Professional Documents

Culture Documents

Project Profile On Bee - Metallurgical Coke

Project Profile On Bee - Metallurgical Coke

Uploaded by

AjmalCopyright:

Available Formats

You might also like

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- Ceramic Art Wares SchemeDocument2 pagesCeramic Art Wares SchemeMuazNo ratings yet

- Project Profile On Liquid DetergentDocument2 pagesProject Profile On Liquid DetergentdivyabhaveshsharmaNo ratings yet

- Model Project Profile On Plastic Bottle (Pcbi)Document2 pagesModel Project Profile On Plastic Bottle (Pcbi)sivanagendrarao beharabhargavaNo ratings yet

- Wrought Iron FurnitureDocument2 pagesWrought Iron FurnitureNilesh RajNo ratings yet

- Project On UrnitureDocument2 pagesProject On UrnituresushilNo ratings yet

- Project Profile On R.C.CDocument2 pagesProject Profile On R.C.Csaubhik goswamiNo ratings yet

- App 25377589Document2 pagesApp 25377589KANNADIGA ANIL KERURKARNo ratings yet

- Project Profile On Exhaust FansDocument2 pagesProject Profile On Exhaust FansPhilip KotlerNo ratings yet

- Project Profile On Aluminium FabricationDocument2 pagesProject Profile On Aluminium FabricationRNo ratings yet

- Project Profile On Ball Pen InkDocument2 pagesProject Profile On Ball Pen Inksavan anvekarNo ratings yet

- Project Profile On Face Cream and Cleansing LotionDocument2 pagesProject Profile On Face Cream and Cleansing LotionJaya PrakashNo ratings yet

- Project Profile On Coconut Oil and Oil Cake Manuafcuring PDFDocument2 pagesProject Profile On Coconut Oil and Oil Cake Manuafcuring PDFnathaanmaniNo ratings yet

- Project Profile On Mustard Oil and Oil Cake ManuafcuringDocument2 pagesProject Profile On Mustard Oil and Oil Cake Manuafcuringnathaanmani100% (1)

- Project Profile On Groundnut Oil and Oil Cake Manuafcuring PDFDocument2 pagesProject Profile On Groundnut Oil and Oil Cake Manuafcuring PDFnathaanmani100% (2)

- Kurkure Type SnacksDocument2 pagesKurkure Type SnacksVikas KumarNo ratings yet

- Project Profile On Kurkure Type Snacks PDFDocument2 pagesProject Profile On Kurkure Type Snacks PDFSundeep Yadav100% (4)

- Project Profile On Canvas ShoesDocument2 pagesProject Profile On Canvas ShoesPandey DivyNo ratings yet

- Project Profile On Chemical Etching On WoodDocument2 pagesProject Profile On Chemical Etching On Woodquraishi831No ratings yet

- Project Profile On Sattu ManufacturingDocument2 pagesProject Profile On Sattu ManufacturingKunal SinhaNo ratings yet

- Project Profile On Naphthalene BallsDocument2 pagesProject Profile On Naphthalene BallsOmkar KshirsagarNo ratings yet

- Project Profile On Chemical Porcelain (Mbi)Document2 pagesProject Profile On Chemical Porcelain (Mbi)Arsh GujralNo ratings yet

- Khadi & Village Industries Commission Project Profile For Gramodyog Rojgar Yojana Papad ManufacturingDocument2 pagesKhadi & Village Industries Commission Project Profile For Gramodyog Rojgar Yojana Papad ManufacturingAMIT SRIVASTAVANo ratings yet

- Project Profile On Gingilee Oil and Oil Cake ManuafcuringDocument2 pagesProject Profile On Gingilee Oil and Oil Cake ManuafcuringnathaanmaniNo ratings yet

- Project Profile On Gingilee Oil and Oil Cake Manuafcuring PDFDocument2 pagesProject Profile On Gingilee Oil and Oil Cake Manuafcuring PDFnathaanmaniNo ratings yet

- Bubble Packing PaperDocument2 pagesBubble Packing PaperKanta AgarwalNo ratings yet

- Ceramic Table Wares and Allied Items in Stoneware Earthenware Semi Vitreous WareDocument2 pagesCeramic Table Wares and Allied Items in Stoneware Earthenware Semi Vitreous WareVarun AgrawalNo ratings yet

- Ceramic Table Wares and Allied Items in Stoneware Earthenware Semi Vitreousware PDFDocument2 pagesCeramic Table Wares and Allied Items in Stoneware Earthenware Semi Vitreousware PDF124swadeshiNo ratings yet

- 18 Repairs Maintenance Consumer Electronic ProductsDocument2 pages18 Repairs Maintenance Consumer Electronic ProductsArjun GhoshNo ratings yet

- Project Profile On Solar CookerDocument2 pagesProject Profile On Solar CookerVarun AkashNo ratings yet

- ATTACHAKKIDocument2 pagesATTACHAKKIgoutham.lokNo ratings yet

- Project Profile On Oil Crusher Expeller PDFDocument2 pagesProject Profile On Oil Crusher Expeller PDFMallikarjunReddyObbineniNo ratings yet

- Project Profile On Personnelcomputers AssemblyDocument2 pagesProject Profile On Personnelcomputers AssemblyAditya singhNo ratings yet

- Production of Oxalic AcidDocument2 pagesProduction of Oxalic AcidnoviNo ratings yet

- 69 Wrought Iron FurnitureDocument3 pages69 Wrought Iron FurnitureRajib StudioNo ratings yet

- Project Profile On Wooden Toys and Decorative PiecesDocument2 pagesProject Profile On Wooden Toys and Decorative PiecesinfernohubckdNo ratings yet

- Bakery ProjectsDocument2 pagesBakery ProjectsfasmekbakerNo ratings yet

- Two Wheeler Repairing ShopDocument2 pagesTwo Wheeler Repairing Shopkrishna samNo ratings yet

- Agarbatti PDFDocument2 pagesAgarbatti PDFAntony JosephNo ratings yet

- Project Profile On Wheel BarrowsDocument2 pagesProject Profile On Wheel BarrowsLaxman SinghNo ratings yet

- ADDONCARDSFORCOMPUTERDocument2 pagesADDONCARDSFORCOMPUTERAR MOHANRAJNo ratings yet

- Project Profile On Wafer Biscuits Big TypeDocument2 pagesProject Profile On Wafer Biscuits Big Typeabhisheksingh bhumpmirNo ratings yet

- Jam Jelly Murabba Manufacturing ProjectDocument2 pagesJam Jelly Murabba Manufacturing ProjectcasagarteliNo ratings yet

- Beverage Manufacturing Scheme PDFDocument2 pagesBeverage Manufacturing Scheme PDFUjjwal DwivediNo ratings yet

- Beverage Manufacturing SchemeDocument2 pagesBeverage Manufacturing SchemeUjjwal DwivediNo ratings yet

- Khadi & V.I. Commission Project Profile For Gramodyog Rojgar Yojna Beverage Manufacturing SchemeDocument2 pagesKhadi & V.I. Commission Project Profile For Gramodyog Rojgar Yojna Beverage Manufacturing SchemeUjjwal DwivediNo ratings yet

- Beverage PDFDocument2 pagesBeverage PDFUjjwal DwivediNo ratings yet

- Beverage Manufacturing SchemeDocument2 pagesBeverage Manufacturing SchemenathaanmaniNo ratings yet

- Besan Manufacturing Unit PDFDocument2 pagesBesan Manufacturing Unit PDFDev MoryaNo ratings yet

- TWO WHEELER REPAIRING SHOP ProjectDocument2 pagesTWO WHEELER REPAIRING SHOP ProjectBhanwar SinghNo ratings yet

- C. Polymer and Chemical Based Industries PCBIDocument2 pagesC. Polymer and Chemical Based Industries PCBIAntony JosephNo ratings yet

- Laundarysoap PDFDocument2 pagesLaundarysoap PDFTanya KaushalNo ratings yet

- Ice-Cream ParlourDocument2 pagesIce-Cream ParlourRupesh SharmaNo ratings yet

- Khadi & Village Industries Commission Project Profile For Gramodyog Rojgar Yojana Bamboo Article Manufacturing UnitDocument2 pagesKhadi & Village Industries Commission Project Profile For Gramodyog Rojgar Yojana Bamboo Article Manufacturing UnitAakash sableNo ratings yet

- Project Profile On Gem Cutting and PolishingDocument2 pagesProject Profile On Gem Cutting and Polishingpramod kumar singh100% (1)

- Daliya Manufacturing Unit PDFDocument2 pagesDaliya Manufacturing Unit PDFpardeepNo ratings yet

- 18 Repairs Maintenance Consumer Electronic ProductsDocument2 pages18 Repairs Maintenance Consumer Electronic Productsrachanabali1999No ratings yet

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- Eczema and SwimmingDocument4 pagesEczema and SwimmingzoruaNo ratings yet

- LOT1 CONCRETE Mixes 27-03-2019 - REV 9.1Document7 pagesLOT1 CONCRETE Mixes 27-03-2019 - REV 9.1Soundar PachiappanNo ratings yet

- Performance of Fittings For Use With Gasketed Mechanical Couplings Used in Piping ApplicationsDocument4 pagesPerformance of Fittings For Use With Gasketed Mechanical Couplings Used in Piping ApplicationsDarwin DarmawanNo ratings yet

- Datasheet Resistores PDFDocument14 pagesDatasheet Resistores PDFCristiano SilvaNo ratings yet

- Qdoc - Tips Physical Metallurgy Principles and Practice ThirdDocument2 pagesQdoc - Tips Physical Metallurgy Principles and Practice ThirdAkhil KumarNo ratings yet

- Carrier Oil Shelf LifeDocument3 pagesCarrier Oil Shelf LifeAna ThesecretiveNo ratings yet

- Chemistry and Technology of Epoxy Resins - B. Ellis (1993) PDFDocument342 pagesChemistry and Technology of Epoxy Resins - B. Ellis (1993) PDFIsadora HenriquesNo ratings yet

- Concrete Pavement ConstructionDocument6 pagesConcrete Pavement ConstructionEngineeri TadiyosNo ratings yet

- 1.2 FS Pipeline PDFDocument233 pages1.2 FS Pipeline PDFmaheshdabli0% (1)

- VULCAN® XC 72 - CabotDocument2 pagesVULCAN® XC 72 - CabotAhadNo ratings yet

- Steel Castings, General Requirements, For Pressure-Containing PartsDocument16 pagesSteel Castings, General Requirements, For Pressure-Containing Partsle hoang vietNo ratings yet

- Matsui Tech White 301Document1 pageMatsui Tech White 301SinbeeHate Keepfvking MetalsquadNo ratings yet

- Astm A 240 A 240M C05Document12 pagesAstm A 240 A 240M C05cvazquez999No ratings yet

- Chemistry Question and Answer 2013-2017Document52 pagesChemistry Question and Answer 2013-2017Chikuta ShingaliliNo ratings yet

- f73999416 ERECTION PROGRESS REPORT GWC-QAFDocument4 pagesf73999416 ERECTION PROGRESS REPORT GWC-QAFAbdulrahman AlkilaniNo ratings yet

- Assignment Technical Specifications Division 7Document3 pagesAssignment Technical Specifications Division 7Patrisha SantosNo ratings yet

- DirectoryDocument160 pagesDirectoryDhungel PrabhuNo ratings yet

- Collector Beads CatalogDocument34 pagesCollector Beads Catalogsudhanshu_12juneNo ratings yet

- 1000 XXXX HY80 HSLA100Document2 pages1000 XXXX HY80 HSLA100srb metallurgNo ratings yet

- Sanitary Fittings 20190523 PDFDocument12 pagesSanitary Fittings 20190523 PDFMuhammad Farhan GulNo ratings yet

- Impex Chemicals Product ListDocument11 pagesImpex Chemicals Product Listakartepe1999No ratings yet

- Titeflex Transportation CatalogDocument4 pagesTiteflex Transportation Catalogkrzys10No ratings yet

- Teflon PTFE Properties HandbookDocument40 pagesTeflon PTFE Properties HandbookRob100% (1)

- واکنشهای شیمیائی و موازنه استوکیومتریDocument24 pagesواکنشهای شیمیائی و موازنه استوکیومتریapi-3706290100% (2)

- Aalco Metals LTD Stainless Steel 14301 Sheet and Plate 343Document3 pagesAalco Metals LTD Stainless Steel 14301 Sheet and Plate 343Manoj ManivasagamNo ratings yet

- ARMOX500TDocument2 pagesARMOX500TKalpesh JainNo ratings yet

- MatterDocument38 pagesMattergabbie dumpNo ratings yet

- Cavity Plug XEOA - Full - en - Us - LetterDocument1 pageCavity Plug XEOA - Full - en - Us - LetterHassan KhattabNo ratings yet

- New Dimensions of SoftnessDocument9 pagesNew Dimensions of SoftnessEugene PaiNo ratings yet

Project Profile On Bee - Metallurgical Coke

Project Profile On Bee - Metallurgical Coke

Uploaded by

AjmalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Profile On Bee - Metallurgical Coke

Project Profile On Bee - Metallurgical Coke

Uploaded by

AjmalCopyright:

Available Formats

MBI

PROJECT PROFILE ON BEE - METALLURGICAL COKE

Introduction :

Metallurgical Cokes are hard coke used in blast furnace for producing pig iron and in cupolas for the

production of grey iron castings. Integrated Steel Plants have their own Coke oven battery in the premises to produce

better quality of Metallurgical coke. Cokes used in Cupola are of inferior quality in comparison to coke used in the blast

furnace. Due to some inherent characteristics like hardness, porosity, and abrasive strength,(Metallurgical cokes are

being used in these furnaces. Metallurgical coke is produced by Carbonisation (heating of pulverised coking coal in

absence of air) of coking coal i.e. bituminous coal in coke oven battery. Due to shortage of cooking coal in our country,

now a days coke is also being produced by blending of coking coal, Non-coking and some additives. Process of

Manufacture: I. Bituminous coal is pulverized by ball mill into fine powder.ii)Fine coal is heated in coke oven battery

at 700-900 C in absence of air. This process is called Carbonisation.Soaking at this temperature for about 7-8 hrs.,it is

allowed to cool in the furnace. Due to coking property of bituminous coal powdered coal converts into lump size and

becomes very hard and highly porous.iii)After cooling, the coke produced is crushed into desired size. Strength of the

coke, fixed Carbon,sulphur content and ash content is determined in the testing laboratory for justifying the quality of the

coke.iv)By-products like tar may also be collected during carbonisation process.

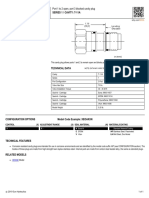

1 Name of the Product : METALLURGICAL COKE

2 Project Cost :

a Capital Expenditure

Land : Own

Workshed in sq.ft 300 Rs. 60,000.00

Equipment : Rs. 150,000.00

Coke oven battery to produce 800 kg Coke per batch-3,Coat

crusher-2,Ball Mill(cap.200kg)-3,Material handling

equipment/tools etc.-L.S.,Testing laboratory-L.S.,Platform

type weighing balance-1,Office equipment.

Total Capital Expenditure Rs. 210,000.00

b Working Capital Rs. 80,000.00

TOTAL PROJECT COST : Rs. 290,000.00

3 Estimated Annual Production Capacity: (Rs. in Lakhs)

Sr.No. Particulars Capacity in Quintals Rate Total Value

1 Metallurgical coke 839.40

TOTAL 0.00 0.00 839.40

4 Raw Material : Rs. 232,000.00

5 Packing Material : Rs. 15,000.00

6 Wages (2- Skilled & 2- Unskilled) : Rs. 288,000.00

7 Salaries Manager-1 Rs. : 120,000.00

PAGE ( 2 )

8 Administrative Expenses : Rs. 75,000.00

9 Overheads : Rs. 60,000.00

10 Miscellaneous Expenses : Rs. 10,000.00

11 Depreciation : Rs. 18,000.00

12 Insurance : Rs. 2,100.00

13 Interest (As per the PLR)

a. C.E.Loan : Rs. 27,300.00

b. W.C.Loan : Rs. 10,400.00

Total Interest Rs. 37,700.00

14 Working Capital Requirement :

Fixed Cost Rs. 234,400.00

Variable Cost Rs. 605,400.00

Requirement of WC per Cycle Rs. 139,967.00

15 Cost Analysis

Sr.No. Particulars Capacity Utilization(Rs in '000)

100% 60% 70% 80%

1 Fixed Cost 234.40 140.64 164.08 187.52

2 Variable Cost 605.00 363.00 423.50 484.00

3 Cost of Production 839.40 503.64 587.58 611.02

4 Projected Sales 900.00 540.00 630.00 720.00

5 Gross Surplus 60.60 36.36 42.42 48.48

6 Expected Net Surplus 43.00 18.00 24.00 30.00

Note : 1. All figures mentioned above are only indicative.

2. If the investment on Building is replaced by Rental then

a. Total Cost of Project will be reduced.

b. Profitability will be increased.

c. Interest on C.E.will be reduced.

You might also like

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- Ceramic Art Wares SchemeDocument2 pagesCeramic Art Wares SchemeMuazNo ratings yet

- Project Profile On Liquid DetergentDocument2 pagesProject Profile On Liquid DetergentdivyabhaveshsharmaNo ratings yet

- Model Project Profile On Plastic Bottle (Pcbi)Document2 pagesModel Project Profile On Plastic Bottle (Pcbi)sivanagendrarao beharabhargavaNo ratings yet

- Wrought Iron FurnitureDocument2 pagesWrought Iron FurnitureNilesh RajNo ratings yet

- Project On UrnitureDocument2 pagesProject On UrnituresushilNo ratings yet

- Project Profile On R.C.CDocument2 pagesProject Profile On R.C.Csaubhik goswamiNo ratings yet

- App 25377589Document2 pagesApp 25377589KANNADIGA ANIL KERURKARNo ratings yet

- Project Profile On Exhaust FansDocument2 pagesProject Profile On Exhaust FansPhilip KotlerNo ratings yet

- Project Profile On Aluminium FabricationDocument2 pagesProject Profile On Aluminium FabricationRNo ratings yet

- Project Profile On Ball Pen InkDocument2 pagesProject Profile On Ball Pen Inksavan anvekarNo ratings yet

- Project Profile On Face Cream and Cleansing LotionDocument2 pagesProject Profile On Face Cream and Cleansing LotionJaya PrakashNo ratings yet

- Project Profile On Coconut Oil and Oil Cake Manuafcuring PDFDocument2 pagesProject Profile On Coconut Oil and Oil Cake Manuafcuring PDFnathaanmaniNo ratings yet

- Project Profile On Mustard Oil and Oil Cake ManuafcuringDocument2 pagesProject Profile On Mustard Oil and Oil Cake Manuafcuringnathaanmani100% (1)

- Project Profile On Groundnut Oil and Oil Cake Manuafcuring PDFDocument2 pagesProject Profile On Groundnut Oil and Oil Cake Manuafcuring PDFnathaanmani100% (2)

- Kurkure Type SnacksDocument2 pagesKurkure Type SnacksVikas KumarNo ratings yet

- Project Profile On Kurkure Type Snacks PDFDocument2 pagesProject Profile On Kurkure Type Snacks PDFSundeep Yadav100% (4)

- Project Profile On Canvas ShoesDocument2 pagesProject Profile On Canvas ShoesPandey DivyNo ratings yet

- Project Profile On Chemical Etching On WoodDocument2 pagesProject Profile On Chemical Etching On Woodquraishi831No ratings yet

- Project Profile On Sattu ManufacturingDocument2 pagesProject Profile On Sattu ManufacturingKunal SinhaNo ratings yet

- Project Profile On Naphthalene BallsDocument2 pagesProject Profile On Naphthalene BallsOmkar KshirsagarNo ratings yet

- Project Profile On Chemical Porcelain (Mbi)Document2 pagesProject Profile On Chemical Porcelain (Mbi)Arsh GujralNo ratings yet

- Khadi & Village Industries Commission Project Profile For Gramodyog Rojgar Yojana Papad ManufacturingDocument2 pagesKhadi & Village Industries Commission Project Profile For Gramodyog Rojgar Yojana Papad ManufacturingAMIT SRIVASTAVANo ratings yet

- Project Profile On Gingilee Oil and Oil Cake ManuafcuringDocument2 pagesProject Profile On Gingilee Oil and Oil Cake ManuafcuringnathaanmaniNo ratings yet

- Project Profile On Gingilee Oil and Oil Cake Manuafcuring PDFDocument2 pagesProject Profile On Gingilee Oil and Oil Cake Manuafcuring PDFnathaanmaniNo ratings yet

- Bubble Packing PaperDocument2 pagesBubble Packing PaperKanta AgarwalNo ratings yet

- Ceramic Table Wares and Allied Items in Stoneware Earthenware Semi Vitreous WareDocument2 pagesCeramic Table Wares and Allied Items in Stoneware Earthenware Semi Vitreous WareVarun AgrawalNo ratings yet

- Ceramic Table Wares and Allied Items in Stoneware Earthenware Semi Vitreousware PDFDocument2 pagesCeramic Table Wares and Allied Items in Stoneware Earthenware Semi Vitreousware PDF124swadeshiNo ratings yet

- 18 Repairs Maintenance Consumer Electronic ProductsDocument2 pages18 Repairs Maintenance Consumer Electronic ProductsArjun GhoshNo ratings yet

- Project Profile On Solar CookerDocument2 pagesProject Profile On Solar CookerVarun AkashNo ratings yet

- ATTACHAKKIDocument2 pagesATTACHAKKIgoutham.lokNo ratings yet

- Project Profile On Oil Crusher Expeller PDFDocument2 pagesProject Profile On Oil Crusher Expeller PDFMallikarjunReddyObbineniNo ratings yet

- Project Profile On Personnelcomputers AssemblyDocument2 pagesProject Profile On Personnelcomputers AssemblyAditya singhNo ratings yet

- Production of Oxalic AcidDocument2 pagesProduction of Oxalic AcidnoviNo ratings yet

- 69 Wrought Iron FurnitureDocument3 pages69 Wrought Iron FurnitureRajib StudioNo ratings yet

- Project Profile On Wooden Toys and Decorative PiecesDocument2 pagesProject Profile On Wooden Toys and Decorative PiecesinfernohubckdNo ratings yet

- Bakery ProjectsDocument2 pagesBakery ProjectsfasmekbakerNo ratings yet

- Two Wheeler Repairing ShopDocument2 pagesTwo Wheeler Repairing Shopkrishna samNo ratings yet

- Agarbatti PDFDocument2 pagesAgarbatti PDFAntony JosephNo ratings yet

- Project Profile On Wheel BarrowsDocument2 pagesProject Profile On Wheel BarrowsLaxman SinghNo ratings yet

- ADDONCARDSFORCOMPUTERDocument2 pagesADDONCARDSFORCOMPUTERAR MOHANRAJNo ratings yet

- Project Profile On Wafer Biscuits Big TypeDocument2 pagesProject Profile On Wafer Biscuits Big Typeabhisheksingh bhumpmirNo ratings yet

- Jam Jelly Murabba Manufacturing ProjectDocument2 pagesJam Jelly Murabba Manufacturing ProjectcasagarteliNo ratings yet

- Beverage Manufacturing Scheme PDFDocument2 pagesBeverage Manufacturing Scheme PDFUjjwal DwivediNo ratings yet

- Beverage Manufacturing SchemeDocument2 pagesBeverage Manufacturing SchemeUjjwal DwivediNo ratings yet

- Khadi & V.I. Commission Project Profile For Gramodyog Rojgar Yojna Beverage Manufacturing SchemeDocument2 pagesKhadi & V.I. Commission Project Profile For Gramodyog Rojgar Yojna Beverage Manufacturing SchemeUjjwal DwivediNo ratings yet

- Beverage PDFDocument2 pagesBeverage PDFUjjwal DwivediNo ratings yet

- Beverage Manufacturing SchemeDocument2 pagesBeverage Manufacturing SchemenathaanmaniNo ratings yet

- Besan Manufacturing Unit PDFDocument2 pagesBesan Manufacturing Unit PDFDev MoryaNo ratings yet

- TWO WHEELER REPAIRING SHOP ProjectDocument2 pagesTWO WHEELER REPAIRING SHOP ProjectBhanwar SinghNo ratings yet

- C. Polymer and Chemical Based Industries PCBIDocument2 pagesC. Polymer and Chemical Based Industries PCBIAntony JosephNo ratings yet

- Laundarysoap PDFDocument2 pagesLaundarysoap PDFTanya KaushalNo ratings yet

- Ice-Cream ParlourDocument2 pagesIce-Cream ParlourRupesh SharmaNo ratings yet

- Khadi & Village Industries Commission Project Profile For Gramodyog Rojgar Yojana Bamboo Article Manufacturing UnitDocument2 pagesKhadi & Village Industries Commission Project Profile For Gramodyog Rojgar Yojana Bamboo Article Manufacturing UnitAakash sableNo ratings yet

- Project Profile On Gem Cutting and PolishingDocument2 pagesProject Profile On Gem Cutting and Polishingpramod kumar singh100% (1)

- Daliya Manufacturing Unit PDFDocument2 pagesDaliya Manufacturing Unit PDFpardeepNo ratings yet

- 18 Repairs Maintenance Consumer Electronic ProductsDocument2 pages18 Repairs Maintenance Consumer Electronic Productsrachanabali1999No ratings yet

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- Eczema and SwimmingDocument4 pagesEczema and SwimmingzoruaNo ratings yet

- LOT1 CONCRETE Mixes 27-03-2019 - REV 9.1Document7 pagesLOT1 CONCRETE Mixes 27-03-2019 - REV 9.1Soundar PachiappanNo ratings yet

- Performance of Fittings For Use With Gasketed Mechanical Couplings Used in Piping ApplicationsDocument4 pagesPerformance of Fittings For Use With Gasketed Mechanical Couplings Used in Piping ApplicationsDarwin DarmawanNo ratings yet

- Datasheet Resistores PDFDocument14 pagesDatasheet Resistores PDFCristiano SilvaNo ratings yet

- Qdoc - Tips Physical Metallurgy Principles and Practice ThirdDocument2 pagesQdoc - Tips Physical Metallurgy Principles and Practice ThirdAkhil KumarNo ratings yet

- Carrier Oil Shelf LifeDocument3 pagesCarrier Oil Shelf LifeAna ThesecretiveNo ratings yet

- Chemistry and Technology of Epoxy Resins - B. Ellis (1993) PDFDocument342 pagesChemistry and Technology of Epoxy Resins - B. Ellis (1993) PDFIsadora HenriquesNo ratings yet

- Concrete Pavement ConstructionDocument6 pagesConcrete Pavement ConstructionEngineeri TadiyosNo ratings yet

- 1.2 FS Pipeline PDFDocument233 pages1.2 FS Pipeline PDFmaheshdabli0% (1)

- VULCAN® XC 72 - CabotDocument2 pagesVULCAN® XC 72 - CabotAhadNo ratings yet

- Steel Castings, General Requirements, For Pressure-Containing PartsDocument16 pagesSteel Castings, General Requirements, For Pressure-Containing Partsle hoang vietNo ratings yet

- Matsui Tech White 301Document1 pageMatsui Tech White 301SinbeeHate Keepfvking MetalsquadNo ratings yet

- Astm A 240 A 240M C05Document12 pagesAstm A 240 A 240M C05cvazquez999No ratings yet

- Chemistry Question and Answer 2013-2017Document52 pagesChemistry Question and Answer 2013-2017Chikuta ShingaliliNo ratings yet

- f73999416 ERECTION PROGRESS REPORT GWC-QAFDocument4 pagesf73999416 ERECTION PROGRESS REPORT GWC-QAFAbdulrahman AlkilaniNo ratings yet

- Assignment Technical Specifications Division 7Document3 pagesAssignment Technical Specifications Division 7Patrisha SantosNo ratings yet

- DirectoryDocument160 pagesDirectoryDhungel PrabhuNo ratings yet

- Collector Beads CatalogDocument34 pagesCollector Beads Catalogsudhanshu_12juneNo ratings yet

- 1000 XXXX HY80 HSLA100Document2 pages1000 XXXX HY80 HSLA100srb metallurgNo ratings yet

- Sanitary Fittings 20190523 PDFDocument12 pagesSanitary Fittings 20190523 PDFMuhammad Farhan GulNo ratings yet

- Impex Chemicals Product ListDocument11 pagesImpex Chemicals Product Listakartepe1999No ratings yet

- Titeflex Transportation CatalogDocument4 pagesTiteflex Transportation Catalogkrzys10No ratings yet

- Teflon PTFE Properties HandbookDocument40 pagesTeflon PTFE Properties HandbookRob100% (1)

- واکنشهای شیمیائی و موازنه استوکیومتریDocument24 pagesواکنشهای شیمیائی و موازنه استوکیومتریapi-3706290100% (2)

- Aalco Metals LTD Stainless Steel 14301 Sheet and Plate 343Document3 pagesAalco Metals LTD Stainless Steel 14301 Sheet and Plate 343Manoj ManivasagamNo ratings yet

- ARMOX500TDocument2 pagesARMOX500TKalpesh JainNo ratings yet

- MatterDocument38 pagesMattergabbie dumpNo ratings yet

- Cavity Plug XEOA - Full - en - Us - LetterDocument1 pageCavity Plug XEOA - Full - en - Us - LetterHassan KhattabNo ratings yet

- New Dimensions of SoftnessDocument9 pagesNew Dimensions of SoftnessEugene PaiNo ratings yet