Professional Documents

Culture Documents

DQS251 - Piling - Spun Piles - Tutorial-Drwgs-Dec 2019 - pg11

DQS251 - Piling - Spun Piles - Tutorial-Drwgs-Dec 2019 - pg11

Uploaded by

MUHAMMAD DANIAL AMRAMCopyright:

Available Formats

You might also like

- Method Statement For Tie-Ins During ShutdownDocument17 pagesMethod Statement For Tie-Ins During ShutdownAnyanele Nnamdi Felix86% (7)

- Curriculum Vitae: Personal DateDocument2 pagesCurriculum Vitae: Personal DateVannak CHen70% (10)

- DQS206 20224 Assignment 1 - CBADocument4 pagesDQS206 20224 Assignment 1 - CBAMUHAMMAD DANIAL AMRAMNo ratings yet

- Method Statement For Installation of Rmu: Al Naboodah Mep L.L.CDocument5 pagesMethod Statement For Installation of Rmu: Al Naboodah Mep L.L.Csujan198050% (2)

- Construction Method For Installation of Pig TrapDocument11 pagesConstruction Method For Installation of Pig TrapMuhammad Irsyadi100% (2)

- Working Piles Design Report Rev 1Document115 pagesWorking Piles Design Report Rev 1Nauman Mumtaz100% (3)

- Faculty - Architecture, Planning, and Surveying - 2022 - Session 1 - Diploma - DQS251Document8 pagesFaculty - Architecture, Planning, and Surveying - 2022 - Session 1 - Diploma - DQS251Humaira MairaNo ratings yet

- Cec DWG Duct 101 Rev C SHT 3 5Document1 pageCec DWG Duct 101 Rev C SHT 3 5Kingsly NovaNo ratings yet

- Fakulti Kejuruteraan Awam Universiti Teknologi Mara Marks: I. II. Iii. IV. Group LecturerDocument6 pagesFakulti Kejuruteraan Awam Universiti Teknologi Mara Marks: I. II. Iii. IV. Group Lecturerdzakirin hannanNo ratings yet

- Alshihabi For Steel Structure: Eng: Safwan Alhaj AbdoDocument10 pagesAlshihabi For Steel Structure: Eng: Safwan Alhaj AbdosafwanNo ratings yet

- Lab 9 Consolidation Oedometer Ecg263Document9 pagesLab 9 Consolidation Oedometer Ecg263Azim GamingNo ratings yet

- Universiti Teknologi Mara Assignment 3: Page 1 of 9Document9 pagesUniversiti Teknologi Mara Assignment 3: Page 1 of 9ABDUL MOHIMIN HAFIZUL BIN MOHD HANAPIAHNo ratings yet

- 2015 BT Development Siva SaiDocument35 pages2015 BT Development Siva SaiSushantNo ratings yet

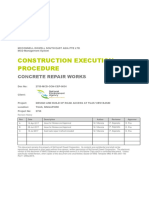

- 2755-MCD-CON-CEP-0070 - Concrete Repair Works For Cold JointDocument19 pages2755-MCD-CON-CEP-0070 - Concrete Repair Works For Cold JointNURLINURLINDANo ratings yet

- ASS 220 ETS S3110 0170 ED Rev.2Document112 pagesASS 220 ETS S3110 0170 ED Rev.2Omar MostafaNo ratings yet

- 3795-210-S10-E99-0002-Rev.3 PLC Io Mapping List Including Time Synchronize SDocument7 pages3795-210-S10-E99-0002-Rev.3 PLC Io Mapping List Including Time Synchronize SFomaa ElsayedNo ratings yet

- General Arrangement. Complete Steam Plant Including Two Steam Engines (1cyl + 2cyl Vertical)Document12 pagesGeneral Arrangement. Complete Steam Plant Including Two Steam Engines (1cyl + 2cyl Vertical)Trung NguyenNo ratings yet

- Report PDFDocument108 pagesReport PDFNavneeth Kumar KorleparaNo ratings yet

- LUC-Ex-CIV-MECH-MELE-002 V4Document1 pageLUC-Ex-CIV-MECH-MELE-002 V4Mr ElEcTrOnNo ratings yet

- Method Statement For Repair of Bulged Concrete UsingDocument8 pagesMethod Statement For Repair of Bulged Concrete Usingbureau servicesNo ratings yet

- BOQ Fire SystemDocument90 pagesBOQ Fire SystemDSAKNo ratings yet

- Faculty - Architecture, Planning, and Surveying - 2022 - Session 1 - Diploma - DQS151Document3 pagesFaculty - Architecture, Planning, and Surveying - 2022 - Session 1 - Diploma - DQS151STAR LILINo ratings yet

- Optical Properties of Silica Carbon Hybrid Nanostructure: Project ReportDocument13 pagesOptical Properties of Silica Carbon Hybrid Nanostructure: Project Reportswatentra TMU studentNo ratings yet

- 6 Bqes4102 Industrial Training Evaluation FormDocument15 pages6 Bqes4102 Industrial Training Evaluation FormChee HernNo ratings yet

- A1 Site ClearanceDocument4 pagesA1 Site ClearanceMOHAMAD AMIR BIN HALIDNo ratings yet

- ST - Mary'S Polytechnic College, Palakkad: (November 2019)Document13 pagesST - Mary'S Polytechnic College, Palakkad: (November 2019)chandhu thilakhNo ratings yet

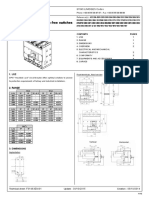

- Data Sheet DPX3 - 1600MT - ENGv5 PDFDocument10 pagesData Sheet DPX3 - 1600MT - ENGv5 PDFEdwin Armando Abella P.No ratings yet

- Painting Procedure: Service Water Storage TankDocument5 pagesPainting Procedure: Service Water Storage TankRanu JanuarNo ratings yet

- Erection of TanksDocument9 pagesErection of TanksZubair Ahmed KhaskheliNo ratings yet

- Pembinaan Mitrajaya SDN BHD Pmj/Mts/Con/PtwDocument2 pagesPembinaan Mitrajaya SDN BHD Pmj/Mts/Con/PtwkamarulNo ratings yet

- 000-Za-E-M09412 - A Ms For Fiber Optic Cable Installation - 13!08!2019Document20 pages000-Za-E-M09412 - A Ms For Fiber Optic Cable Installation - 13!08!2019syam prasadNo ratings yet

- TSP Composite Flanges PMTDocument14 pagesTSP Composite Flanges PMTBhargav PatelNo ratings yet

- SpecsDocument4 pagesSpecsSharon JNo ratings yet

- Method Statement For Installation of Access ScafoldingDocument9 pagesMethod Statement For Installation of Access Scafoldingbureau servicesNo ratings yet

- Grounding Installation Method: 3X330 MW Power Plant Project Indramayu-West JavaDocument10 pagesGrounding Installation Method: 3X330 MW Power Plant Project Indramayu-West JavaIzar IrhamniNo ratings yet

- UG Course Offer SEM I 20172018 16.05Document1 pageUG Course Offer SEM I 20172018 16.05Hafizuddin AdnanNo ratings yet

- Nandagopal (1) .Project SeniorDocument95 pagesNandagopal (1) .Project Seniorsridharan29No ratings yet

- Report Setting OutDocument25 pagesReport Setting Outaqilah dianaNo ratings yet

- Excel Engineering College (Autonomous) : Application For The End Semester Examinations - Nov / Dec - 2023Document1 pageExcel Engineering College (Autonomous) : Application For The End Semester Examinations - Nov / Dec - 2023mandalsanoj544No ratings yet

- Estimator Cum Draughtsman ResumeDocument2 pagesEstimator Cum Draughtsman Resumemohan0% (1)

- Bouri New Floating Storage Offloading (Fso) Project: Mellitah Oil and Gas B.VDocument12 pagesBouri New Floating Storage Offloading (Fso) Project: Mellitah Oil and Gas B.Vbudi DharmaNo ratings yet

- CV Riswanto SutomoDocument5 pagesCV Riswanto Sutomonaval_09100% (1)

- Weam Simulation Completion Report-Mar292019Document10 pagesWeam Simulation Completion Report-Mar292019Anonymous jlLBRMAr3ONo ratings yet

- E-021 SLDDocument1 pageE-021 SLDSyedNo ratings yet

- Method Statement - Underground Cable Laying Rev04Document26 pagesMethod Statement - Underground Cable Laying Rev04Ahamed UmarNo ratings yet

- MS For Fabrication & Erection of PipingDocument24 pagesMS For Fabrication & Erection of PipingravikumarNo ratings yet

- Major Project ReportDocument26 pagesMajor Project ReportAthar HussainNo ratings yet

- Examination Slip Semester 1 Academic Session 2017/2018: Date Printed:19-December - 2017Document1 pageExamination Slip Semester 1 Academic Session 2017/2018: Date Printed:19-December - 2017zulNo ratings yet

- Project Report On Autocad AutdeskDocument58 pagesProject Report On Autocad AutdeskSahil KaushikNo ratings yet

- Time Scheduler Project Tangki Timbun Dan Terminal BBM - CirebonDocument1 pageTime Scheduler Project Tangki Timbun Dan Terminal BBM - CirebondaehankoreaindoprimaNo ratings yet

- MS For Cable Tray Installation (IFC, Rev.00)Document11 pagesMS For Cable Tray Installation (IFC, Rev.00)noelNo ratings yet

- Method Statement For Irrigation 2Document12 pagesMethod Statement For Irrigation 2ashwinNo ratings yet

- Split 2721619866860034902Document1 pageSplit 2721619866860034902elvisngwa757No ratings yet

- Be 243046 001 - Tip 0023Document67 pagesBe 243046 001 - Tip 0023sarangpuneNo ratings yet

- All Course Civilfam AppDocument4 pagesAll Course Civilfam AppHarshavardhan A KNo ratings yet

- Project Proposal 10Document4 pagesProject Proposal 10Rolando Peralta JrNo ratings yet

- ZEE Pipeline Engineering Capability Statement PDFDocument17 pagesZEE Pipeline Engineering Capability Statement PDFHASHMI MAHMOODNo ratings yet

- P6012MAB 000 51 1 M321 VOA (MS For Deep Excavation)Document9 pagesP6012MAB 000 51 1 M321 VOA (MS For Deep Excavation)Vasilica BarbarasaNo ratings yet

- METHOD STATEMENT FOR PIPING REV 01 16 June 2021Document20 pagesMETHOD STATEMENT FOR PIPING REV 01 16 June 2021Moh'd SameerNo ratings yet

- MOS CeilingDocument7 pagesMOS CeilingKHAIRULSHAH FIRDAUSNo ratings yet

- Nioec SP 80 24 CPDocument13 pagesNioec SP 80 24 CPMahdiNo ratings yet

- DQS258 20232 A1 - Part B - FinaleDocument11 pagesDQS258 20232 A1 - Part B - FinaleMUHAMMAD DANIAL AMRAMNo ratings yet

- DQS259 - Assignment 2 - Mar-Aug 2023Document12 pagesDQS259 - Assignment 2 - Mar-Aug 2023MUHAMMAD DANIAL AMRAMNo ratings yet

- DQS256 Lecture On Cost Analysis NotesDocument53 pagesDQS256 Lecture On Cost Analysis NotesMUHAMMAD DANIAL AMRAMNo ratings yet

- DQS251 - Tutorial No. 2 - Basement - April 2023 ALLDocument5 pagesDQS251 - Tutorial No. 2 - Basement - April 2023 ALLMUHAMMAD DANIAL AMRAMNo ratings yet

- Flywheel Energy StorageDocument2 pagesFlywheel Energy Storagehayat umar bhatNo ratings yet

- Slide 5 Metal Forming IntroDocument72 pagesSlide 5 Metal Forming IntrogunjanNo ratings yet

- ASLP Newsletter (Issue 2, June 13) PDFDocument26 pagesASLP Newsletter (Issue 2, June 13) PDFAslp LibrariansNo ratings yet

- 4 Spark CassandraDocument15 pages4 Spark CassandrausernameusernaNo ratings yet

- Nurs 3020 FinalDocument9 pagesNurs 3020 Finalapi-240933601No ratings yet

- Multi-Criteria Decision MakingDocument22 pagesMulti-Criteria Decision MakingSeema DeviNo ratings yet

- SankhyaDocument376 pagesSankhyaRohit SahuNo ratings yet

- Least Learned Skills in CSS 9Document4 pagesLeast Learned Skills in CSS 9meltdownxNo ratings yet

- Curex KG 1 1819Document13 pagesCurex KG 1 1819nunikNo ratings yet

- Internal Assessment Mark Worksheet 2010 - 2011Document24 pagesInternal Assessment Mark Worksheet 2010 - 2011saranya_btechitNo ratings yet

- Richard Epstein - How To Create - or Destroy - Wealth in Real PropertyDocument28 pagesRichard Epstein - How To Create - or Destroy - Wealth in Real PropertyVitorsolianoNo ratings yet

- MIT6 034F10 Assn3Document11 pagesMIT6 034F10 Assn3Raj AkhaniNo ratings yet

- How To Setup Network Once Ntos 7Document2 pagesHow To Setup Network Once Ntos 7mrlamb711No ratings yet

- The Teacher: Decision MakerDocument24 pagesThe Teacher: Decision Makerapi-353014166No ratings yet

- Global Supply Chain Control TowersDocument16 pagesGlobal Supply Chain Control TowersTebaterror100% (2)

- Answer: Option C Explanation:: Direction (For Q.No. 2)Document21 pagesAnswer: Option C Explanation:: Direction (For Q.No. 2)sadhanarddNo ratings yet

- Huawei B932 Modem User GuideDocument15 pagesHuawei B932 Modem User GuideFlabiano Ojendiz Aley0% (1)

- CITY FLEUVE Ecology KalDocument77 pagesCITY FLEUVE Ecology Kalkashjustin100% (1)

- ĐỀ 509Document3 pagesĐỀ 509Dũng HoàngNo ratings yet

- 199307Document87 pages199307vtvuckovicNo ratings yet

- Census Literacy 2011Document40 pagesCensus Literacy 2011arpit_optimismNo ratings yet

- Bacteria From PrescottDocument19 pagesBacteria From PrescottYekitaSNo ratings yet

- Hybrid Journals in Mathematics Can They Be Successful?: Mathematical Sciences PublishersDocument15 pagesHybrid Journals in Mathematics Can They Be Successful?: Mathematical Sciences PublishersPoohzain PuspaNo ratings yet

- "IKIGAI - Find Your Purpose For Being": DescriptionDocument3 pages"IKIGAI - Find Your Purpose For Being": DescriptionashindeNo ratings yet

- 3 - 4 Cse-1 Ay-2017-18Document1 page3 - 4 Cse-1 Ay-2017-18Shantha KumarNo ratings yet

- Unit 1 Introduction To Microeconomics - DT-PostedDocument63 pagesUnit 1 Introduction To Microeconomics - DT-PostedKereth WhittleNo ratings yet

- Recommended Table-Type Management Review Format - For NIA Regional Offices - Rev 2021 - 1Document4 pagesRecommended Table-Type Management Review Format - For NIA Regional Offices - Rev 2021 - 1Kang DanielNo ratings yet

- Fil 111-TOS Midterm Final Copy 2Document2 pagesFil 111-TOS Midterm Final Copy 2Criselda Garcia SarioNo ratings yet

- Driver ServerDocument10 pagesDriver ServerGeraldoadriNo ratings yet

DQS251 - Piling - Spun Piles - Tutorial-Drwgs-Dec 2019 - pg11

DQS251 - Piling - Spun Piles - Tutorial-Drwgs-Dec 2019 - pg11

Uploaded by

MUHAMMAD DANIAL AMRAMOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DQS251 - Piling - Spun Piles - Tutorial-Drwgs-Dec 2019 - pg11

DQS251 - Piling - Spun Piles - Tutorial-Drwgs-Dec 2019 - pg11

Uploaded by

MUHAMMAD DANIAL AMRAMCopyright:

Available Formats

CONFIDENTIAL AP/DEC2019/DQS251

UNIVERSITI TEKNOLOGI MARA

FINAL EXAMINATION

COURSE MEASUREMENT OF CONSTRUCTION WORKS IV

COURSE CODE DQS251

EXAMINATION DECEMBER 2019

TIME 3 HOURS

INSTRUCTIONS TO CANDIDATES

This question paper consists of one (1) question.

Answer the question in the Slip-sort Papers and Schedule Papers.

All measurement shall be in strict accordance with the principles laid down in the Malaysia

Standard Method of Measurement of Building Works (Second Edition) (SMM2).

Do not bring any material into the examination room unless permission is given by the

invigilator.

Please check to make sure that this examination pack consists of:

i) the Question Paper

ii) a six - page Appendix 1

iii) Slip-sort Papers - provided by the Faculty

iv) Schedule Papers - provided by the Faculty

v) an Answer Booklet's Cover - provided by the Faculty

vi) SMM2 - provided by the Faculty

Answer ALL questions in English.

DO NOT TURN THIS PAGE UNTIL YOU ARE TOLD TO DO SO

This examination paperconsists of 2 printed pages

© Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

CONFIDENTIAL 2 AP/DEC 2019/DQS251

QUESTION 1

Based on the drawings and specification notes given in the drawing number

PUB/DQS251/1-6, prepare the followings:

a) Take off quantities for all spun piles using piling schedule.

b) Draft bill of quantities using slip sort for 500mm diameter spun piles only.

You are advised to read the specification notes in the drawings before proceeding with your

taking-off.

(100 marks)

END OF QUESTION PAPER

© Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

CONFIDENTIAL APPENDIX 1(1) AP/DEC2019/DQS251

Notes

1. Take off all Pre-tensioned Spun Concrete Piles as shown in the drawings.

2. Ground water level established at 3.50m below original ground level on 04 February 2019.

3. 3 nos of boreholes were sunk on the site.

4. The works id about 400.00m from Sungai Tapah.

5. All piles is expected to start from ground level.

6. 1PA denotes as raking piles (1 in 5.6715) and the length is taken the same as 1P vertical piles.

7. The piles shall be supplied of 6.00m (initial pile) and 6.00m (extension pile)

8. 3 Nos. of pile from pile cap 1P shall be used as trial piles.

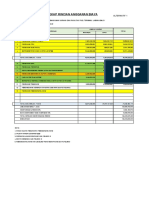

9. Based level:

1P- 86.00

2P-81.30

3P - 80.70

4P - 82.00

5P - 79.50

6P-76.35

7P - 74.70

8P - 75.00

9P - 73.00

10P- 81.75

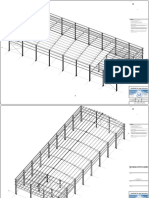

PROJECT : DRAWING TITLE : SUBJECT DRAWN BY MONASH

CHECKED BY : NOR FAIZAH

CADANGAN MEMBINA DAN MENYIAPKAN NOTES FOR PILING WORKS MEASUREMENT OF DATE AS SHOWN

SEBUAH KOMPLEKS PENTADBIRAN NEGERI

CONSTRUCTION DATE DECEMBER 2019

MUKIM BAGAN DATUK

TEraOLOGI DAERAH BAGAN DATUK COURSE CODE WORKS IV DRAWING NO. :

PERAK DARUL RIDZUAN DQS251 PUB/DQS251/1

©Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

CONFIDENTIAL APPENDIX I (2) AP/DEC2019/DQS251

©Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

CONFIDENTIAL APPENDIX I (3) AP/DEC2019/DQS251

NOTES: g ROOF LEV.

5. DRIVING OF PILE SHALL BE BY HYDRAULIC HAMMER.

1. ALL PILE SHOULD BE OF APPROVED TYPE Of

-COLUMN TO DETAIL -COLUMN TO DETAIL DRIVING PILE MUST BE IN VERY CONTROL MANNER,

a & 350mm DIA. 400mm DIA. 4 500mm DIA. SPUN

CAREFULL OBSERVATION SHALL BE CARRIED OUT

PILE ; GRADE 80 PILES CLASS C. ON THE EXISTING STRUCTURES DUE TO PILE DRIVING

RNISH GRD LVL RNISH GRD LVL GRD LEVEL 2. PILES SHALL COMPLY WITH B.S. 8004 1986 BRITISH ACTIVITIES.

GRD LEVEL

mm STANDARD CODE OF PRACTICE FOR FOUNDATION

GROUND BEAM 1 GROUND BEAM 6. ALL WELD TO BE PENETRATED WELDS AND WELDING

AND MS 1314: PART 4 : 2004.

OF STEEL GRADE 50B TO B.S 4360 SHALL COMPLY

3. THE DESIGN WORKING LOAD FOR EACH PILE IS TAKEN WITH BS 5135.

i STUMP- -3T10 STUMP — -3TI0

AS 500 KN ( 50 TONNE). 7. ELECTRODES USED FOR ALL WELDING SHALL COMPLY

4. PILE TO BE TESe TILL TWICE ITS WORKING LOAD WITH BS 639,1976.

-6T20 B/W -6T20 B/W

OF 1000 KN (100 TONNE). BY MAINTAINED LOAD

Hu -50mm THK. LEAN

a -50mm THK. LEAN

TEST AFTER 28 DAYS DRIVEN OF PILE (FRICTION PILE).

8. ALL PILE JOINT SHALL BE PAINTED WITH EPOXY PAINT

FOR CORROSION PROTECTION.

i^r V3RD.,m,5KFLR. LEV.

CONCRETE CONCRETE

-0350 SPUN PILES TO -«50 SPUN PILES

BE DRIVEN36m LENGTH

0350-1P

-COLUMN TO DETAIL

-COLUMN TO DETAIL

RNISH GRD LVL ,,,..ip LEVEL

RNISH GRD LVL GRD LEVEL mm®

GROUND BEAM

GROUND BEAU

T12-200 c/c STUMP- r-5T12 a T12-200 c/c V2N0. FLR.LEV.

STUMP— r -5T12

-14T25

-13T25

-14T25 B/W

_50mm THK. LEAN £r 50mm THK. LEAN

T

CONCRETE

CONCRETE

-0400 SPUN PILES

-0350 SPUN PILES

035O-3P 04OO-4P

y 1ST. FLR. LEV.

VARIES ]_ GRD. LEV.

800 2000

50mm THK. LEAN

CONCRETE 400 , 600 600 . 400

I

0350 SPUN PILES

035O-2P 4' 44-} 4+-} ,450 Mir 450 MIN

8

2000

1

-H—

1

L.__

JXL

400 , 600 600 , 400

( 44)

^ i

44-} S CO

i

CO DvJ) OJI tX.1

44-}

4-+A. _ 4- - 4-+-y 400 | 600 1 600 I 400 4> TYPICAL COLUMN DETAILS

(NOT TO SCALE)

2000

PROJECT : DRAWING TITLE : SUBJECT DRAWN BY MONASH

CHECKED BY : NOR FAIZAH

CADANGAN MEMBINA DAN MENYIAPKAN PILE CAP DETAIL -1 MEASUREMENT OF DATE : 1 : 50

SEBUAH KOMPLEKS PENTADBIRAN NEGERI

UMjWERSITI MUKIM BAGAN DATUK

CONSTRUCTION DATE : DECEMBER 2019

TElOfOLOGI DAE RAH BAGAN DATUK COURSE CODE : WORKS IV DRAWING NO. :

PERAK DARUL RIDZUAN DQS251 PUB/DQS251/3

©Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

CONFIDENTIAL APPENDIX I (4) AP/DEC2019/DQS251

-COLUMN TO DETAIL -COLUMN TO DETAIL

RNISH GRD LVL RNISH GRD LVL GRD LEVEL

GRD LEVEL GRD LEVEL

GROUND BEAM GROUND BEAM

T12-200 c/c STUMP- -5T12 T12-200 c/c STUMP — -5T12 T12-200 c/c

-22T25

17T25 B/W t=f -22T25

-14T25 -19T25

50mm THK. LEAN

ry?«Egy^v:M.:r^r->.' BBMBBEBBMHBgB -50mm THK. LEAN spi -50mm THK. LEAN

CONCRETE

CONCRETE CONCRETE

0400 SPUN PILES -0400 SPUN PILES -0500 SPUN PILES

NOJESl

05OO-7P 1. ALL PILE SHOULD BE OF APPROVED TYPE OF

04OO-5P 04OO-6P

350mm DIA. 400mm DIA. 4 500mm DIA. SPUN

3200 PILE ; GRADE 80 PILES CLASS C.

400 200 400 600 , 600 . 400 ,200 400 2. PILES SHALL COMPLY WITH B.S. 8004 1986

2500 BRITISH STANDARD CODE OF PRACTICE FOR

400 , 850 850 , 400 3200 i i i i i i i FOUNDATION AND MS 1314: PART 4 : 2004.

400 1200 1200 400 3. THE DESIGN WORKING LOAD FOR EACH PILE

IS TAKEN AS 500 KN ( 50 TONNE).

4. PILE TO BE TESTED TILL TWICE ITS WORKING

LOAD OF 1000 KN (100 TONNE). BY MAINTAINED

4-i.L LOAD TEST AFTER 28 DAYS DRIVEN OF PILE

4-4} 44-} 4-+-} (FRICTION PILE).

5. DRIVING OF PILE SHALL BE BY HYDRAULIC HAMMER.

! DRIVING PILE MUST BE IN VERY CONTROL MANNER,

4-4--} —i— CAREFULL OBSERVATION SHALL BE CARRIED OUT ON

i THE EXISTING STRUCTURES DUE TO PILE DRIVING

ACTIVITIES.

4-4-} 4-4} 4-4} 6. ALL WELD TO BE PENETRATED WELDS AND WELDING

OF STEEL GRADE 50B TO B.S 4360 SHALL COMPLY

*4-> 44-} WITH BS 5135.

7. ELECTRODES USED FOR ALL WELDING SHALL COMPLY

WITH BS 639,1976.

400 600 600 400 8. ALL PILE JOINT SHALL BE PAINTED WITH EPOXY PAINT

FOR CORROSION PROTECTION.

PROJECT : DRAWING TITLE : SUBJECT DRAWN BY MONASH

CHECKED BY NOR FAIZAH

CADANGAN MEMBINA DAN MENYIAPKAN PILE CAP DETAIL - 2 MEASUREMENT OF DATE 1 : 50

SEBUAH KOMPLEKS PENTADBIRAN NEGERI

MUKIM BAGAN DATUK CONSTRUCTION DATE DECEMBER 2019

TEKMOLOOI DAE RAH BAGAN DATUK COURSE CODE WORKS IV DRAWING NO. :

PERAK DARUL RIDZUAN DQS251 PUB/DQS251/4

© Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

CONFIDENTIAL APPENDIX I (5) AP/DEC2019/DQS251

-COLUMN TO DETAIL -COLUMN TO DETAIL -COLUMN TO DETAIL

RNISH GRD LVL RNISH GRD LVL RNISH GRD LVL GRD LEVEL

, GRD LEVEL GRD LEVEL

BEAM GROUND BEAM GROUND BEAM

STUMP — i—6T12 T12-2O0 c/c STU! -6T12 T12-200 c/c STUMP— -6T12 -T12-200 c/c

J.

Ml B I f=4^F? -30T25

-19T25

m -22T25

-19T25

-22T25 B/W

-50mm THK. LEAN j@ - WV^.W-T'.^ff. -50mm THK. LEAN -50mm THK. LEAN

ipl set

CONCRETE CONCRETE CONCRETE

-0500 SPUN PILES

-0500 SPUN PILES -0500 SPUN PILES

05OO-9P

0500-1 OP 05OO-8P

NOTES:

3200 1. ALL PILE SHOULD BE OF APPROVED TYPE OF

4400 3200 400 1200 1200 400 350mm DIA. 400mm DIA. 4 500mm DIA. SPUN

400 200. 400 400 1200 1200 400 PILE ; GRADE 80 PILES CLASS C.

400 200 400 600 600 , 600 600

2. PILES SHALL COMPLY WITH B.S. 8004 1986

TT BRITISH STANDARD CODE OF PRACTICE FOR

-k .k -k FOUNDATION AND MS 1314: PART 4 : 2004.

-k -k ^k ^k 44-} 4-+-} 4-4-} 3. THE DESIGN WORKING LOAD FOR EACH PILE

4-4} 44-} 4-4-} 4-+-} ^iy

r

V-L^

r

VJ_^

r IS TAKEN AS 500 KN ( 50 TONNE).

v Ls V_L^ ^.J_^

r r t 4. PILE TO BE TESTED TILL TWICE ITS WORKING

LOAD OF 1000 KN (100 TONNE). BY MAINTAINED

LOAD TEST AFTER 28 DAYS DRIVEN OF PILE

^k i /.u i ^k -k A -k (FRICTION PILE).

4-+-} —H— 4-4--} —l._ 4-+-} 44-} 4-+-} 4-4} 5. DRIVING OF PILE SHALL BE BY HYDRAULIC HAMMER.

v.lV

r 1 V i V v_Lv

r

v.L''

r

^Ls

t DRIVING PILE MUST BE IN VERY CONTROL MANNER,

CAREFUL! OBSERVATION SHALL BE CARRIED OUT ON

THE EXISTING STRUCTURES DUE TO PILE DRIVING

ACTIVITIES.

-k A* ^k ^k

4-4-} 4-4} 4-+-} 4-+-} -k .k -k

6. ALL WELD TO BE PENETRATED WELDS AND WELDING

OF STEEL GRADE 50B TO B.S 4360 SHALL COMPLY

v V V 4-+-} 4-4--} 4-4} WITH BS 5135.

V V V 7. ELECTRODES USED FOR ALL WELDING SHALL COMPLY

400 600 600 600 600 400 WITH BS 639,1976.

1200 1200 1200

8. ALL PILE JOINT SHALL BE PAINTED WITH EPOXY PAINT

FOR CORROSION PROTECTION.

PROJECT : DRAWING TITLE : SUBJECT : DRAWN BY : MONASH

CHECKED BY : NOR FAIZAH

CADANGAN MEMBINA DAN MENYIAPKAN

PILE CAP DETAIL - 3 MEASUREMENT OF DATE : 1 :50

SEBUAH KOMPLEKS PENTADBIRAN NEGERI

UMHVERBra MUKIM BAGAN DATUK CONSTRUCTION DATE : DECEMBER 2019

TE1MOL0OI DAERAH BAGAN DATUK COURSE CODE : WORKS IV DRAWING NO. :

PERAK DARUL RIDZUAN DQS251 PUB/DQS251/5

©Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

CONFIDENTIAL APPENDIX I (6) AP/DEC2019/DQS251

t'mm Thick

16mm Thick M.S.

DIIC PAD

10mm Thick Fillet sni , \ */1/ "\

V CUT OF LEVEL

\\ -4/

L

8

ELEVATION ^ .

.•c SOFFIT OF PILECAP

* . '« '

WTB • „"•.• *"«!'

*i •:;'.'. "s :>:" V

M

PLAN • •'. A

NOT TO SCALE

Pin 9f)0 r/r

* A

•. \1. •'•• 8

PILE SHOE DETAILS - CROSS FIN SHOE m

DETAIL 'Y'

(All dimensions are in mm) NOT TO SCALE ''"'"

4*'- .

Pile CO d s h t D

9Snmrn<a 9PIIN Pll F

16 10 350 WELD ED TO PLATE

350 350 50 .'• • • '• a •

400 400 16 50 10 400

500 500 16 50 10 500 UPPER PILE STEEL BAND

1 >.0mm THK. M.S PLATE AS FORMWORK

SEE DETAIL V

A • "0 RECEIVE IN-SITU CONCRETE PLUG

6mm THK. FILLET WELD All ROUND

V

END PLATE -^22 DEGRE DETAIL FOR PILE DOWEL BAR

END PLATE RQNFORCING BAND NOT TO SCALE

150 X 300 X 12.7

BUTT WELD ALL ROUND

UPPER PILE LOWER PILE STEEL BAND NOTES:

EFFECTIVE THROAT 9mm THK.

1. ALL PILE SHOULD BE OF APPROVED TYPE OF 350mm DIA.

A 400mm DIA 4 500mm DIA SPUN PILE ; GRADE 80

END PLATE PILES CLASS C.

DETAIL Z

2. PILES SHALL COMPLY WITH B.S. 8004 1986

SEE DETAIL ~Z NOT TO SCALE

BRITISH STANDARD CODE OF PRACTICE FOR FOUNDATION

AND MS 1314: PART 4 : 2004.

RQNFORCING BAND 3. THE DESIGN WORKING LOAD FOR EACH PILE IS TAKEN

150 X 300 X 12.7 AS 500 KN ( 50 TONNE).

4. PILE TO BE TESTED TILL TWICE ITS WORKING LOAD OF

r-250mm 0 SPUN PILE 1000 KN (100 TONNE). BY MAINTAINED LOAD TEST AFTER

28 DAYS DRIVEN OF PILE (FRICTION PILE).

LOWER PILE 5. DRIVING OF PILE SHALL BE BY HYDRAULIC HAMMER.

DRIVING PILE MUST BE IN VERY CONTROL MANNER, CAREFULL

OBSERVATION SHALL BE CARRIED OUT ON THE EXISTING

REINFORCING BAND STRUCTURES DUE TO PILE DRIVING ACTIVITIES.

150 X 300 X 12.7

6. ALL WELD TO BE PENETRATED WELDS AND WELDING OF

STEEL GRADE 50B TO B.S 4360 SHALL COMPLY WITH

BS 5135.

7. ELECTRODES USED FOR ALL WELDING SHALL COMPLY WITH

BS 639,1976.

SECTION A-A 8. ALL PILE JOINT SHALL BE PAINTED WITH EPOXY PAINT

DETAIL OF EXTENSION JOINT FOR CORROSION PROTECTION.

NOT TO SCALE

NOT TO SCALE

PROJECT : DRAWING TITLE : SUBJECT DRAWN BY : MONASH

CHECKED BY : NOR FAIZAH

CADANGAN MEMBINA DAN MENYIAPKAN

PILE CAP DETAIL - 4 MEASUREMENT OF DATE

SEBUAH KOMPLEKS PENTADBIRAN NEGERI : AS SHOWN

UMIVERSITII MUKIM BAGAN DATUK CONSTRUCTION DATE : DECEMBER 2019

Tekmologi DAE RAH BAGAN DATUK COURSE CODE : WORKS IV DRAWING NO. :

PERAK DARUL RIDZUAN DQS251 PUB/DQS251/6

©Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

You might also like

- Method Statement For Tie-Ins During ShutdownDocument17 pagesMethod Statement For Tie-Ins During ShutdownAnyanele Nnamdi Felix86% (7)

- Curriculum Vitae: Personal DateDocument2 pagesCurriculum Vitae: Personal DateVannak CHen70% (10)

- DQS206 20224 Assignment 1 - CBADocument4 pagesDQS206 20224 Assignment 1 - CBAMUHAMMAD DANIAL AMRAMNo ratings yet

- Method Statement For Installation of Rmu: Al Naboodah Mep L.L.CDocument5 pagesMethod Statement For Installation of Rmu: Al Naboodah Mep L.L.Csujan198050% (2)

- Construction Method For Installation of Pig TrapDocument11 pagesConstruction Method For Installation of Pig TrapMuhammad Irsyadi100% (2)

- Working Piles Design Report Rev 1Document115 pagesWorking Piles Design Report Rev 1Nauman Mumtaz100% (3)

- Faculty - Architecture, Planning, and Surveying - 2022 - Session 1 - Diploma - DQS251Document8 pagesFaculty - Architecture, Planning, and Surveying - 2022 - Session 1 - Diploma - DQS251Humaira MairaNo ratings yet

- Cec DWG Duct 101 Rev C SHT 3 5Document1 pageCec DWG Duct 101 Rev C SHT 3 5Kingsly NovaNo ratings yet

- Fakulti Kejuruteraan Awam Universiti Teknologi Mara Marks: I. II. Iii. IV. Group LecturerDocument6 pagesFakulti Kejuruteraan Awam Universiti Teknologi Mara Marks: I. II. Iii. IV. Group Lecturerdzakirin hannanNo ratings yet

- Alshihabi For Steel Structure: Eng: Safwan Alhaj AbdoDocument10 pagesAlshihabi For Steel Structure: Eng: Safwan Alhaj AbdosafwanNo ratings yet

- Lab 9 Consolidation Oedometer Ecg263Document9 pagesLab 9 Consolidation Oedometer Ecg263Azim GamingNo ratings yet

- Universiti Teknologi Mara Assignment 3: Page 1 of 9Document9 pagesUniversiti Teknologi Mara Assignment 3: Page 1 of 9ABDUL MOHIMIN HAFIZUL BIN MOHD HANAPIAHNo ratings yet

- 2015 BT Development Siva SaiDocument35 pages2015 BT Development Siva SaiSushantNo ratings yet

- 2755-MCD-CON-CEP-0070 - Concrete Repair Works For Cold JointDocument19 pages2755-MCD-CON-CEP-0070 - Concrete Repair Works For Cold JointNURLINURLINDANo ratings yet

- ASS 220 ETS S3110 0170 ED Rev.2Document112 pagesASS 220 ETS S3110 0170 ED Rev.2Omar MostafaNo ratings yet

- 3795-210-S10-E99-0002-Rev.3 PLC Io Mapping List Including Time Synchronize SDocument7 pages3795-210-S10-E99-0002-Rev.3 PLC Io Mapping List Including Time Synchronize SFomaa ElsayedNo ratings yet

- General Arrangement. Complete Steam Plant Including Two Steam Engines (1cyl + 2cyl Vertical)Document12 pagesGeneral Arrangement. Complete Steam Plant Including Two Steam Engines (1cyl + 2cyl Vertical)Trung NguyenNo ratings yet

- Report PDFDocument108 pagesReport PDFNavneeth Kumar KorleparaNo ratings yet

- LUC-Ex-CIV-MECH-MELE-002 V4Document1 pageLUC-Ex-CIV-MECH-MELE-002 V4Mr ElEcTrOnNo ratings yet

- Method Statement For Repair of Bulged Concrete UsingDocument8 pagesMethod Statement For Repair of Bulged Concrete Usingbureau servicesNo ratings yet

- BOQ Fire SystemDocument90 pagesBOQ Fire SystemDSAKNo ratings yet

- Faculty - Architecture, Planning, and Surveying - 2022 - Session 1 - Diploma - DQS151Document3 pagesFaculty - Architecture, Planning, and Surveying - 2022 - Session 1 - Diploma - DQS151STAR LILINo ratings yet

- Optical Properties of Silica Carbon Hybrid Nanostructure: Project ReportDocument13 pagesOptical Properties of Silica Carbon Hybrid Nanostructure: Project Reportswatentra TMU studentNo ratings yet

- 6 Bqes4102 Industrial Training Evaluation FormDocument15 pages6 Bqes4102 Industrial Training Evaluation FormChee HernNo ratings yet

- A1 Site ClearanceDocument4 pagesA1 Site ClearanceMOHAMAD AMIR BIN HALIDNo ratings yet

- ST - Mary'S Polytechnic College, Palakkad: (November 2019)Document13 pagesST - Mary'S Polytechnic College, Palakkad: (November 2019)chandhu thilakhNo ratings yet

- Data Sheet DPX3 - 1600MT - ENGv5 PDFDocument10 pagesData Sheet DPX3 - 1600MT - ENGv5 PDFEdwin Armando Abella P.No ratings yet

- Painting Procedure: Service Water Storage TankDocument5 pagesPainting Procedure: Service Water Storage TankRanu JanuarNo ratings yet

- Erection of TanksDocument9 pagesErection of TanksZubair Ahmed KhaskheliNo ratings yet

- Pembinaan Mitrajaya SDN BHD Pmj/Mts/Con/PtwDocument2 pagesPembinaan Mitrajaya SDN BHD Pmj/Mts/Con/PtwkamarulNo ratings yet

- 000-Za-E-M09412 - A Ms For Fiber Optic Cable Installation - 13!08!2019Document20 pages000-Za-E-M09412 - A Ms For Fiber Optic Cable Installation - 13!08!2019syam prasadNo ratings yet

- TSP Composite Flanges PMTDocument14 pagesTSP Composite Flanges PMTBhargav PatelNo ratings yet

- SpecsDocument4 pagesSpecsSharon JNo ratings yet

- Method Statement For Installation of Access ScafoldingDocument9 pagesMethod Statement For Installation of Access Scafoldingbureau servicesNo ratings yet

- Grounding Installation Method: 3X330 MW Power Plant Project Indramayu-West JavaDocument10 pagesGrounding Installation Method: 3X330 MW Power Plant Project Indramayu-West JavaIzar IrhamniNo ratings yet

- UG Course Offer SEM I 20172018 16.05Document1 pageUG Course Offer SEM I 20172018 16.05Hafizuddin AdnanNo ratings yet

- Nandagopal (1) .Project SeniorDocument95 pagesNandagopal (1) .Project Seniorsridharan29No ratings yet

- Report Setting OutDocument25 pagesReport Setting Outaqilah dianaNo ratings yet

- Excel Engineering College (Autonomous) : Application For The End Semester Examinations - Nov / Dec - 2023Document1 pageExcel Engineering College (Autonomous) : Application For The End Semester Examinations - Nov / Dec - 2023mandalsanoj544No ratings yet

- Estimator Cum Draughtsman ResumeDocument2 pagesEstimator Cum Draughtsman Resumemohan0% (1)

- Bouri New Floating Storage Offloading (Fso) Project: Mellitah Oil and Gas B.VDocument12 pagesBouri New Floating Storage Offloading (Fso) Project: Mellitah Oil and Gas B.Vbudi DharmaNo ratings yet

- CV Riswanto SutomoDocument5 pagesCV Riswanto Sutomonaval_09100% (1)

- Weam Simulation Completion Report-Mar292019Document10 pagesWeam Simulation Completion Report-Mar292019Anonymous jlLBRMAr3ONo ratings yet

- E-021 SLDDocument1 pageE-021 SLDSyedNo ratings yet

- Method Statement - Underground Cable Laying Rev04Document26 pagesMethod Statement - Underground Cable Laying Rev04Ahamed UmarNo ratings yet

- MS For Fabrication & Erection of PipingDocument24 pagesMS For Fabrication & Erection of PipingravikumarNo ratings yet

- Major Project ReportDocument26 pagesMajor Project ReportAthar HussainNo ratings yet

- Examination Slip Semester 1 Academic Session 2017/2018: Date Printed:19-December - 2017Document1 pageExamination Slip Semester 1 Academic Session 2017/2018: Date Printed:19-December - 2017zulNo ratings yet

- Project Report On Autocad AutdeskDocument58 pagesProject Report On Autocad AutdeskSahil KaushikNo ratings yet

- Time Scheduler Project Tangki Timbun Dan Terminal BBM - CirebonDocument1 pageTime Scheduler Project Tangki Timbun Dan Terminal BBM - CirebondaehankoreaindoprimaNo ratings yet

- MS For Cable Tray Installation (IFC, Rev.00)Document11 pagesMS For Cable Tray Installation (IFC, Rev.00)noelNo ratings yet

- Method Statement For Irrigation 2Document12 pagesMethod Statement For Irrigation 2ashwinNo ratings yet

- Split 2721619866860034902Document1 pageSplit 2721619866860034902elvisngwa757No ratings yet

- Be 243046 001 - Tip 0023Document67 pagesBe 243046 001 - Tip 0023sarangpuneNo ratings yet

- All Course Civilfam AppDocument4 pagesAll Course Civilfam AppHarshavardhan A KNo ratings yet

- Project Proposal 10Document4 pagesProject Proposal 10Rolando Peralta JrNo ratings yet

- ZEE Pipeline Engineering Capability Statement PDFDocument17 pagesZEE Pipeline Engineering Capability Statement PDFHASHMI MAHMOODNo ratings yet

- P6012MAB 000 51 1 M321 VOA (MS For Deep Excavation)Document9 pagesP6012MAB 000 51 1 M321 VOA (MS For Deep Excavation)Vasilica BarbarasaNo ratings yet

- METHOD STATEMENT FOR PIPING REV 01 16 June 2021Document20 pagesMETHOD STATEMENT FOR PIPING REV 01 16 June 2021Moh'd SameerNo ratings yet

- MOS CeilingDocument7 pagesMOS CeilingKHAIRULSHAH FIRDAUSNo ratings yet

- Nioec SP 80 24 CPDocument13 pagesNioec SP 80 24 CPMahdiNo ratings yet

- DQS258 20232 A1 - Part B - FinaleDocument11 pagesDQS258 20232 A1 - Part B - FinaleMUHAMMAD DANIAL AMRAMNo ratings yet

- DQS259 - Assignment 2 - Mar-Aug 2023Document12 pagesDQS259 - Assignment 2 - Mar-Aug 2023MUHAMMAD DANIAL AMRAMNo ratings yet

- DQS256 Lecture On Cost Analysis NotesDocument53 pagesDQS256 Lecture On Cost Analysis NotesMUHAMMAD DANIAL AMRAMNo ratings yet

- DQS251 - Tutorial No. 2 - Basement - April 2023 ALLDocument5 pagesDQS251 - Tutorial No. 2 - Basement - April 2023 ALLMUHAMMAD DANIAL AMRAMNo ratings yet

- Flywheel Energy StorageDocument2 pagesFlywheel Energy Storagehayat umar bhatNo ratings yet

- Slide 5 Metal Forming IntroDocument72 pagesSlide 5 Metal Forming IntrogunjanNo ratings yet

- ASLP Newsletter (Issue 2, June 13) PDFDocument26 pagesASLP Newsletter (Issue 2, June 13) PDFAslp LibrariansNo ratings yet

- 4 Spark CassandraDocument15 pages4 Spark CassandrausernameusernaNo ratings yet

- Nurs 3020 FinalDocument9 pagesNurs 3020 Finalapi-240933601No ratings yet

- Multi-Criteria Decision MakingDocument22 pagesMulti-Criteria Decision MakingSeema DeviNo ratings yet

- SankhyaDocument376 pagesSankhyaRohit SahuNo ratings yet

- Least Learned Skills in CSS 9Document4 pagesLeast Learned Skills in CSS 9meltdownxNo ratings yet

- Curex KG 1 1819Document13 pagesCurex KG 1 1819nunikNo ratings yet

- Internal Assessment Mark Worksheet 2010 - 2011Document24 pagesInternal Assessment Mark Worksheet 2010 - 2011saranya_btechitNo ratings yet

- Richard Epstein - How To Create - or Destroy - Wealth in Real PropertyDocument28 pagesRichard Epstein - How To Create - or Destroy - Wealth in Real PropertyVitorsolianoNo ratings yet

- MIT6 034F10 Assn3Document11 pagesMIT6 034F10 Assn3Raj AkhaniNo ratings yet

- How To Setup Network Once Ntos 7Document2 pagesHow To Setup Network Once Ntos 7mrlamb711No ratings yet

- The Teacher: Decision MakerDocument24 pagesThe Teacher: Decision Makerapi-353014166No ratings yet

- Global Supply Chain Control TowersDocument16 pagesGlobal Supply Chain Control TowersTebaterror100% (2)

- Answer: Option C Explanation:: Direction (For Q.No. 2)Document21 pagesAnswer: Option C Explanation:: Direction (For Q.No. 2)sadhanarddNo ratings yet

- Huawei B932 Modem User GuideDocument15 pagesHuawei B932 Modem User GuideFlabiano Ojendiz Aley0% (1)

- CITY FLEUVE Ecology KalDocument77 pagesCITY FLEUVE Ecology Kalkashjustin100% (1)

- ĐỀ 509Document3 pagesĐỀ 509Dũng HoàngNo ratings yet

- 199307Document87 pages199307vtvuckovicNo ratings yet

- Census Literacy 2011Document40 pagesCensus Literacy 2011arpit_optimismNo ratings yet

- Bacteria From PrescottDocument19 pagesBacteria From PrescottYekitaSNo ratings yet

- Hybrid Journals in Mathematics Can They Be Successful?: Mathematical Sciences PublishersDocument15 pagesHybrid Journals in Mathematics Can They Be Successful?: Mathematical Sciences PublishersPoohzain PuspaNo ratings yet

- "IKIGAI - Find Your Purpose For Being": DescriptionDocument3 pages"IKIGAI - Find Your Purpose For Being": DescriptionashindeNo ratings yet

- 3 - 4 Cse-1 Ay-2017-18Document1 page3 - 4 Cse-1 Ay-2017-18Shantha KumarNo ratings yet

- Unit 1 Introduction To Microeconomics - DT-PostedDocument63 pagesUnit 1 Introduction To Microeconomics - DT-PostedKereth WhittleNo ratings yet

- Recommended Table-Type Management Review Format - For NIA Regional Offices - Rev 2021 - 1Document4 pagesRecommended Table-Type Management Review Format - For NIA Regional Offices - Rev 2021 - 1Kang DanielNo ratings yet

- Fil 111-TOS Midterm Final Copy 2Document2 pagesFil 111-TOS Midterm Final Copy 2Criselda Garcia SarioNo ratings yet

- Driver ServerDocument10 pagesDriver ServerGeraldoadriNo ratings yet