesCircular MCQ Mergeddrprachishende19No ratings yet

- Index: P-Anisidine Value 77-8Document8 pagesIndex: P-Anisidine Value 77-8jamaljamal20No ratings yet

- 3 s2.0 B9780124531505500353 MainDocument5 pages3 s2.0 B9780124531505500353 MainMateo MascardoNo ratings yet

- IndexDocument5 pagesIndexMirela FrandesNo ratings yet

- Index: See AlsoDocument14 pagesIndex: See AlsoErick RodriguesNo ratings yet

- Polymers Regenerative MedicineDocument240 pagesPolymers Regenerative MedicineAmanda CookeNo ratings yet

- Keyword Index: World Journal of Microbiology & Biotechnology 13, 721 723Document3 pagesKeyword Index: World Journal of Microbiology & Biotechnology 13, 721 723sggdgdNo ratings yet

- Index - 2014 - Industrial Wastewater Treatment Recycling and ReuseDocument18 pagesIndex - 2014 - Industrial Wastewater Treatment Recycling and ReuseRichardNo ratings yet

- Index - 2014 - The Organic Chemistry of Drug Design and Drug ActionDocument11 pagesIndex - 2014 - The Organic Chemistry of Drug Design and Drug Actionahmed ahmedNo ratings yet

- Review Brewing and Brewing Research: Past, Present and FutureDocument8 pagesReview Brewing and Brewing Research: Past, Present and FuturejucalimaNo ratings yet

- Index: N-Methylated Analogues, 100Document6 pagesIndex: N-Methylated Analogues, 100SilaxNo ratings yet

- Subject IndexDocument4 pagesSubject IndexChristopher LlanosNo ratings yet

- Index - 2016 - Equations of State and PVT AnalysisDocument9 pagesIndex - 2016 - Equations of State and PVT AnalysisFernando CastelblancoNo ratings yet

- Principles of Molecular VirologyDocument8 pagesPrinciples of Molecular VirologyAJCannNo ratings yet

- Index (Pages 209-214)Document6 pagesIndex (Pages 209-214)MostafaOmidNo ratings yet

- Subcritical Water Hydrolysis of Fresh and Waste Cooking Oils To Fatty Acids Followed by Esterification To Fatty Acid Methyl Esters Detailed Characterization of Feedstocks and ProductsDocument14 pagesSubcritical Water Hydrolysis of Fresh and Waste Cooking Oils To Fatty Acids Followed by Esterification To Fatty Acid Methyl Esters Detailed Characterization of Feedstocks and ProductsCemerlang StudiNo ratings yet

- Kinetic Modeling of Simultaneous Saccharification and Fermentation of Corn Starch For Ethanol ProductionDocument10 pagesKinetic Modeling of Simultaneous Saccharification and Fermentation of Corn Starch For Ethanol ProductionSeba GelsuminoNo ratings yet

- Synthetic Multivalent Molecules: Concepts and Biomedical ApplicationsFrom EverandSynthetic Multivalent Molecules: Concepts and Biomedical ApplicationsNo ratings yet

- About The Author - 2013 - Bioprocess EngineeringDocument1 pageAbout The Author - 2013 - Bioprocess EngineeringCarmen HdzNo ratings yet

- List of Plates - 2013 - Bioprocess EngineeringDocument1 pageList of Plates - 2013 - Bioprocess EngineeringCarmen HdzNo ratings yet

- List of Figures - 2013 - Bioprocess EngineeringDocument3 pagesList of Figures - 2013 - Bioprocess EngineeringCarmen HdzNo ratings yet

- Front-Matter 2013 Bioprocess-EngineeringDocument3 pagesFront-Matter 2013 Bioprocess-EngineeringCarmen HdzNo ratings yet

- Activities SynonymsDocument2 pagesActivities SynonymsCarmen HdzNo ratings yet

- POSSESSIVE Activity 3Document1 pagePOSSESSIVE Activity 3Carmen HdzNo ratings yet

- The Stolen Space SuitDocument1 pageThe Stolen Space SuitCarmen HdzNo ratings yet

- Late Modern EnglishDocument3 pagesLate Modern EnglishCarmen HdzNo ratings yet

- Activity 2Document1 pageActivity 2Carmen HdzNo ratings yet

- Phrasal VerbsDocument1 pagePhrasal VerbsCarmen HdzNo ratings yet

- Acid Hydrolysis of Shrimp-Shell Wastes and TheDocument6 pagesAcid Hydrolysis of Shrimp-Shell Wastes and TheCarmen HdzNo ratings yet

- Excersice 1Document1 pageExcersice 1Carmen HdzNo ratings yet

- EXCERSICE Too, Also, or As WellDocument1 pageEXCERSICE Too, Also, or As WellCarmen HdzNo ratings yet

- Chater 8 - Transformational-Generative GrammarDocument20 pagesChater 8 - Transformational-Generative GrammarCarmen HdzNo ratings yet

- Molecules 24 00219Document21 pagesMolecules 24 00219Carmen HdzNo ratings yet

- Traditional GrammarDocument3 pagesTraditional GrammarCarmen HdzNo ratings yet

- Traditional Grammar TeachingDocument3 pagesTraditional Grammar TeachingCarmen HdzNo ratings yet

- 4 M Ncov Insert L28mcov1enr0 en 20200228Document2 pages4 M Ncov Insert L28mcov1enr0 en 20200228SantiagoAFNo ratings yet

- 2019 - Using Genetically Incorporated Unnatural AminoDocument30 pages2019 - Using Genetically Incorporated Unnatural AminodymscientificNo ratings yet

- Robert Hooke (1665) - Who Named The Biological Unit Cell Cell Theory 1839 - byDocument11 pagesRobert Hooke (1665) - Who Named The Biological Unit Cell Cell Theory 1839 - byKamlesh RatnamNo ratings yet

- Multiple Choice Question On CytokinesDocument6 pagesMultiple Choice Question On CytokinesRimsha Naveed100% (1)

- 227s FullDocument29 pages227s FullAugusto OsmNo ratings yet

- NSF-ITR: EIA-0086015: Structural DNA NanotechnologyDocument93 pagesNSF-ITR: EIA-0086015: Structural DNA NanotechnologyShashank GargNo ratings yet

- MTBDRplusV2 0615 304A-06-02Document14 pagesMTBDRplusV2 0615 304A-06-02TallulahNo ratings yet

- Bioloy Notes From NCERT (Mahendra Coaching NotesDocument385 pagesBioloy Notes From NCERT (Mahendra Coaching NotesBabu VermaNo ratings yet

- KPL ELISA Technical GuideDocument44 pagesKPL ELISA Technical GuidejuanescribdNo ratings yet

- Figure 4-8 Composite Diagram of An Animal Cell: AnimatedDocument1 pageFigure 4-8 Composite Diagram of An Animal Cell: AnimatedElrey AnatolNo ratings yet

- Monday Test 7 SolutionDocument11 pagesMonday Test 7 Solutionbiotecnika_test100% (1)

- Molecular Basis of Craniofacial Development and GrowthDocument2 pagesMolecular Basis of Craniofacial Development and GrowthCornelia GheorghitaNo ratings yet

- Ap21 Chief Reader Report BiologyDocument15 pagesAp21 Chief Reader Report BiologyEric ChiangNo ratings yet

- Define Gene Therapy.: 3. Explain The Ethical Considerations in Germ Line Gene TherapyDocument5 pagesDefine Gene Therapy.: 3. Explain The Ethical Considerations in Germ Line Gene TherapyJake AlarconNo ratings yet

- CMB Lab 1 9 1Document19 pagesCMB Lab 1 9 1rexartooz100% (1)

- Antigen & AntibodiesDocument16 pagesAntigen & AntibodiesYing Ming TangNo ratings yet

- GCSE Biology - Enzymes - How They Work - Worksheet 11Document2 pagesGCSE Biology - Enzymes - How They Work - Worksheet 11Risali KarunarathnaNo ratings yet

- Chapter 1.1. IB Biology ReviewDocument8 pagesChapter 1.1. IB Biology ReviewLaura WNo ratings yet

- KREB's Cycle PDFDocument30 pagesKREB's Cycle PDFRitwik ChakrabortyNo ratings yet

- Humatrol P Lote 0004Document2 pagesHumatrol P Lote 0004L Carvallo Miguel75% (4)

- The Chemistry of LifeDocument32 pagesThe Chemistry of LifeHaniel David BesaNo ratings yet

- Genomics Worksheet 1Document2 pagesGenomics Worksheet 1fali92No ratings yet

- Activity Sheet - Parts of CellDocument3 pagesActivity Sheet - Parts of CellRichilyn PaganaNo ratings yet

- MacromoleculesDocument20 pagesMacromoleculesCelestial QueenNo ratings yet

- Full Download Biotechnology 2nd Edition Clark Test BankDocument32 pagesFull Download Biotechnology 2nd Edition Clark Test Bankhildasavardpro100% (38)

- Solomon-121012140059-Phpapp02 130Document1 pageSolomon-121012140059-Phpapp02 130Elrey AnatolNo ratings yet