Professional Documents

Culture Documents

Dodge Quantis Gear Box Brochure

Dodge Quantis Gear Box Brochure

Uploaded by

sitaCopyright:

Available Formats

You might also like

- CompleteCatalog PDFDocument116 pagesCompleteCatalog PDFgume pesaNo ratings yet

- Cat 769D 12-2001 Dumper PDFDocument28 pagesCat 769D 12-2001 Dumper PDFAbo Achraf LaalawiNo ratings yet

- Manual Expansora de TubosDocument21 pagesManual Expansora de TubosAlejandro DuranNo ratings yet

- Ica1603 0513 WebDocument292 pagesIca1603 0513 WebayavuzbvsNo ratings yet

- 2010 Freightliner Meritor 14X Tandem Drive AxleDocument8 pages2010 Freightliner Meritor 14X Tandem Drive AxlekelyamigasNo ratings yet

- Surface Belt Structure: Cema C & D SeriesDocument8 pagesSurface Belt Structure: Cema C & D SeriesSari Ully Sibarani100% (1)

- GP - AF - Low 1Document8 pagesGP - AF - Low 1maguilar20No ratings yet

- Bearing Solutions For The Material Handling IndustryDocument8 pagesBearing Solutions For The Material Handling IndustryMarceloNo ratings yet

- Catalogo 35zDocument50 pagesCatalogo 35zproseryobNo ratings yet

- Serie 2Document36 pagesSerie 2camiloNo ratings yet

- Dodge AbbDocument16 pagesDodge AbbHenry DelgadoNo ratings yet

- Motorized Pulley 320L, 320M & 320H Ø 320 MM: L For Light-DutyDocument8 pagesMotorized Pulley 320L, 320M & 320H Ø 320 MM: L For Light-DutynoelfarmarNo ratings yet

- P 7102 BGMDocument2 pagesP 7102 BGMearrNo ratings yet

- Berco BMU 424GBDocument20 pagesBerco BMU 424GBEdgar Alves100% (3)

- Meritor RT-46-160, RT-46-160A, RT-46-160P, RT-46-169: 46,000 Lbs. GAWRDocument2 pagesMeritor RT-46-160, RT-46-160A, RT-46-160P, RT-46-169: 46,000 Lbs. GAWRZamir Andres SencioNo ratings yet

- Model 20 HT and GT AgitatorsDocument12 pagesModel 20 HT and GT AgitatorsKarthimeena MeenaNo ratings yet

- Solutions For Small Parts MachiningDocument20 pagesSolutions For Small Parts MachininggkhnNo ratings yet

- Psi Mud Agitators Product SheetDocument2 pagesPsi Mud Agitators Product SheetPRASHANT KANTENo ratings yet

- DHB5A MS Range PDFDocument32 pagesDHB5A MS Range PDFAshutosh PandeyNo ratings yet

- Rental Equipment MontgomeryDocument4 pagesRental Equipment Montgomeryapi-293201621No ratings yet

- Goulds - ICO I-Frame SeriesDocument16 pagesGoulds - ICO I-Frame SeriesAlexNo ratings yet

- Precision Gear Technology Guide: Nidec-Shimpo CorporationDocument16 pagesPrecision Gear Technology Guide: Nidec-Shimpo CorporationTungNo ratings yet

- Brake Rotors: MotorcraftDocument1 pageBrake Rotors: MotorcraftMafer CabezasNo ratings yet

- 318D L Series 2: Hydraulic ExcavatorDocument32 pages318D L Series 2: Hydraulic ExcavatorFelipe Pisklevits LaubeNo ratings yet

- POLEASengineered Class PulleysDocument4 pagesPOLEASengineered Class Pulleysmaxneiker13No ratings yet

- GMN BallBearingCatalog 4000.0911Document100 pagesGMN BallBearingCatalog 4000.0911Nebojša ObradovićNo ratings yet

- Drilling Solutions CatalogDocument15 pagesDrilling Solutions Catalogعلی محمودیNo ratings yet

- Drill Bits - Taurex PDFDocument14 pagesDrill Bits - Taurex PDFCarlos Antonio Padra PerezNo ratings yet

- RCSiemens BDC 12h 1Document2 pagesRCSiemens BDC 12h 1Simon AcevedoNo ratings yet

- Highly Efficient, Grease Lubricated, Compact Design: U. S. PAT. NO. 5,203,231 U.S. PAT. NO. 5,375,479Document4 pagesHighly Efficient, Grease Lubricated, Compact Design: U. S. PAT. NO. 5,203,231 U.S. PAT. NO. 5,375,479lucas quarchioniNo ratings yet

- GT E 201808 LowDocument32 pagesGT E 201808 Lowwataneta valveNo ratings yet

- Catlogo Motorreductores Boston Gears AlimenticioDocument72 pagesCatlogo Motorreductores Boston Gears Alimenticiometalcernaw rodriguezNo ratings yet

- Catlogo Motorreductores Boston Gears AlimenticioDocument72 pagesCatlogo Motorreductores Boston Gears Alimenticiometalcernaw rodriguezNo ratings yet

- Roll Crusher BrochureDocument4 pagesRoll Crusher BrochureWaris La Joi Wakatobi100% (1)

- Chemineer™ Model 20 HT/GT Agitators: Efficient and Versatile PerformanceDocument12 pagesChemineer™ Model 20 HT/GT Agitators: Efficient and Versatile PerformanceJuan MendozaNo ratings yet

- 29156Document4 pages29156Gus adiNo ratings yet

- GTDocument30 pagesGTAbhishek VelagaNo ratings yet

- Unist Uni-Roller Systems Brochure - 00037Document4 pagesUnist Uni-Roller Systems Brochure - 00037Mann Sales & MarketingNo ratings yet

- Hi-Q BearingDocument50 pagesHi-Q BearingDreamon YaNo ratings yet

- Waste HandlerDocument8 pagesWaste HandlerDharmesh patelNo ratings yet

- 05a - MSM 86 - e PDFDocument2 pages05a - MSM 86 - e PDFMuhammad Nur CahyadiNo ratings yet

- Catalogo SKFDocument165 pagesCatalogo SKFanon_769144622No ratings yet

- All You Want: and Everything You DemandDocument4 pagesAll You Want: and Everything You DemandZamir Andres SencioNo ratings yet

- MG330 2MGE CatalogueDocument72 pagesMG330 2MGE CatalogueLeonardo MosqueraNo ratings yet

- Cat - Dcs.cmms - Servlet 992G PDFDocument24 pagesCat - Dcs.cmms - Servlet 992G PDFFloyd MenaNo ratings yet

- MST-Series Gear BoxDocument2 pagesMST-Series Gear Boxtratorpecas001No ratings yet

- 1322 Talent SeriesDocument12 pages1322 Talent Seriespc100xohmNo ratings yet

- Link Belt Series E4000 IdlersDocument20 pagesLink Belt Series E4000 IdlersKarthikeyan Mallika100% (1)

- Boomer S2 Sales Presentation v2Document37 pagesBoomer S2 Sales Presentation v2rolando mora zapata0% (1)

- 313D GC Series 2: Hydraulic ExcavatorDocument24 pages313D GC Series 2: Hydraulic ExcavatorAkhmad SebehNo ratings yet

- ELATHE-500 GearboxDocument205 pagesELATHE-500 GearboxRC VilledaNo ratings yet

- P 7102 BGMDocument2 pagesP 7102 BGMKishan PatelNo ratings yet

- Everything You Need To Keep On RollingDocument8 pagesEverything You Need To Keep On RollingAlexander GoezNo ratings yet

- NOV Prochem Bulletin 720 - v02Document10 pagesNOV Prochem Bulletin 720 - v02saulomonNo ratings yet

- American Marh 460series Osd OsgDocument12 pagesAmerican Marh 460series Osd Osgjuan davidNo ratings yet

- Sitecollectiondocuments Downloads Global Brochures En-Gb C-2940-131Document24 pagesSitecollectiondocuments Downloads Global Brochures En-Gb C-2940-131Rudra DasNo ratings yet

- Dodge Disc Coupling Brochure PDFDocument16 pagesDodge Disc Coupling Brochure PDFCESARNo ratings yet

- Prochem Bulletin 720 WEB 6 PDFDocument10 pagesProchem Bulletin 720 WEB 6 PDFmember1000No ratings yet

- CM Company ProfileDocument11 pagesCM Company ProfilePreet Inder SinghNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Flexteral HoseDocument56 pagesFlexteral HosesitaNo ratings yet

- FLEXICHEVRON-Mist-Eliminators Type VIIIDocument12 pagesFLEXICHEVRON-Mist-Eliminators Type VIIIsitaNo ratings yet

- C236385 WithakerDocument2 pagesC236385 WithakersitaNo ratings yet

- Penta (OleDocument4 pagesPenta (OlesitaNo ratings yet

- BOR 165 (3500 A 82) Cable ProtectorDocument1 pageBOR 165 (3500 A 82) Cable ProtectorsitaNo ratings yet

- DetronicDocument217 pagesDetronicsitaNo ratings yet

- American MFG Co Oilfield Products and Capabilities Blue Eagle Valves and Pistons PDFDocument50 pagesAmerican MFG Co Oilfield Products and Capabilities Blue Eagle Valves and Pistons PDFsita100% (1)

- Red SkinDocument1 pageRed SkinsitaNo ratings yet

- TERERICEDocument3 pagesTERERICEsitaNo ratings yet

- Star Pump PDFDocument2 pagesStar Pump PDFsitaNo ratings yet

- CAm TECH AgentDocument1 pageCAm TECH AgentsitaNo ratings yet

- Advanced Rock Properties (Core Lab)Document3 pagesAdvanced Rock Properties (Core Lab)sitaNo ratings yet

- Part and Lists Drawing Page 5Document1 pagePart and Lists Drawing Page 5sitaNo ratings yet

- Watson PackerDocument2 pagesWatson PackersitaNo ratings yet

- Team Oil ToolsDocument54 pagesTeam Oil ToolssitaNo ratings yet

- BOTIL Cement RetainerDocument1 pageBOTIL Cement RetainersitaNo ratings yet

- Check Valve 13701Document1 pageCheck Valve 13701sitaNo ratings yet

- 178 SeriesDocument1 page178 SeriessitaNo ratings yet

- Goosneck VentDocument3 pagesGoosneck VentsitaNo ratings yet

- N BridgingDocument1 pageN BridgingsitaNo ratings yet

- Edited CatalogDocument8 pagesEdited CatalogsitaNo ratings yet

- For KevinDocument6 pagesFor KevinsitaNo ratings yet

- NC3M 4 1-16 3K X 4 600 Ansi RF 3 Trim Spec Dims 11.31 X 10.75Document1 pageNC3M 4 1-16 3K X 4 600 Ansi RF 3 Trim Spec Dims 11.31 X 10.75sitaNo ratings yet

- Original Messag1Document1 pageOriginal Messag1sitaNo ratings yet

- Sling ShackelDocument1 pageSling ShackelsitaNo ratings yet

- Vogt BrochureDocument1 pageVogt BrochuresitaNo ratings yet

- General Product Catalogue SmallDocument88 pagesGeneral Product Catalogue SmallsitaNo ratings yet

- ABB AMD Motor BrochureDocument4 pagesABB AMD Motor BrochuresitaNo ratings yet

- Westco Thortle Cylinder AssyDocument1 pageWestco Thortle Cylinder AssysitaNo ratings yet

- Spareparts ListDocument5 pagesSpareparts ListsitaNo ratings yet

- Chuan Doan He Banh RangDocument14 pagesChuan Doan He Banh RangAlexander VovaNo ratings yet

- Flexview InstallationDocument25 pagesFlexview InstallationGeorgios MariolisNo ratings yet

- Gears 4Document30 pagesGears 4Kaushik SreenivasNo ratings yet

- SolutionDocument35 pagesSolutionMariel MirafloresNo ratings yet

- Caterpillar Service Manual CT S GuideDocument6 pagesCaterpillar Service Manual CT S GuideJosé Luis Cavas OlmosNo ratings yet

- Limitorque - 1203 - L120-190-2000 EnglishDocument61 pagesLimitorque - 1203 - L120-190-2000 EnglishansliNo ratings yet

- Use and Maintenance of Gear UnitDocument4 pagesUse and Maintenance of Gear UnitRaphael LinoNo ratings yet

- TRDocument33 pagesTRErhan GencNo ratings yet

- Eaton Gear PumpsDocument20 pagesEaton Gear PumpsLjubisa IgnjatovNo ratings yet

- ZF6HP26 A PDFDocument5 pagesZF6HP26 A PDFJesus UrrietaNo ratings yet

- GTU Syllabus BE MechanicalDocument10 pagesGTU Syllabus BE MechanicalAshwinNo ratings yet

- Volvo FH4 D13K500 Cylinder HeadDocument98 pagesVolvo FH4 D13K500 Cylinder HeadGregg BaffledonNo ratings yet

- McCoyDrillingCompletionsCatalog LowResDocument65 pagesMcCoyDrillingCompletionsCatalog LowResAlvin Garcia PalancaNo ratings yet

- Slewing Bearing Slewing Ring Slewing Gear Swing CircleDocument16 pagesSlewing Bearing Slewing Ring Slewing Gear Swing Circlezczc32z5No ratings yet

- Optimization of Gear Reduction Unit Through Ray DiagramDocument7 pagesOptimization of Gear Reduction Unit Through Ray Diagramأحمد دعبس100% (1)

- Heating Above Transformation Range Usually, 1300 F To 1350 F, and To Soften The Metal and Increase in MachiningDocument1,900 pagesHeating Above Transformation Range Usually, 1300 F To 1350 F, and To Soften The Metal and Increase in MachiningEmil Aderian AmadoNo ratings yet

- 2 5801 Gewindeformen GBDocument4 pages2 5801 Gewindeformen GBks2000n1No ratings yet

- Automobile PDFDocument58 pagesAutomobile PDFjaycee68No ratings yet

- EXP PR EQ180 en R0 - 1 Reduction UnitsDocument24 pagesEXP PR EQ180 en R0 - 1 Reduction UnitsbaliNo ratings yet

- Machining Operations and Machine ToolsDocument64 pagesMachining Operations and Machine ToolsBlessing FajemirokunNo ratings yet

- Transmission Assembly, Secondary Shaft, Two Wheel or Four Wheel DriveDocument4 pagesTransmission Assembly, Secondary Shaft, Two Wheel or Four Wheel DriveJESUSNo ratings yet

- Back To Iiasics, ... : Design Involute GearDocument11 pagesBack To Iiasics, ... : Design Involute Gearabdul rachim100% (1)

- Gear EquationsDocument71 pagesGear EquationsMickloSoberan50% (2)

- Eurochain VR GB New1Document7 pagesEurochain VR GB New1Mahmoud AllamNo ratings yet

- Company NameDocument26 pagesCompany NameShilpa SharmaNo ratings yet

- Tecumseh Service Repair Manual VH80 VH100 HH80 HH100 HH120 Oh120 Oh140 Oh160 Oh180 8HP Thru 18HP Cast Iron Engines 691462a PDFDocument78 pagesTecumseh Service Repair Manual VH80 VH100 HH80 HH100 HH120 Oh120 Oh140 Oh160 Oh180 8HP Thru 18HP Cast Iron Engines 691462a PDFGeorge Petrakos100% (1)

- Service Manual 6 Speed Eaton TransmissionDocument84 pagesService Manual 6 Speed Eaton TransmissionPatricio Alejandro Castro LopezNo ratings yet

- Iso 6336-2-2006Document40 pagesIso 6336-2-2006SaiKrishnaImmaneniNo ratings yet

- Maag WA One-Stage Gear Unit: For Horizontal Mill DrivesDocument8 pagesMaag WA One-Stage Gear Unit: For Horizontal Mill DrivesMuhammadNo ratings yet

Dodge Quantis Gear Box Brochure

Dodge Quantis Gear Box Brochure

Uploaded by

sitaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dodge Quantis Gear Box Brochure

Dodge Quantis Gear Box Brochure

Uploaded by

sitaCopyright:

Available Formats

Product Brochure

Quantis® gearmotors & reducers

We provide motors, generators and mechanical power transmission products,

services and expertise to save energy and improve customers ‚ processes over

the total lifecycle of our products, and beyond.

2 ABB | Motors and Generators | Quantis® gearmotors & reducers

Dodge® Quantis®

The Dodge Quantis product line offers a full line of modular

gear drives engineered for flexibility, greater torque density in

a compact housing configuration, and increased horsepower

capability from 0.18 to 55 kW (0.25 to 75 hp).

The Quantis family of products offers the customer three

types of gear reducers: In-Line Helical (ILH), Right-Angle

MSM

Helical Bevel (RHB) and Motorized Shaft Mount (MSM).

All three types of reducers are dimensionally interchangeable

with major global competitors.

RHB

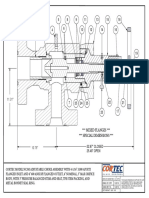

Quantis in-line helical (ILH)

Designed to achieve greater output torque ratings, increased

horsepower ratings and expanded ratio range, the Quantis

ILH product line may allow the customer to downsize from

existing units, resulting in a reduced product cost. ILH

− Eight sizes: 38, 48, 68, 88, 108,128,148, and 168

− Torque ratings up to 14,000 Nm (122,000 lb-in)

− Ratio: 1.4 to 360:1

− Single, Double, Triple Reduction

− Input power of 0.18 - 55 kW (0.25hp -75hp)

− Concentric sizes (38-128)

− Two output flange options: B5 and B14 Time saving removal and replacement design

− Adjustable slide bases

− Optional XT harsh duty output seal for wet and abrasive 1) Multiple input options – integral motor, separate input shaft,

environments. This seal features a quadra lip design, and two B5 flange options – clamp collar and 3-piece

rubber coated inner and outer seals and a protected seal coupled

running surface

− Scoop mount motor/reducer option 2) All gearboxes are filled with Mobilgear 600 XP 220 mineral

oil prior to shipment to insure proper oil grade and fill level

3) Reducer housings are constructed of class 30 gray iron

with cast internal ribbing for added strength

4) Spring loaded double lip seals of nitrile rubber (NBR)

material. All seals are rubber coated to eliminate seal-to-

bore joint leakage

3

1

5) Output shafts available with metric and inch dimensions

6) Gearing is of single helical design and ground to provide

an ellipsoid tooth form which eliminates tooth wearing and

6

4

assures meshing in the strongest tooth area.

2

− Gear material is alloy steel

5

− All gears are case hardened and ground to DIN Class 6 to

ensure high surface durability and resilient tooth core for

greater impact resistance and longer service life

− 20 degree pressure angle to minimize noise characteristics

− Up to 98% efficient per stage

ABB | Motors and Generators | Quantis® gearmotors & reducers 3

Dodge® Quantis®

Quantis right-angle helical bevel (RHB)

The Quantis RHB product line features a helical-bevel-helical

gear train that offers cost-effective, high and low-speed

solutions with efficiency ratings up to 94%.

−− Eight sizes: 38, 48, 68, 88, 108, 128, 148, and 168

−− Torque ratings up to 13,500 Nm (119,000 lb-in)

−− Ratio: 4:1 to 307:1

−− Input power of 0.18 - 55 kW (0.25 - 75 hp)

−− Two output flange options: B5 and B14

−− Tie rod kit option

−− Optional XT harsh duty output seal for wet and abrasive

environments.

− − CEMA screw conveyor drive option

− − Twin Tapered bushings (Standard and Short Shaft)

Time saving removal and replacement design

1) Spring loaded double lip seals of nitrile rubber (NBR) −− Gear material is alloy steel

material. All seals are rubber coated to eliminate seal-to- − − All gears are case hardened and ground to DIN Class 6 to

bore joint leakage insure high surface durability and resilient tooth core for

greater impact resistance and longer service life

2) Multiple output options – solid shaft, double shaft, straight − − 20 degree pressure angle to minimize noise characteristics

hollow bore, shrink disk and tapered hollow in both metric

and inch dimensions

3) Reducer housings are constructed of class 30 gray iron

with cast internal ribbing for added strength

3

4) All gearboxes are filled with Mobilgear 600 XP 220 mineral

oil prior to shipment to insure proper oil grade and fill level

1

2

5) Multiple input options – integral motor, separate input shaft, 6

4

and two B5 flange options – clamp collar and 3-piece

coupled

6) Gearing is of single helical design and ground to provide

an ellipsoid tooth form which eliminates tooth wearing and

assures meshing in the strongest tooth area. RHB units

also utilize spiral bevel gearing 5

4 ABB | Motors and Generators | Quantis® gearmotors & reducers

Dodge® Quantis®

Motorized shaft mount (MSM)

The Quantis motorized shaft mount (MSM) universal housing

accommodates either footed or flanged configurations.

− Eight sizes: 38, 48, 68, 88, 108, 128,148, and 168

− Torque ratings up to 13,500 Nm (119,000 lb-in)

− Ratio: 6:1 to 350:1

− Input power of 0.18 - 55 kW (0.25 - 73.76 hp)

− XT harsh duty output seal option for wet and harsh

environments

− Torque-Arm bushing option

− Two output flange options: B5 and B14

− CEMA screw conveyor drive option

− Twin Tapered bushings (Standard and Short Shaft)

Time saving removal and replacement design

1) Spring loaded double lip seals of nitrile rubber (NBR) − Gear material is alloy steel

material. All seals are rubber coated to eliminate seal-to- − All gears are case hardened and ground to DIN Class 6 to

bore joint leakage ensure high surface durability and resilient tooth core for

greater impact resistance and longer service life

2) Multiple output options – solid shaft, straight hollow bore, − 20 degree pressure angle to minimize noise characteristics

shrink disk and tapered hollow in both inch and metric − Up to 98% efficient per stage

dimensions

3) Reducer housings are constructed of class 30 gray iron

with cast internal ribbing for added strength

4) All gearboxes are filled with Mobilgear 600 XP 220 mineral

oil prior to shipment to insure proper oil grade and fill level

4

5) Multiple input options – integral motor, separate input shaft,

and two B5 flange options – clamp collar and 3-piece 5

coupled 6

6) Gearing is of single helical design and ground to provide

an ellipsoid tooth form which eliminates tooth wearing and

2

assures meshing in the strongest tooth area

1

ABB | Motors and Generators | Quantis® gearmotors & reducers 5

Dodge® Quantis® E-Z Kleen®

The robust protection features of a Quantis E-Z Kleen reducer

make it the right choice for harsh duty environments including

washdown, food handling, packaging and pharmaceutical

applications. Quantis E-Z Kleen is offered in five sizes: 38,

48, 68, 88 and 108 for the ILH, RHB and MSM housing

styles. Either the clamp collar or the 3-piece coupled input is

available for mounting a c-face motor. Separate inputs also

available.

E-Z Kleen reducers are manufactured with a 13 step coating

system that provides more than three times the corrosion

ILH E-Z Kleen

resistance of standard epoxy-painted units. Furthermore, to

ensure the interior is as protected as the exterior, E-Z Kleen

reducers have a two piece, harsh duty sealing system that

protects against high pressure sprays and sanitizing solutions.

E-Z Kleen (washdown) features:

− Unique coating system provides greater than three times

the corrosion resistance of standard epoxy paint

− White or Stainless steel color top coat

− XT harsh duty output seal features nitrile material and a

quadra-lip design RHB E-Z Kleen

− Thin dense nickel composite (TDNC) plated output shafts

− Non-cavity hardware

− Factory filled with mineral, synthetic or food grade USDA

H-1 lubrication

− Water tight gasket on c-face input between motor and

reducer

− One way washdown spring loaded breather

EZ-Kleen accessories MSM E-Z Kleen reducer with

− TDNC twin tapered bushings (inch or metric) Baldor washdown motor

− E-Z Kleen tie rod kit

− E-Z Kleen Torque Arm bracket

− E-Z Kleen B5 flange output bracket

Housing

XT harsh duty seal 3

− Protected running surface for shaft seal (1)

− No risk of damage during assembly

− Additional seal-lips against dust (2) 4

− Separate sealing system prevents damage to the shaft 2

through corrosion and dust

− Rubber coated inner ring and outer ring (3) 4

− Grease prevents dry run of lip of seals (4)

1

3

Axis

6 ABB | Motors and Generators | Quantis® gearmotors & reducers

Dodge® Quantis® Configurations

Dodge Quantis

in-line helical (ILH) single reduction

Dodge Quantis single reduction is complementary to our

double and triple In-Line Helical (ILH) gearing products. This

gearbox can be used in pump applications where low ratios

are required, or combine with ILH, RHB, MSM EZ or Right

Angle Helical Bevel (RHB) gearboxes to make a tandem

Quantis gearbox achieving ratios greater than 300 to 1.

− ILH sizes 38 – 88

− Output shafts – inch and metric

− Output flanges – B14, B5, and NEMA

− Input ratings up to 31 kW (41 hp)

− Output torque ratings up to 432 Nm (320 lb-ft)

− 98% efficiency

− Ratings listed in the Quantis gear engineering catalog and

Quantis configurator

Dodge Quantis tandem gear reducers

Dodge Quantis tandem gear reducers are available for

applications that require ratios above 300 to 1. This is

accomplished by mounting the Dodge Quantis ILH Single

Reduction to the primary ILH, RHB, or MSM reducer. There

are many ratios and configurations available to meet your

requirements.

− Maximum ratio up to 3600:1

− Maximum output torque 13,600 Nm (120,000 lb-in)

− Typical service factor recommendation is Class II

− Tandem reducer is assembled at the manufacturing facility

− Contact application engineering for selection assistance

ABB | Motors and Generators | Quantis® gearmotors & reducers 7

Dodge® Quantis® modularity

Output group

9

6 8

1 7

2

Input group

4 17

5

Output group modularity ILH, MSM & RHB Input group modularity ILH, MSM & RHB

This illustration shows the modularity on the output side of This illustration shows the modularity on the input side of

ILH, MSM and RHB. All three styles can be furnished in a ILH, MSM and RHB. All three styles can be furnished in

variety of output shaft configurations. All output shaft styles a variety of input configurations: integral motor, separate

can be used with or without an output flange, depending on input shaft and two B5 flange options – clamp collar and

the customer’s application. 3-piece coupled.

Output model configurations:

Solid output shaft (metric or inch)

− ILH, RHB and MSM

Twin tapered bushings (metric or inch)

− RHB & MSM

Hollow bore (metric or inch)

− RHB and MSM

Double output shaft (metric or inch)

− RHB

Shrink disk (metric)

− RHB & MSM

8 ABB | Motors and Generators | Quantis® gearmotors & reducers

16

15

14

13

11

10

12

9

23

22

21

20

19

18

25

24

Output group

14) ILH single reduction flange mounted

1) Twin tapered bushings 15) B5 flange

2) Hollow bore 16) Single shaft

3) Shrink disk

4) Double shaft Input group

5) Single shaft 17) Separate

6) B5 flange 18) IEC 3-pc coupled

7) RHB flange mounted 19) IEC clamp collar

8) RHB foot mounted 20) NEMA 3-pc coupled

9) MSM 21) NEMA clamp collar

10) ILH foot mounted 22) Integral brakemotor

11) ILH flange mounted 23) Integral motor

12) Adapter plate 24) IEC motor

13 ILH single reduction foot mounted 25) NEMA C-Face motor

ABB | Motors and Generators | Quantis® gearmotors & reducers 9

Optional Quantis® accessories

Standard twin-tapered bushing kits CEMA adjustable adapter assembly

An easy on, easy off, no wobble bushing The RHB & MSM screw conveyor

system featuring a fully split, ductile adapter assembly is available with two

iron 8-degree taper and reliable twin options, standard and harsh duty. The

support. Available in metric and inch standard option includes the adapter

bores. with bolts, two double lip seals and

hardware. The harsh duty option

Short shaft bushing kits includes the adapter with bolts, two

Eliminates the need for full length shafts. double lip seals, packing retainer, three

Constructed with ductile iron, it has all braided seals and hardware.

the features of our standard bushing

system. Available in both inch and CEMA screw conveyor drive shaft

metric bores. Screw conveyor drive shafts are made

from high alloy steel material, designed

Internal backstop with three bolt holes and engineered to

Helps prevent reverse rotation in high CEMA dimensions. The screw conveyor

stop-start loads, and results in less wear drive shaft connects to either the RHB

and longer life. Its centrifugal throw or MSM straight hollow bore reducer

out design eliminates sprag sliding and with the keeper plate and bolt assembly.

reduces wear. It operates with standard

and EP lubricants and requires no RHB tie rod kit

external lubrication. For use with three- The RHB tie rod kit utilizes the “BF”

piece coupling and separate inputs. style housing. RHB tie rod kits are

available for restraining hollow shaft

XT harsh duty output seal reducers. Each kit includes the

The rubber coated nitrile output seal mounting block, tie rods, turnbuckle,

consists of 2 parts; the inner sleeve fulcrum and mounting hardware.

and outer sleeve. The vertical flange of

the inner sleeve protects the lip from RHB torque arm bracket

high pressure washdown spray and the For RHB shaft mounted applications

outer sleeve holds the actual lip. Two using the “BF” style housing. The RHB

additional dirt excluder lips help to fling torque arm bracket includes the bracket

dirt away and provide a labyrinth. and hardware.

ILH adjustable slide base ILH scoop mount

Positions the reducer, providing Scoop mount are steel fabricated

simplified installation and servicing of assemblies to provide customers with

belt and chain drives. alternative means of supporting the

motor.

10 ABB | Motors and Generators | Quantis® gearmotors & reducers

ABB | Motors and Generators | Quantis® gearmotors & reducers 11

Contact:

www.abb.com/mechanicalpowertransmission Note:

MPT products ROW EN 2012-11 Printed in USA 2000 IBR1603

We reserve the right to make technical changes ot

modify the contents of this document without prior

notice. With regard to purchase orders, the agreed

particulars shall prevail. ABB Ltd does not accept

any responsibility whatsoever for potential errors or

possible lack of information in this document.

We reserve the rights in this document and in the

subject matter and illustrations contained therein.

Any reproduction, disclosure to third parties or

utilization of its contents - in whole or in parts - is

forbidden without prior written consent of ABB Ltd.

Copyright© 2012 ABB

All rights reserved

You might also like

- CompleteCatalog PDFDocument116 pagesCompleteCatalog PDFgume pesaNo ratings yet

- Cat 769D 12-2001 Dumper PDFDocument28 pagesCat 769D 12-2001 Dumper PDFAbo Achraf LaalawiNo ratings yet

- Manual Expansora de TubosDocument21 pagesManual Expansora de TubosAlejandro DuranNo ratings yet

- Ica1603 0513 WebDocument292 pagesIca1603 0513 WebayavuzbvsNo ratings yet

- 2010 Freightliner Meritor 14X Tandem Drive AxleDocument8 pages2010 Freightliner Meritor 14X Tandem Drive AxlekelyamigasNo ratings yet

- Surface Belt Structure: Cema C & D SeriesDocument8 pagesSurface Belt Structure: Cema C & D SeriesSari Ully Sibarani100% (1)

- GP - AF - Low 1Document8 pagesGP - AF - Low 1maguilar20No ratings yet

- Bearing Solutions For The Material Handling IndustryDocument8 pagesBearing Solutions For The Material Handling IndustryMarceloNo ratings yet

- Catalogo 35zDocument50 pagesCatalogo 35zproseryobNo ratings yet

- Serie 2Document36 pagesSerie 2camiloNo ratings yet

- Dodge AbbDocument16 pagesDodge AbbHenry DelgadoNo ratings yet

- Motorized Pulley 320L, 320M & 320H Ø 320 MM: L For Light-DutyDocument8 pagesMotorized Pulley 320L, 320M & 320H Ø 320 MM: L For Light-DutynoelfarmarNo ratings yet

- P 7102 BGMDocument2 pagesP 7102 BGMearrNo ratings yet

- Berco BMU 424GBDocument20 pagesBerco BMU 424GBEdgar Alves100% (3)

- Meritor RT-46-160, RT-46-160A, RT-46-160P, RT-46-169: 46,000 Lbs. GAWRDocument2 pagesMeritor RT-46-160, RT-46-160A, RT-46-160P, RT-46-169: 46,000 Lbs. GAWRZamir Andres SencioNo ratings yet

- Model 20 HT and GT AgitatorsDocument12 pagesModel 20 HT and GT AgitatorsKarthimeena MeenaNo ratings yet

- Solutions For Small Parts MachiningDocument20 pagesSolutions For Small Parts MachininggkhnNo ratings yet

- Psi Mud Agitators Product SheetDocument2 pagesPsi Mud Agitators Product SheetPRASHANT KANTENo ratings yet

- DHB5A MS Range PDFDocument32 pagesDHB5A MS Range PDFAshutosh PandeyNo ratings yet

- Rental Equipment MontgomeryDocument4 pagesRental Equipment Montgomeryapi-293201621No ratings yet

- Goulds - ICO I-Frame SeriesDocument16 pagesGoulds - ICO I-Frame SeriesAlexNo ratings yet

- Precision Gear Technology Guide: Nidec-Shimpo CorporationDocument16 pagesPrecision Gear Technology Guide: Nidec-Shimpo CorporationTungNo ratings yet

- Brake Rotors: MotorcraftDocument1 pageBrake Rotors: MotorcraftMafer CabezasNo ratings yet

- 318D L Series 2: Hydraulic ExcavatorDocument32 pages318D L Series 2: Hydraulic ExcavatorFelipe Pisklevits LaubeNo ratings yet

- POLEASengineered Class PulleysDocument4 pagesPOLEASengineered Class Pulleysmaxneiker13No ratings yet

- GMN BallBearingCatalog 4000.0911Document100 pagesGMN BallBearingCatalog 4000.0911Nebojša ObradovićNo ratings yet

- Drilling Solutions CatalogDocument15 pagesDrilling Solutions Catalogعلی محمودیNo ratings yet

- Drill Bits - Taurex PDFDocument14 pagesDrill Bits - Taurex PDFCarlos Antonio Padra PerezNo ratings yet

- RCSiemens BDC 12h 1Document2 pagesRCSiemens BDC 12h 1Simon AcevedoNo ratings yet

- Highly Efficient, Grease Lubricated, Compact Design: U. S. PAT. NO. 5,203,231 U.S. PAT. NO. 5,375,479Document4 pagesHighly Efficient, Grease Lubricated, Compact Design: U. S. PAT. NO. 5,203,231 U.S. PAT. NO. 5,375,479lucas quarchioniNo ratings yet

- GT E 201808 LowDocument32 pagesGT E 201808 Lowwataneta valveNo ratings yet

- Catlogo Motorreductores Boston Gears AlimenticioDocument72 pagesCatlogo Motorreductores Boston Gears Alimenticiometalcernaw rodriguezNo ratings yet

- Catlogo Motorreductores Boston Gears AlimenticioDocument72 pagesCatlogo Motorreductores Boston Gears Alimenticiometalcernaw rodriguezNo ratings yet

- Roll Crusher BrochureDocument4 pagesRoll Crusher BrochureWaris La Joi Wakatobi100% (1)

- Chemineer™ Model 20 HT/GT Agitators: Efficient and Versatile PerformanceDocument12 pagesChemineer™ Model 20 HT/GT Agitators: Efficient and Versatile PerformanceJuan MendozaNo ratings yet

- 29156Document4 pages29156Gus adiNo ratings yet

- GTDocument30 pagesGTAbhishek VelagaNo ratings yet

- Unist Uni-Roller Systems Brochure - 00037Document4 pagesUnist Uni-Roller Systems Brochure - 00037Mann Sales & MarketingNo ratings yet

- Hi-Q BearingDocument50 pagesHi-Q BearingDreamon YaNo ratings yet

- Waste HandlerDocument8 pagesWaste HandlerDharmesh patelNo ratings yet

- 05a - MSM 86 - e PDFDocument2 pages05a - MSM 86 - e PDFMuhammad Nur CahyadiNo ratings yet

- Catalogo SKFDocument165 pagesCatalogo SKFanon_769144622No ratings yet

- All You Want: and Everything You DemandDocument4 pagesAll You Want: and Everything You DemandZamir Andres SencioNo ratings yet

- MG330 2MGE CatalogueDocument72 pagesMG330 2MGE CatalogueLeonardo MosqueraNo ratings yet

- Cat - Dcs.cmms - Servlet 992G PDFDocument24 pagesCat - Dcs.cmms - Servlet 992G PDFFloyd MenaNo ratings yet

- MST-Series Gear BoxDocument2 pagesMST-Series Gear Boxtratorpecas001No ratings yet

- 1322 Talent SeriesDocument12 pages1322 Talent Seriespc100xohmNo ratings yet

- Link Belt Series E4000 IdlersDocument20 pagesLink Belt Series E4000 IdlersKarthikeyan Mallika100% (1)

- Boomer S2 Sales Presentation v2Document37 pagesBoomer S2 Sales Presentation v2rolando mora zapata0% (1)

- 313D GC Series 2: Hydraulic ExcavatorDocument24 pages313D GC Series 2: Hydraulic ExcavatorAkhmad SebehNo ratings yet

- ELATHE-500 GearboxDocument205 pagesELATHE-500 GearboxRC VilledaNo ratings yet

- P 7102 BGMDocument2 pagesP 7102 BGMKishan PatelNo ratings yet

- Everything You Need To Keep On RollingDocument8 pagesEverything You Need To Keep On RollingAlexander GoezNo ratings yet

- NOV Prochem Bulletin 720 - v02Document10 pagesNOV Prochem Bulletin 720 - v02saulomonNo ratings yet

- American Marh 460series Osd OsgDocument12 pagesAmerican Marh 460series Osd Osgjuan davidNo ratings yet

- Sitecollectiondocuments Downloads Global Brochures En-Gb C-2940-131Document24 pagesSitecollectiondocuments Downloads Global Brochures En-Gb C-2940-131Rudra DasNo ratings yet

- Dodge Disc Coupling Brochure PDFDocument16 pagesDodge Disc Coupling Brochure PDFCESARNo ratings yet

- Prochem Bulletin 720 WEB 6 PDFDocument10 pagesProchem Bulletin 720 WEB 6 PDFmember1000No ratings yet

- CM Company ProfileDocument11 pagesCM Company ProfilePreet Inder SinghNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Flexteral HoseDocument56 pagesFlexteral HosesitaNo ratings yet

- FLEXICHEVRON-Mist-Eliminators Type VIIIDocument12 pagesFLEXICHEVRON-Mist-Eliminators Type VIIIsitaNo ratings yet

- C236385 WithakerDocument2 pagesC236385 WithakersitaNo ratings yet

- Penta (OleDocument4 pagesPenta (OlesitaNo ratings yet

- BOR 165 (3500 A 82) Cable ProtectorDocument1 pageBOR 165 (3500 A 82) Cable ProtectorsitaNo ratings yet

- DetronicDocument217 pagesDetronicsitaNo ratings yet

- American MFG Co Oilfield Products and Capabilities Blue Eagle Valves and Pistons PDFDocument50 pagesAmerican MFG Co Oilfield Products and Capabilities Blue Eagle Valves and Pistons PDFsita100% (1)

- Red SkinDocument1 pageRed SkinsitaNo ratings yet

- TERERICEDocument3 pagesTERERICEsitaNo ratings yet

- Star Pump PDFDocument2 pagesStar Pump PDFsitaNo ratings yet

- CAm TECH AgentDocument1 pageCAm TECH AgentsitaNo ratings yet

- Advanced Rock Properties (Core Lab)Document3 pagesAdvanced Rock Properties (Core Lab)sitaNo ratings yet

- Part and Lists Drawing Page 5Document1 pagePart and Lists Drawing Page 5sitaNo ratings yet

- Watson PackerDocument2 pagesWatson PackersitaNo ratings yet

- Team Oil ToolsDocument54 pagesTeam Oil ToolssitaNo ratings yet

- BOTIL Cement RetainerDocument1 pageBOTIL Cement RetainersitaNo ratings yet

- Check Valve 13701Document1 pageCheck Valve 13701sitaNo ratings yet

- 178 SeriesDocument1 page178 SeriessitaNo ratings yet

- Goosneck VentDocument3 pagesGoosneck VentsitaNo ratings yet

- N BridgingDocument1 pageN BridgingsitaNo ratings yet

- Edited CatalogDocument8 pagesEdited CatalogsitaNo ratings yet

- For KevinDocument6 pagesFor KevinsitaNo ratings yet

- NC3M 4 1-16 3K X 4 600 Ansi RF 3 Trim Spec Dims 11.31 X 10.75Document1 pageNC3M 4 1-16 3K X 4 600 Ansi RF 3 Trim Spec Dims 11.31 X 10.75sitaNo ratings yet

- Original Messag1Document1 pageOriginal Messag1sitaNo ratings yet

- Sling ShackelDocument1 pageSling ShackelsitaNo ratings yet

- Vogt BrochureDocument1 pageVogt BrochuresitaNo ratings yet

- General Product Catalogue SmallDocument88 pagesGeneral Product Catalogue SmallsitaNo ratings yet

- ABB AMD Motor BrochureDocument4 pagesABB AMD Motor BrochuresitaNo ratings yet

- Westco Thortle Cylinder AssyDocument1 pageWestco Thortle Cylinder AssysitaNo ratings yet

- Spareparts ListDocument5 pagesSpareparts ListsitaNo ratings yet

- Chuan Doan He Banh RangDocument14 pagesChuan Doan He Banh RangAlexander VovaNo ratings yet

- Flexview InstallationDocument25 pagesFlexview InstallationGeorgios MariolisNo ratings yet

- Gears 4Document30 pagesGears 4Kaushik SreenivasNo ratings yet

- SolutionDocument35 pagesSolutionMariel MirafloresNo ratings yet

- Caterpillar Service Manual CT S GuideDocument6 pagesCaterpillar Service Manual CT S GuideJosé Luis Cavas OlmosNo ratings yet

- Limitorque - 1203 - L120-190-2000 EnglishDocument61 pagesLimitorque - 1203 - L120-190-2000 EnglishansliNo ratings yet

- Use and Maintenance of Gear UnitDocument4 pagesUse and Maintenance of Gear UnitRaphael LinoNo ratings yet

- TRDocument33 pagesTRErhan GencNo ratings yet

- Eaton Gear PumpsDocument20 pagesEaton Gear PumpsLjubisa IgnjatovNo ratings yet

- ZF6HP26 A PDFDocument5 pagesZF6HP26 A PDFJesus UrrietaNo ratings yet

- GTU Syllabus BE MechanicalDocument10 pagesGTU Syllabus BE MechanicalAshwinNo ratings yet

- Volvo FH4 D13K500 Cylinder HeadDocument98 pagesVolvo FH4 D13K500 Cylinder HeadGregg BaffledonNo ratings yet

- McCoyDrillingCompletionsCatalog LowResDocument65 pagesMcCoyDrillingCompletionsCatalog LowResAlvin Garcia PalancaNo ratings yet

- Slewing Bearing Slewing Ring Slewing Gear Swing CircleDocument16 pagesSlewing Bearing Slewing Ring Slewing Gear Swing Circlezczc32z5No ratings yet

- Optimization of Gear Reduction Unit Through Ray DiagramDocument7 pagesOptimization of Gear Reduction Unit Through Ray Diagramأحمد دعبس100% (1)

- Heating Above Transformation Range Usually, 1300 F To 1350 F, and To Soften The Metal and Increase in MachiningDocument1,900 pagesHeating Above Transformation Range Usually, 1300 F To 1350 F, and To Soften The Metal and Increase in MachiningEmil Aderian AmadoNo ratings yet

- 2 5801 Gewindeformen GBDocument4 pages2 5801 Gewindeformen GBks2000n1No ratings yet

- Automobile PDFDocument58 pagesAutomobile PDFjaycee68No ratings yet

- EXP PR EQ180 en R0 - 1 Reduction UnitsDocument24 pagesEXP PR EQ180 en R0 - 1 Reduction UnitsbaliNo ratings yet

- Machining Operations and Machine ToolsDocument64 pagesMachining Operations and Machine ToolsBlessing FajemirokunNo ratings yet

- Transmission Assembly, Secondary Shaft, Two Wheel or Four Wheel DriveDocument4 pagesTransmission Assembly, Secondary Shaft, Two Wheel or Four Wheel DriveJESUSNo ratings yet

- Back To Iiasics, ... : Design Involute GearDocument11 pagesBack To Iiasics, ... : Design Involute Gearabdul rachim100% (1)

- Gear EquationsDocument71 pagesGear EquationsMickloSoberan50% (2)

- Eurochain VR GB New1Document7 pagesEurochain VR GB New1Mahmoud AllamNo ratings yet

- Company NameDocument26 pagesCompany NameShilpa SharmaNo ratings yet

- Tecumseh Service Repair Manual VH80 VH100 HH80 HH100 HH120 Oh120 Oh140 Oh160 Oh180 8HP Thru 18HP Cast Iron Engines 691462a PDFDocument78 pagesTecumseh Service Repair Manual VH80 VH100 HH80 HH100 HH120 Oh120 Oh140 Oh160 Oh180 8HP Thru 18HP Cast Iron Engines 691462a PDFGeorge Petrakos100% (1)

- Service Manual 6 Speed Eaton TransmissionDocument84 pagesService Manual 6 Speed Eaton TransmissionPatricio Alejandro Castro LopezNo ratings yet

- Iso 6336-2-2006Document40 pagesIso 6336-2-2006SaiKrishnaImmaneniNo ratings yet

- Maag WA One-Stage Gear Unit: For Horizontal Mill DrivesDocument8 pagesMaag WA One-Stage Gear Unit: For Horizontal Mill DrivesMuhammadNo ratings yet