Professional Documents

Culture Documents

ASTM C547 - 11e1 (Jan. 2012)

ASTM C547 - 11e1 (Jan. 2012)

Uploaded by

Melih SENTURKCopyright:

Available Formats

You might also like

- Astm C578 PDFDocument7 pagesAstm C578 PDFraja qammar100% (2)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- D5470-12 Standard Test Method For Thermal Transmission Properties of Thermally Conductive Electrical Insulation MaterialsDocument6 pagesD5470-12 Standard Test Method For Thermal Transmission Properties of Thermally Conductive Electrical Insulation Materialsastewayb_964354182No ratings yet

- ASTM C533-17 (Aislamiento Térmico)Document4 pagesASTM C533-17 (Aislamiento Térmico)Àngel RodriguezNo ratings yet

- Astm C578-19. (2019) PDFDocument8 pagesAstm C578-19. (2019) PDFgeologist840% (1)

- Astm C656Document3 pagesAstm C656alokjha_03No ratings yet

- Astm C 1290 - Fibrous Glass Balnket For DuctsDocument4 pagesAstm C 1290 - Fibrous Glass Balnket For DuctsleandroschroederNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- ASTM C547-17 (Aislamiento Térmico)Document7 pagesASTM C547-17 (Aislamiento Térmico)Àngel RodriguezNo ratings yet

- ASTM C592 Mineral Fiber Blanket InsulationDocument7 pagesASTM C592 Mineral Fiber Blanket InsulationMike DukasNo ratings yet

- Astm C547Document7 pagesAstm C547DilaFirizqinaNo ratings yet

- C592 13Document9 pagesC592 13Ichwan Ciptadi100% (1)

- Astm C552Document7 pagesAstm C552DilaFirizqinaNo ratings yet

- Extruded Preformed Flexible Cellular Polyolefin Thermal Insulation in Sheet and Tubular FormDocument5 pagesExtruded Preformed Flexible Cellular Polyolefin Thermal Insulation in Sheet and Tubular FormDanZel DanNo ratings yet

- Unfaced Preformed Rigid Cellular Polyisocyanurate Thermal InsulationDocument9 pagesUnfaced Preformed Rigid Cellular Polyisocyanurate Thermal InsulationBalaraman SNo ratings yet

- ASTM C610-17 (Aislamiento Térmico)Document4 pagesASTM C610-17 (Aislamiento Térmico)Àngel RodriguezNo ratings yet

- C547 PDFDocument4 pagesC547 PDFAhmedNo ratings yet

- Molded Expanded Perlite Block and Pipe Thermal Insulation: Standard Specification ForDocument4 pagesMolded Expanded Perlite Block and Pipe Thermal Insulation: Standard Specification ForBalaraman SNo ratings yet

- Astm C552 21Document4 pagesAstm C552 21goushbashaNo ratings yet

- Astm C 578-2019Document8 pagesAstm C 578-2019Mohammed AliNo ratings yet

- C890 Ceramic Fiber PDFDocument6 pagesC890 Ceramic Fiber PDFKf LiauNo ratings yet

- ASTM C610 (2011) - Standard Specification For Molded Expanded Perlite Block and Pipe Thermal InsulationDocument4 pagesASTM C610 (2011) - Standard Specification For Molded Expanded Perlite Block and Pipe Thermal InsulationLambert Nathaniel AcordaNo ratings yet

- Astm C591 20Document7 pagesAstm C591 20Endang Reta LazuardiNo ratings yet

- C 687 - 12Document10 pagesC 687 - 12Roberto ColoniaNo ratings yet

- Astm C591 - 22Document10 pagesAstm C591 - 22sgjsevenpNo ratings yet

- Mineral Fiber Blanket Thermal Insulation For Commercial and Industrial ApplicationsDocument5 pagesMineral Fiber Blanket Thermal Insulation For Commercial and Industrial ApplicationsmansurudinNo ratings yet

- Astm C578 - 22Document8 pagesAstm C578 - 22rtiyer1970No ratings yet

- Astm C552Document6 pagesAstm C552hadefNo ratings yet

- Mineral Wool Roof Insulation Board: Standard Specification ForDocument4 pagesMineral Wool Roof Insulation Board: Standard Specification ForMina RemonNo ratings yet

- ASTM C764 Mineral Fiber Loose-Fill InsulationDocument5 pagesASTM C764 Mineral Fiber Loose-Fill InsulationMike DukasNo ratings yet

- Cellulosic Fiber Loose-Fill Thermal Insulation: Standard Specification ForDocument11 pagesCellulosic Fiber Loose-Fill Thermal Insulation: Standard Specification ForingluisalejoNo ratings yet

- Spray-Applied Mineral Fiber Thermal and Sound Absorbing InsulationDocument3 pagesSpray-Applied Mineral Fiber Thermal and Sound Absorbing Insulationmohammed ;arasnehNo ratings yet

- Astm 1484-01Document12 pagesAstm 1484-01Mohamed GaballahNo ratings yet

- C 552Document7 pagesC 552milecsaNo ratings yet

- C591-05 Polyisocyanurate (PIR)Document6 pagesC591-05 Polyisocyanurate (PIR)FuNnY and EdUcAtIoNal TV for KIDS VIDEOSNo ratings yet

- Aluminum Jacketing For InsulationDocument7 pagesAluminum Jacketing For InsulationCK CkkouNo ratings yet

- Mineral Fiber Blanket Thermal Insulation For Commercial and Industrial ApplicationsDocument4 pagesMineral Fiber Blanket Thermal Insulation For Commercial and Industrial ApplicationsreneeNo ratings yet

- Astm C 547Document4 pagesAstm C 547israel.serrano.rodriguezNo ratings yet

- ASTM C592-22aDocument9 pagesASTM C592-22a22238.spoNo ratings yet

- C 533 - 95 Qzuzmy05nqDocument4 pagesC 533 - 95 Qzuzmy05nqM RNo ratings yet

- C 578 - 03 - Qzu3oc0wm0iDocument6 pagesC 578 - 03 - Qzu3oc0wm0iMohamed SayedNo ratings yet

- AstmDocument3 pagesAstmMuhammad NaumanNo ratings yet

- Testing Cellular Glass Insulation Block: Standard Test Methods ofDocument4 pagesTesting Cellular Glass Insulation Block: Standard Test Methods ofMina RemonNo ratings yet

- Estimating The Maximum Use Temperature of Thermal InsulationsDocument3 pagesEstimating The Maximum Use Temperature of Thermal InsulationsXiaodong LiNo ratings yet

- C-1767 Standard Specification For Stainless Steel Jacketing For Insulation1e - Insulation CladdingDocument7 pagesC-1767 Standard Specification For Stainless Steel Jacketing For Insulation1e - Insulation CladdingYogalingam ArumugamNo ratings yet

- ASTM C533 95reaprovedDocument4 pagesASTM C533 95reaproveddeivisbtsNo ratings yet

- Astm C153-07Document4 pagesAstm C153-07JacarreroNo ratings yet

- Polyisocyanurate Thermal InsulationDocument5 pagesPolyisocyanurate Thermal Insulationnisha_khanNo ratings yet

- ASTM C 196 Standard Specification For Expanded or Exfoliated Vermiculite Thermal Insulating CemenDocument3 pagesASTM C 196 Standard Specification For Expanded or Exfoliated Vermiculite Thermal Insulating CemenRyan LasacaNo ratings yet

- Mineral Fiber Blanket Thermal Insulation For Commercial and Industrial ApplicationsDocument5 pagesMineral Fiber Blanket Thermal Insulation For Commercial and Industrial ApplicationsAhnaf BarajaNo ratings yet

- Calcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForDocument4 pagesCalcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForNour MasmoudiNo ratings yet

- C 591 - Norma AstmDocument3 pagesC 591 - Norma AstmAmanda TezotoNo ratings yet

- Astm C 592-04Document7 pagesAstm C 592-04Hung DinhNo ratings yet

- C534C534MDocument6 pagesC534C534MLupita RamirezNo ratings yet

- Calcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForDocument4 pagesCalcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForRizal Mohamad Al-AyyubiNo ratings yet

- Astm C 592Document9 pagesAstm C 592hoseinNo ratings yet

- ASTM C 195 Standard Specification For Mineral Fiber Thermal Insulating CementDocument3 pagesASTM C 195 Standard Specification For Mineral Fiber Thermal Insulating CementRyan LasacaNo ratings yet

- Astm C578 PDFDocument7 pagesAstm C578 PDFcahyo hutomoNo ratings yet

- C 533 Calcium SilicateDocument4 pagesC 533 Calcium SilicatereneeNo ratings yet

- Selecting Temperatures For Evaluating and Reporting Thermal Properties of Thermal InsulationDocument3 pagesSelecting Temperatures For Evaluating and Reporting Thermal Properties of Thermal InsulationAsmaa RamadanNo ratings yet

- 6000-B-90-01-P-0142-00-E - Painting & Coating Touch Up and RepairDocument4 pages6000-B-90-01-P-0142-00-E - Painting & Coating Touch Up and RepairMelih SENTURKNo ratings yet

- C0007B - Daily Report - 2023-08-27 - ALL SPDocument1 pageC0007B - Daily Report - 2023-08-27 - ALL SPMelih SENTURKNo ratings yet

- Field Painting and Coating: Standard Work Process ProcedureDocument16 pagesField Painting and Coating: Standard Work Process ProcedureMelih SENTURKNo ratings yet

- Iq345 100 CN MST 00009 - RaDocument5 pagesIq345 100 CN MST 00009 - RaMelih SENTURKNo ratings yet

- Pages From 0000-SP-50!22!2 Thermal Insulation SpecificationDocument1 pagePages From 0000-SP-50!22!2 Thermal Insulation SpecificationMelih SENTURKNo ratings yet

- 4MP-T81-03222 Rev 1 FLD Painting and CoatingDocument16 pages4MP-T81-03222 Rev 1 FLD Painting and CoatingMelih SENTURKNo ratings yet

- Pages From 0000-SP-50-22 - 2 - Thermal - Insulation - Specification-2Document1 pagePages From 0000-SP-50-22 - 2 - Thermal - Insulation - Specification-2Melih SENTURKNo ratings yet

- 6000-B-90-01-P-0142-00-E - Painting & Coating Touch Up and RepairDocument4 pages6000-B-90-01-P-0142-00-E - Painting & Coating Touch Up and RepairMelih SENTURKNo ratings yet

- Ys-Fr-24 Bina Son Kontrol Raporu-02Document1 pageYs-Fr-24 Bina Son Kontrol Raporu-02Melih SENTURKNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Ys-Fr-32 Hangar Son Kontrol Raporu-01Document1 pageYs-Fr-32 Hangar Son Kontrol Raporu-01Melih SENTURKNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument4 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURK100% (1)

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Definition of Inspection and Test Plan SymbolsDocument2 pagesProject: Baladna Dairy Farm Phase-2: Definition of Inspection and Test Plan SymbolsMelih SENTURKNo ratings yet

- CAMX2015-Composite Design and AnalysisDocument86 pagesCAMX2015-Composite Design and AnalysisSabanSaulicNo ratings yet

- Scalgun BDocument2 pagesScalgun Bdevadoss kishoreNo ratings yet

- Ucs Crushed SandDocument1 pageUcs Crushed SandMohammed SalhinNo ratings yet

- Chemical Engineering ScienceDocument7 pagesChemical Engineering ScienceclaudiosldfNo ratings yet

- Part 7-Shear DesignDocument11 pagesPart 7-Shear Designangelojonard71No ratings yet

- Stress Classification in Pressure Vessels and Piping As Per ASME B31 and BPVC CodesDocument16 pagesStress Classification in Pressure Vessels and Piping As Per ASME B31 and BPVC CodeslorenzoNo ratings yet

- Batch and Continuous Distillation - FINALDocument8 pagesBatch and Continuous Distillation - FINALPenny GildoNo ratings yet

- Hvac PFD CotyDocument21 pagesHvac PFD CotyNews EconomicNo ratings yet

- Yield Line Analysisof Various Shapesof RCSlabsDocument90 pagesYield Line Analysisof Various Shapesof RCSlabsTafaraNo ratings yet

- Reaffirmed 1996Document13 pagesReaffirmed 1996Ritesh kumarNo ratings yet

- Hydraulic OilsDocument6 pagesHydraulic OilsGeorgina SuleNo ratings yet

- Nice Neotech - Phototherapy 4000 - 12Document1 pageNice Neotech - Phototherapy 4000 - 12David Gnana DuraiNo ratings yet

- Heat Exchanger LabDocument17 pagesHeat Exchanger LabMuhammad HanzalaNo ratings yet

- Fermi ProblemsDocument3 pagesFermi Problemsrc735iNo ratings yet

- Tam-Sc-2-B Doorsheet Removal and Reinstallation: February 2003 © Chevrontexaco 1 of 9Document9 pagesTam-Sc-2-B Doorsheet Removal and Reinstallation: February 2003 © Chevrontexaco 1 of 9Herlys Pereira100% (1)

- Chapter 2 Waves and Oscillation (Compatibility Mode) PDFDocument77 pagesChapter 2 Waves and Oscillation (Compatibility Mode) PDFVaibhavNo ratings yet

- MEENG 317 - Lubrication and Bearing - Part 1Document10 pagesMEENG 317 - Lubrication and Bearing - Part 1King Cyruz PabloNo ratings yet

- MCQ Unit 3Document15 pagesMCQ Unit 3abcd100% (1)

- The Institution of Engineers Sri Lanka (Iesl) Kilinochchi District CenterDocument2 pagesThe Institution of Engineers Sri Lanka (Iesl) Kilinochchi District CenterInoshan Madushika JayawickramaNo ratings yet

- Air Cooled Packaged Inverter Floor Standing Type - Heat Pump 50Hz - APCVDT1512Document54 pagesAir Cooled Packaged Inverter Floor Standing Type - Heat Pump 50Hz - APCVDT1512Phanhai Kaka100% (1)

- MAGNETISM AND MATTER ModuleDocument24 pagesMAGNETISM AND MATTER Modulehydr0gen001No ratings yet

- Effect of Air Velocity in Relative HumidityDocument12 pagesEffect of Air Velocity in Relative HumiditybananaNo ratings yet

- Lumbang Integrated National High SchoolDocument5 pagesLumbang Integrated National High SchoolLorena DizonNo ratings yet

- CT4145 CT2031 Mechanics of Structures Module Introduction Into Continuum MechanicsDocument80 pagesCT4145 CT2031 Mechanics of Structures Module Introduction Into Continuum MechanicsMarcoNo ratings yet

- Class2 - NewtonDocument54 pagesClass2 - NewtonAARUSH DESHPANDENo ratings yet

- LTMC - Fibre Optic Cable: DescriptionDocument5 pagesLTMC - Fibre Optic Cable: DescriptionTiziano D'IncàNo ratings yet

- 885F Embrittlement of Duplex Stainless SteelDocument4 pages885F Embrittlement of Duplex Stainless Steeljaymin444No ratings yet

- 2.0 Cegeotech2 Lec m1 (Intro)Document19 pages2.0 Cegeotech2 Lec m1 (Intro)Mineski Prince GarmaNo ratings yet

- Concentration Cell PDFDocument5 pagesConcentration Cell PDFMd. Masud RanaNo ratings yet

ASTM C547 - 11e1 (Jan. 2012)

ASTM C547 - 11e1 (Jan. 2012)

Uploaded by

Melih SENTURKOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM C547 - 11e1 (Jan. 2012)

ASTM C547 - 11e1 (Jan. 2012)

Uploaded by

Melih SENTURKCopyright:

Available Formats

Designation: C547 – 11´1

Standard Specification for

Mineral Fiber Pipe Insulation1

This standard is issued under the fixed designation C547; the number immediately following the designation indicates the year of

--``,,`,`,````,``,`,````,,,,`,,,-`-`,,`,,`,`,,`---

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´1 NOTE—Table 1 was editorially corrected in January 2012.

1. Scope 2. Referenced Documents

1.1 This specification covers mineral fiber insulation pro- 2.1 ASTM Standards:2

duced to form hollow cylinders for standard pipe and tubing C167 Test Methods for Thickness and Density of Blanket or

sizes. The mineral fiber pipe insulation may be molded or Batt Thermal Insulations

precision v-grooved, with one or more walls split longitudi- C168 Terminology Relating to Thermal Insulation

nally for use on pipe temperatures up to 1400°F (760°C). C177 Test Method for Steady-State Heat Flux Measure-

1.2 For satisfactory performance, properly installed protec- ments and Thermal Transmission Properties by Means of

tive vapor retarders or barriers should be used on sub-ambient the Guarded-Hot-Plate Apparatus

temperature applications to reduce movement of moisture C302 Test Method for Density and Dimensions of Pre-

through or around the insulation to the colder surface. Failure formed Pipe-Covering-Type Thermal Insulation

to use a vapor barrier can lead to insulation and system C335 Test Method for Steady-State Heat Transfer Proper-

damage. Refer to Practice C921 to aid material selection. ties of Pipe Insulation

1.3 Flexible mineral fiber wrap products such as C356 Test Method for Linear Shrinkage of Preformed

perpendicular-oriented fiber insulation rolls, non-precision or High-Temperature Thermal Insulation Subjected to Soak-

manually scored block or board, or flexible boards or blankets ing Heat

used as pipe insulation, are not covered by this specification. C390 Practice for Sampling and Acceptance of Thermal

1.4 The values stated in inch-pound units are to be regarded Insulation Lots

as standard. The values given in parentheses are mathematical C411 Test Method for Hot-Surface Performance of High-

conversions to SI units that are provided for information only Temperature Thermal Insulation

and are not considered standard. C447 Practice for Estimating the Maximum Use Tempera-

1.5 For Naval Sea Systems Command (NAVSEA) accep- ture of Thermal Insulations

tance, materials must also comply with Supplemental Require- C585 Practice for Inner and Outer Diameters of Thermal

ments. See Annex A1 of this standard. Insulation for Nominal Sizes of Pipe and Tubing

1.6 The following safety hazards caveat applies to the test C612 Specification for Mineral Fiber Block and Board

methods portion, Section 11, only: This standard does not Thermal Insulation

purport to address all of the safety concerns, if any, associated C795 Specification for Thermal Insulation for Use in Con-

with its use. It is the responsibility of the user of this standard tact with Austenitic Stainless Steel

to establish appropriate safety and health practices and C921 Practice for Determining the Properties of Jacketing

determine the applicability of regulatory limitations prior to Materials for Thermal Insulation

use. C1045 Practice for Calculating Thermal Transmission Prop-

erties Under Steady-State Conditions

C1058 Practice for Selecting Temperatures for Evaluating

1

This specification is under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.20 on

2

Homogeneous Inorganic Thermal Insulations. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved June 1, 2011. Published July 2011. Originally approved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 1964. Last previous edition approved in 2007 as C547 – 07 ´1. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

C0547-11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International

Provided by IHS under license with ASTM

1Licensee=Committee on Institutional Cooperation/5967164001

No reproduction or networking permitted without license from IHS Not for Resale, 02/13/2012 22:05:23 MST

C547 – 11´1

and Reporting Thermal Properties of Thermal Insulation 4.2 Binder decomposition at elevated temperature may be a

C1104/C1104M Test Method for Determining the Water limiting factor in certain applications. Consult the manufac-

Vapor Sorption of Unfaced Mineral Fiber Insulation turer regarding special heat rate considerations.

E84 Test Method for Surface Burning Characteristics of

Building Materials 5. Materials and Manufacturer

2.2 Other Standards: 5.1 Composition— The mineral fiber insulation for pipes

UL 723 Tests for Surface Burning of Building Materials3 shall be manufactured from mineral substance such as rock,

NFPA 255 Method of Tests of Surface Burning Character- slag, or glass, processed from a molten state into fibrous form

istics of Building Materials4 with binder. Asbestos shall not be used as an ingredient or

CAN/ULC-S102 Standard Method of Test for Surface component part. Some products may also contain adhesive.

Burning Characteristics of Building Materials and Assem- 5.2 Jackets (Facings)—The user of this specification has the

blies 5 option to specify that the insulation be jacketed.

NOTE 2—The user is advised that the maximum use temperature of

3. Terminology factory-applied facings and adhesives may be lower than the maximum

use temperature of the insulation. The specifier shall ensure that sufficient

3.1 The definitions in Terminology C168 shall apply to the

insulation thickness is installed so none of these accessory items (facings

terms used in this specification. and adhesives) are exposed to temperatures above their maximum use

3.2 Definitions of Terms Specific to This Standard: temperature. The products covered by this standard are predominantly

3.2.1 molded—refers to products preformed via a molding inorganic in nature. Organic facings, adhesives and binders are also used

process to yield full-round cylindrical pipe insulation sections. in the construction of these products. The resulting composite therefore

3.2.2 precision v-groove—refers to products fabricated from could have increased combustibility.

machined board via a precision cutting process. Machined

6. Physical Requirements

segments are adhered to a backing to form a full-round

cylindrical pipe insulation section. Due to the precision of the 6.1 The product shall conform to the following require-

process, the product has no gaps when installed. ments in addition to those specified in Table 1.

6.2 Hot Surface Performance:

4. Classification 6.2.1 The product shall not crack, warp, flame, or glow

during hot surface exposure. No evidence of melting or fiber

4.1 Products covered by this specification are classified

degradation shall be evident upon post test inspection.

according to maximum use temperature as follows:

6.2.2 The insulation’s internal temperature rise (exotherm)

4.1.1 Type I—Molded, for use to 850°F (454°C).

shall not exceed the pipe temperature by more than 200°F

Grade A—Requires no heat-up schedule

(111°C).

Grade B—Heat-up schedule is required

6.3 Non-fibrous (Shot) Content:

4.1.2 Type II—Molded, for use to 1200°F (650°C).

6.3.1 The non-fibrous content of a rock- or slag-based

Grade A—Requires no heat-up schedule

product shall not exceed 25 % by weight.

Grade B—Heat-up schedule is required

6.4 For Naval Sea Systems Command (NAVSEA) accep-

4.1.3 Type III—Precision v-groove, for use to 1200°F

tance, materials must also comply with Supplemental Require-

(650°C).

ments. See Annex A1 of this standard.

Grade A—Requires no heat-up schedule

Grade B—Heat-up schedule is required 7. Standard Shapes, Sizes, and Dimensions

4.1.4 Type IV—Molded, for use to 1000°F (538°C). 7.1 The basic shape of mineral fiber pipe insulation forms a

Grade A—Requires no heat-up schedule right annular cylinder, which is radially slit on at least one side

Grade B—Heat-up schedule is required of the cylinder axis. It is furnished in sections or segments

4.1.5 Type V—Molded, for use to 1400°F (760°C) designed to fit standard sizes of pipe and tubing.

Grade A—Requires no heat-up schedule 7.2 Typical available thicknesses range from nominal 1⁄2-in.

Grade B—Heat-up schedule is required (13 mm) to nominal 6-in. (152 mm), single or double layer, in

1⁄2-in. increments for most pipe and tubing sizes.

NOTE 1—Warning: Grade B may not be suitable for applications

requiring hot installation capability at the maximum temperature indi- 7.3 Individual dimensions for inner diameter and wall

cated. Products having a Grade B designation are designed to be used with thickness shall conform to Practice C585.

a heat-up schedule. Failure to use a heat-up schedule with Grade B 7.4 Standard section or segment length shall be 3 ft (0.91m)

products may lead to an exothermic reaction. This is dependent on

or as agreed upon between the buyer and seller.

thickness and temperature. Consult the manufacturer or manufacturer’s

literature for special heat rate considerations. 8. Dimensional Tolerances

8.1 Length equals 61⁄8-in. (3 mm).

8.2 When installed on a nominal pipe or tubing size as

3

Available from Underwriters Laboratories (UL), 2600 N.W. Lake Rd., Camas, defined in Practice C585, the insulation shall fit snugly and

WA 98607-8542, http://www.ul.com.

4

have tight longitudinal and circumferential joints.

Available from National Fire Protection Association (NFPA), 1 Batterymarch

Park, Quincy, MA 02169-7471, http://www.nfpa.org.

8.3 The inner and outer bore of the insulation shall be

5

Available from Underwriters Laboratories of Canada, 7 Crouse Road, Scarbor- concentric to the outer surface. The deviation from concentric-

ough, Ontario MIR3A9. ity shall not exceed 3⁄16 in. (5 mm).

--``,,`,`,````,``,`,````,,,,`,,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

2Licensee=Committee on Institutional Cooperation/5967164001

No reproduction or networking permitted without license from IHS Not for Resale, 02/13/2012 22:05:23 MST

C547 – 11´1

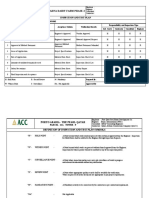

TABLE 1 Requirements of Mineral Fiber Pipe Insulation (Grades A & B)

Property Type I Type II Type III Type IV Type V

(Grades A (Grades A (Grades A (Grades A (Grades A

andB) and B) and B) and B) and B

Use temperature, max, °F (°C) 850 (454) 1200 (650) 1200 (650) 1000 (538) 1400 (760)

Sag resistance, max, % 5 5 5 5 5

thickness change

Linear shrinkage (length), max, 2 2 2 2 2

% change after change

after soaking heat at maximum

use temperature

Water vapor sorption, max, % 5 5 5 5 5

by weight

Surface burning characteristics,

max

Flame spread index 25 25 25 25 25

Smoke developed index 50 50 50 50 50

Apparent thermal conductivity,

max, Btu.in./h,ft2, °F(W/m.K)

Mean temperatureA

°F (°C)

100 (38) 0.25 (0.036) 0.25 (0.036) 0.25 (0.036) 0.25 (0.036) 0.25 (0.036)

200 (93) 0.31 (0.045) 0.31 (0.045) 0.31 (0.045) 0.31 (0.045) 0.31 (0.045)

300 (149) 0.40 (0.058) 0.37 (0.053) 0.37 (0.053) 0.37 (0.053) 0.37 (0.053)

400 (204) 0.51 (0.074) 0.45 (0.065) 0.45 (0.065) 0.45 (0.065) 0.45 (0.065)

500 (260)† 0.64 (0.092) 0.54 (0.078) 0.54 (0.078) 0.54 (0.078) 0.54 (0.078)

600 (316) 0.65 (0.094) 0.65 (0.094) 0.65 (0.094) 0.65 (0.094)

700 (371) 0.77 (0.111) 0.77 (0.111) 0.77 (0.111) 0.77 (0.111)

A

The user is advised that retrofit applications (where new insulation is being applied over existing) could require knowing the thermal conductivity of the existing layer

at mean temperatures above those shown. Consult a manufacturer for data at mean temperatures exceeding those listed.

†

Editorially corrected in January 2012.

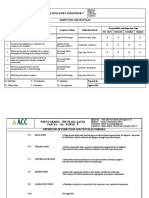

TABLE 2 Requirements of Mineral Fiber Pipe Insulation is greater than, or equal to, the hot limit of the temperature

(Grade A Only) range of desired data and at least one test where the cold

Type I Type II Type III Type IV Type V surface temperature is less than, or equal to, the cold limit of

Property

(Grade A) (Grade A) (Grade A) (Grade A) (Grade A)

the temperature range desired. At least two additional tests

Maximum 200 200 200 200 200 shall be distributed somewhat evenly over the rest of the

Internal Temp. Rise (111) (111) (111) (111) (111)

(Grade A Only), °F (°C) temperature range.

11.1.3.4 Final analysis of the thermal data shall be con-

ducted in accordance with C1045 to generate a thermal

9. Workmanship conductivity versus temperature relationship for the specimen.

--``,,`,`,````,``,`,````,,,,`,,,-`-`,,`,,`,`,,`---

9.1 The insulation shall not have defects that will adversely 11.1.3.5 The final step of C1045 analysis is to calculate the

affect installation or service quality. thermal conductivity using the equations generated at a set of

mean temperatures for comparison to the

10. Sampling specification.Warning—While it is recommended that the

10.1 When specified in the purchase order or contract, specification data be presented as thermal conductivity versus

sampling and acceptance shall be in accordance with Practice temperature, several existing specifications may contain mean

C390. temperature data from tests conducted at specific hot and cold

surface temperatures. In these cases, the conductivity as a

11. Test Methods function of temperature from the C1045 analysis may provide

11.1 The properties in this specification shall be determined different results. To insure that the data is compatible, a C680

in accordance with the following test methods, with jacketing analysis, using the thermal conductivity versus temperature

excluded unless stated otherwise. relationship from C1045 and the specific hot and cold surface

11.1.1 Density and Dimensions—Test Method C302. temperatures, is required to determine the effective thermal

11.1.2 Linear Shrinkage— Test Method C356. conductivity for comparison to the specification requirements.

11.1.3 Thermal Conductivity—Test Method C335. 11.1.4 Water Vapor Sorption—Test Method C1104/

11.1.3.1 Thermal performance shall be characterized on a C1104M.

3-in. NPS 3 2-in. pipe insulation size. Thermal performance 11.1.5 Surface Burning Characteristics—Test Method E84.

must be assessed on actual pipe insulation sections. Data 11.1.5.1 Flat specimens otherwise identical in composition

obtained on flat samples, using Test Method C177, shall not be to pipe insulation shall be used. This applies to plain and

used to state compliance with this specification. factory-jacketed products, with and without self-sealing longi-

11.1.3.2 Practice C1058 may be used to obtain recom- tudinal lap closure systems.

mended test temperature combinations for testing purposes. 11.1.5.2 Test Methods UL 723 or NFPA 255 may be substi-

11.1.3.3 As specified in C1045, the range of test conditions tuted for Test Method E84. These methods are largely consid-

must include at least one test where the hot surface temperature ered synonymous by most building officials.

Copyright ASTM International

Provided by IHS under license with ASTM

3Licensee=Committee on Institutional Cooperation/5967164001

No reproduction or networking permitted without license from IHS Not for Resale, 02/13/2012 22:05:23 MST

C547 – 11´1

11.1.5.3 For Canada, test in accordance with Test Method 11.1.8 Non-fibrous Content (Shot)—For rock or slag based

CAN/ULC-S102. When the referenced Canadian document in products non-fibrous content shall be determined in accordance

this specification is referred to in applicable Canadian building with Test Method C1335.

codes, the editions, referenced by those building codes, shall 11.1.9 Stress Corrosion Performance—Compliance with

govern. Specification C795 is necessary only when requested to assess

11.1.6 Hot Surface Performance—Test Method C411 and corrosivity when the insulation is applied to austenitic stainless

Standard Practice C447. steel pipe.

11.1.6.1 A 3-in. (75-mm) nominal pipe size or larger shall 12. Qualification Requirements

be used. A test specimen shall be at least 36-in. (914-mm) in

12.1 The following requirements shall be employed for the

length. All types shall be tested at 6-in. (150-mm) nominal

purpose of product qualification:

thickness, in either single or multiple layer configurations.

12.1.1 Density and dimensions,

11.1.6.2 All products shall be tested without jacketing, with 12.1.2 Linear shrinkage,

the exception of products where the jacket is an integral part 12.1.3 Apparent thermal conductivity,

necessary to hold the insulation together such as precision 12.1.4 Surface burning characteristics,

v-groove. The test pipe shall be at the Type I, Type II, Type III, 12.1.5 Hot surface performance,

or Type IV temperature specified in 4.1, when the insulation is 12.1.6 Sag resistance,

applied. For Class B material any special requirement for 12.1.7 Water vapor sorption, and

heat-up shall be specified by the manufacturer shall be used. 12.1.8 Non-fibrous content (shot).

11.1.6.3 Immediately upon application to the pipe, the

internal temperature rise shall be measured as prescribed in the 13. Inspection

Hot Surface Performance section of Standard Practice C447. 13.1 When agreed upon between the purchaser and manu-

11.1.7 Sag Resistance: facturer or supplier, the inspection of material shall be made at

11.1.7.1 Scope—This procedure is used to determine thick- either the point of shipment or the point of delivery. The

ness loss as a result of exposure to maximum service during the following requirements are generally employed for the pur-

hot surface performance test. poses of acceptance and sampling of lots, on shipments of

11.1.7.2 Significance and Use—Products having excessive qualified insulation:

thickness loss at elevated temperature could yield less than 13.1.1 Dimensional tolerances, and Workmanship.

expected in-service performance. 13.2 Rejection—Material that fails to conform to the re-

11.1.7.3 Definition—Sag is defined as the extent of thick- quirements of this specification may be rejected. Rejection

ness loss due to material fatigue or decomposition due to should be reported to the manufacturer or supplier promptly

elevated temperature. and in writing. The manufacturer and supplier have the right to

verify rejected products.

11.1.7.4 Procedure—For the sag determination, measure

the thickness of the test length before and after 96-h hot surface 14. Packaging and Package Marking

exposure. A pin gage suitable for this is described by Test 14.1 Packaging—Mineral fiber preformed pipe insulation

Methods C167. The measurement shall be taken at the top shall be packaged in the manufacturer’s standard commercial

longitudinal center of the horizontally mounted test specimen. container unless otherwise agreed upon between the buyer,

The pin gage shall be vertically inserted through the insulation seller, and the manufacturer.

to obtain tip contact with the hot pipe surface. The pin gage 14.2 Unless otherwise specified, each container shall be

shall be read with a steel rule to the nearest 1⁄32-in. (1 mm). marked with the manufacturer’s lot or date code identification,

Calculate the thickness sag as follows: and facing, if any, on the material in the container. When

% change 5 ~~t1 2 t2!/t1! 3 100 (1) specified in the purchase order or contract, each container shall

also be marked with the appropriate Specification C547 type

where: and maximum use temperature.

t1 = starting thickness, and

t2 = thickness after 96 h. 15. Keywords

11.1.7.5 Precision and Bias—See Method C167, “Standard 15.1 mineral fiber thermal insulation; molded; physical

Test Methods for Thickness and Density of Blanket or Batt properties; pipe insulation; precision v-groove; thermal

Thermal Insulations”. properties

--``,,`,`,````,``,`,````,,,,`,,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

4Licensee=Committee on Institutional Cooperation/5967164001

No reproduction or networking permitted without license from IHS Not for Resale, 02/13/2012 22:05:23 MST

C547 – 11´1

ANNEX

(Mandatory Information)

A1. MINERAL FIBER PIPE INSULATION COMPRESSION RESILIENCY FOR NAVSEA

A1.1 Scope A1.5 Sample Preparation

A1.1.1 In addition to the requirements of this standard, A1.5.1 Three 12-in. (305 mm) long, half-round segments of

additional compression resiliency testing is required for Naval 332-in. (80 mm by 50 mm) mineral fiber pipe insulation are

Sea System Command (NAVSEA) acceptance. cut from a full-round section.

A1.2 Background A1.6 Thickness Determination

A1.6.1 A half-round 12-in. (305 mm) length of 3 3 2-in. (80

A1.2.1 NAVSEA engineers, builds and supports America’s

by 50 mm) pipe insulation is placed on a 3-in. (80 mm) NPS

Fleet of ships and combat systems. This test is only required if

pipe and measured for thickness using the pin gauge and steel

NAVSEA acceptance is desired.

rule. The measurements are in the center of the insulation

length and 3-in. (75 mm) from each end. These values are

A1.3 Test Overview

recorded as the initial thickness. The measurement points are

A1.3.1 Three 12-in. segments of half-round 3 by 2 in. (80 marked as the re-measurement points after compression. See

by 50 mm) thick mineral fiber pipe insulation are measured for Fig. A1.1.

initial thickness, then compressed 10 times to a maximum load

of 200 lbs., then re-measured for thickness recovery after A1.7 Compression Saddle

compression. A1.7.1 The sheet metal comprising the radius of the saddle

shall be 1⁄32 in. (13 gauge) (2 mm) or greater. See Fig. A1.2.

A1.4 Apparatus A1.7.2 An alternative to metal is to use a half round of 8-in.

A1.4.1 Universal testing machine, nominal (280 mm) Schedule 80 PVC piping which has an

A1.4.2 Pin gauge as specified in Test Methods C167, average inside diameter of 7.565 in. (192 mm).

A1.7.3 The wooden portion shall be mechanically fastened

A1.4.3 Steel rule graduated in 1⁄32 in. (1 mm),

to the radial portion with wood screws.

A1.4.4 A 12 in. (305 mm) length of schedule 40, 3-in. (80

mm) nominal pipe size (NPS), A1.8 Compression Resiliency Test

A1.4.5 A 12 in. (305 mm) length of channel or I-beam for A1.8.1 The half round insulation segment is placed in the

supporting the 3-in. pipe, half-round compression saddle designed to test pipe insulation

A1.4.6 A sample of 3-in. x 2-in. (80 mm by 50 mm) thick (See Fig. A1.3). The saddle may be placed on top of the half

mineral fiber pipe insulation, and round segment, or the segment may rest in the saddle (upside

A1.4.7 A 12-in. (305 mm) saddle conforming to the outside down from the figures provided). If the saddle is placed on top,

diameter of the insulation. and is not fixed to the crosshead of the testing machine, then its

FIG. A1.1 Thickness Determination

--``,,`,`,````,``,`,````,,,,`,,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

5Licensee=Committee on Institutional Cooperation/5967164001

No reproduction or networking permitted without license from IHS Not for Resale, 02/13/2012 22:05:23 MST

C547 – 11´1

FIG. A1.2 Compression Saddle Configuration

FIG. A1.3 Test Set-up for Compression Resiliency

--``,,`,`,````,``,`,````,,,,`,,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

6Licensee=Committee on Institutional Cooperation/5967164001

No reproduction or networking permitted without license from IHS Not for Resale, 02/13/2012 22:05:23 MST

C547 – 11´1

mass shall be taken into account as part of the pounds force

applied to the half round section. If the saddle is on the bottom,

% Comp. Resiliency 5 S D

Average Recovered Thickness

Average Initial Thickness x 100

then the 3 in. (80 mm) NPS pipe shall be fixed to the (A1.1)

cross-head of the universal testing machine. Hence there would

be no apparatus mass to be accounted for. A1.10 Requirement

A1.8.2 Using the universal testing machine, the half-round A1.10.1 The average of three tests shall have a thickness

section shall be loaded to a force of 200 lbs. (90 kg) and recovery after compression of greater than or equal to 90

released. This is repeated a total of ten times. The test speed percent.

shall be 0.5 in. (12 mm) per minute.

A1.8.3 The compressed sample is re-measured for thickness

A1.11 Precision and Bias

after 15 min rest after the last compression and recorded. (See

Fig. A1.1), A1.11.1 No precision or bias is presented for the C 547

A1.8.4 Three 12-in. (305 mm) long, half-sections shall be Annex A1 Compression Resilience test since the test is a

tested. NAVSEA only requirement.

A1.9 Calculation

A1.9.1 The percent of thickness recovery after enduring ten

loading of a force equal to 200 lbs. per lineal foot (90 kg per

0.305 m) is calculated as follows for the three tests:

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

--``,,`,`,````,``,`,````,,,,`,,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

7Licensee=Committee on Institutional Cooperation/5967164001

No reproduction or networking permitted without license from IHS Not for Resale, 02/13/2012 22:05:23 MST

You might also like

- Astm C578 PDFDocument7 pagesAstm C578 PDFraja qammar100% (2)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- D5470-12 Standard Test Method For Thermal Transmission Properties of Thermally Conductive Electrical Insulation MaterialsDocument6 pagesD5470-12 Standard Test Method For Thermal Transmission Properties of Thermally Conductive Electrical Insulation Materialsastewayb_964354182No ratings yet

- ASTM C533-17 (Aislamiento Térmico)Document4 pagesASTM C533-17 (Aislamiento Térmico)Àngel RodriguezNo ratings yet

- Astm C578-19. (2019) PDFDocument8 pagesAstm C578-19. (2019) PDFgeologist840% (1)

- Astm C656Document3 pagesAstm C656alokjha_03No ratings yet

- Astm C 1290 - Fibrous Glass Balnket For DuctsDocument4 pagesAstm C 1290 - Fibrous Glass Balnket For DuctsleandroschroederNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- ASTM C547-17 (Aislamiento Térmico)Document7 pagesASTM C547-17 (Aislamiento Térmico)Àngel RodriguezNo ratings yet

- ASTM C592 Mineral Fiber Blanket InsulationDocument7 pagesASTM C592 Mineral Fiber Blanket InsulationMike DukasNo ratings yet

- Astm C547Document7 pagesAstm C547DilaFirizqinaNo ratings yet

- C592 13Document9 pagesC592 13Ichwan Ciptadi100% (1)

- Astm C552Document7 pagesAstm C552DilaFirizqinaNo ratings yet

- Extruded Preformed Flexible Cellular Polyolefin Thermal Insulation in Sheet and Tubular FormDocument5 pagesExtruded Preformed Flexible Cellular Polyolefin Thermal Insulation in Sheet and Tubular FormDanZel DanNo ratings yet

- Unfaced Preformed Rigid Cellular Polyisocyanurate Thermal InsulationDocument9 pagesUnfaced Preformed Rigid Cellular Polyisocyanurate Thermal InsulationBalaraman SNo ratings yet

- ASTM C610-17 (Aislamiento Térmico)Document4 pagesASTM C610-17 (Aislamiento Térmico)Àngel RodriguezNo ratings yet

- C547 PDFDocument4 pagesC547 PDFAhmedNo ratings yet

- Molded Expanded Perlite Block and Pipe Thermal Insulation: Standard Specification ForDocument4 pagesMolded Expanded Perlite Block and Pipe Thermal Insulation: Standard Specification ForBalaraman SNo ratings yet

- Astm C552 21Document4 pagesAstm C552 21goushbashaNo ratings yet

- Astm C 578-2019Document8 pagesAstm C 578-2019Mohammed AliNo ratings yet

- C890 Ceramic Fiber PDFDocument6 pagesC890 Ceramic Fiber PDFKf LiauNo ratings yet

- ASTM C610 (2011) - Standard Specification For Molded Expanded Perlite Block and Pipe Thermal InsulationDocument4 pagesASTM C610 (2011) - Standard Specification For Molded Expanded Perlite Block and Pipe Thermal InsulationLambert Nathaniel AcordaNo ratings yet

- Astm C591 20Document7 pagesAstm C591 20Endang Reta LazuardiNo ratings yet

- C 687 - 12Document10 pagesC 687 - 12Roberto ColoniaNo ratings yet

- Astm C591 - 22Document10 pagesAstm C591 - 22sgjsevenpNo ratings yet

- Mineral Fiber Blanket Thermal Insulation For Commercial and Industrial ApplicationsDocument5 pagesMineral Fiber Blanket Thermal Insulation For Commercial and Industrial ApplicationsmansurudinNo ratings yet

- Astm C578 - 22Document8 pagesAstm C578 - 22rtiyer1970No ratings yet

- Astm C552Document6 pagesAstm C552hadefNo ratings yet

- Mineral Wool Roof Insulation Board: Standard Specification ForDocument4 pagesMineral Wool Roof Insulation Board: Standard Specification ForMina RemonNo ratings yet

- ASTM C764 Mineral Fiber Loose-Fill InsulationDocument5 pagesASTM C764 Mineral Fiber Loose-Fill InsulationMike DukasNo ratings yet

- Cellulosic Fiber Loose-Fill Thermal Insulation: Standard Specification ForDocument11 pagesCellulosic Fiber Loose-Fill Thermal Insulation: Standard Specification ForingluisalejoNo ratings yet

- Spray-Applied Mineral Fiber Thermal and Sound Absorbing InsulationDocument3 pagesSpray-Applied Mineral Fiber Thermal and Sound Absorbing Insulationmohammed ;arasnehNo ratings yet

- Astm 1484-01Document12 pagesAstm 1484-01Mohamed GaballahNo ratings yet

- C 552Document7 pagesC 552milecsaNo ratings yet

- C591-05 Polyisocyanurate (PIR)Document6 pagesC591-05 Polyisocyanurate (PIR)FuNnY and EdUcAtIoNal TV for KIDS VIDEOSNo ratings yet

- Aluminum Jacketing For InsulationDocument7 pagesAluminum Jacketing For InsulationCK CkkouNo ratings yet

- Mineral Fiber Blanket Thermal Insulation For Commercial and Industrial ApplicationsDocument4 pagesMineral Fiber Blanket Thermal Insulation For Commercial and Industrial ApplicationsreneeNo ratings yet

- Astm C 547Document4 pagesAstm C 547israel.serrano.rodriguezNo ratings yet

- ASTM C592-22aDocument9 pagesASTM C592-22a22238.spoNo ratings yet

- C 533 - 95 Qzuzmy05nqDocument4 pagesC 533 - 95 Qzuzmy05nqM RNo ratings yet

- C 578 - 03 - Qzu3oc0wm0iDocument6 pagesC 578 - 03 - Qzu3oc0wm0iMohamed SayedNo ratings yet

- AstmDocument3 pagesAstmMuhammad NaumanNo ratings yet

- Testing Cellular Glass Insulation Block: Standard Test Methods ofDocument4 pagesTesting Cellular Glass Insulation Block: Standard Test Methods ofMina RemonNo ratings yet

- Estimating The Maximum Use Temperature of Thermal InsulationsDocument3 pagesEstimating The Maximum Use Temperature of Thermal InsulationsXiaodong LiNo ratings yet

- C-1767 Standard Specification For Stainless Steel Jacketing For Insulation1e - Insulation CladdingDocument7 pagesC-1767 Standard Specification For Stainless Steel Jacketing For Insulation1e - Insulation CladdingYogalingam ArumugamNo ratings yet

- ASTM C533 95reaprovedDocument4 pagesASTM C533 95reaproveddeivisbtsNo ratings yet

- Astm C153-07Document4 pagesAstm C153-07JacarreroNo ratings yet

- Polyisocyanurate Thermal InsulationDocument5 pagesPolyisocyanurate Thermal Insulationnisha_khanNo ratings yet

- ASTM C 196 Standard Specification For Expanded or Exfoliated Vermiculite Thermal Insulating CemenDocument3 pagesASTM C 196 Standard Specification For Expanded or Exfoliated Vermiculite Thermal Insulating CemenRyan LasacaNo ratings yet

- Mineral Fiber Blanket Thermal Insulation For Commercial and Industrial ApplicationsDocument5 pagesMineral Fiber Blanket Thermal Insulation For Commercial and Industrial ApplicationsAhnaf BarajaNo ratings yet

- Calcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForDocument4 pagesCalcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForNour MasmoudiNo ratings yet

- C 591 - Norma AstmDocument3 pagesC 591 - Norma AstmAmanda TezotoNo ratings yet

- Astm C 592-04Document7 pagesAstm C 592-04Hung DinhNo ratings yet

- C534C534MDocument6 pagesC534C534MLupita RamirezNo ratings yet

- Calcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForDocument4 pagesCalcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForRizal Mohamad Al-AyyubiNo ratings yet

- Astm C 592Document9 pagesAstm C 592hoseinNo ratings yet

- ASTM C 195 Standard Specification For Mineral Fiber Thermal Insulating CementDocument3 pagesASTM C 195 Standard Specification For Mineral Fiber Thermal Insulating CementRyan LasacaNo ratings yet

- Astm C578 PDFDocument7 pagesAstm C578 PDFcahyo hutomoNo ratings yet

- C 533 Calcium SilicateDocument4 pagesC 533 Calcium SilicatereneeNo ratings yet

- Selecting Temperatures For Evaluating and Reporting Thermal Properties of Thermal InsulationDocument3 pagesSelecting Temperatures For Evaluating and Reporting Thermal Properties of Thermal InsulationAsmaa RamadanNo ratings yet

- 6000-B-90-01-P-0142-00-E - Painting & Coating Touch Up and RepairDocument4 pages6000-B-90-01-P-0142-00-E - Painting & Coating Touch Up and RepairMelih SENTURKNo ratings yet

- C0007B - Daily Report - 2023-08-27 - ALL SPDocument1 pageC0007B - Daily Report - 2023-08-27 - ALL SPMelih SENTURKNo ratings yet

- Field Painting and Coating: Standard Work Process ProcedureDocument16 pagesField Painting and Coating: Standard Work Process ProcedureMelih SENTURKNo ratings yet

- Iq345 100 CN MST 00009 - RaDocument5 pagesIq345 100 CN MST 00009 - RaMelih SENTURKNo ratings yet

- Pages From 0000-SP-50!22!2 Thermal Insulation SpecificationDocument1 pagePages From 0000-SP-50!22!2 Thermal Insulation SpecificationMelih SENTURKNo ratings yet

- 4MP-T81-03222 Rev 1 FLD Painting and CoatingDocument16 pages4MP-T81-03222 Rev 1 FLD Painting and CoatingMelih SENTURKNo ratings yet

- Pages From 0000-SP-50-22 - 2 - Thermal - Insulation - Specification-2Document1 pagePages From 0000-SP-50-22 - 2 - Thermal - Insulation - Specification-2Melih SENTURKNo ratings yet

- 6000-B-90-01-P-0142-00-E - Painting & Coating Touch Up and RepairDocument4 pages6000-B-90-01-P-0142-00-E - Painting & Coating Touch Up and RepairMelih SENTURKNo ratings yet

- Ys-Fr-24 Bina Son Kontrol Raporu-02Document1 pageYs-Fr-24 Bina Son Kontrol Raporu-02Melih SENTURKNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Ys-Fr-32 Hangar Son Kontrol Raporu-01Document1 pageYs-Fr-32 Hangar Son Kontrol Raporu-01Melih SENTURKNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument4 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURK100% (1)

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Definition of Inspection and Test Plan SymbolsDocument2 pagesProject: Baladna Dairy Farm Phase-2: Definition of Inspection and Test Plan SymbolsMelih SENTURKNo ratings yet

- CAMX2015-Composite Design and AnalysisDocument86 pagesCAMX2015-Composite Design and AnalysisSabanSaulicNo ratings yet

- Scalgun BDocument2 pagesScalgun Bdevadoss kishoreNo ratings yet

- Ucs Crushed SandDocument1 pageUcs Crushed SandMohammed SalhinNo ratings yet

- Chemical Engineering ScienceDocument7 pagesChemical Engineering ScienceclaudiosldfNo ratings yet

- Part 7-Shear DesignDocument11 pagesPart 7-Shear Designangelojonard71No ratings yet

- Stress Classification in Pressure Vessels and Piping As Per ASME B31 and BPVC CodesDocument16 pagesStress Classification in Pressure Vessels and Piping As Per ASME B31 and BPVC CodeslorenzoNo ratings yet

- Batch and Continuous Distillation - FINALDocument8 pagesBatch and Continuous Distillation - FINALPenny GildoNo ratings yet

- Hvac PFD CotyDocument21 pagesHvac PFD CotyNews EconomicNo ratings yet

- Yield Line Analysisof Various Shapesof RCSlabsDocument90 pagesYield Line Analysisof Various Shapesof RCSlabsTafaraNo ratings yet

- Reaffirmed 1996Document13 pagesReaffirmed 1996Ritesh kumarNo ratings yet

- Hydraulic OilsDocument6 pagesHydraulic OilsGeorgina SuleNo ratings yet

- Nice Neotech - Phototherapy 4000 - 12Document1 pageNice Neotech - Phototherapy 4000 - 12David Gnana DuraiNo ratings yet

- Heat Exchanger LabDocument17 pagesHeat Exchanger LabMuhammad HanzalaNo ratings yet

- Fermi ProblemsDocument3 pagesFermi Problemsrc735iNo ratings yet

- Tam-Sc-2-B Doorsheet Removal and Reinstallation: February 2003 © Chevrontexaco 1 of 9Document9 pagesTam-Sc-2-B Doorsheet Removal and Reinstallation: February 2003 © Chevrontexaco 1 of 9Herlys Pereira100% (1)

- Chapter 2 Waves and Oscillation (Compatibility Mode) PDFDocument77 pagesChapter 2 Waves and Oscillation (Compatibility Mode) PDFVaibhavNo ratings yet

- MEENG 317 - Lubrication and Bearing - Part 1Document10 pagesMEENG 317 - Lubrication and Bearing - Part 1King Cyruz PabloNo ratings yet

- MCQ Unit 3Document15 pagesMCQ Unit 3abcd100% (1)

- The Institution of Engineers Sri Lanka (Iesl) Kilinochchi District CenterDocument2 pagesThe Institution of Engineers Sri Lanka (Iesl) Kilinochchi District CenterInoshan Madushika JayawickramaNo ratings yet

- Air Cooled Packaged Inverter Floor Standing Type - Heat Pump 50Hz - APCVDT1512Document54 pagesAir Cooled Packaged Inverter Floor Standing Type - Heat Pump 50Hz - APCVDT1512Phanhai Kaka100% (1)

- MAGNETISM AND MATTER ModuleDocument24 pagesMAGNETISM AND MATTER Modulehydr0gen001No ratings yet

- Effect of Air Velocity in Relative HumidityDocument12 pagesEffect of Air Velocity in Relative HumiditybananaNo ratings yet

- Lumbang Integrated National High SchoolDocument5 pagesLumbang Integrated National High SchoolLorena DizonNo ratings yet

- CT4145 CT2031 Mechanics of Structures Module Introduction Into Continuum MechanicsDocument80 pagesCT4145 CT2031 Mechanics of Structures Module Introduction Into Continuum MechanicsMarcoNo ratings yet

- Class2 - NewtonDocument54 pagesClass2 - NewtonAARUSH DESHPANDENo ratings yet

- LTMC - Fibre Optic Cable: DescriptionDocument5 pagesLTMC - Fibre Optic Cable: DescriptionTiziano D'IncàNo ratings yet

- 885F Embrittlement of Duplex Stainless SteelDocument4 pages885F Embrittlement of Duplex Stainless Steeljaymin444No ratings yet

- 2.0 Cegeotech2 Lec m1 (Intro)Document19 pages2.0 Cegeotech2 Lec m1 (Intro)Mineski Prince GarmaNo ratings yet

- Concentration Cell PDFDocument5 pagesConcentration Cell PDFMd. Masud RanaNo ratings yet