Professional Documents

Culture Documents

Drill Jig

Drill Jig

Uploaded by

vino pooOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drill Jig

Drill Jig

Uploaded by

vino pooCopyright:

Available Formats

301166924

Project 1 – Assembly

Description Grade Comment

1 Assy Drg – 3 views, + Exploded 4

2 Production part clearly shown 4

3 Sandwich jig submitted 4

4 Clearance above part 4

5 Clearance under part 4

6 Jig plate clamped 4

7 Jig plate located 4

8 Part clamped 4

Looks like production part is drawn slightly wrong, But location

9 Part located – Long ref. Side 4

seems OK

Looks like production part is drawn slightly wrong, But location

10 Part located – Short ref, side 4

seems OK

11 Part error proofed 4

12 Modular construction 4

See rules for drill bushings and purchased parts. Drill bushings

13 Drill Bushings correctly defined 2

are not “stock” items.

14 B.O.M. Exists 4

15 B.O.M. All parts Ballooned 4

16 B.O.M. All Manuf. parts I.D. & Mat'l 4

17 B.O.M. All Purch parts I.D. 4

18 B.O.M. All Quantities shown 4

19 B.O.M. Format correct/notes 4

20 General formatting – title block 3 Initials & Dwg No. – see rules

Project 1 – Parts

Description Grade Comment

1 Misc. Manuf parts drawn if reqd 4

2 Purchased parts NOT drawn 4

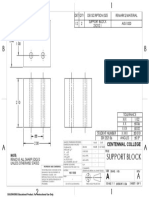

Support blocks (Note: 17Cr3 is a foreign (European) standard

special steel. CRS would be fine here. I doubt if you could

purchase European special steels easily in North America. If

you must specify the steel for this project AISI 1018 or 1020

3 All parts Det#,Qty,Mat'l on dwg 3

would be a much better choice. Many years ago I specified

EN31 (a British high strength alloy steel) and found out no one

locally had any idea what it was.)

Support Block 1 is identified as Det 19, but is really Det 18.

Support block 1

1. Hole sizes missing. Clearance frill for #10 screws is #9 drill

or #7 drill.

Support Block 2

4 Manuf misc parts dimns 3 1. Clearance drill for 1/4” thread is 17/64” Dia.

Note:- In North America, for inch size drills we specify drills in

fractions of an inch or as standard number or letter sizes.

Charts are readily available on the internet

5 Manuf misc parts tolerances 0 Tolerance block – See rules.

6 Top plate Det#,Qty,Matl on dwg 4 Best not to use European material standards in North America

7 Top plate dimns from ref. 0 See Content/Extras/Tolerance and Location – also 50% rule

8 Top plate other dimns 4 We do not normally specify tap drill sizes for toolmakers.

9 Top plate ref tols 0 See Content/Extras/Tolerance and Location – also 50% rule

10 Top plate other tols 0 Tolerance block – See rules.

11 Base plate Det#,Qty,Matl on dwg 4 Best not to use European material standards in North America

12 Extrusions NOT used 4

13 Base plate dimn from ref. 0 See Content/Extras/Tolerance and Location – also 50% rule

Defining countersink causes extra machining. Better to just add

a note “REMOVE ALL SHARP EDGES UNLESS OTHERWISE

14 Base plate other dimns. 4

STATED.” works. There are hand held deburr tools for holes

that are very quick and easy to use.

15 Base plate ref tols 0 See Content/Extras/Tolerance and Location – also 50% rule

16 Base plate other tols 0 Tolerance block – See rules.

0, 10, 20 ,30, 40 or 50 Penalty %

Grading scheme Grade

Non-compliant 0

25% compliance 1

50% compliance 2

75% compliance 3

100% compliance 4

Page 1

You might also like

- mb5 SpekDocument52 pagesmb5 SpekhectorgunawanNo ratings yet

- Jake Bernstein's Seasonal Trader's Bible - The Best of The Best in Seasonal Trades - Jake Bernstein (1996) PDFDocument561 pagesJake Bernstein's Seasonal Trader's Bible - The Best of The Best in Seasonal Trades - Jake Bernstein (1996) PDF林耀明100% (4)

- How To Read A Balance Sheet, by ILO PDFDocument240 pagesHow To Read A Balance Sheet, by ILO PDFsathish kumar100% (4)

- Compressor Inspection Report PLQDocument15 pagesCompressor Inspection Report PLQkhairul muzamil khairuddinNo ratings yet

- 1362-Mould Design Verification ChecklistDocument6 pages1362-Mould Design Verification Checklistrajesh100% (1)

- Welding Joint Design and Welding SymbolsDocument43 pagesWelding Joint Design and Welding SymbolsMohammed Ady GanjarNo ratings yet

- The Market EconomyDocument298 pagesThe Market Economylg50% (2)

- CommentsDocument1 pageCommentsvino pooNo ratings yet

- Fixture JigDocument1 pageFixture Jigvino pooNo ratings yet

- Unit 1. Pattern Making: Question Bank Manufacturing Processes - I F.Y. B. Tech (Tpe)Document5 pagesUnit 1. Pattern Making: Question Bank Manufacturing Processes - I F.Y. B. Tech (Tpe)Sanket chavanNo ratings yet

- FTF Handrail Catalogue PDFDocument16 pagesFTF Handrail Catalogue PDFlopezmedgarNo ratings yet

- Welders Visual Inspection Handbook-2013 WEB PDFDocument77 pagesWelders Visual Inspection Handbook-2013 WEB PDFketanNo ratings yet

- CoreDocument20 pagesCoreAdrianoTavaresNo ratings yet

- FTF Handrail CatalogueDocument16 pagesFTF Handrail Catalogueparag7676No ratings yet

- JBMMA F PE 38 01 - Static Check FormatsDocument13 pagesJBMMA F PE 38 01 - Static Check FormatsTarang ShandilyaNo ratings yet

- Printed in GermanyDocument11 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Smaw 9 Q3 W2-3Document8 pagesSmaw 9 Q3 W2-3Words Wero MascarinasNo ratings yet

- Chapter 13Document19 pagesChapter 13Naved AlamNo ratings yet

- Mold Drop Check SheetDocument1 pageMold Drop Check SheetRS MANIKANDANNo ratings yet

- Macro & Weld Symbol CSWIPDocument54 pagesMacro & Weld Symbol CSWIPSuryaprakashNo ratings yet

- Large-Diameter Fabricated Carbon Steel Flanges: Standard Specification ForDocument3 pagesLarge-Diameter Fabricated Carbon Steel Flanges: Standard Specification ForEduardoNo ratings yet

- A Brief Synopsis ofDocument54 pagesA Brief Synopsis ofpatel ketan100% (2)

- Lecture 3: Parts of Weld Joints and Welding SymbolDocument41 pagesLecture 3: Parts of Weld Joints and Welding SymbolNavneet KumarNo ratings yet

- Welder Visual Inspection HandbookDocument77 pagesWelder Visual Inspection HandbookfaizalzolNo ratings yet

- Visual Guide-Deck Sockets & Other FittingsDocument6 pagesVisual Guide-Deck Sockets & Other FittingsStylianosNo ratings yet

- Welding Joint Design and Welding SymbolsDocument20 pagesWelding Joint Design and Welding SymbolsvijayNo ratings yet

- Checker's Checklist PDFDocument6 pagesChecker's Checklist PDFJimmy SanDiegoNo ratings yet

- Weld Joint & CSWIP3.1 DutuesDocument70 pagesWeld Joint & CSWIP3.1 DutuesRamzi BEN AHMEDNo ratings yet

- Tradesman - Sheet metal-TEDDocument5 pagesTradesman - Sheet metal-TEDDeekshith DileepNo ratings yet

- MPM 312 03 07Document5 pagesMPM 312 03 07Mousa PetrolNo ratings yet

- Welding Joint Design and Welding SymbolsDocument43 pagesWelding Joint Design and Welding Symbolsnavas hassanNo ratings yet

- Part Current Issues: Wrong Rim Supply (Look A Likes - Inset Difference, Bore Id Differences Etc)Document4 pagesPart Current Issues: Wrong Rim Supply (Look A Likes - Inset Difference, Bore Id Differences Etc)Durai NaiduNo ratings yet

- 496-3018 - V-Belt Drive Failure Poster Nov 2009 PDFDocument1 page496-3018 - V-Belt Drive Failure Poster Nov 2009 PDFArikNo ratings yet

- Chapter 5 - Welding Joint Design and Welding SymbolsDocument43 pagesChapter 5 - Welding Joint Design and Welding Symbolsyves suarezNo ratings yet

- Incoming F5 2nd Shroud Segment 1401-01Document18 pagesIncoming F5 2nd Shroud Segment 1401-01Ali Ramezani KhoozestaniNo ratings yet

- WeldersVisual Inspection HandbookDocument77 pagesWeldersVisual Inspection HandbookJesus Placedes100% (1)

- 2024Weld JointDocument70 pages2024Weld JointLeduc HanhNo ratings yet

- Trouble Shooting For Injection Moulding 2014 PDFDocument24 pagesTrouble Shooting For Injection Moulding 2014 PDFchemikas8389No ratings yet

- Welders Visual Inspection Handbook-2013 WEB PDFDocument77 pagesWelders Visual Inspection Handbook-2013 WEB PDFquiron2014No ratings yet

- Incoming Nozzle F5 2nd GheshmDocument18 pagesIncoming Nozzle F5 2nd GheshmAli Ramezani KhoozestaniNo ratings yet

- Microsoft Word - WET GAS COMPRESSOR OVERHAULING REPORTDocument8 pagesMicrosoft Word - WET GAS COMPRESSOR OVERHAULING REPORTAbhi SharmaNo ratings yet

- DownloadDocument47 pagesDownloadGajanVashishth100% (1)

- Aion Refractor Centaur DocumentationDocument8 pagesAion Refractor Centaur Documentationpmacs10No ratings yet

- Reinforcing Detailing of R.C.C Members - K.kaviTHADocument47 pagesReinforcing Detailing of R.C.C Members - K.kaviTHAGurupriyaNo ratings yet

- Weld Plan D00651285Document14 pagesWeld Plan D00651285sandeepNo ratings yet

- Protomold - Design For Mold AbilityDocument16 pagesProtomold - Design For Mold Abilitylanning15No ratings yet

- Lecture 8 Chapter 10 Weldin Joints 12 - 3 - 2020Document20 pagesLecture 8 Chapter 10 Weldin Joints 12 - 3 - 2020Adnan WattooNo ratings yet

- Jed 588Document5 pagesJed 588sateeshkoriNo ratings yet

- Checklist - Civil WorksDocument25 pagesChecklist - Civil WorksJagoan Neon0% (1)

- Me FinalDocument10 pagesMe FinalPrathamesh PrabhavaleNo ratings yet

- Visual INSPECTION OF WELDSDocument49 pagesVisual INSPECTION OF WELDSpraveentienNo ratings yet

- Detailing StandardsDocument31 pagesDetailing StandardsJovito EdillonNo ratings yet

- Mould Check List / Trial Record: FG Control Tube FG H-TopDocument8 pagesMould Check List / Trial Record: FG Control Tube FG H-ToprajeshNo ratings yet

- Do-It-Yourself Gun Repair: Gunsmithing at HomeFrom EverandDo-It-Yourself Gun Repair: Gunsmithing at HomeRating: 2 out of 5 stars2/5 (1)

- Carpentry and Framing Inspection Notes: Up to CodeFrom EverandCarpentry and Framing Inspection Notes: Up to CodeRating: 5 out of 5 stars5/5 (1)

- The Marmo Method Modelbuilding Guide #6: Building The Williams Bros. 1/72 scale Curtiss C-46A CommandoFrom EverandThe Marmo Method Modelbuilding Guide #6: Building The Williams Bros. 1/72 scale Curtiss C-46A CommandoNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- DrawingDocument1 pageDrawingvino pooNo ratings yet

- Top PlateDocument1 pageTop Platevino pooNo ratings yet

- Support BlockDocument1 pageSupport Blockvino pooNo ratings yet

- CommentsDocument1 pageCommentsvino pooNo ratings yet

- Fixture JigDocument1 pageFixture Jigvino pooNo ratings yet

- Cutting Tool Part 1Document4 pagesCutting Tool Part 1vino pooNo ratings yet

- Jigs and Fixture Locating PrinciplesDocument89 pagesJigs and Fixture Locating Principlesvino pooNo ratings yet

- Dwnload Full Environmental Economics Canadian 4th Edition Field Solutions Manual PDFDocument35 pagesDwnload Full Environmental Economics Canadian 4th Edition Field Solutions Manual PDFjaydejakabfx100% (13)

- Pag IbigDocument1 pagePag IbigVenus AgustinNo ratings yet

- Manual de Operação XZ40K - 1Document34 pagesManual de Operação XZ40K - 1DORIVAN JÚNIORNo ratings yet

- 1 PBDocument8 pages1 PBLaurensia Karin HaryadmoNo ratings yet

- Does Foreign Aid Help To Achieve Economic Stability - Essay For CSSDocument7 pagesDoes Foreign Aid Help To Achieve Economic Stability - Essay For CSSIhsaan gulzarNo ratings yet

- CSE Catalog - IndiaDocument67 pagesCSE Catalog - IndiaDheeraj SivadasNo ratings yet

- Rbi Circular On Standardization of Irs ContractsDocument1 pageRbi Circular On Standardization of Irs ContractsKirubakaran KaliaperumalNo ratings yet

- 2023-2024 Fix B PTS KELAS 12Document8 pages2023-2024 Fix B PTS KELAS 12milatrikanti80No ratings yet

- Deakleen MGDocument1 pageDeakleen MGMhd Garry LuthfiNo ratings yet

- Toyo - Soal Dasar Akuntansi UTS - Gasal 2122Document2 pagesToyo - Soal Dasar Akuntansi UTS - Gasal 2122Dita nNo ratings yet

- Parts Catalog PDF 2216 Cd101Document588 pagesParts Catalog PDF 2216 Cd101Diego RodriguezNo ratings yet

- APL Apollo Tubes: Piping Gains Rating: BuyDocument28 pagesAPL Apollo Tubes: Piping Gains Rating: BuygnanaNo ratings yet

- Industrial Attachment-Montex Fabrics LTDDocument82 pagesIndustrial Attachment-Montex Fabrics LTDSohel RanaNo ratings yet

- EY Global Supply Chain Benchmarking Study For The Tire Industry Executive SummaryDocument8 pagesEY Global Supply Chain Benchmarking Study For The Tire Industry Executive SummaryAnonymous Rn5SFJW0No ratings yet

- February (Week 1)Document24 pagesFebruary (Week 1)Swati SiwachNo ratings yet

- TM Iatf 16949Document2 pagesTM Iatf 16949storymaple94No ratings yet

- SWEET ENMOS Training GuidelinesDocument5 pagesSWEET ENMOS Training GuidelinesMICHELLE grace corpuzNo ratings yet

- Warehouses and Headquarters Addresses and Price List TemplateDocument22 pagesWarehouses and Headquarters Addresses and Price List TemplateTudor FlorinNo ratings yet

- Vvneq1m5ymzryny1nuj2swrlwef0dz09 InvoiceDocument2 pagesVvneq1m5ymzryny1nuj2swrlwef0dz09 InvoiceTYCS35 SIDDHESH PENDURKARNo ratings yet

- Colo Springs Office & Commercial - CraigslistDocument1 pageColo Springs Office & Commercial - CraigslistMatthew Alan FlineyNo ratings yet

- IAS 16 Property Plant EquipmentDocument4 pagesIAS 16 Property Plant EquipmentMD Hafizul Islam HafizNo ratings yet

- Lapto Bill HPDocument1 pageLapto Bill HPNehal SinghNo ratings yet

- 2020 English For EconomistsDocument100 pages2020 English For EconomistsZidni AdilaNo ratings yet

- TimirDocument2 pagesTimirSudipa RouthNo ratings yet

- Ok Tamam Group Contract 2023-2024Document16 pagesOk Tamam Group Contract 2023-2024Aiimad RehaiiliaNo ratings yet

- CSS 2018 Past PaperDocument7 pagesCSS 2018 Past PaperPrinxess ParasNo ratings yet

- Til Po - 374Document1 pageTil Po - 374MAHABIR GHOSHNo ratings yet